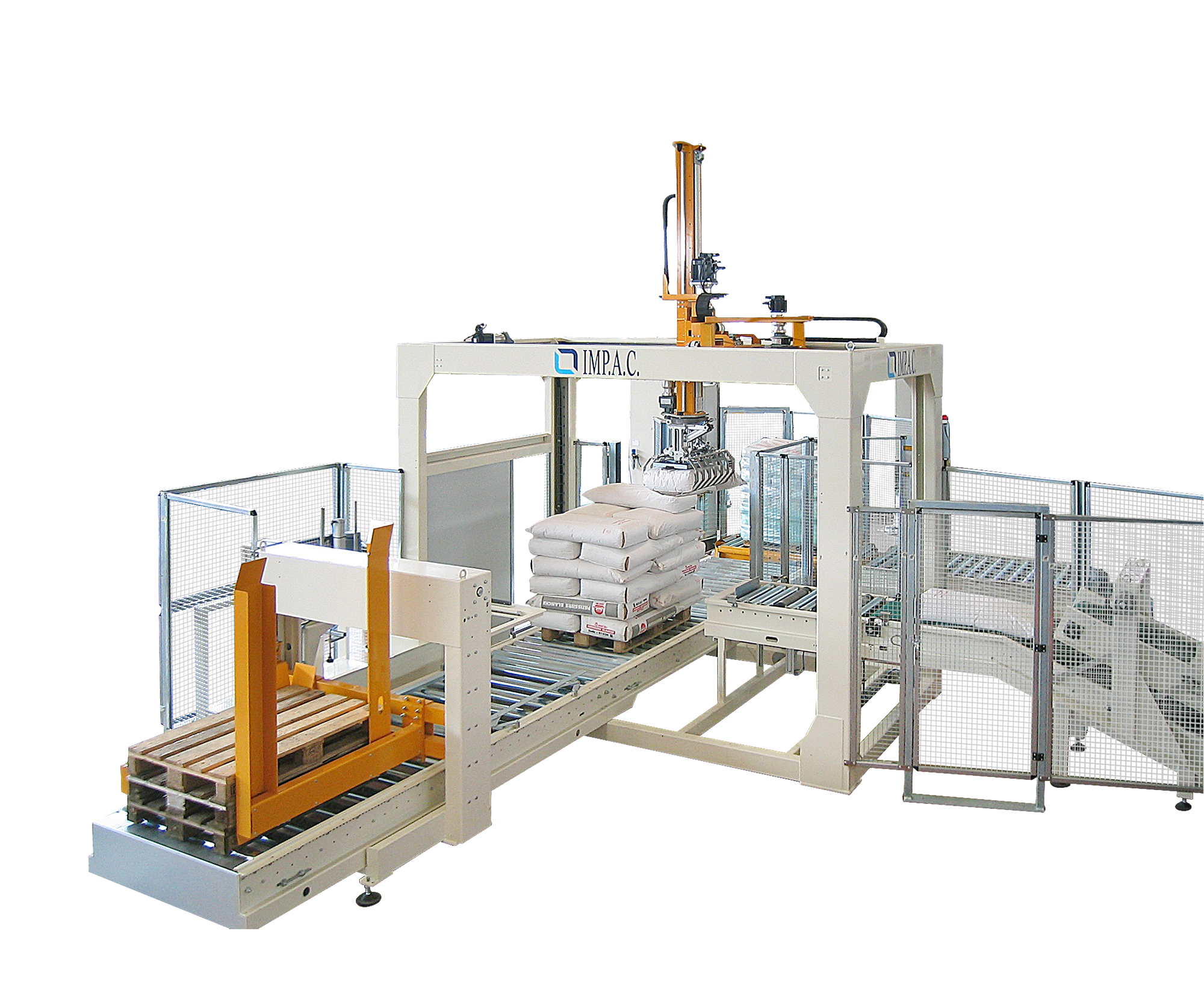

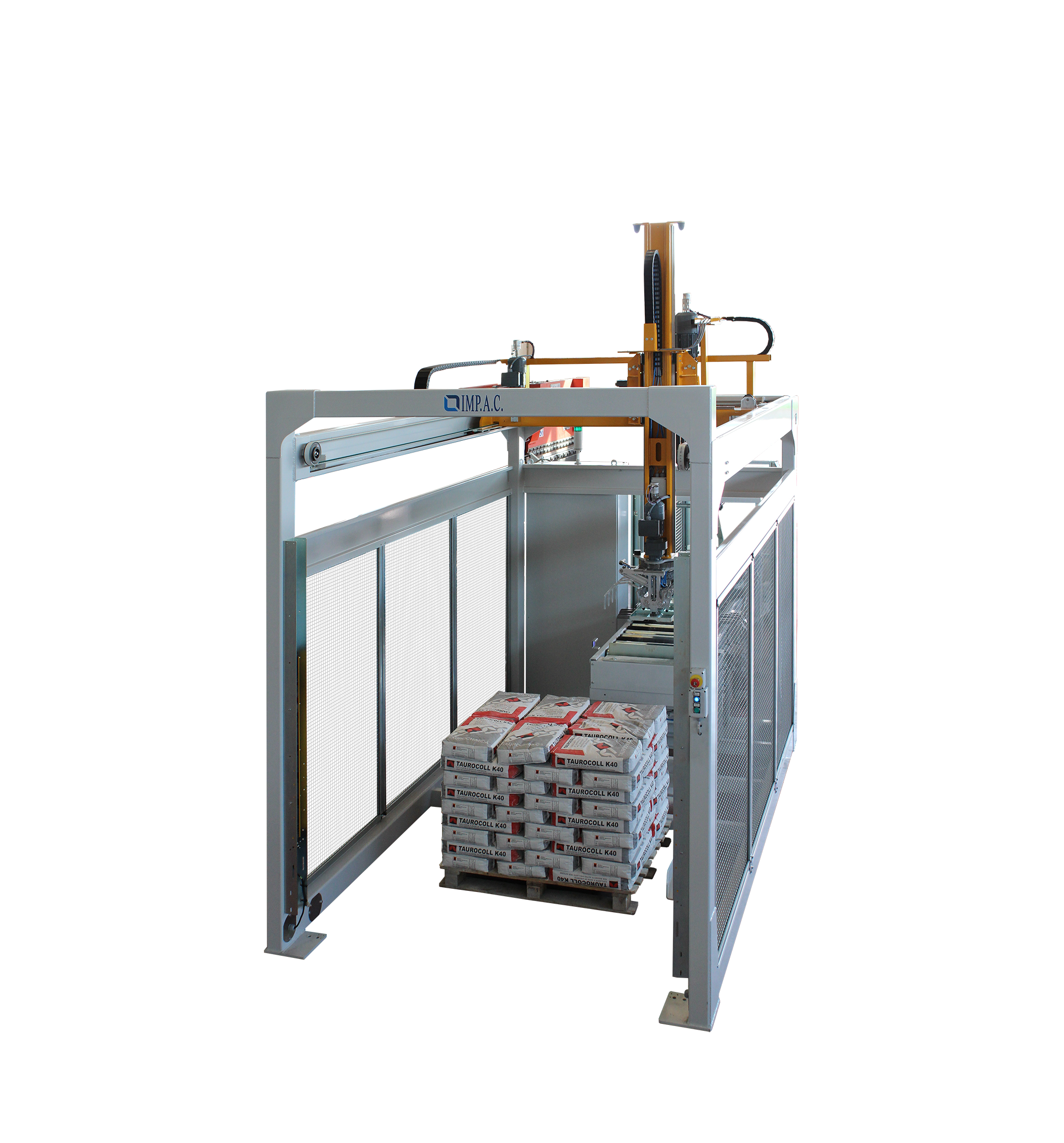

IMP.A.C. ROBOTEX 126 A-PT Cartesian bag palletising robot with floor pallet (also available as multi-pallet version)

The ROBOTEX 126 A-PT IMP.A.C. palletiser is the ideal solution for low throughputs, with a maximum capacity of 300 bags/hour and compact dimensions of just 4000x2400 mm, making it perfect for small and very low spaces

Operation

- Bag pressing: the incoming bag from the upstream line is pressed for uniformity and compactness.

- Transfer to the gripper: the pressed sack is oriented and fed to the positioning station.

- Picking and placing: the gripper picks up the sack, orients it and places it on the pallet according to the set programme.

- Continuous cycle: once a pallet is completed, it is manually evacuated and replaced with an empty one to start a new cycle.

Advantages

- High accuracy and reliability thanks to the Cartesian system.

- Suitable for all types of sacks, even those difficult to handle.

- Compact and versatile, ideal for small spaces.

- Low energy consumption and simplified maintenance.

The ROBOTOEX 126 A-PT model is an excellent choice for optimising low production rates, ensuring quality, efficiency and maximum adaptability to different bag formats.

Compact Cartesian bag palletizer on the pallet at the ground

Cycles: 300 bags/h

Bag dimensions

Max. 1000 x 500 x h. 250 mm

Min. 300 x 200 x h. 80 mm

Pallet Size

Max. 1200 x 1000 x h. 140 mm

Min. 1000 x 800 x h. 80 mm

Maximum layer size

Max. 1300 x 1100 mm

Standard full pallet height

1600 mm

Compressed air consumption

100 Nl/min

Max. full pallet weight

2000 Kg

Operational capacity

300 sacks/hour

Installed power

5 KW

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

3500 Kg

Product benefits

__ Total wrapping pliers

__ Total wrapping pliers

It provides a secure and stable grip for all types of sacks (paper, jute, plastic, valve, sewn or electro-welded), even for difficult sacks such as those that are partially empty or contain viscous materials.

__ Pressing device

__ Pressing device

It ensures optimal compaction of the bag on the pallet for stable and safe palletising.

__ Cartesian movement

__ Cartesian movement

The Cartesian axis system, controlled by encoders, guarantees precise positioning and operational versatility.

__ Advanced automation

__ Advanced automation

Synchronisations and operations coordinated by a programmable modular PLC, which allows bags of different sizes, formations and number of layers to be handled.

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

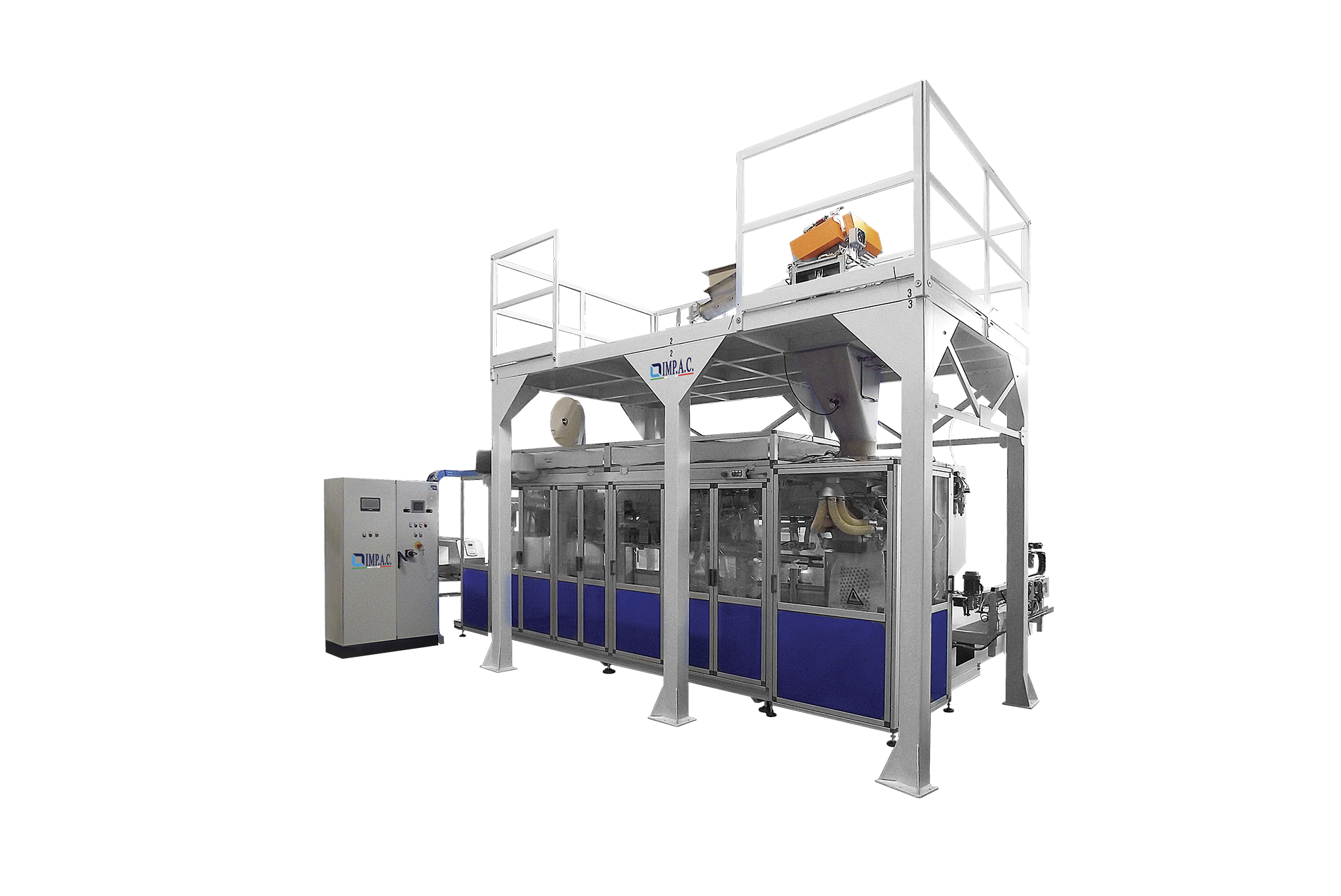

IMP.A.C. ROBOTEX 126 A-SA Cartesian bag palletising robot with built-in semi-automatic winder

IMP.A.C. ROBOTEX 126 A-SA

Compact Cartesian bag palletizer with integrated semi-automatic wrapping system

The ROBOTEX 126 A-SA IMP.A.C. palletiser is designed to optimise the palletising and wrapping process, offering a complete solution for all types of bags (paper, jute, plastic, valve, stitched or electro-welded).

- Advanced gripping system:

The full wrapping gripper precisely handles even difficult bags, such as half-empty bags or bags with high viscosity contents. - Sack pressing:

Each bag is pressed to ensure uniformity and compactness before handling. - Automated process:

- After being oriented and positioned according to the desired formation, the sacks are placed on the pallet.

- During the cycle, the semi-automatic winder stabilises the load directly on the pallet.

- All movements are synchronised by a modular PLC system, ensuring precision and reliability.

- Cartesian handling:

The Cartesian-axis robot, controlled by encoders, ensures high accuracy in positioning the bags. - Continuous cycle:

Once completed, the pallet is automatically evacuated and replaced to start a new cycle.

Main advantages

- Reduced operating space: compatible with small production environments.

- Operational flexibility: ability to handle different types of bags without the need for complex modifications.

- Load stabilisation: perfect for bags that are slippery or difficult to handle.

- Complete automation: reduction of manual intervention thanks to the integrated PLC system.

- Reliability and precision: guaranteed by advanced control systems.

With the IMP.A.C. ROBOTEX 126 A-SA, productivity combines with innovation to meet every palletising need.

Compact Cartesian bag palletizer with integrated semi-automatic wrapping system

Cycles: 300 bags/h

Bag dimensions

Max. 1000 x 500 x h. 250 mm

Min. 300 x 200 x h. 60 mm

Pallet Size

Max. 1200 x 1000 x h. 140 mm

Min. 1000 x 800 x h. 80 mm

Maximum layer size

Max. 1300 x 1100 mm

Standard full pallet height

1600 mm

Compressed air consumption

100 Nl/min

Max. full pallet weight

2000 Kg

Operational capacity

240-300 sacks/h

Installed power

5,5 KW

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

4000 Kg

Product benefits

__ Maximum production

__ Maximum production

300 sacks/hour.

__ Compactness

__ Compactness

Overall dimensions of only 4000×2400 mm, ideal for small spaces.

__ Versatility

__ Versatility

It allows palletising bags of varying sizes and weights (from 5 to 50 kg) with the same equipment.

__ Adaptability

__ Adaptability

Perfect for standard or niche production lines.

__ Load stability

__ Load stability

Thanks to the integrated winder, the load is stabilised even for unstable and slippery sacks.

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

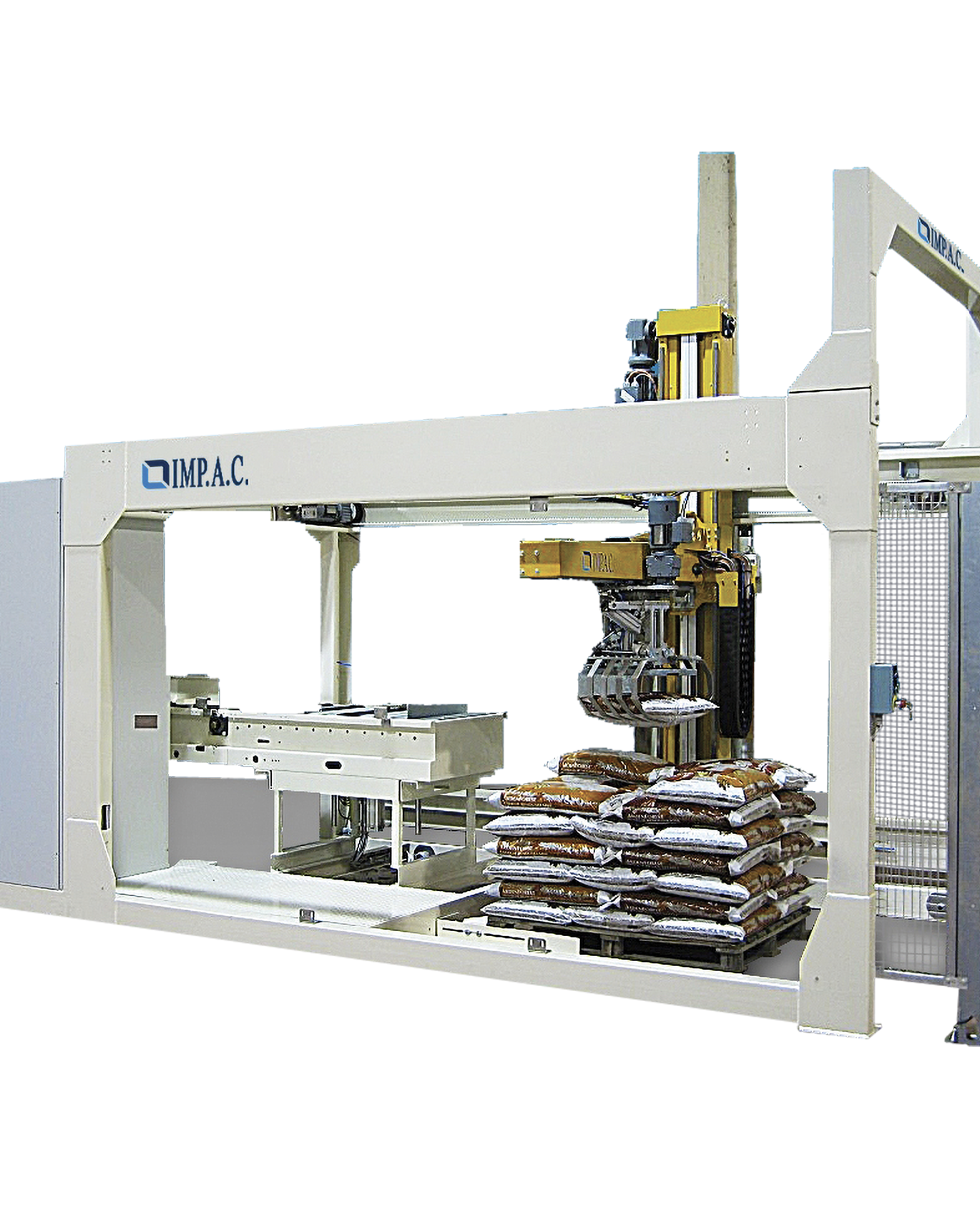

IMP.A.C. ROBOTEX 126 A Compact Cartesian bag palletising robot with roller conveyors (also available in multi-pallet version)

The IMP.A.C. ROBOTEX 126 A palletiser is a fully automatic machine, designed to ensure high efficiency and adaptability in fully automatic production plants, even in reduced height spaces in the absence of an operator.

Operation

- Feeding and positioning:

The bag coming from the upstream line is pressed to be made uniform and compact. - Positioning station:

The sack is started at the positioning station to be picked up by the gripper. - Cartesian handling:

The gripper orients, positions and presses the bag onto the pallet according to the set programme. - Palletising cycle:

The process continues until the pallet is completed, which is automatically evacuated and replaced.

Advanced technology

- Cartesian axis movement:

Controlled by encoders to ensure precision and reliability. - Programmable modular system (PLC):

Synchronises all movements for smooth and customisable operation.

Operational flexibility

The machine is programmable to handle:

- Sacks of different sizes and formats

- Multiple palletising configurations

- Different numbers of layers on the pallet.

Ideal applications

Perfect for fully automated industrial production lines, where high precision, reliability and flexibility in bag handling is required even under critical conditions.

IMP.A.C. ROBOTEX 126 A is the optimal solution for companies requiring efficient and compact palletising with high production performance.

Compact Cartesian bag palletizer

Cycles:

300 sacks/hour basic solution

500 sacks/hour fast solution

Bag dimensions

Max. 1000 x 500 x h. 250 mm

Min. 300 x 200 x h. 80 mm

Pallet Size

Max. 1200 x 1000 x h. 140 mm

Min. 1000 x 800 x h. 80 mm

Maximum layer size

Max. 1300 x 1100 mm

Standard full pallet height

1600 mm

Compressed air consumption

100 Nl/min

Max. full pallet weight

2000 Kg

Operational capacity

300-500 sacks/h

Potenza installata

7 KW

Operating pressure

6 bar

Control voltage

24 V

Peso indicativo

5000 Kg

Product benefits

__ High production capacity

__ High production capacity

Up to 500 sacks/h in the fast configuration.

__ Compact design

__ Compact design

Optimised for small spaces.

__ Advanced gripping system

__ Advanced gripping system

Full wrapping gripper for handling sacks of all types:<br>- Paper, jute, plastic<br>- Valve, sewn or electro-welded sacks<br>Half-empty sacks or sacks containing products at the viscosity limit (e.g. water).

__ Pressing device

__ Pressing device

It ensures uniform and compact sacks.

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

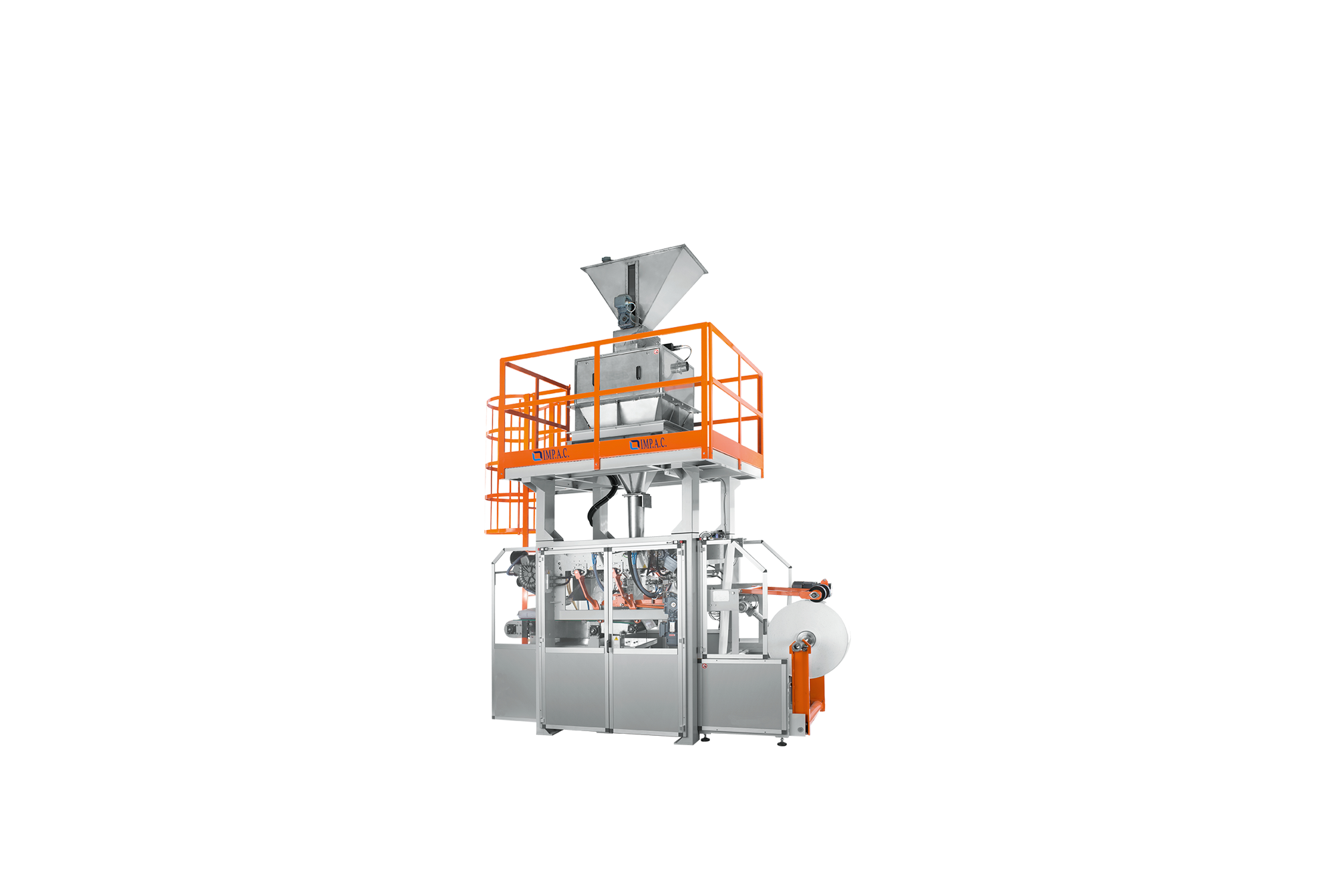

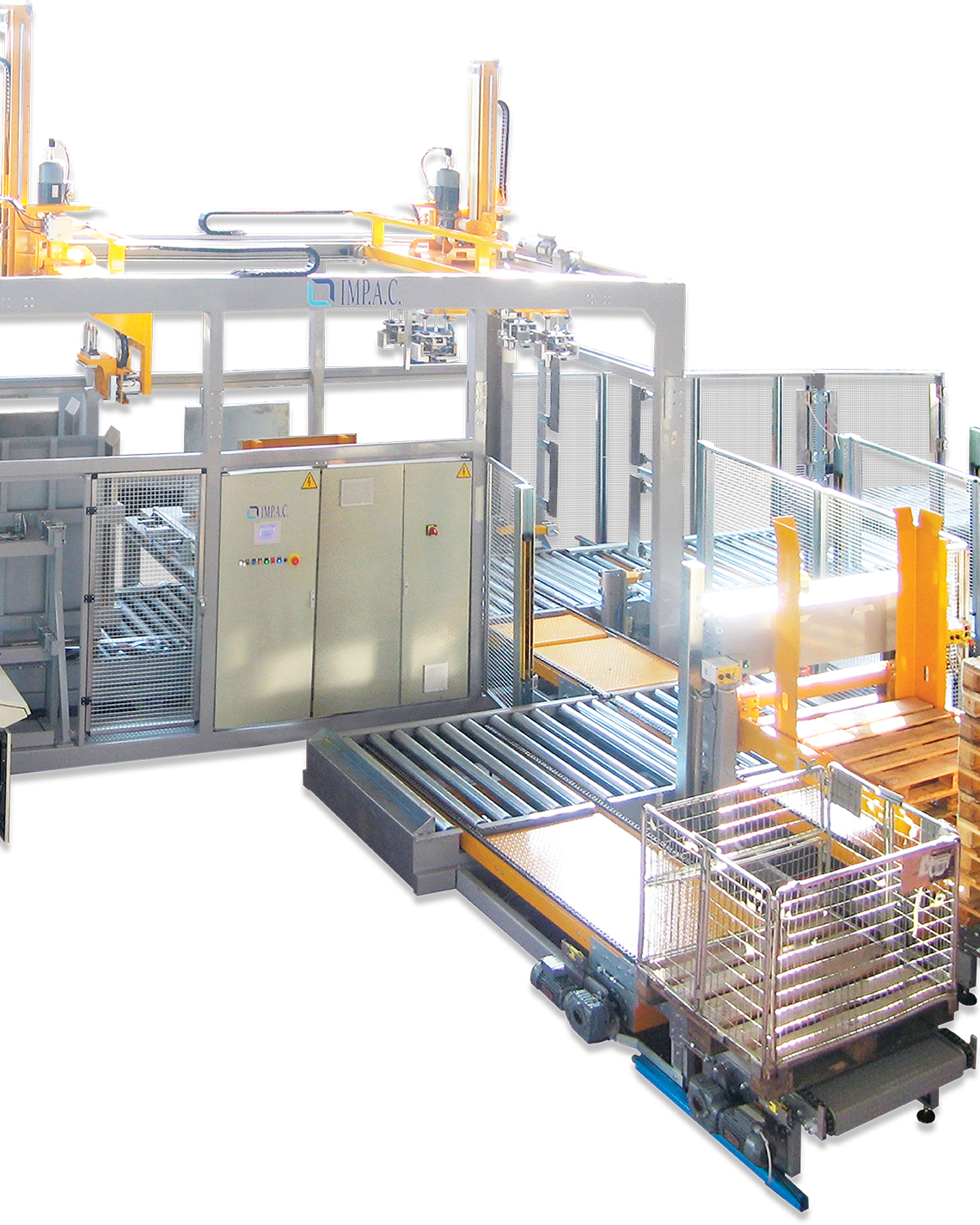

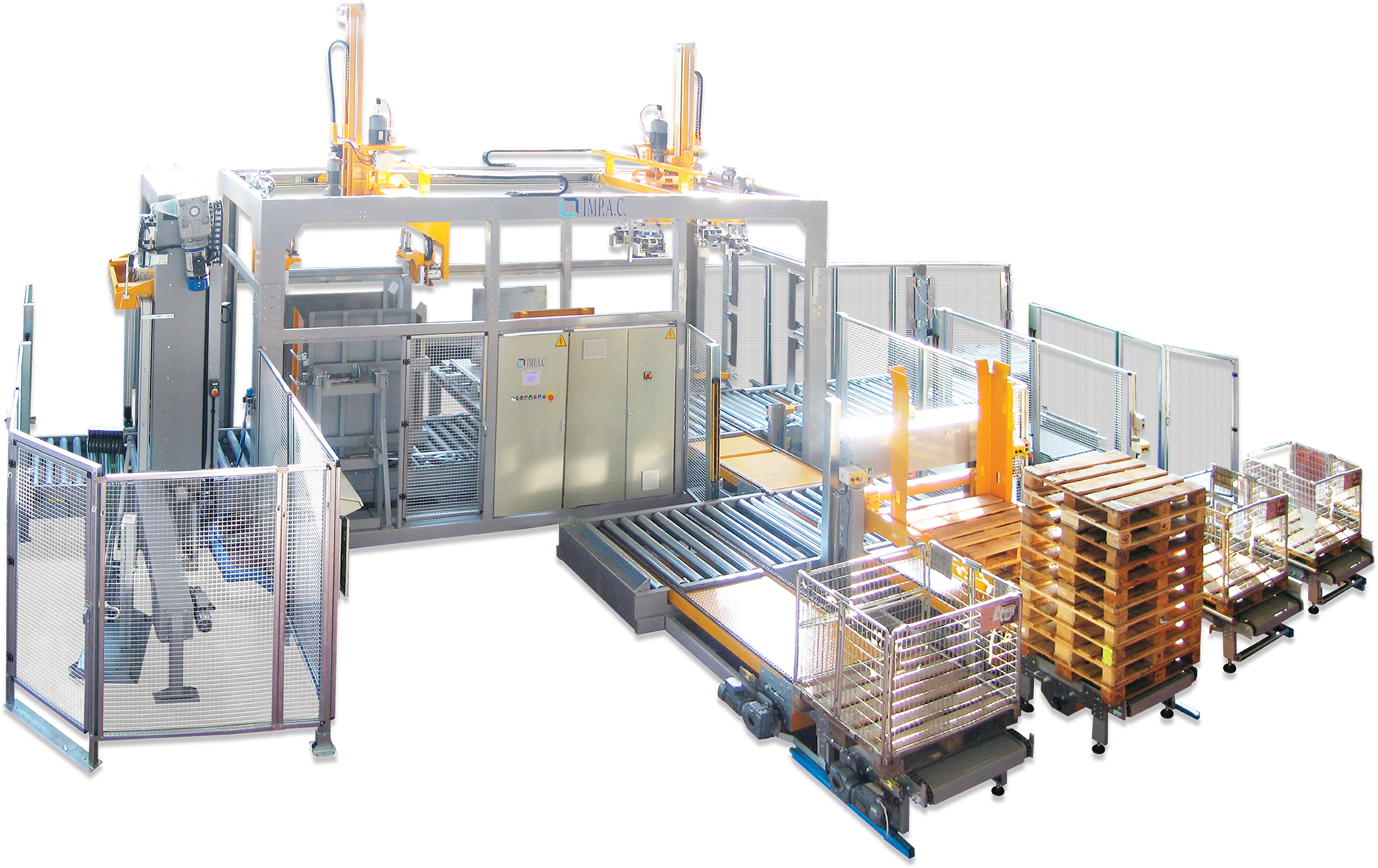

IMP.A.C. ROBOTEX 125 A-PR+TOP Cartesian bag palletising robot with automatic winder and built-in cover top

IMP.A.C. ROBOTEX 125 A-PR+TOP

Cartesian bag palletizer with integrated automatic wrapping system + top cover

The IMP.A.C. ROBOTEX 125 A-PR+TOP palletiser is an innovative, fully automatic solution equipped with roller conveyors for handling empty and full pallets.

Designed to meet the needs of a wide range of users, it offers the following distinctive features.

Operation

The bag coming from the production line is:

- Pressed to be made uniform and compact.

- Started at a positioning station where it is picked up by the gripper.

- Oriented, positioned and pressed on the pallet according to the set programme.

The cycle repeats until the pallet is completed, which is automatically evacuated and replaced to start a new cycle.

Programmazione e controllo

- Sincronismi dei movimenti coordinati da un sistema modulare programmabile (PLC).

- Possibilità di programmare la macchina per diverse dimensioni dei sacchi, configurazioni e numero di strati.

Il IMP.A.C. ROBOTEX 125 A-PR+TOP è la scelta ideale per chi necessita di una soluzione affidabile, compatta e versatile per la pallettizzazione e l’avvolgimento automatico, garantendo la protezione completa del carico anche in condizioni operative complesse.

Cartesian bag palletizer with integrated automatic wrapping system + top cover

Cycles:

230 sacks/hour basic solution

400 bags/hour fast solution

Bag dimensions

Max. 1000 x 500 x h. 250 mm

Min. 300 x 200 x h. 60 mm

Pallet Size

Max. 1200 x 1000 x h. 140 mm

Min. 1000 x 800 x h. 80 mm

Maximum layer size

Max. 1300 x 1100 mm

Standard full pallet height

1600 mm

Compressed air consumption

200 Nl/min

Max. full pallet weight

2000 Kg

Operational capacity

230-400 sacks/h

Installed power

9 KW

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

6000 Kg

Product benefits

__ Total versatility

__ Total versatility

Palletising of all types of sacks (paper, jute, plastic, valve, sewn or electro-welded).<br>Compatibility with sizes and weights from 5 to 50 kg using the same equipment.

__ Load stability and protection

__ Load stability and protection

Automatic pallet winding for maximum stability.<br>Integrated top cover system for additional protection.

__ Compactness

__ Compactness

Compact design ideal for limited spaces, with small overall dimensions.

__ Full automation

__ Full automation

Suitable for fully automatic, unmanned production lines.<br>Production capacity up to 400 bags/h in the fast version.

__ Advanced gripping system

__ Advanced gripping system

Full wrapping gripper for safe handling of complex sacks, including semi-empty sacks or sacks containing viscous materials.<br>Pressing device for uniform positioning of the sack on the pallet.

__ Precision in movements

__ Precision in movements

Cartesian motion system with encoder control to ensure accurate positioning.

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

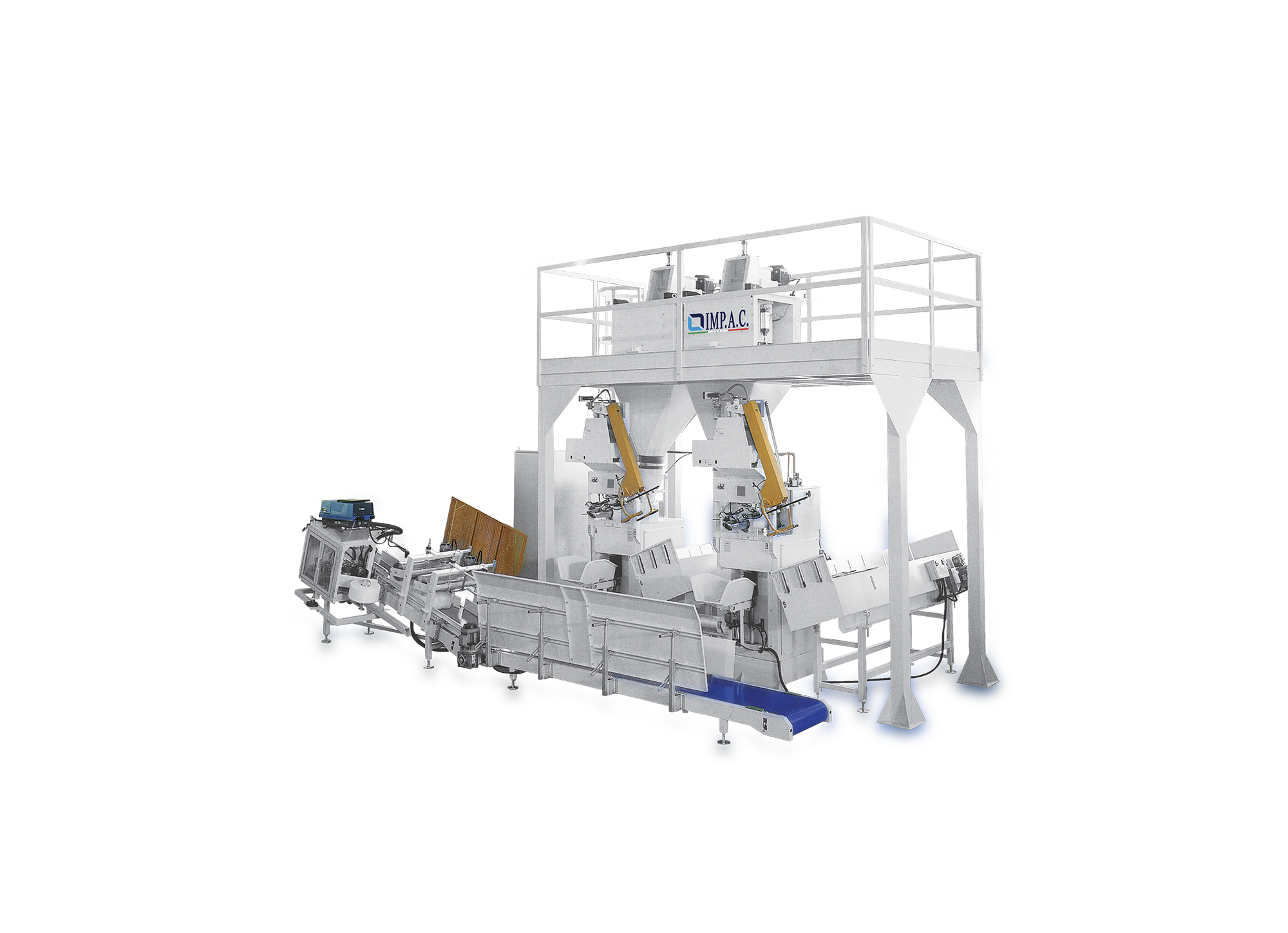

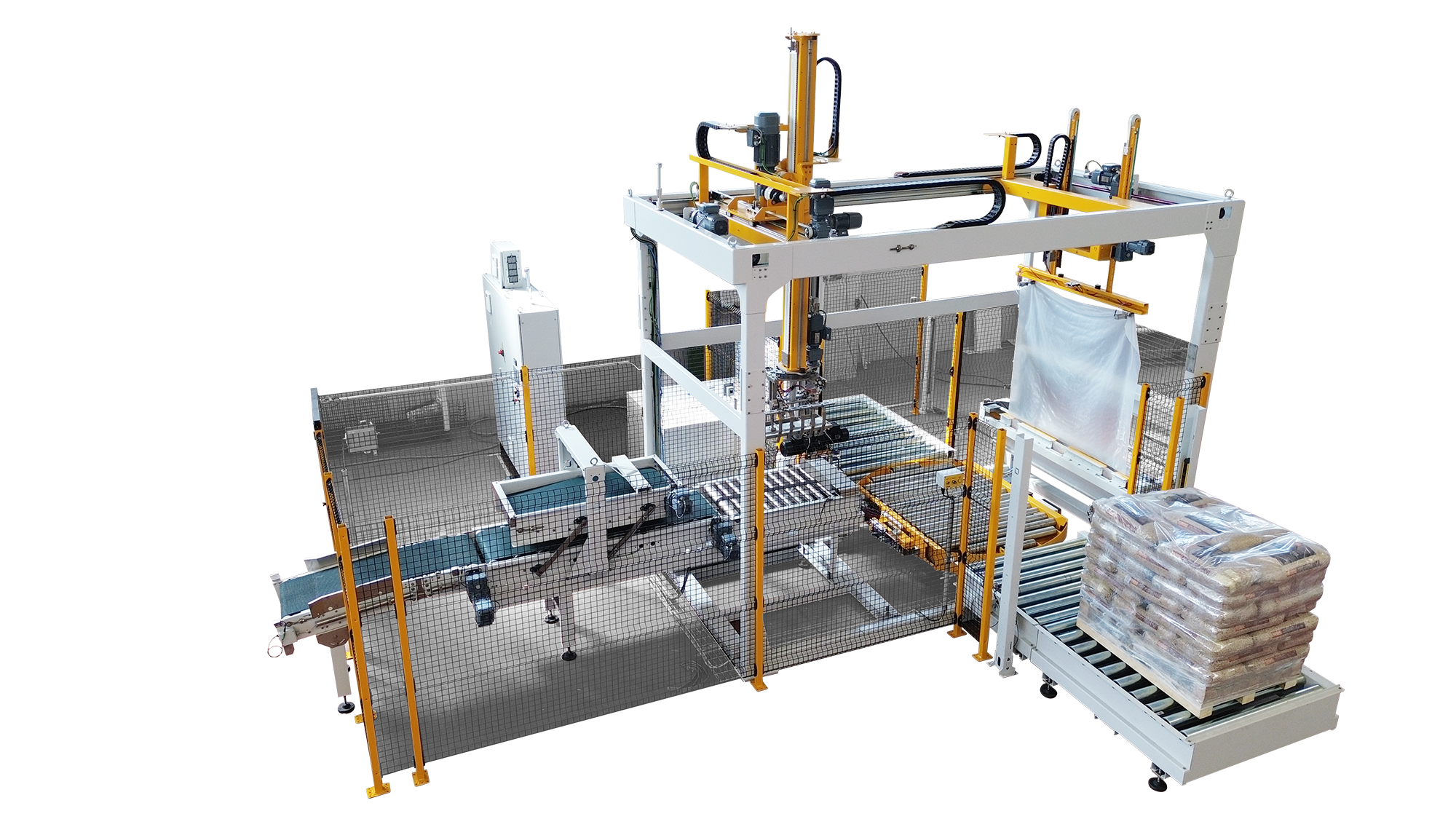

IMP.A.C. ROBOTEX 125 A-PR Cartesian bag palletising robot with built-in automatic winder

IMP.A.C. ROBOTEX 125 A-PR

Cartesian bag palletizer with integrated automatic wrapping system

The ROBOTEX 125 A-PR IMP.A.C. palletiser represents a technologically advanced, fully automatic solution designed to meet palletising and wrapping requirements in an efficient and versatile manner.

Main advantages

- Versatility:

Handles bags with different sizes and weights, from 5 to 50 kg, with one equipment. - Load stability:

Integrates an automatic winding system to ensure the stability of slippery or unstable bags. - Compactness:

Ideal for installation in small spaces due to its compact footprint. - Complete automation:

Designed to work without supervision in automated production plants.

Ideal applications

Designed for fully automated production lines with capacities of up to 450 bags/hour, the ROBOTEX 125 A-PR is the ideal choice for those requiring efficiency, load stability and space optimisation.

Cartesian bag palletizer with integrated automatic wrapping system

Cycles:

270 bags/hour basic solution

450 sacks/hour fast solution

Bag dimensions

Max. 1000 x 500 x h. 250 mm

Min. 300 x 200 x h. 80 mm

Pallet Size

Max. 1200 x 1000 x h. 140 mm

Min. 1000 x 800 x h. 80 mm

Maximum layer size

Max. 1300 x 1100 mm

Standard full pallet height

1600 mm

Compressed air consumption

150 Nl/min

Max. full pallet weight

2000 Kg

Operational capacity

270-450 sacks/h

Installed power

8,5 KW

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

6000 Kg

Product benefits

__ Advanced gripping system

__ Advanced gripping system

The full wrapping gripper allows the handling of paper, jute, plastic, sewn or electro-welded sacks, ensuring optimal handling even for half-empty sacks or sacks containing viscous materials.

__ Automatic palletising

__ Automatic palletising

The bags are pressed for uniformity, oriented and placed on the pallet according to the preset programme.

__ Cartesian movement

__ Cartesian movement

Precise Cartesian axes, controlled by encoders, ensure accurate positioning.

__ Intuitive management

__ Intuitive management

All movements and synchronisms are coordinated by a programmable modular PLC, which can be customised for various bag sizes and formations.

__ Continuous cycle

__ Continuous cycle

Once completed, the pallet is evacuated and automatically replaced to start a new cycle.

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

Cartesian bag palletising robot with built-in semi-automatic winder IMP.A.C. ROBOTEX 125 ASA

IMP.A.C. ROBOTEX 125 A-SA

Cartesian bag palletizer with integrated semi-automatic wrapping system

The IMP.A.C. ROBOTEX 125 A-SA palletiser is designed to optimise the palletising and wrapping process, offering a complete solution for all types of bags (paper, jute, plastic, valve, stitched or electro-welded).

- Advanced gripping system:

The full wrapping gripper precisely handles even difficult bags, such as half-empty bags or bags with high viscosity contents. - Sack pressing:

Each bag is pressed to ensure uniformity and compactness before handling. - Automated process:

- The bags, after being oriented and positioned according to the desired formation, are placed on the pallet and pressed.

- During the cycle, the semi-automatic winder stabilises the load directly on the pallet.

- All movements are synchronised by a modular PLC system, ensuring precision and reliability.

- Cartesian handling:

The Cartesian-axis robot, controlled by encoders, ensures high accuracy in positioning the bags. - Continuous cycle:

Once completed, the pallet is evacuated and replaced manually to start a new cycle.

Main advantages

- Reduced operating space: compatible with small production environments.

- Operational flexibility: ability to handle different types of bags without the need for complex modifications.

- Load stabilisation: perfect for bags that are slippery or difficult to handle.

- Complete cycle automation: reduction of manual interventions thanks to the integrated PLC system.

- Reliability and precision: guaranteed by advanced control systems.

With the IMP.A.C. ROBOTEX 125 A-SA, productivity combines with innovation to meet every palletising need.

Cartesian bag palletizer with integrated semi-automatic wrapping system

Cycles: 300 bags/h

Bag dimensions

Max. 1000 x 500 x h. 250 mm

Min. 300 x 200 x h. 60 mm

Pallet Size

Max. 1200 x 1000 x h. 140 mm

Min. 1000 x 800 x h. 80 mm

Maximum layer size

Max. 1300 x 1100 mm

Standard full pallet height

1600 mm

Compressed air consumption

100 Nl/min

Max. full pallet weight

2000 Kg

Operational capacity

240-300 sacks/h

Installed power

6,5 KW

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

4000 Kg

Product benefits

__ Maximum production

__ Maximum production

300 sacks/hour.

__ Compactness

__ Compactness

Overall dimensions of only 4000×2400 mm, ideal for small spaces.

__ Versatility

__ Versatility

It allows palletising bags of varying sizes and weights (from 5 to 50 kg) with the same equipment.

__ Adaptability

__ Adaptability

Perfect for standard or niche production lines.

__ Load stability

__ Load stability

Thanks to the integrated winder, the load is stabilised even for unstable and slippery sacks.

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

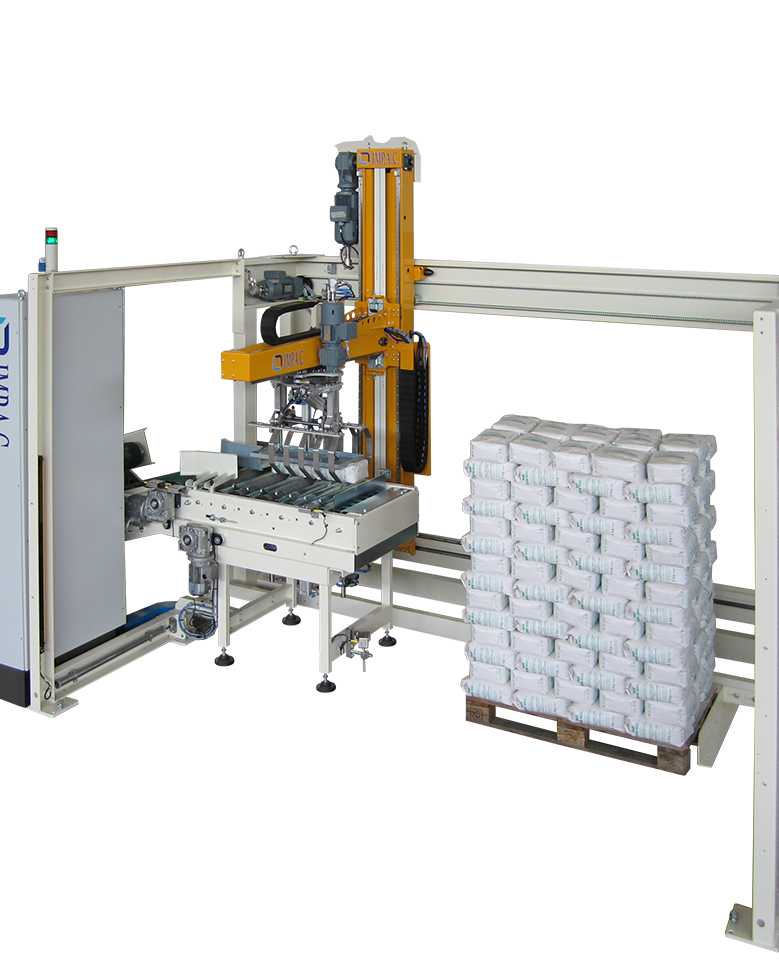

IMP.A.C. ROBOTEX 125 A-PT Cartesian bag palletising robot with floor pallet (also available as multi-pallet version)

IMP.A.C. ROBOTEX 125 A-PTCartesian bag palletising robot with pallet on the ground

(also available as multi-pallet version)

(also available as multi-pallet version)

The IMP.A.C. ROBOTEX 125 A-PT palletizer is the ideal solution for low production volumes, with a maximum capacity of 300 bags/hour and compact dimensions of just 4000x2400 mm, making it perfect for limited spaces.

Operation

- Bag pressing: the bag coming from the upstream line is pressed for uniformity and compactness.

- Transfer to the gripper: the pressed bag is oriented and picked up to be moved to the positioning station.

- Pick and place: the gripper picks up the bag, orients it, and places it on the pallet according to the set program.

- Continuous cycle: once the pallet is completed, it is manually removed and replaced with an empty one to start a new cycle.

Advantages

- High precision and reliability thanks to the cartesian system.

- Suitable for all types of bags, even those that are difficult to handle.

- Compact and versatile, ideal for small spaces.

- Low energy consumption and simplified maintenance.

The ROBOTOEX 125 A-PT model is an excellent choice to optimize low production volumes, ensuring quality, efficiency, and maximum adaptability to different bag formats.

Cartesian bag palletising robot with floor pallet (also available as multi-pallet version)

Cycles: 300 bags/h

Bag dimensions

Max. 1000 x 500 x h. 250 mm<br>Min. 300 x 200 x h. 80 mm

Pallet dimensions

Max. 1200 x 1000 x h. 140 mm<br>Min. 1000 x 800 x h. 80 mm

Maximum layer size

Max. 1300 x 1100 mm

Standard height of full pallet

1600 mm

Compressed air consumption

100 Nl/min

Max weight of full pallet

2000 Kg

Operating capacity

300 sacks/hour

Installed power

5 KW

Pressione di esercizio

6 bar

Control voltage

24 V

Indicative weight

3500 Kg

Product benefits

__ Total wrapping gripper

__ Total wrapping gripper

It provides a secure and stable grip for all types of sacks (paper, jute, plastic, valve, sewn or electro-welded), even for difficult sacks such as those that are partially empty or contain viscous materials.

__ Pressing device

__ Pressing device

It ensures optimal compaction of the bag on the pallet for stable and safe palletising.

__ Cartesian handling

__ Cartesian handling

The Cartesian axis system, controlled by encoders, guarantees precise positioning and operational versatility.

__ Advanced automation

__ Advanced automation

Synchronisations and operations coordinated by a programmable modular PLC, which allows bags of different sizes, formations and number of layers to be handled.

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

IMP.A.C. ROBOTEX 125 A Cartesian bag palletising robot with roller conveyors (also available as multi-pallet version)

The IMP.A.C. ROBOTEX 125 A palletiser is a fully automatic solution designed for production lines where there is no operator presence.

Thanks to its configuration with integrated roller conveyors for handling empty and full pallets, it integrates perfectly as an end-of-line unit in highly automated plants.

Cycles:

- 300 bags/hour (basic solution)

- 500 sacks/h (fast solution)

Advantages

- High productivity: capacity up to 500 bags/h with the fast solution.

- Operational versatility: ideal for bags that are difficult to handle and for multiple formats.

- Unmanned reliability: perfect for fully automated systems.

IMP.A.C. ROBOTEX 125 A offers a combination of precision, flexibility and automation, making it an optimal choice for companies looking for a modern and efficient solution for bag palletising.

Cartesian bag palletizer

Cycles:

300 sacks/hour basic solution

500 sacks/hour fast solution

Bag dimensions

Max. 1000 x 500 x h. 250 mm

Min. 300 x 200 x h. 80 mm

Pallet dimensions

Max. 1200 x 1000 x h. 140 mm

Min. 1000 x 800 x h. 80 mm

Maximum layer size

Max. 1300 x 1100 mm

Standard full pallet height

1600 mm

Compressed air consumption

100 Nl/min

Max. full pallet weight

2000 Kg

Operational capacity

300-500 sacks/h

Installed power

8,5 KW

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

5000 Kg

Product benefits

__ Maximum grip flexibility

__ Maximum grip flexibility

The full wrapping gripper ensures safe handling of any type of bag, including paper, jute, plastic, valve, sewn or electro-welded bags, as well as half-empty bags or bags containing materials with high viscosity.

__ Optimum pressing

__ Optimum pressing

Integrated pressing device to ensure stability of the bag on the pallet.

__ Cartesian movement

__ Cartesian movement

Cartesian axis system for precise positioning, controlled by encoder.

__ Full automation

__ Full automation

All synchronisms are managed by a programmable modular system (PLC), with the possibility of customising programmes for different bag sizes, configurations and number of layers.