The machine makes PE bags from flat foil reels, using Teflon-coated hot bar welding and weighs/weights the required amount of product, filling, closing and ejecting the bag.

PACKAGING UNIT

– Possibility of adjusting bag length: by time, sensor

encoder, encoder + sensor.

– Welding control on each individual unit to ensure the

perfect sealing of the bags, keeping temperatures constant

and homogeneous.

BALANCE

– Variable speed motorised roughing belt.

– Product flow control for the roughing belt.

– Selected product level sensor to prevent partially filled bags.

– Scraper under the roughing belt for constant cleaning.

– Stainless steel load cells.

– Integrated control functions in a single operator panel for maximum efficiency:

(a) Programming and weight setting;

b) Programmable autotare;

c) Automatic control of product in flight;

d) Storage of optimal cycle data;

e) Guarantee that no package is underweight.

Translated with www.DeepL.com/Translator (free version)

BAG FEATURES

– Lateral blowing.

– Rapid elimination of residual air in the sack by means of comb or roller scoops.

– Product settling device.

Automatic and full-leaf plastic bag packaging plant for bags from 10 kg to 50 kg

Max. production

720 / 1500 bags/hour

Max. bag size

500xh.1000 mm

Max. bag volume

50 Lt

Installed power

10 Kw

Pneumatic consumption

650 NL/1’ @ 6 bar

Max. band size

1050 mm

Performance

720 to 1500 bags/hour

Voltage

400V 3F+N+PE

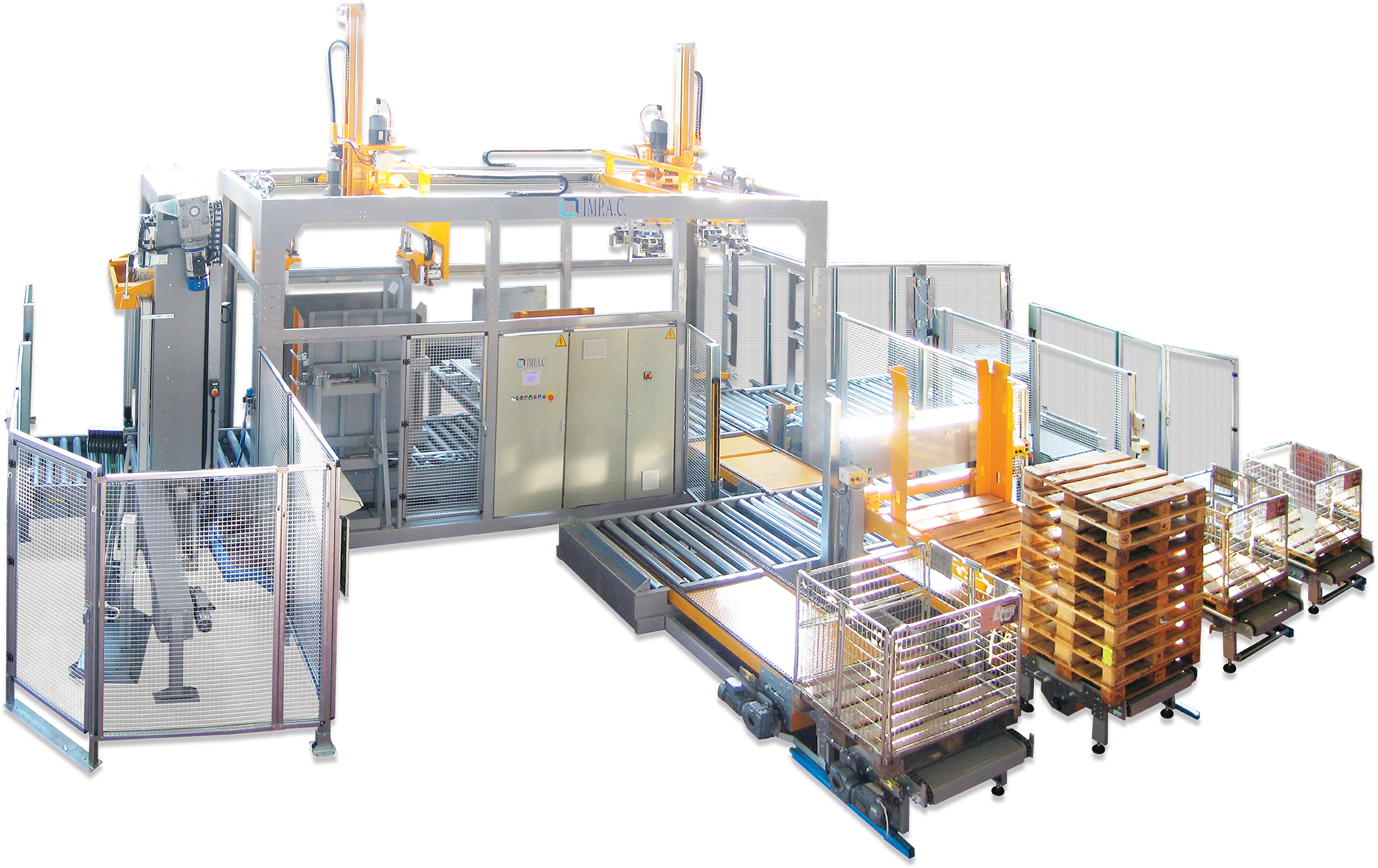

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

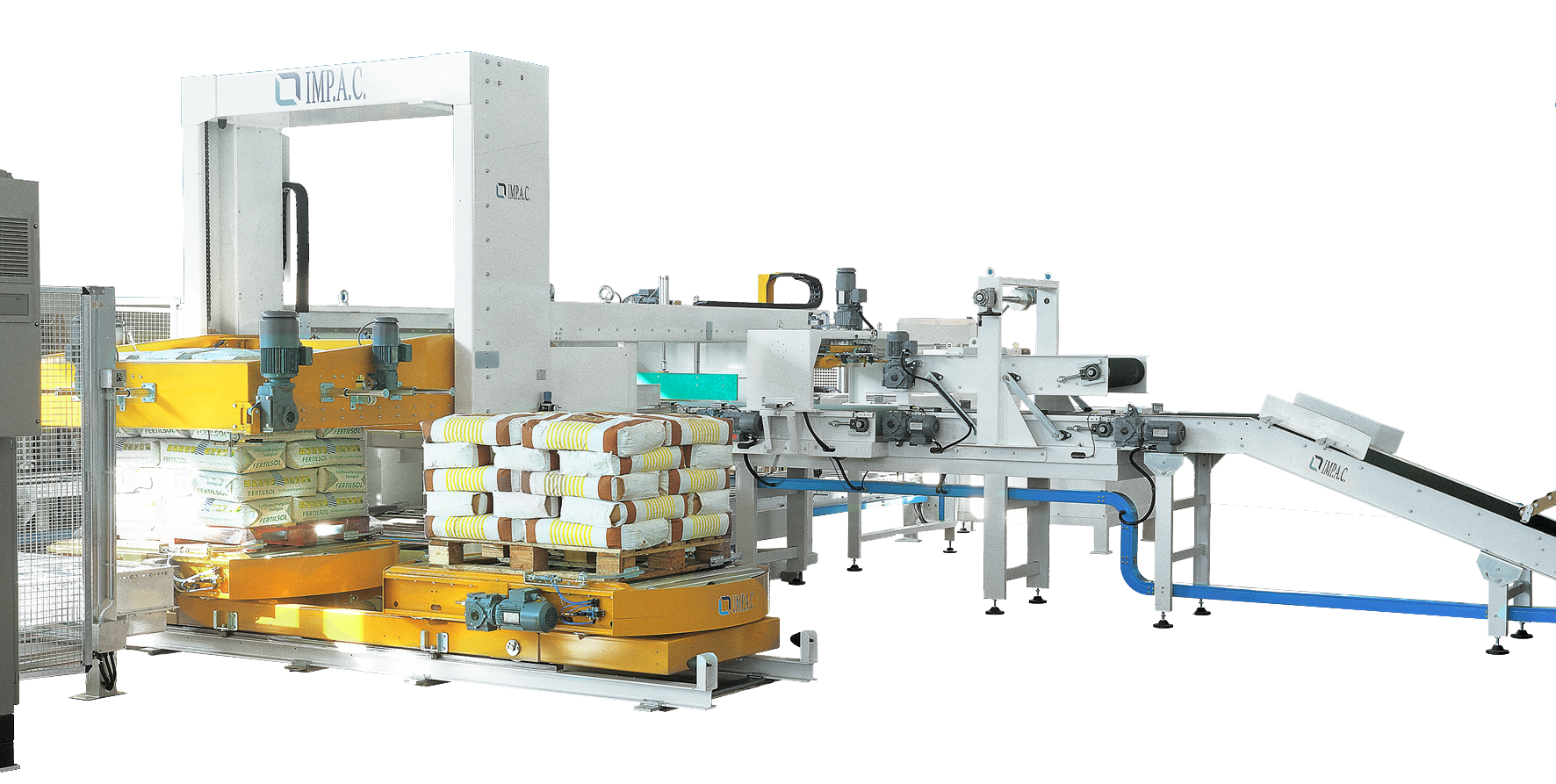

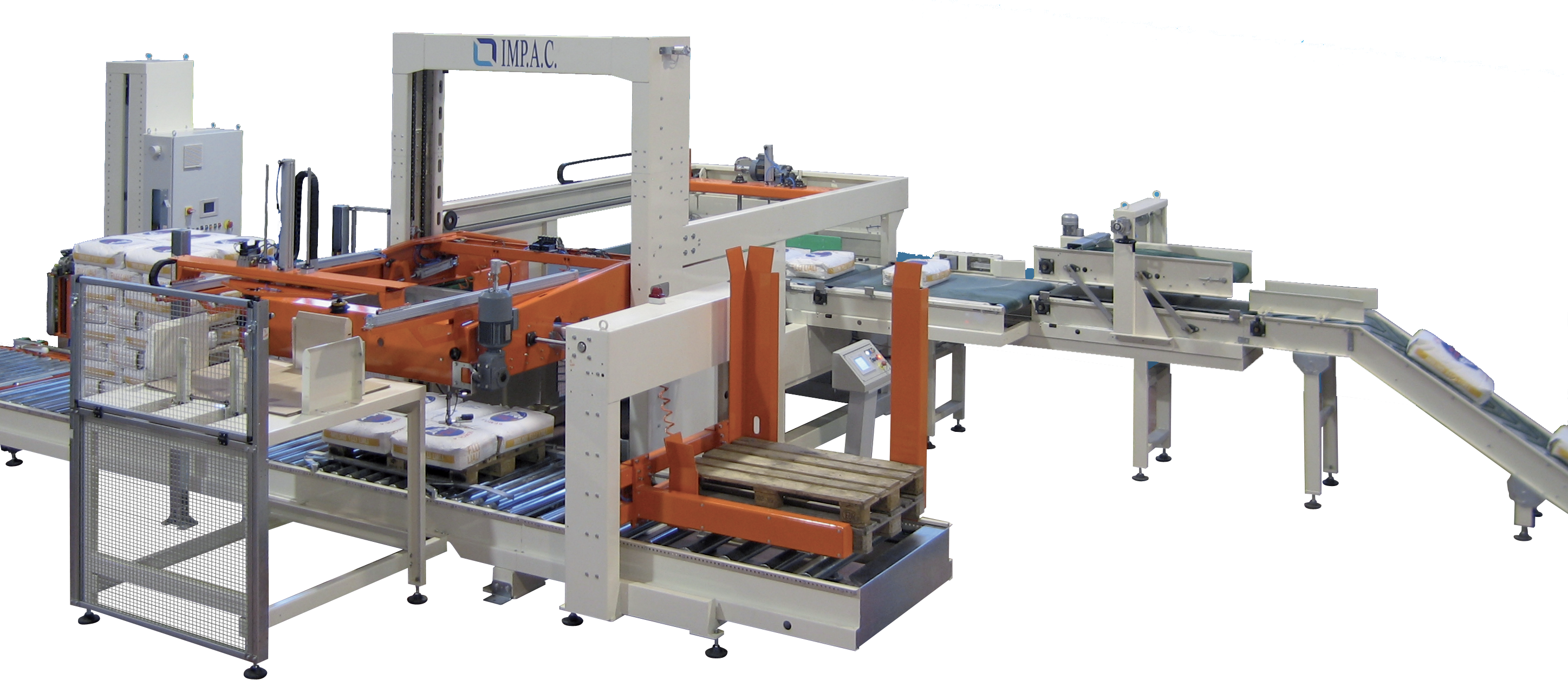

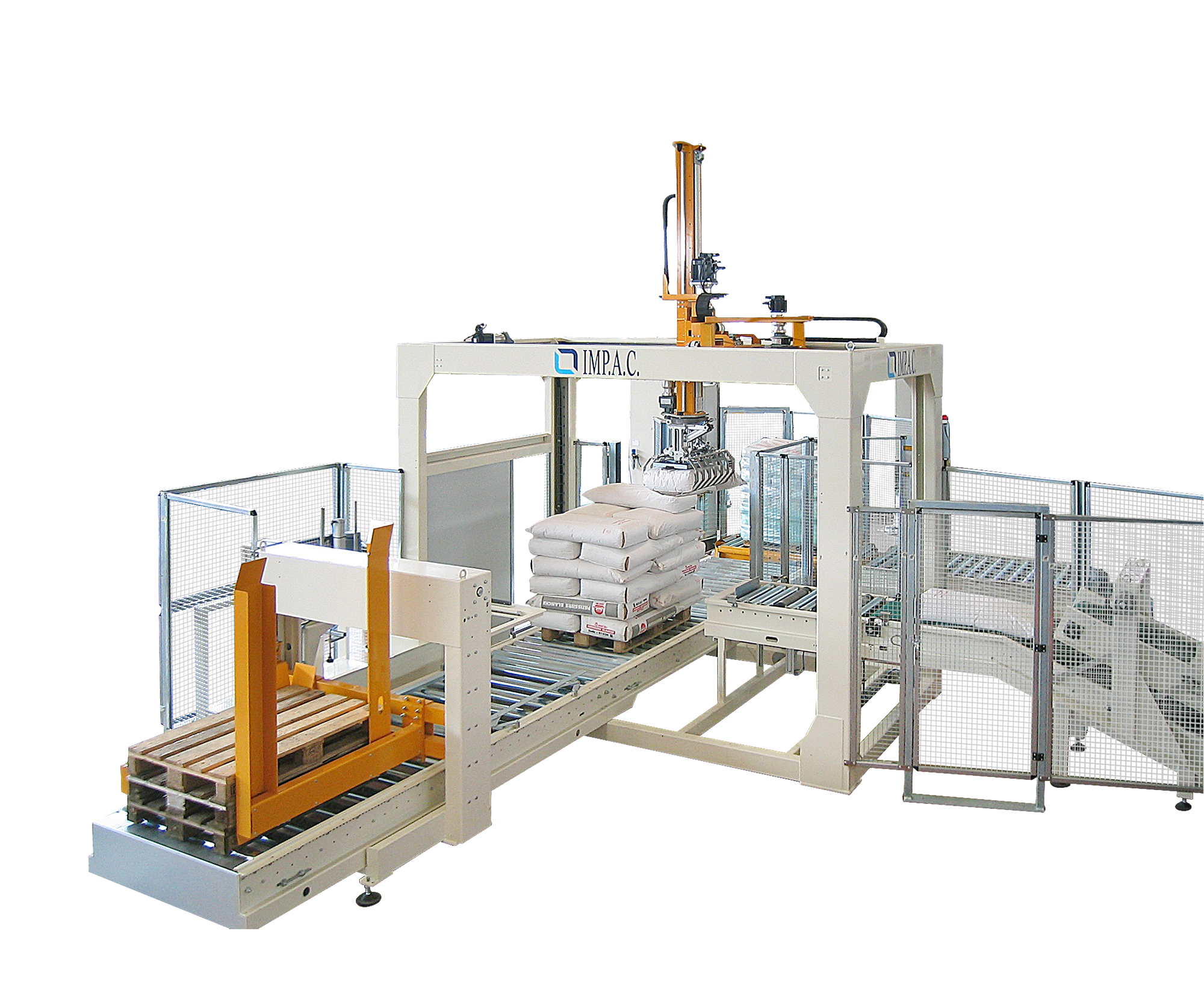

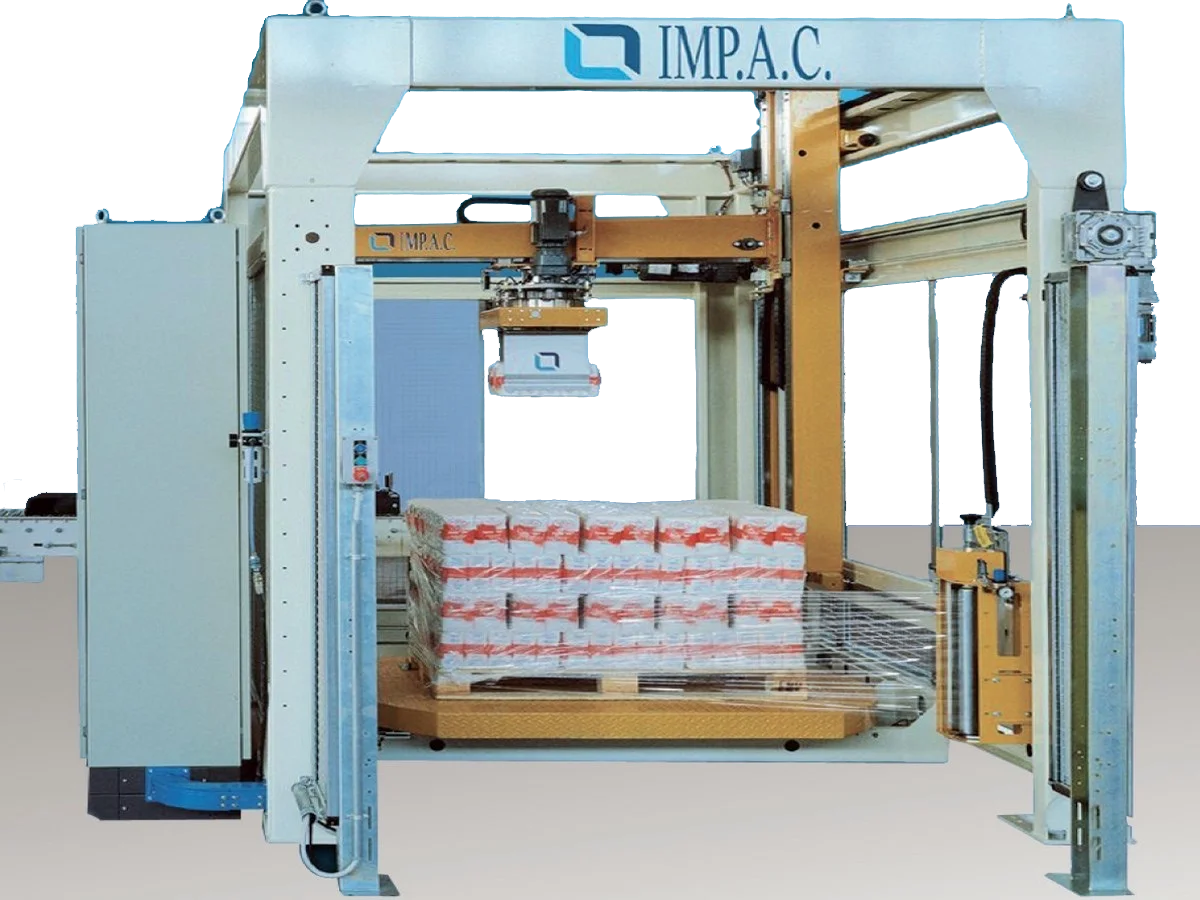

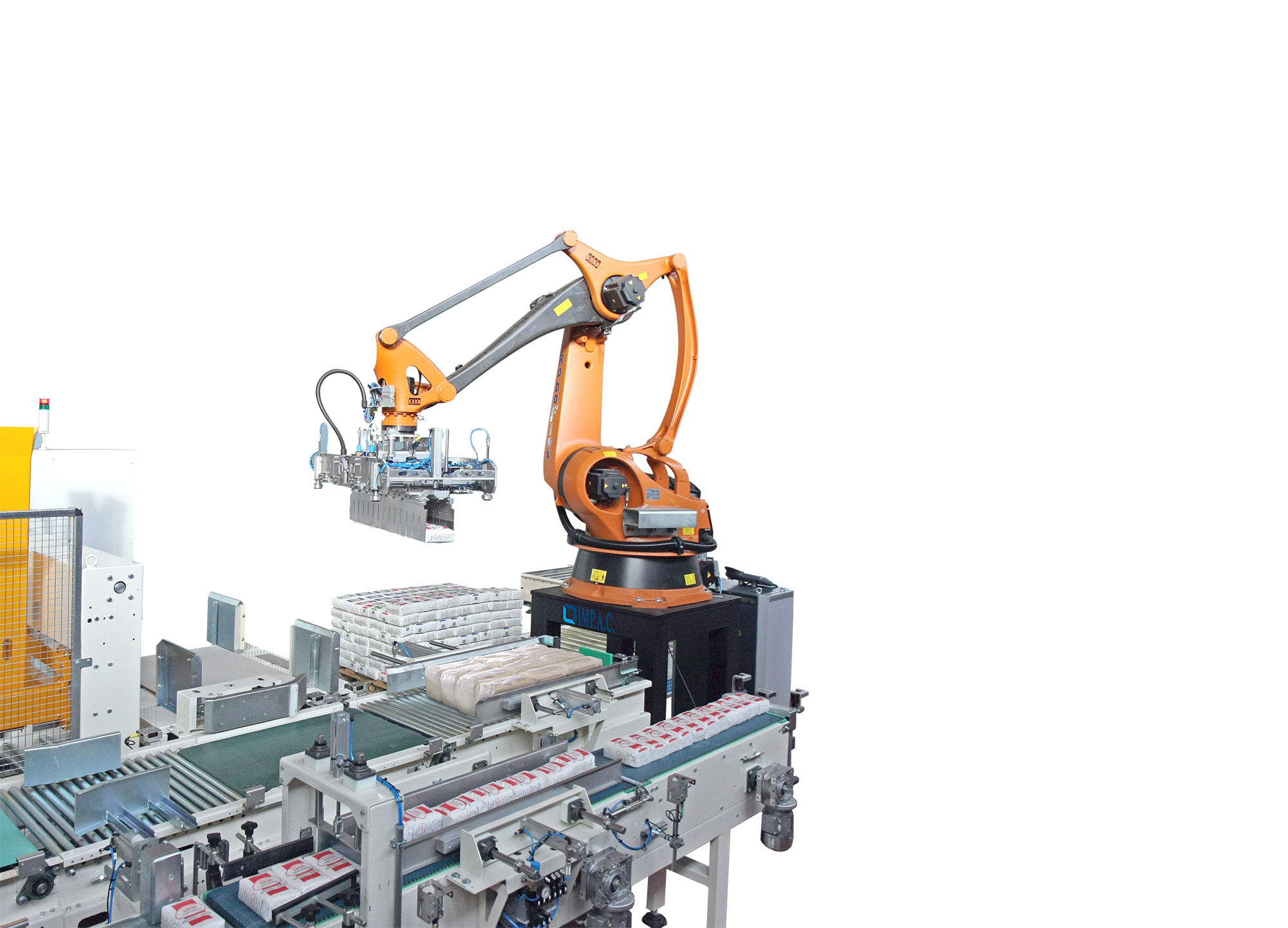

- High-Level palletizer for bags

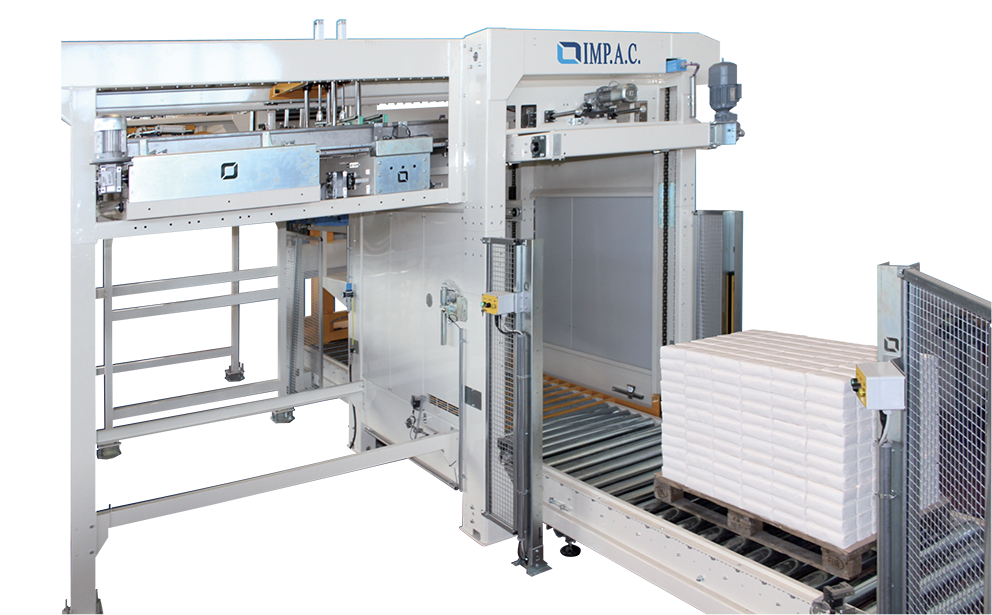

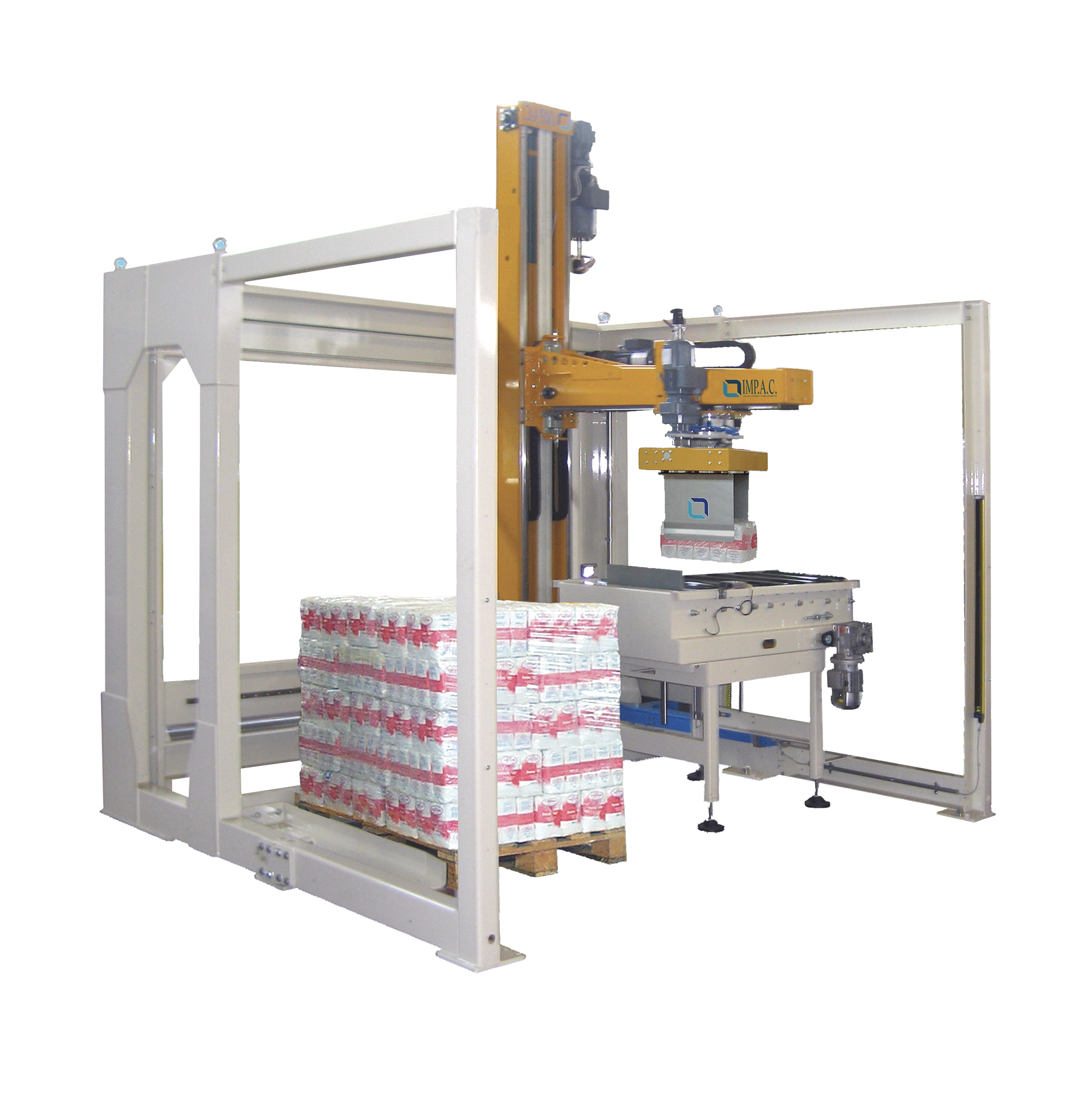

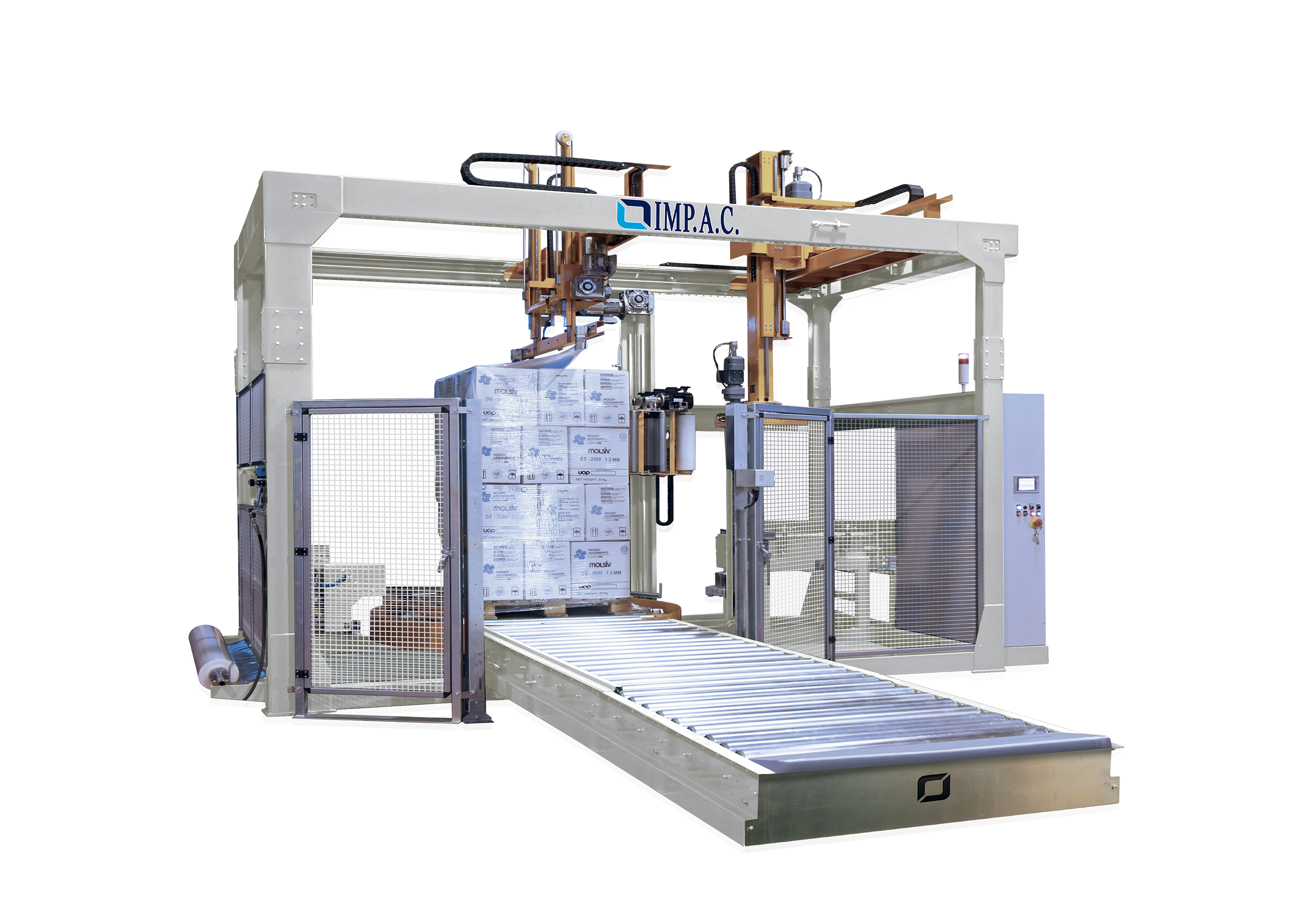

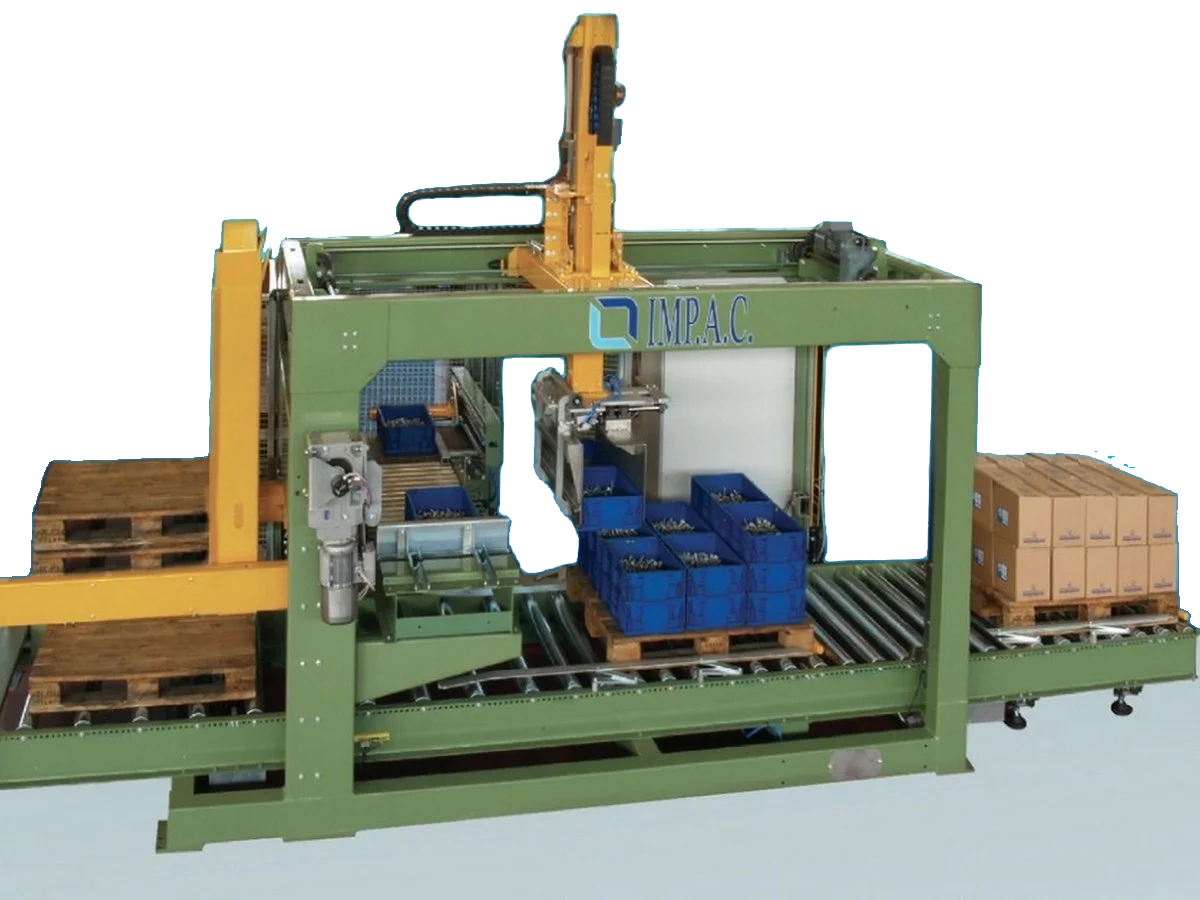

- High level paletizing system for box and bundles

- Low-Level Palletizer for boxes and bundles

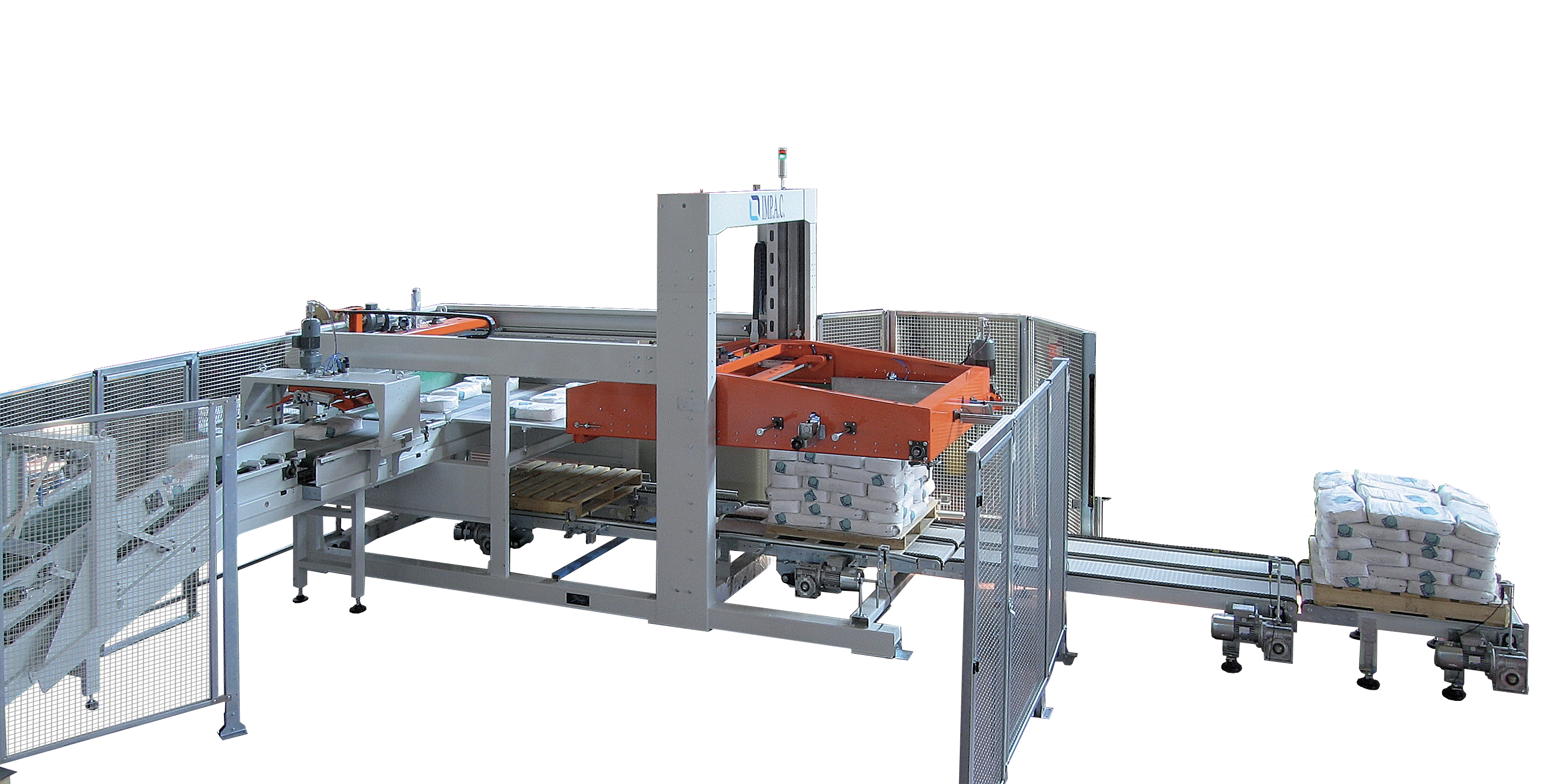

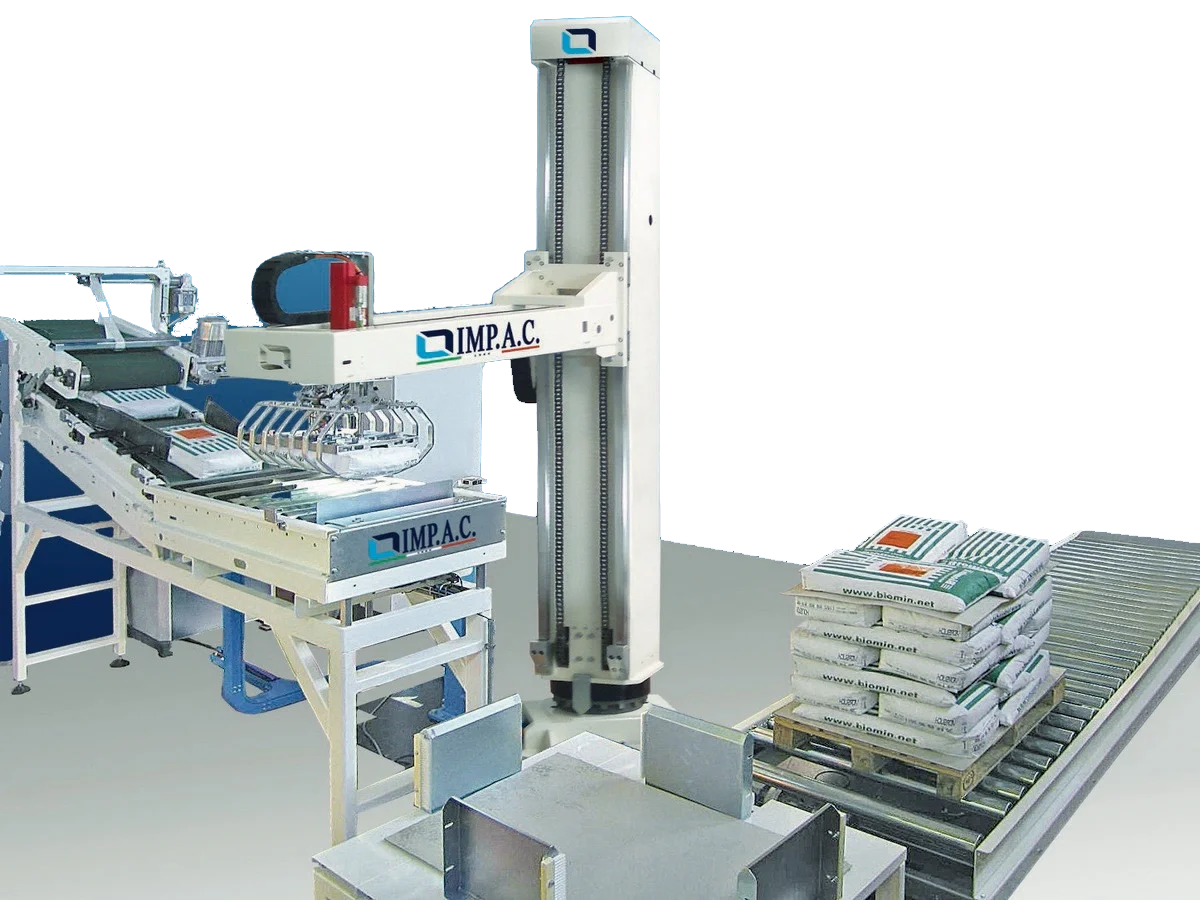

- Low level palletizer for bags

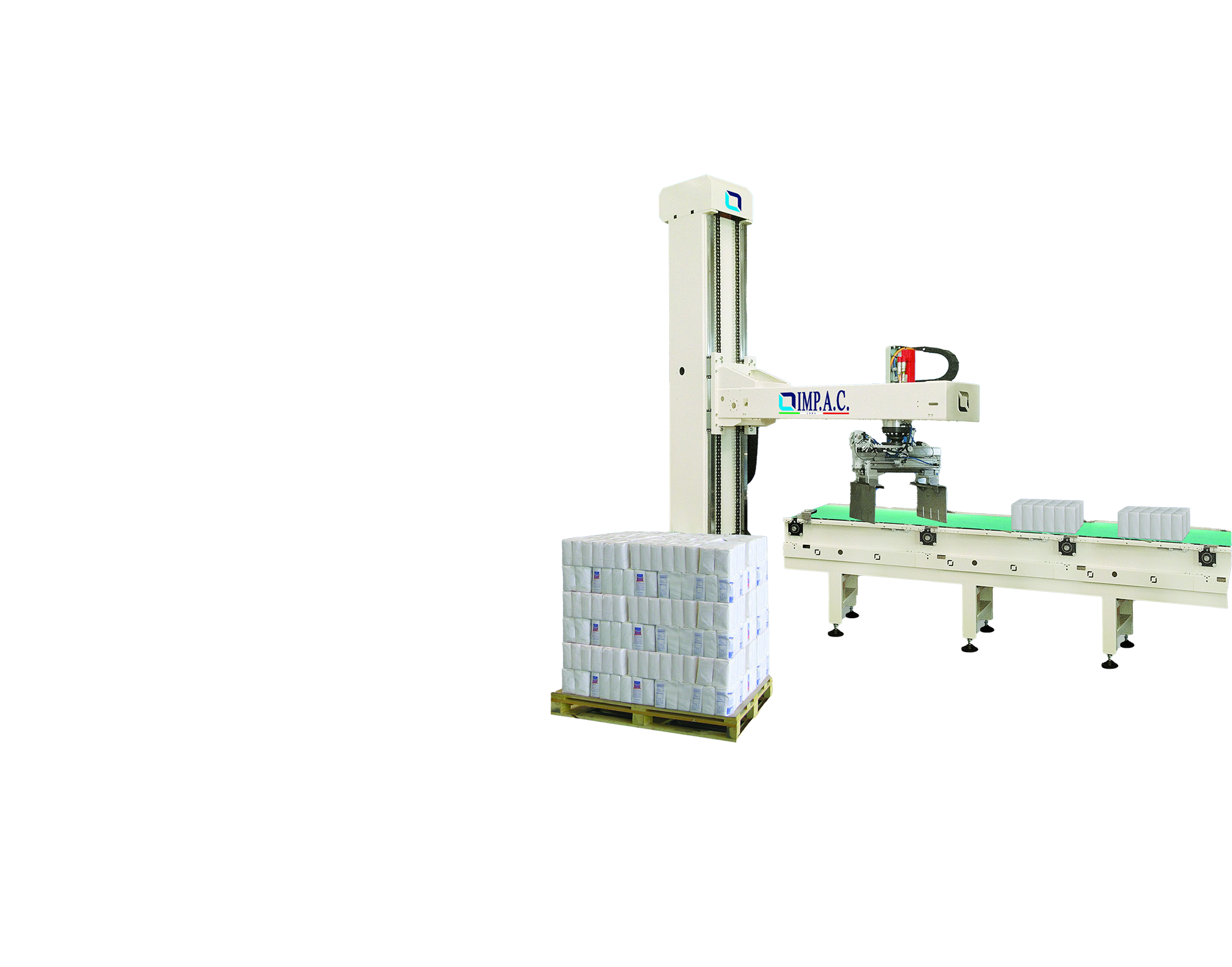

- Cartesian Robot palletizer for bags

- Cartesian Robot palletizer for boxes and bundles

- Mono-column pallettizing system for box and bundles

- Monocolumn Robot Palletizer for bags

- High level robot palletizing system for bags

- High level robot palletizing system for box and bundles

- Anthropomorphic Robot palletizer for bags

- Anthropomorphic Robot palletizer for boxes and bundles

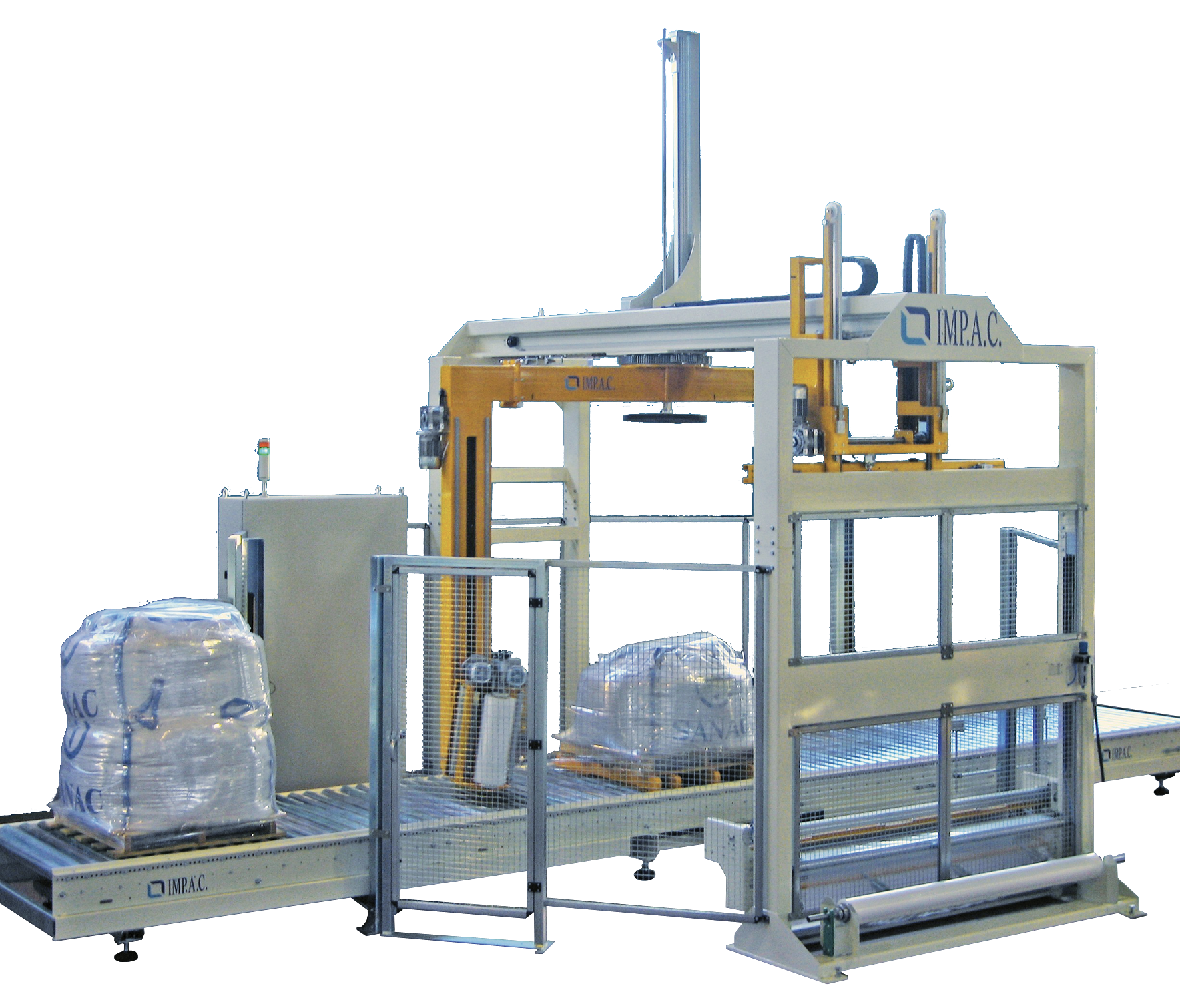

- Stretch wrapping machines

- Stretch hood machines