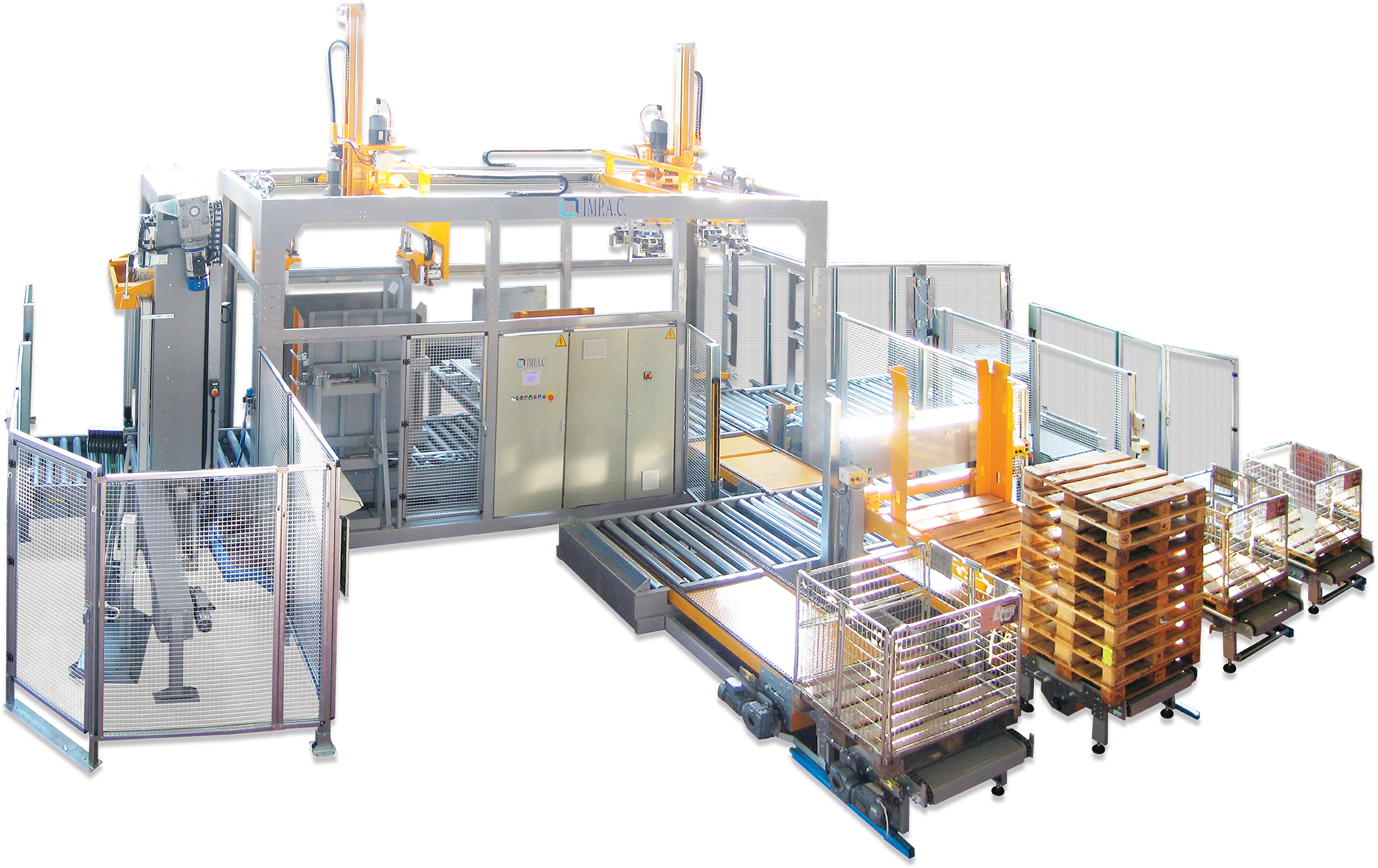

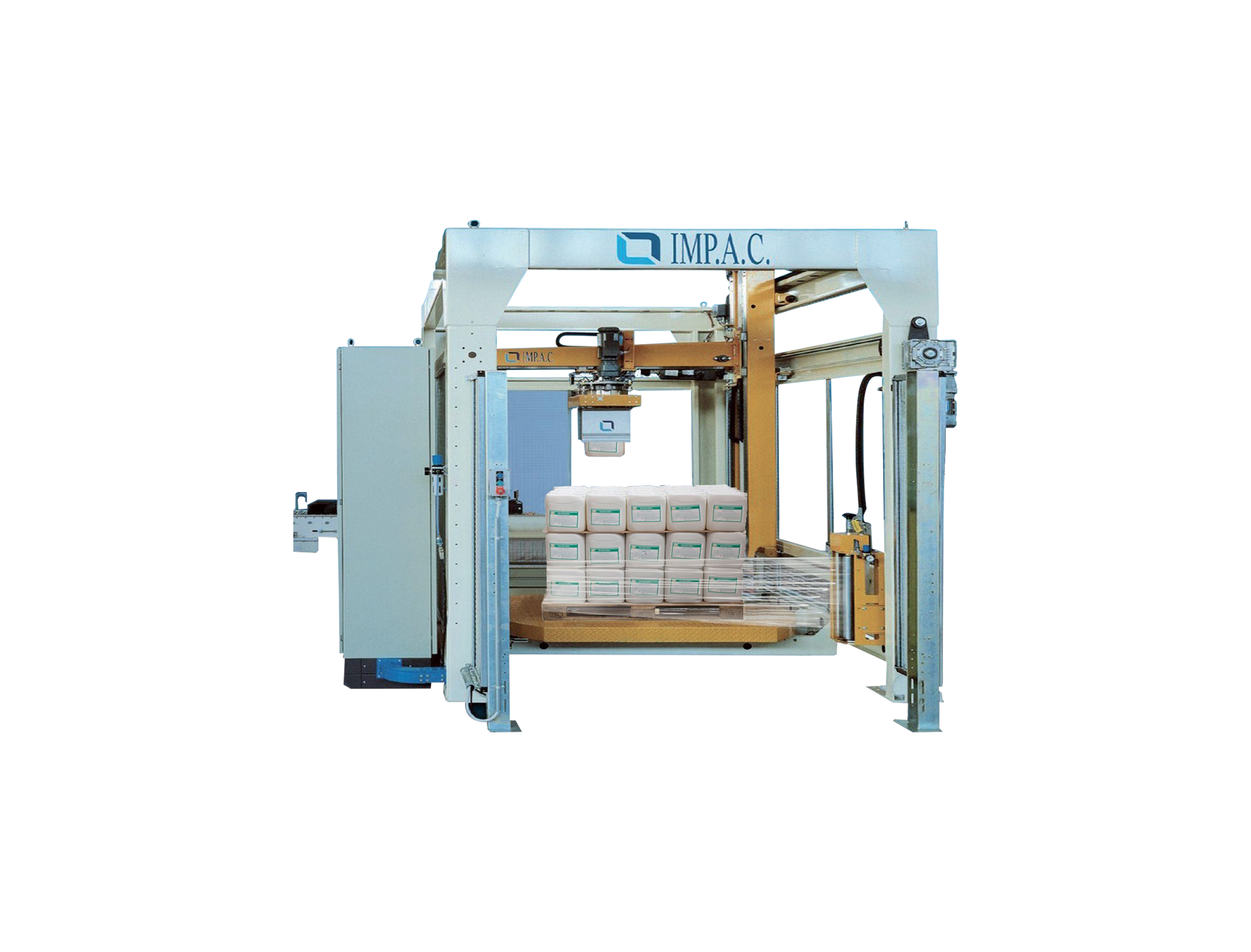

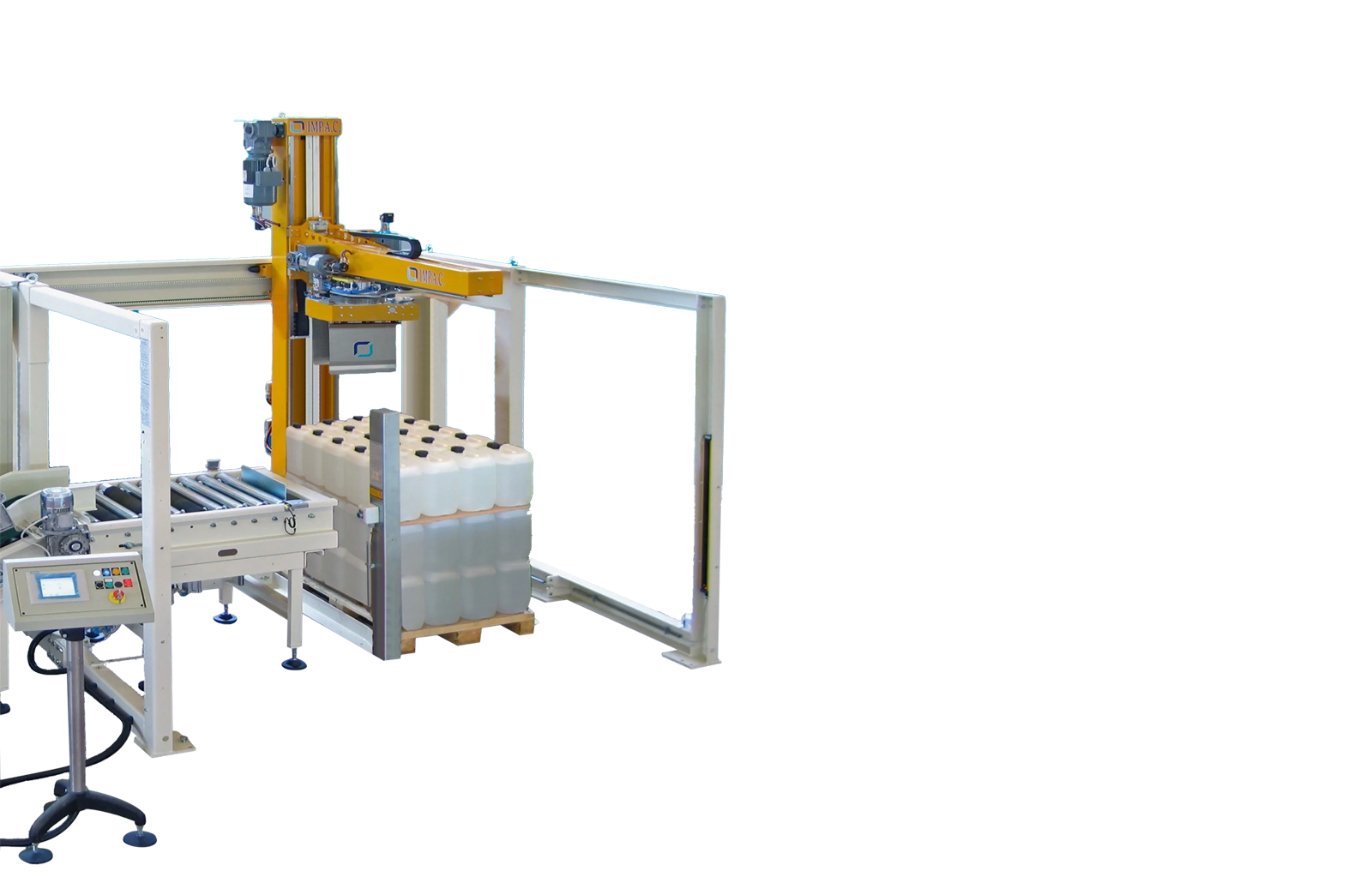

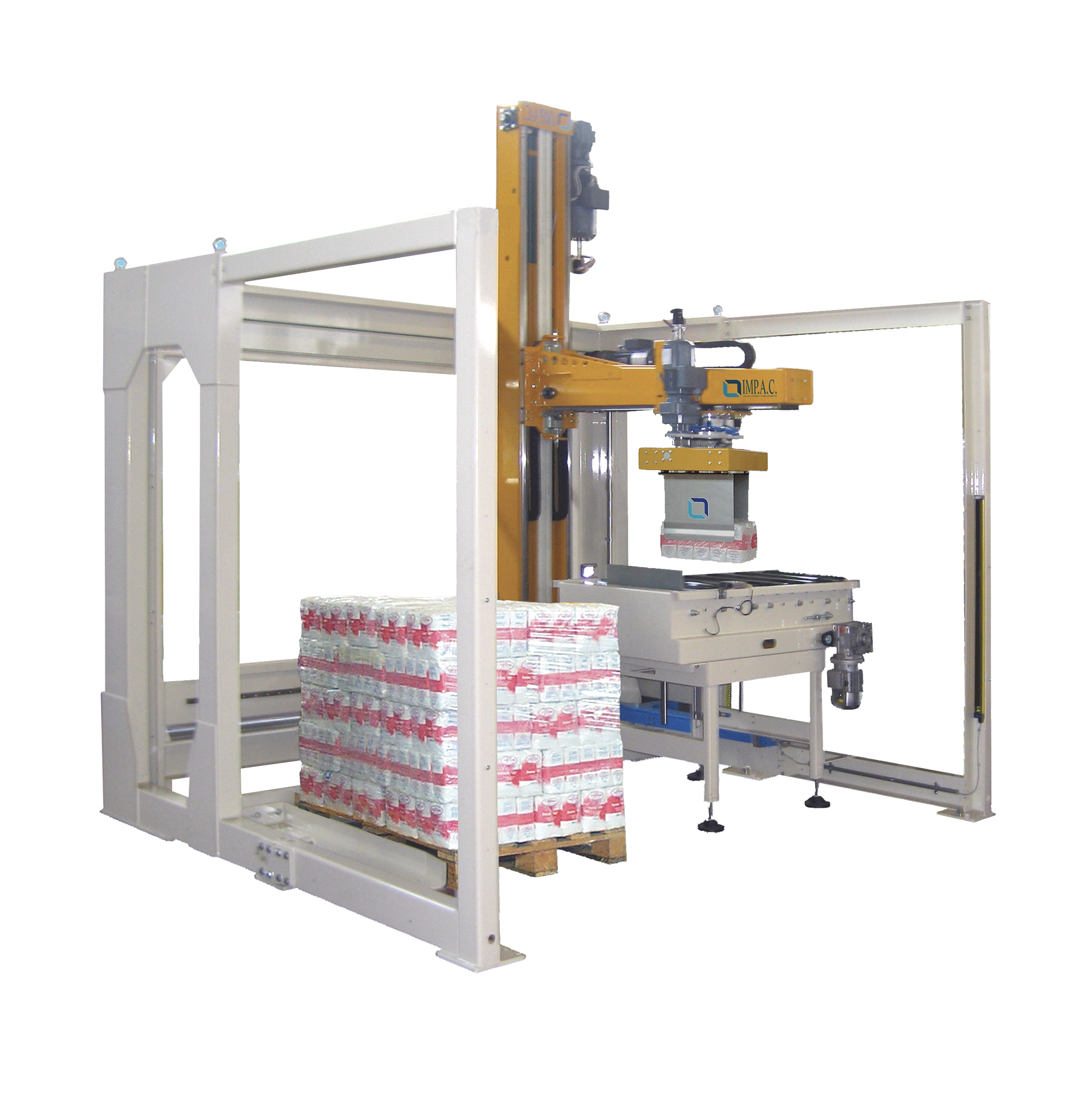

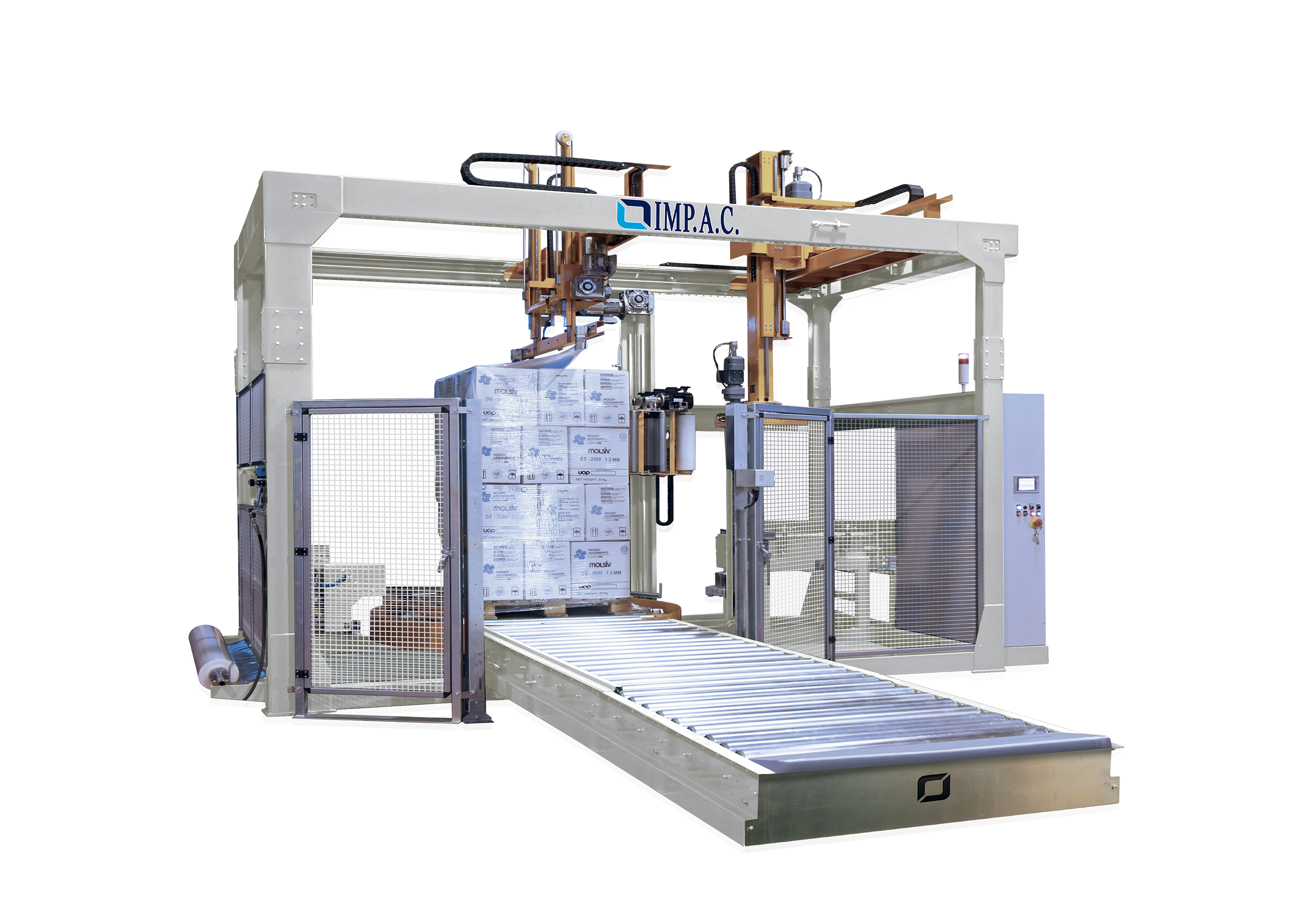

The IMP.A.C. STRETCH AT 100 is a high-speed automatic stretch wrapper, designed for high-production lines (up to 100 pallets/hour).

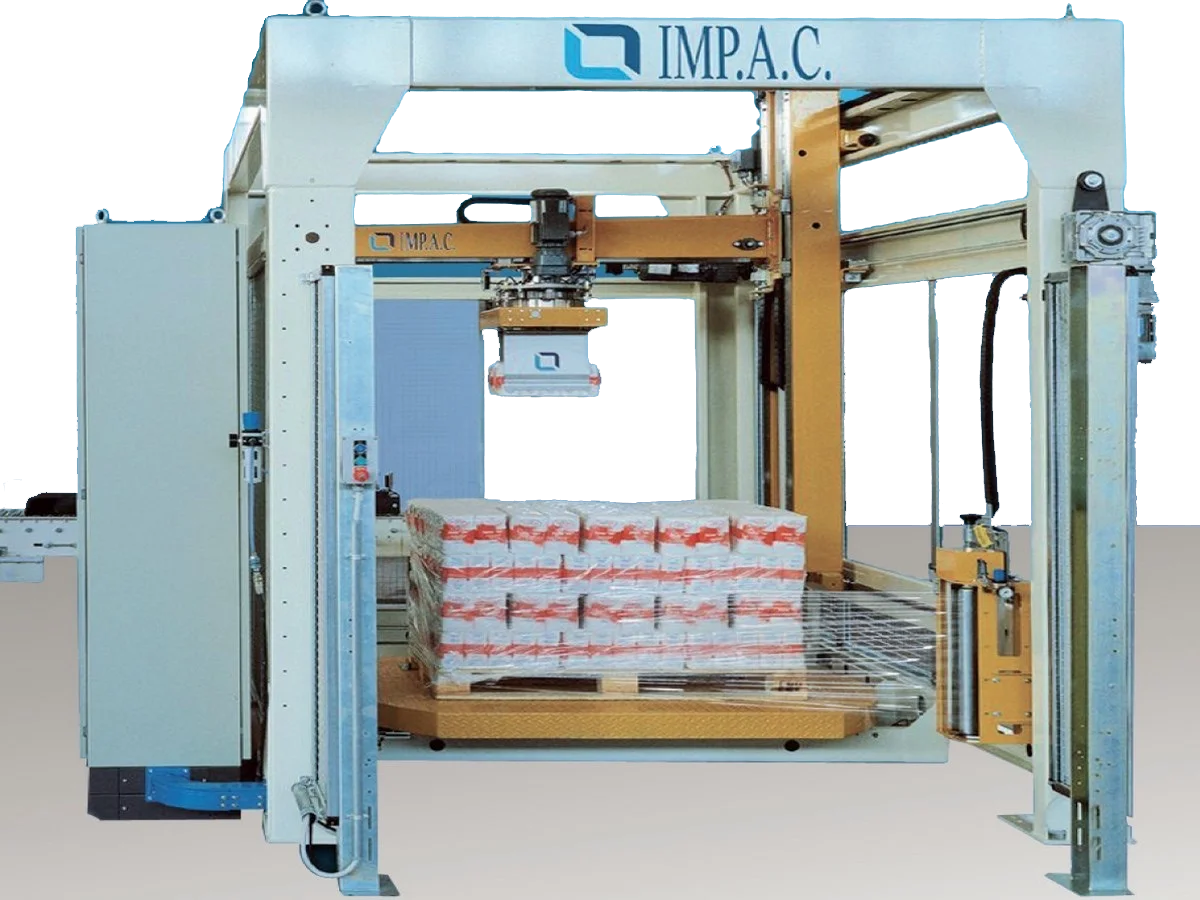

This system ensures complete load protection, thanks to the extension of the cap beneath the pallet, providing stability and security even for unstable products that cannot be handled by traditional wrapping systems, optimized without deformation of the load..

The innovative cold extension technology allows the film to adapt automatically without the need for heating, ensuring an efficient, fast, and safe process.

Technology and Operation

Automated Hooding System

The IMP.A.C. STRETCH AT 100 uses an expandable tubular film, which is cut and sealed to form a cap, then stretched and tightly secured around the pallet.

Automatic adjustment to the load height

Thanks to real-time dimensional detection, the machine automatically adjusts the cap length, reducing material waste and optimizing processing time.

High-performance operating cycle

Pallet entry and dimensional detection.

Unwinding of the film from the tubular reel.

Opening of the film and gripping at four points.

Cutting and sealing to form the hood.

Mechanical crimping of the film through motorized wheels at the four corners.

Unfolding of the hood with shape control via the descent of the mobile frame.

Release of the hood beneath the pallet for an airtight seal.

Automated pallet evacuation.

Maximum ease of use and maintenance.

Patented system.

The IMP.A.C. STRETCH AT 100 represents the ultimate solution for companies with high-speed capping needs, ensuring reliability, precision, and total load protection. The patented system allows for ground-level operation for reel loading and maintenance service.

Automatic stretch hood machine with a patented top down system

Max Production: 100 pallets/hour

Pallet dimensions

Max. 2000 h mm

Min. 500 h mm

Type of film

Stretchable, elastic polyethylene

Auxiliary voltage

24 V

Compressed air consumption

200 Nl/min

Full pallet weight

Max. 2000Kg

Operational capacity

100 pallets/hour

Installed power

14 KW

Film thickness

Max. 200 micron

Min.80 micron

Air pressure

6 bar

Indicative weight

6000 Kg

Product benefits

__ Complete protection

__ Complete protection

The stretch hood seals the load, protecting it from dust, moisture, and environmental agents.

__ Material savings

__ Material savings

Automatic adjustment to optimize film consumption.

__ Fully automatic process

__ Fully automatic process

No manual intervention required, improving efficiency and productivity.

__ Optimal stabilization

__ Optimal stabilization

Perfect for loads that are difficult to handle with traditional wrapping systems.

__ Maximum speed and productivity

__ Maximum speed and productivity

Ideal for high-flow systems, up to 100 pallets/h.

__ Patented system

__ Patented system

With coil loading at ground level.

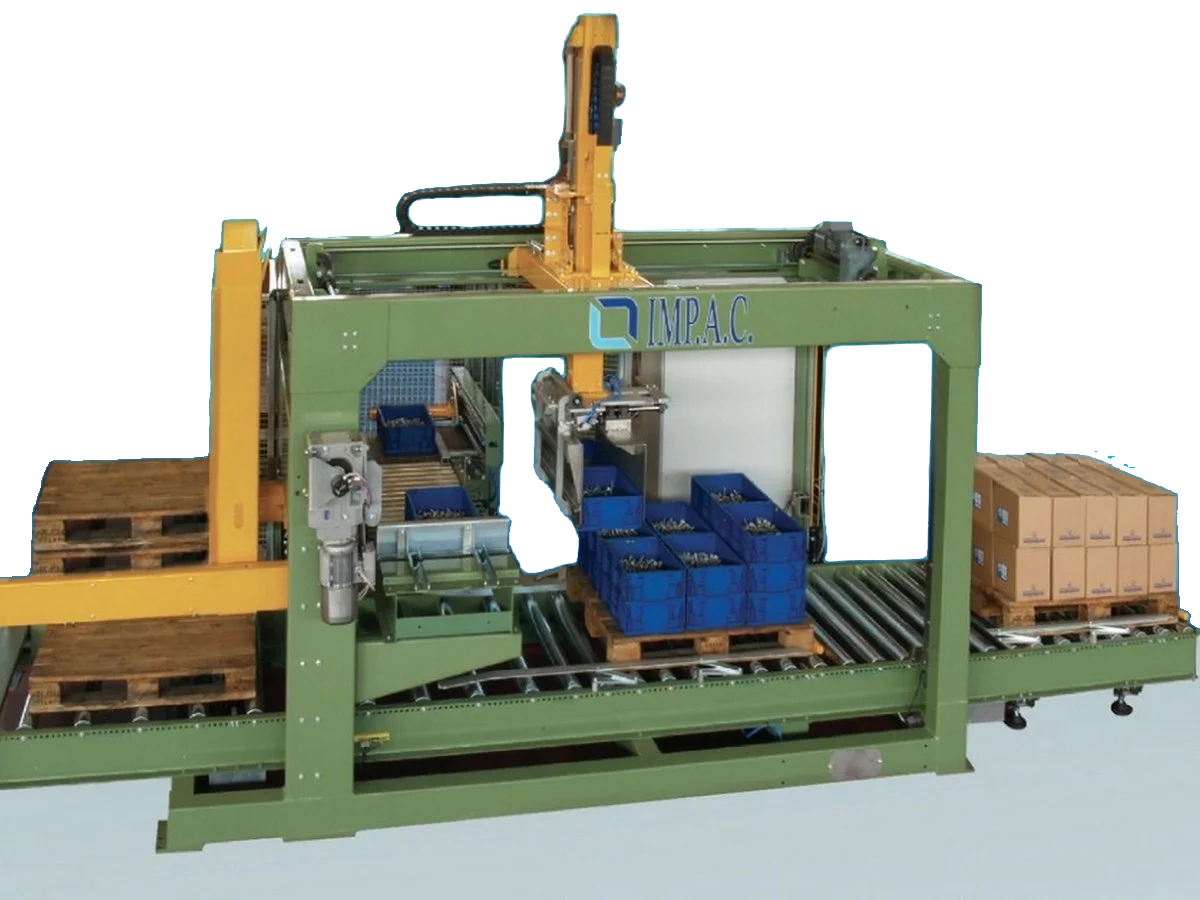

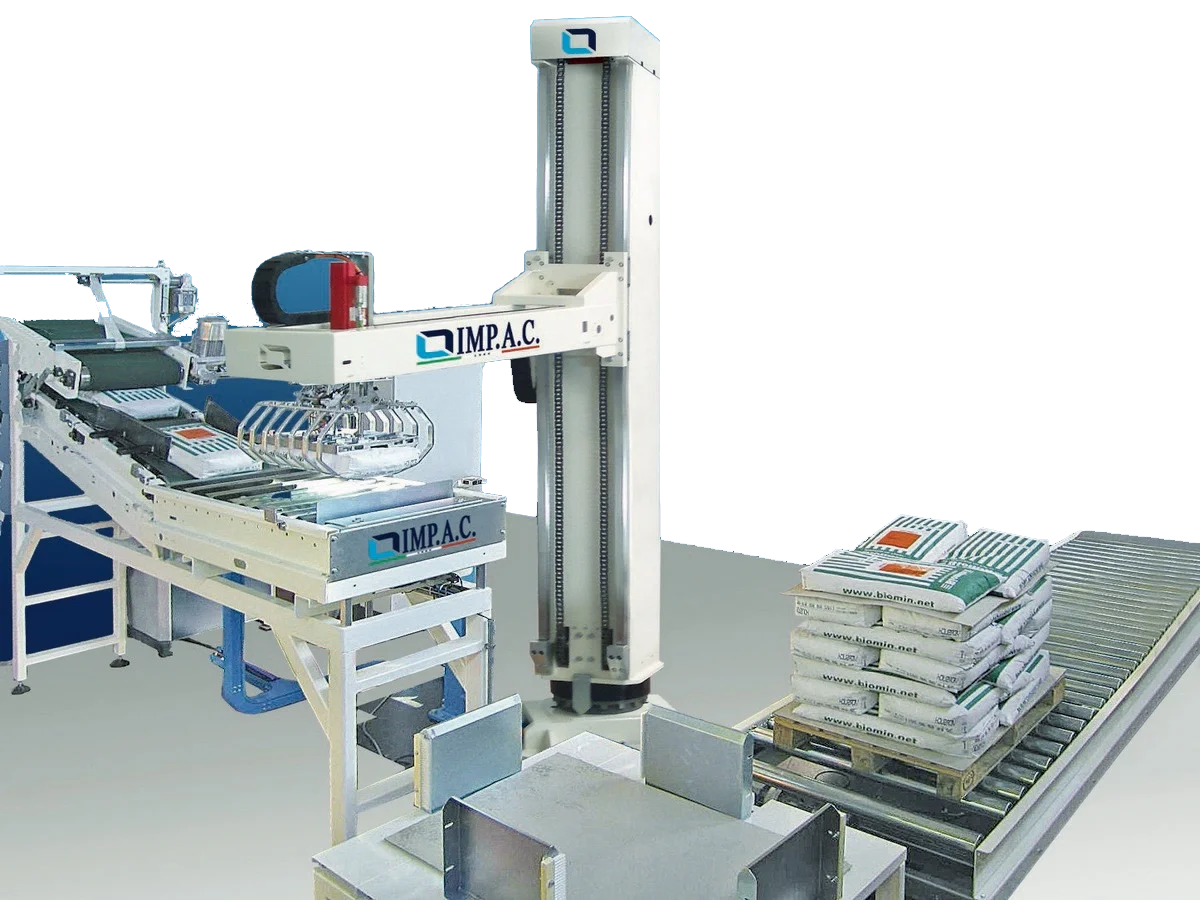

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

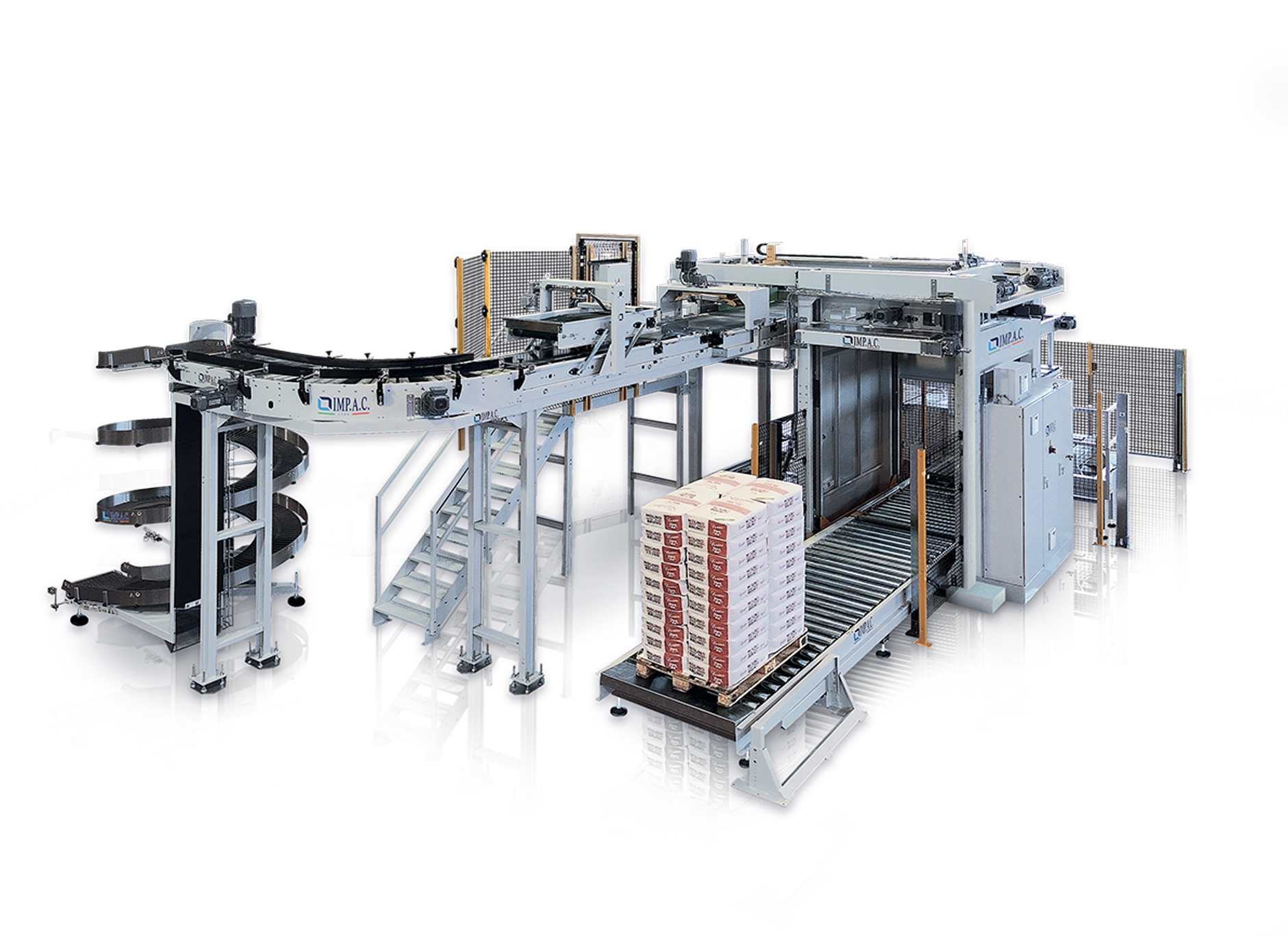

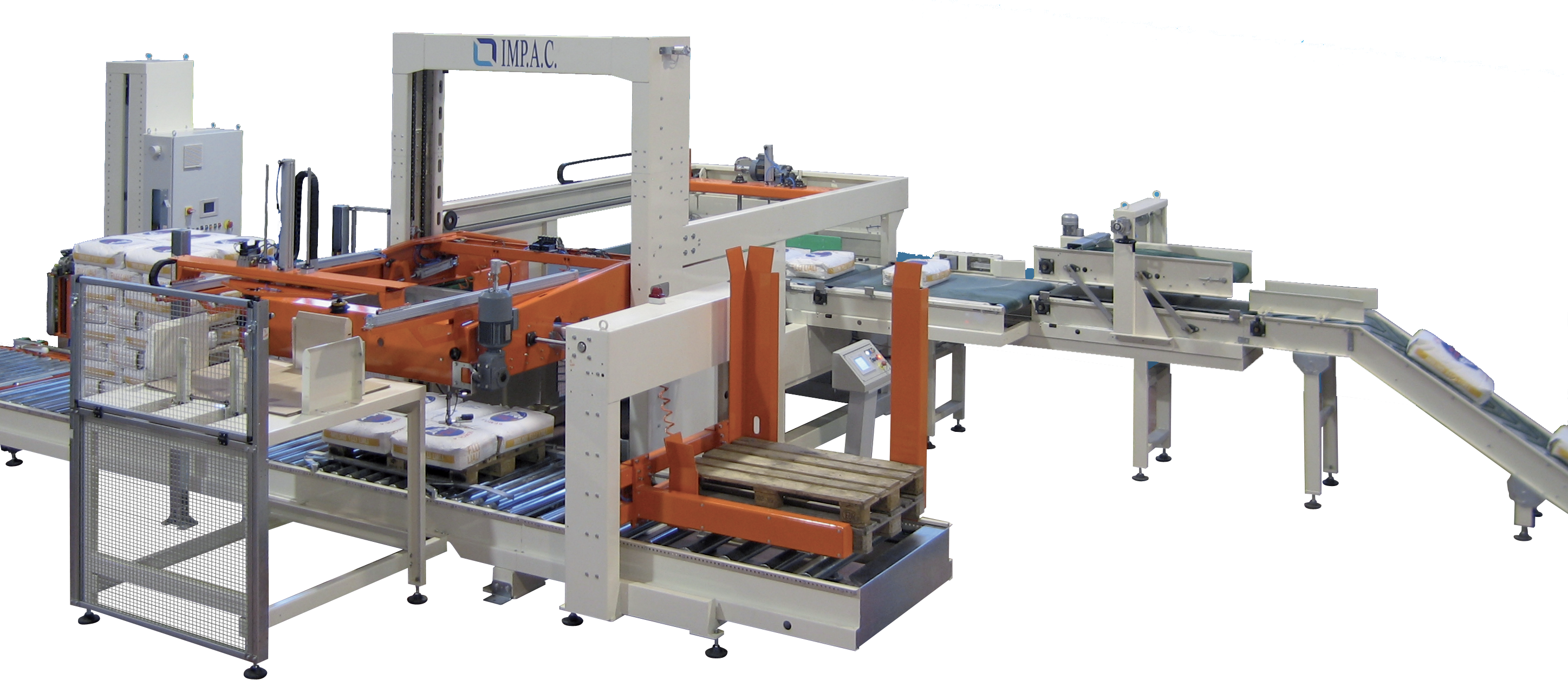

- High level paletizing system for box and bundles

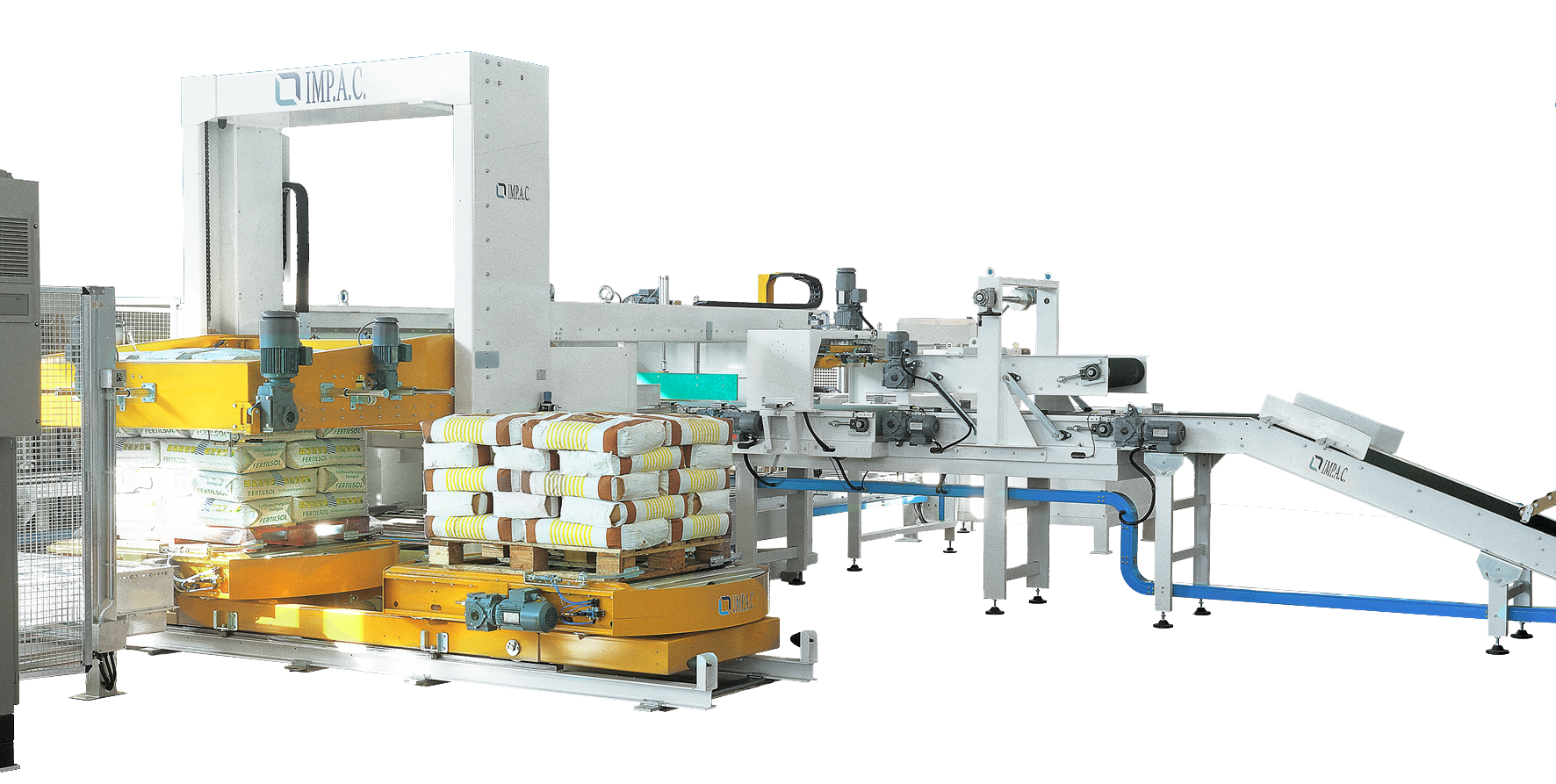

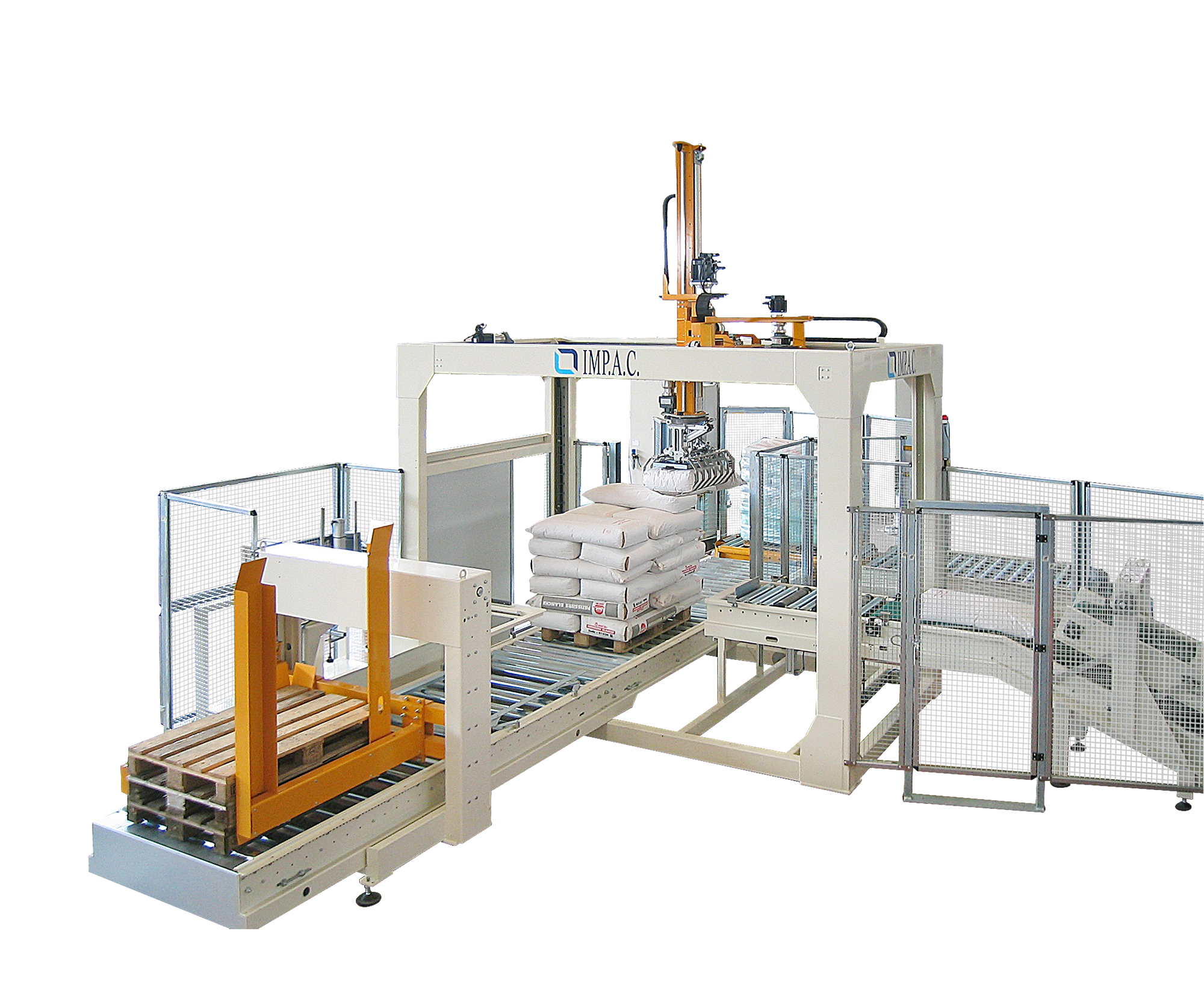

- High-Level palletizer for bags

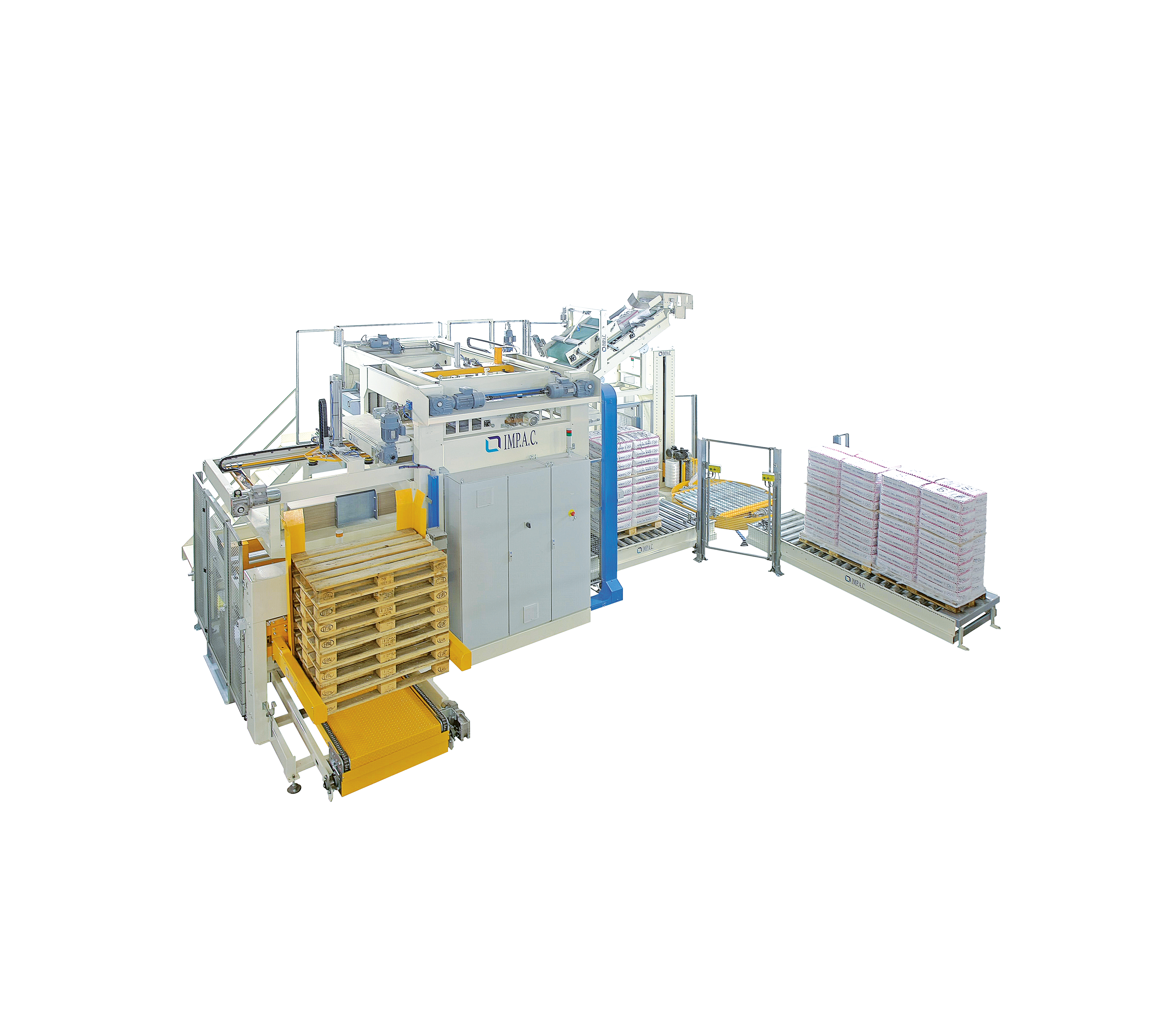

- Low-Level Palletizer for boxes and bundles

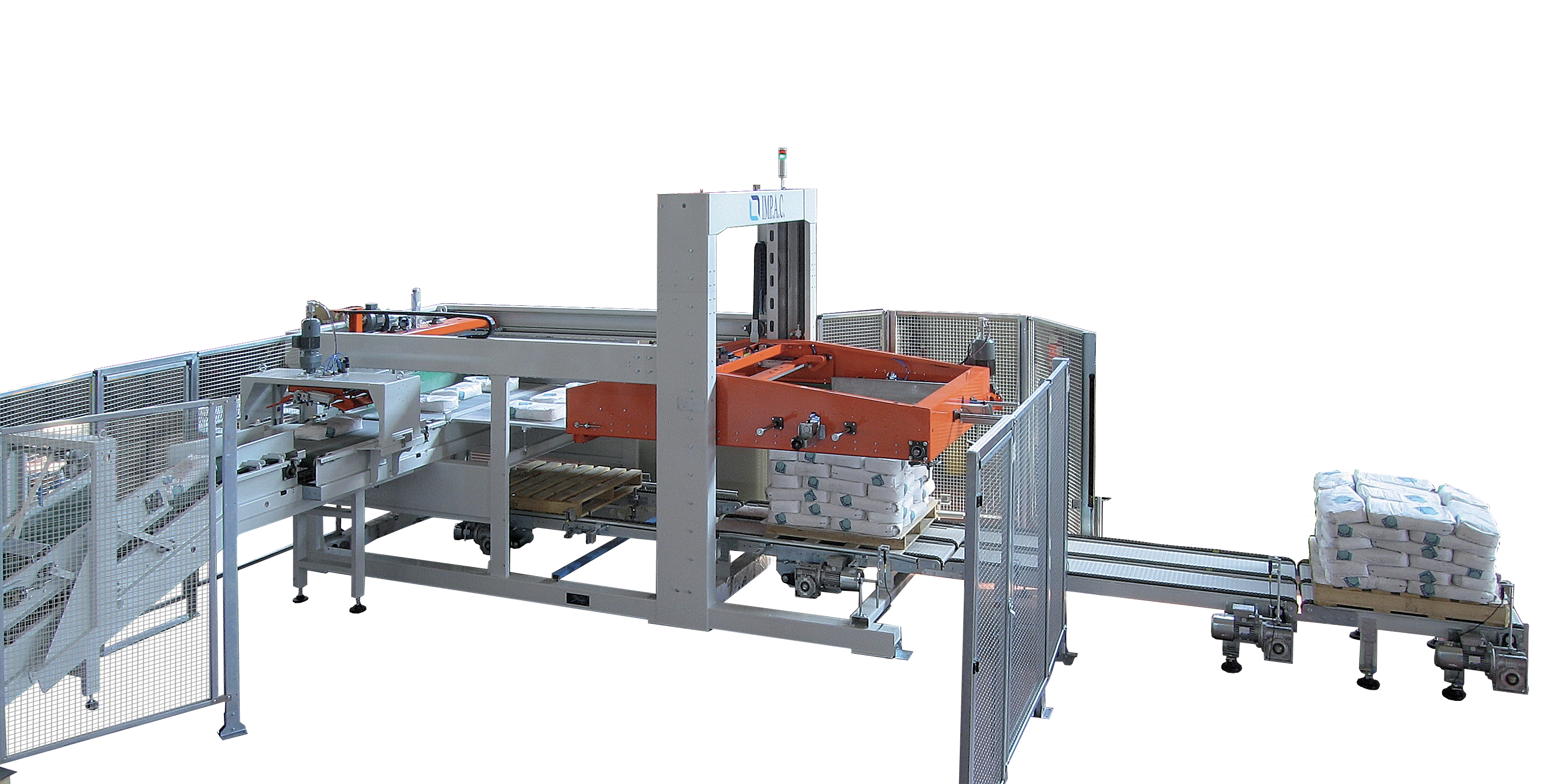

- Low level palletizer for bags

- Low level palletizer for bags

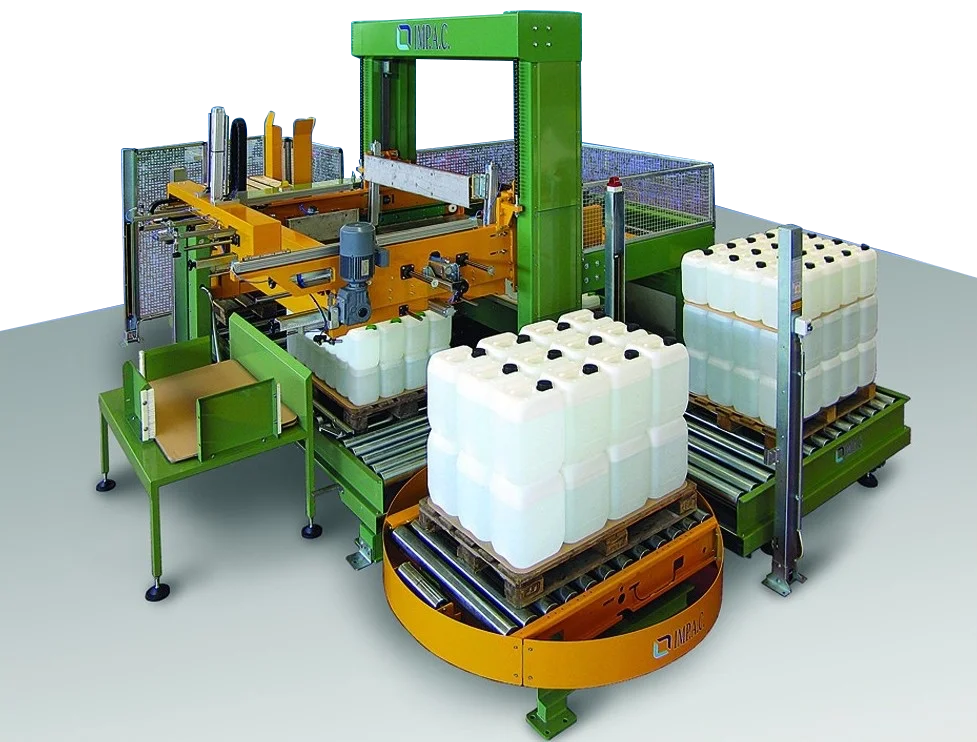

- Low-Level Palletizer for cans

- Cartesian Robot palletizer for bags

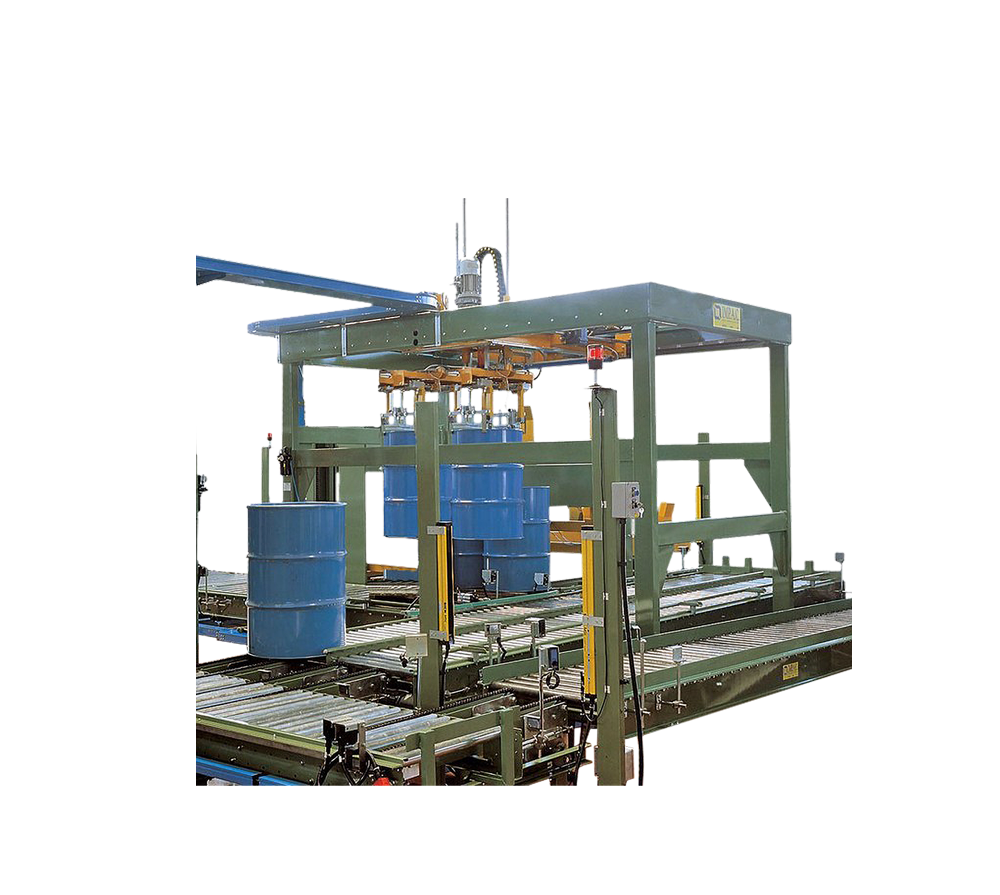

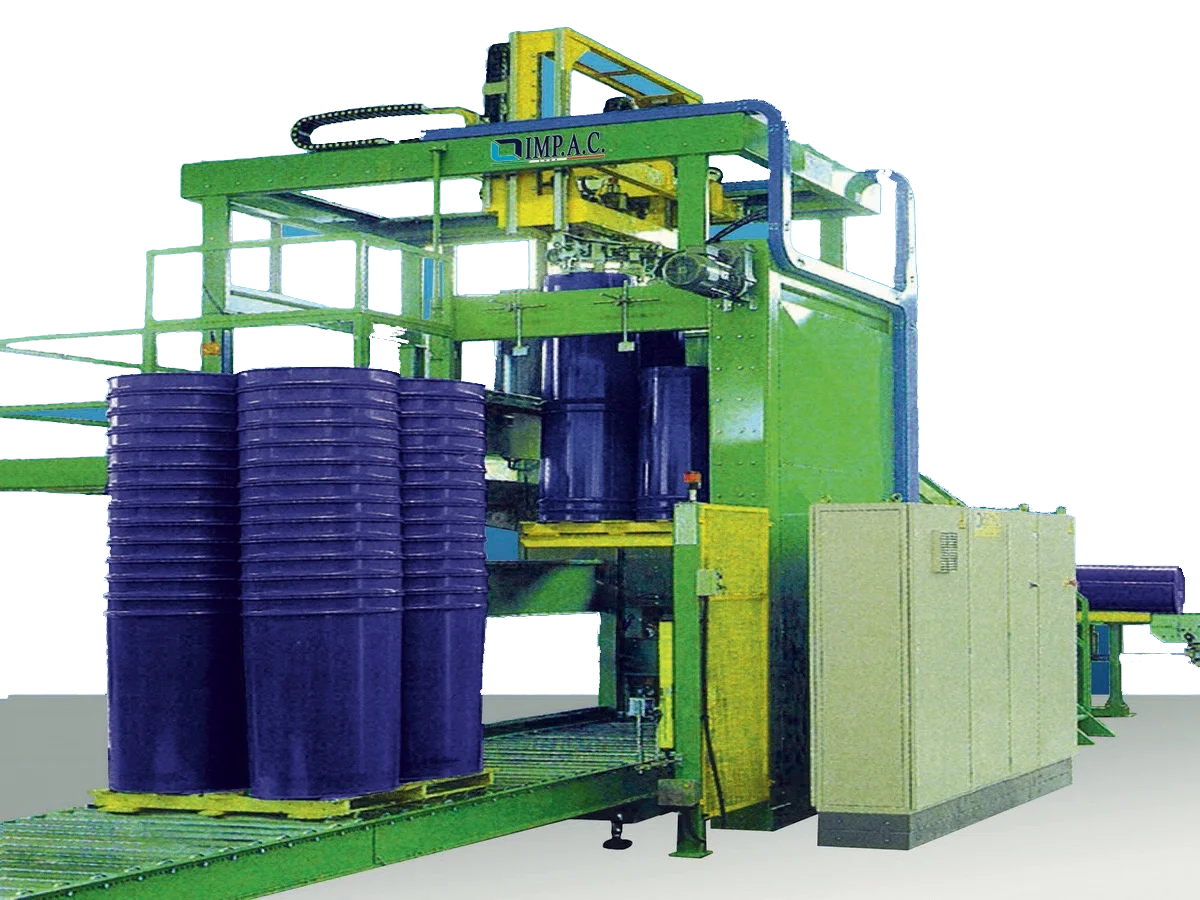

- Cartesian robots for drums, jerrycans and pails

- Cartesian Robot palletizer for boxes and bundles

- Monocolumn Robot Palletizer and Depalletizer for cans pails and drums

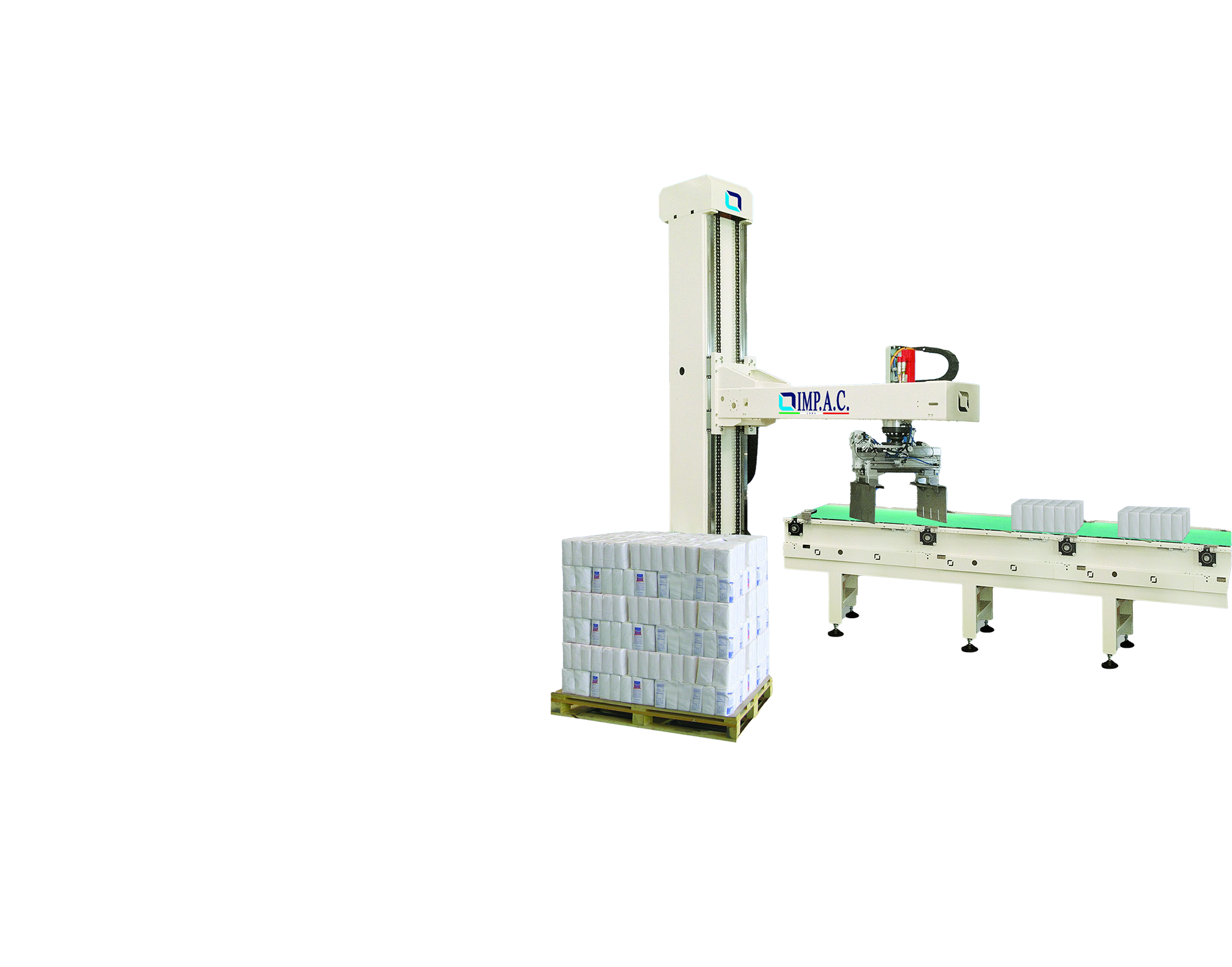

- Monocolumn Robot Palletizer for bags

- Mono-column pallettizing system for box and bundles

- High level robot palletizing system for bags

- High level Robotic palletizer for conical drums

- High level Robotic palletizer for boxes and bundles

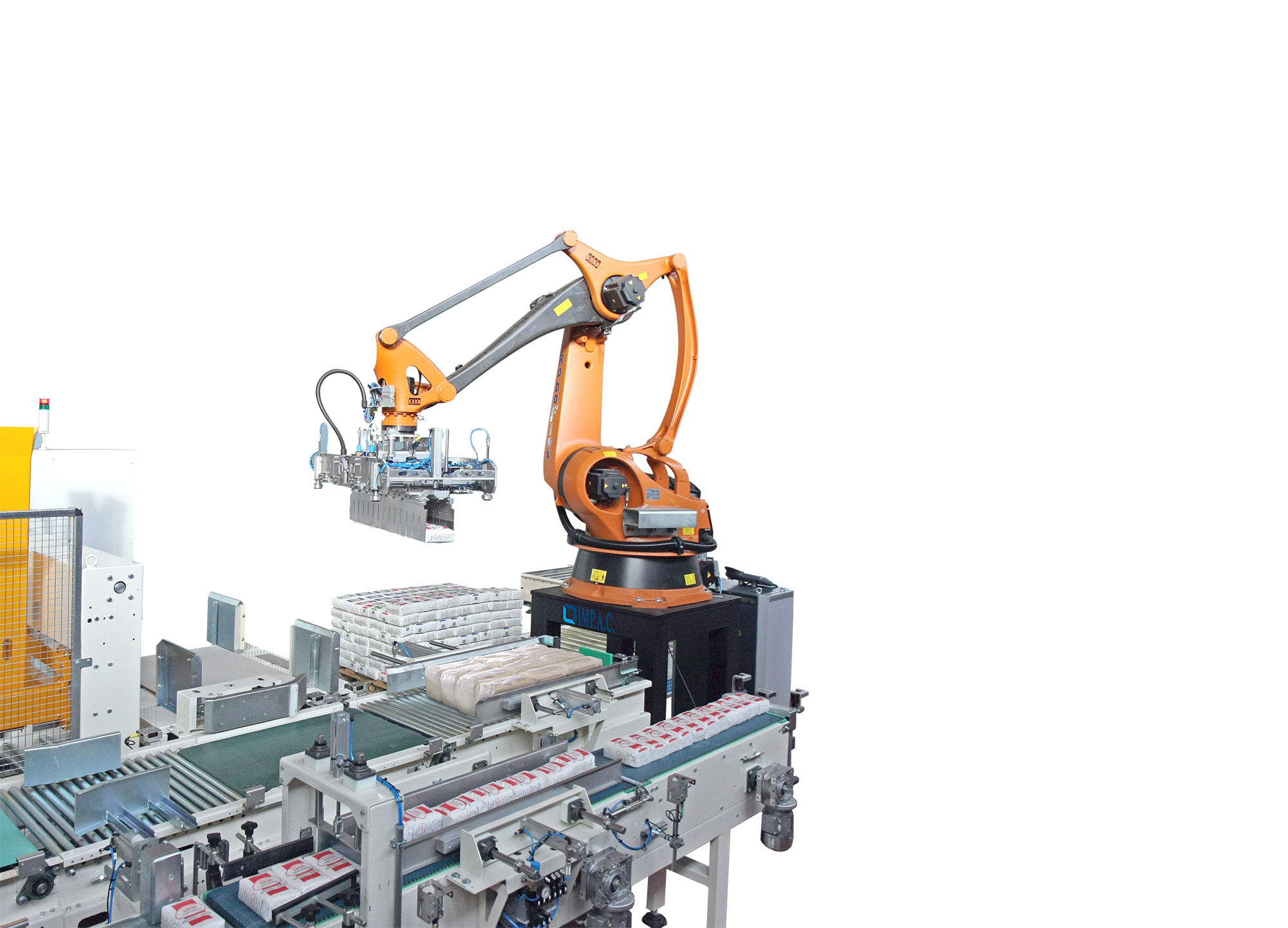

- Anthropomorphic Robot palletizer for boxes and bundles

- Anthropomorphic Robot Palletizer and Depalletizer for cans, pails and drums

- Anthropomorphic Robot palletizer for bags