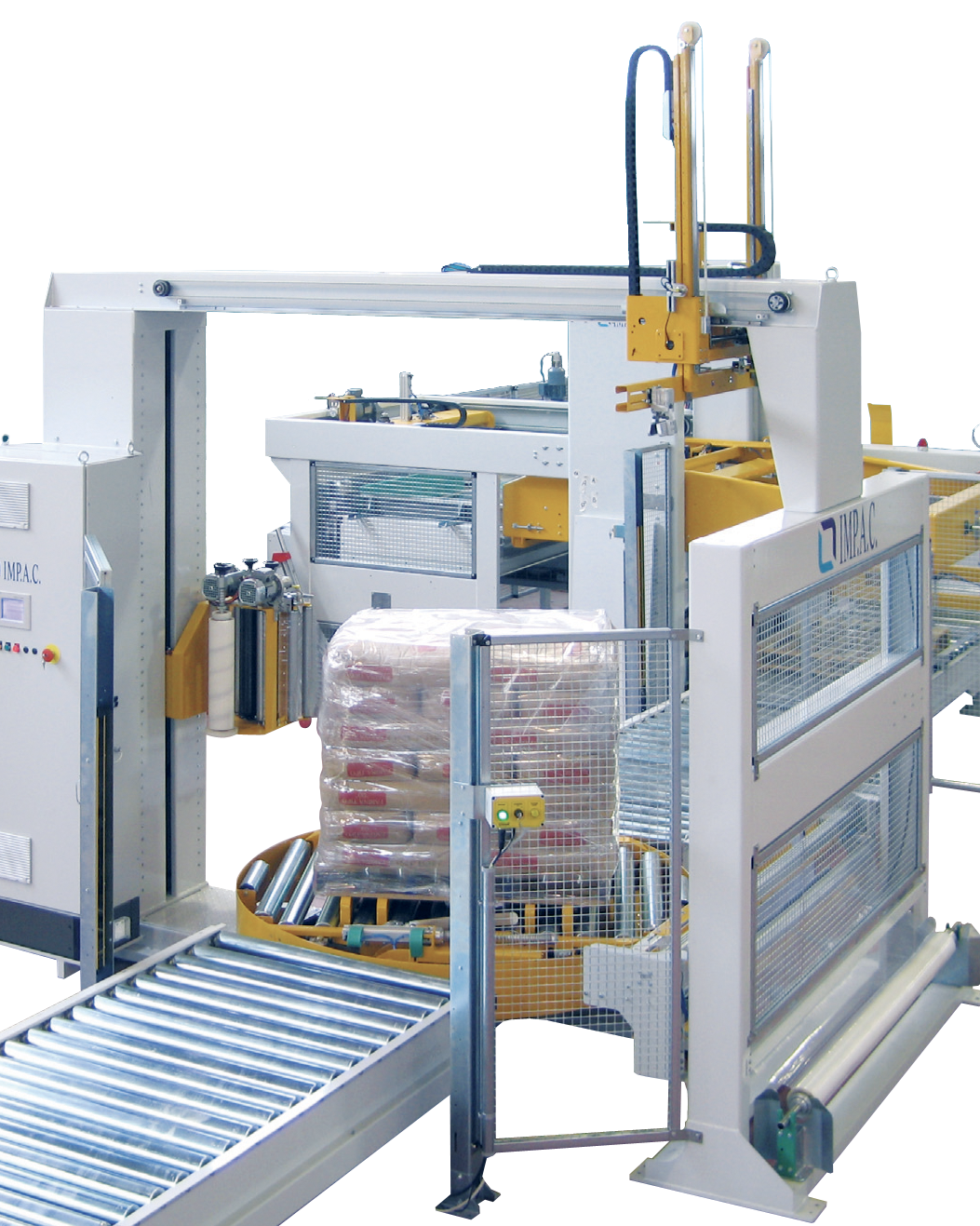

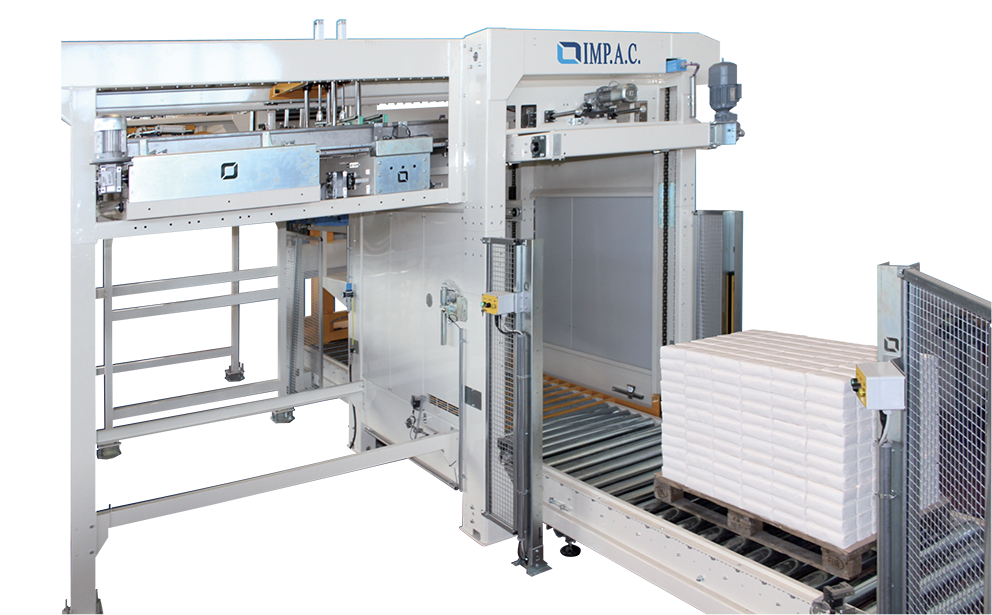

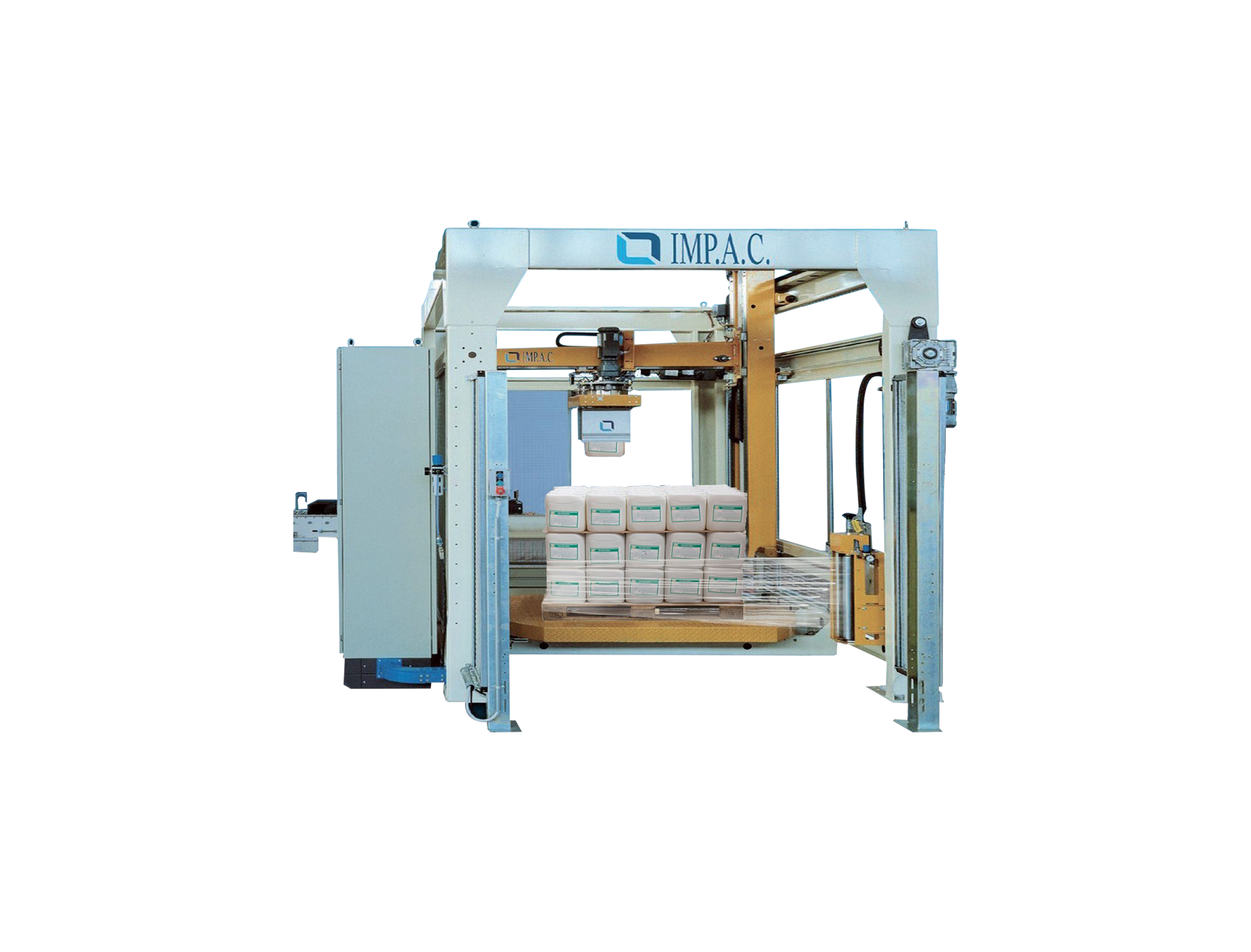

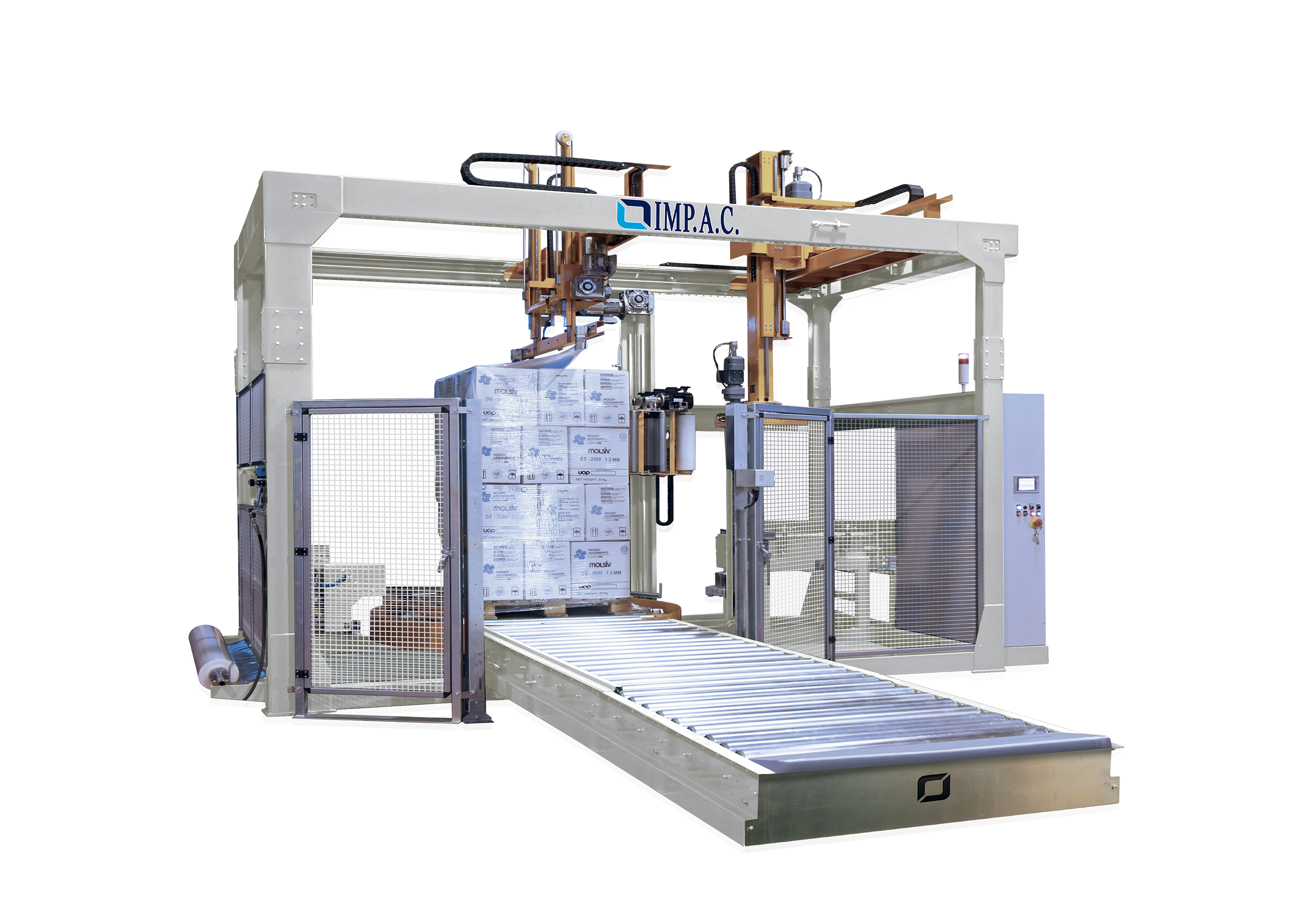

The IMP.A.C. PR A is an automatic pallet wrapper designed to wrap pallets quickly and efficiently in a fully automatic cycle.

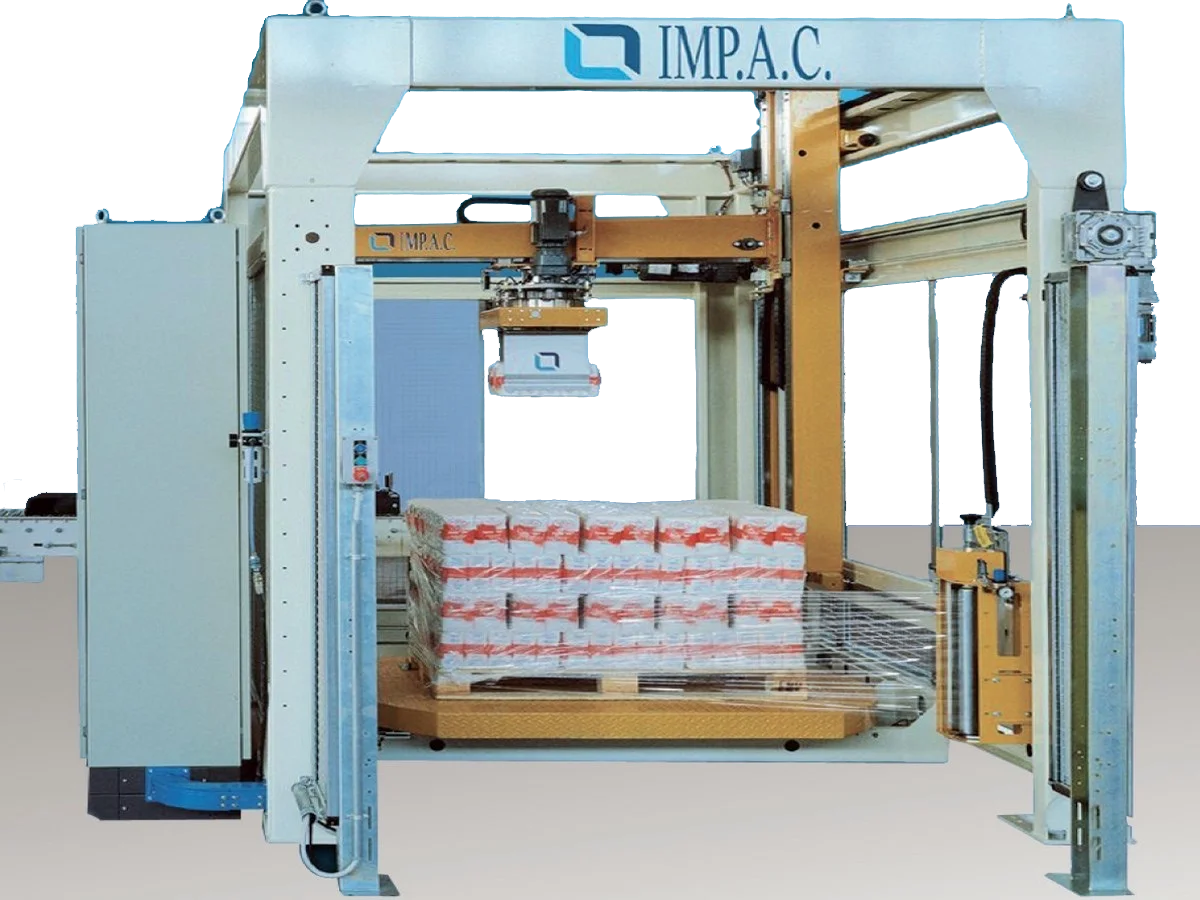

With its rotating platform and rotating pallet, this machine is ideal for medium production applications, handling up to 40 pallets/hour.

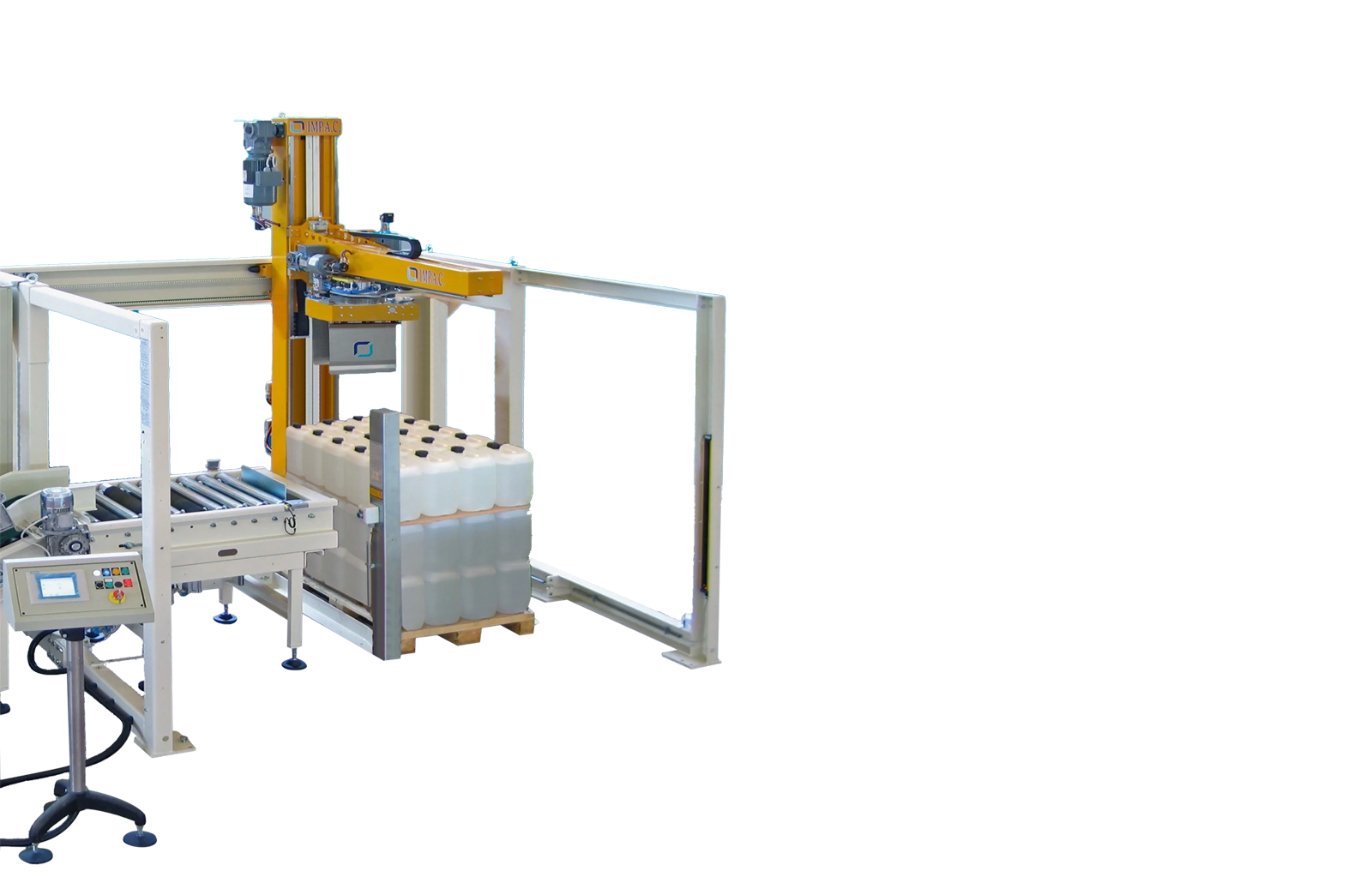

The compact design and motorised roller conveyor ensure low space requirements and easy integration into existing production lines.

Technology and Operation

Full automatic cycle

The winding process is started automatically, with the machine running the cycle without the need for manual intervention.

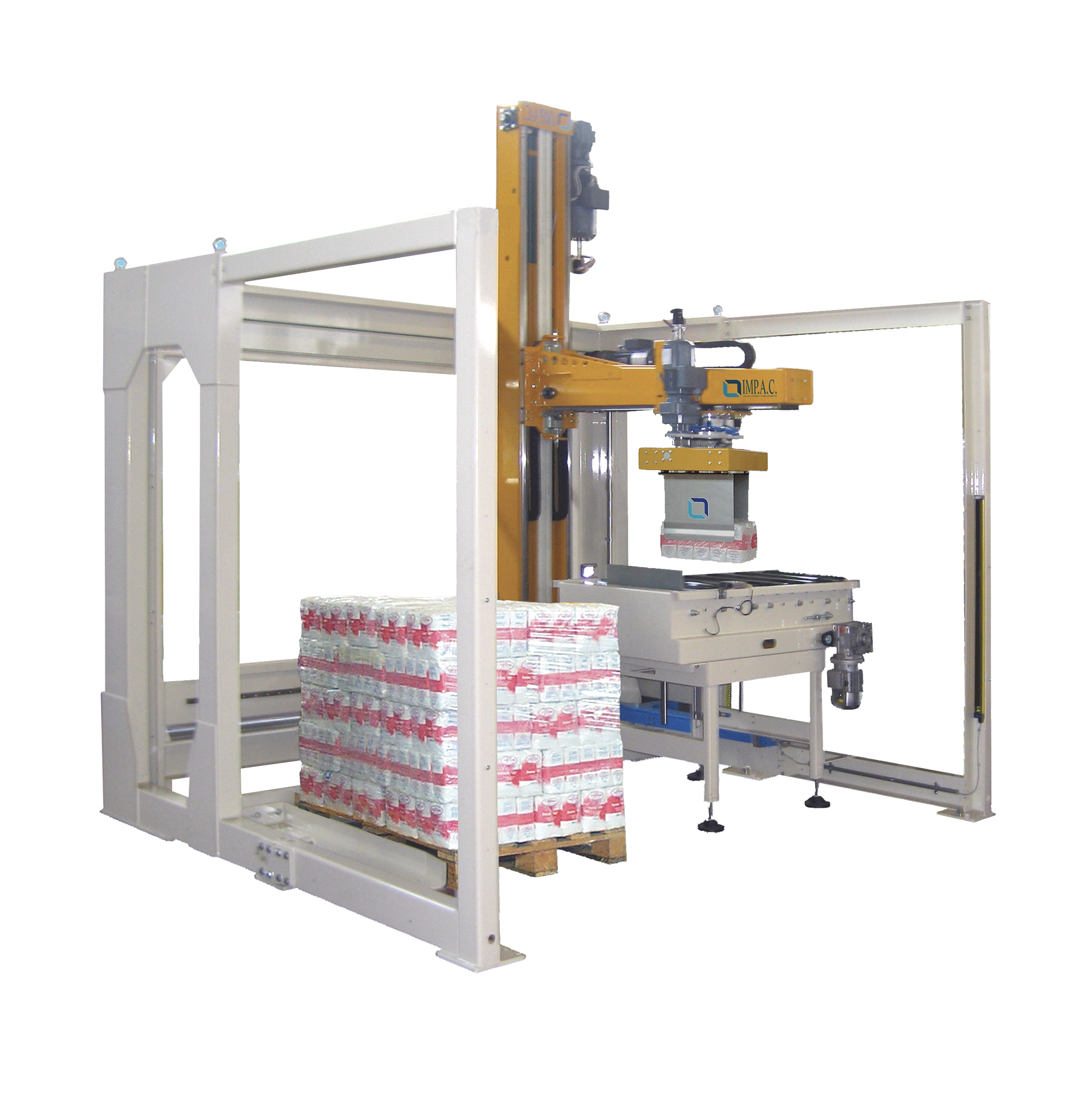

Spiral wrapping system

The winder uses a spiral wrapping technique, which ensures optimal pallet coverage and greater load stability.

Motorised roller conveyor and turntable

The motorised roller conveyor facilitates the movement of the pallet through the machine, while the turntable enables precise and uniform wrapping.

Main advantages

High production speed: up to 40 pallets/h.

Full automation: Reduced manual intervention and improved efficiency.

Suitable for medium production: Optimal for palletising systems with intermediate volumes.

Optional upper press: Additional pallet stabilisation for better results.

Compact design: Small footprint and easy integration into existing systems.

Available for different types of packaging.

Optional accessories:

- Film tensioning/strapping device to ventilate/stabilize the palletized product.

- Welding and film cutting device.

- 300% film pre-stretch device.

- Cardboard placing device for pallet protection, for max. height of 400 mm.

The IMP.A.C. PR A is the ideal choice for those who need an automated pallet wrapping system that combines efficiency, reliability and compactness, perfect for medium-capacity production lines.

Turntable stretch wrapping machine

Max. production: 40 pallets/h

Max pallet dimensions.

Max. 1300 x 1250 mm

Max Film Coil Size

Ø 250 x h 300 mm

Compressed air consumption

70 Nl/min

Auxiliary voltage

24 V

Max weight of full pallet

2000 Kg

Standard full pallet height

2000 mm

Operational capacity

40 pallets/h

Installed power

2,5 KW

Operating pressure

6 bar

Indicative weight

2000 Kg

Product benefits

__ Rotating platform

__ Rotating platform

It ensures a smooth and precise movement for pallet wrapping.

__ Total automation

__ Total automation

The winding cycle is fully automatic, improving efficiency and reducing manual intervention.

__ Motorised roller conveyor

__ Motorised roller conveyor

It ensures the correct positioning and movement of the pallet during the entire wrapping cycle.

__ Upper press option

__ Upper press option

An optional device stabilises the pallet during wrapping, ensuring a better quality of the end result.

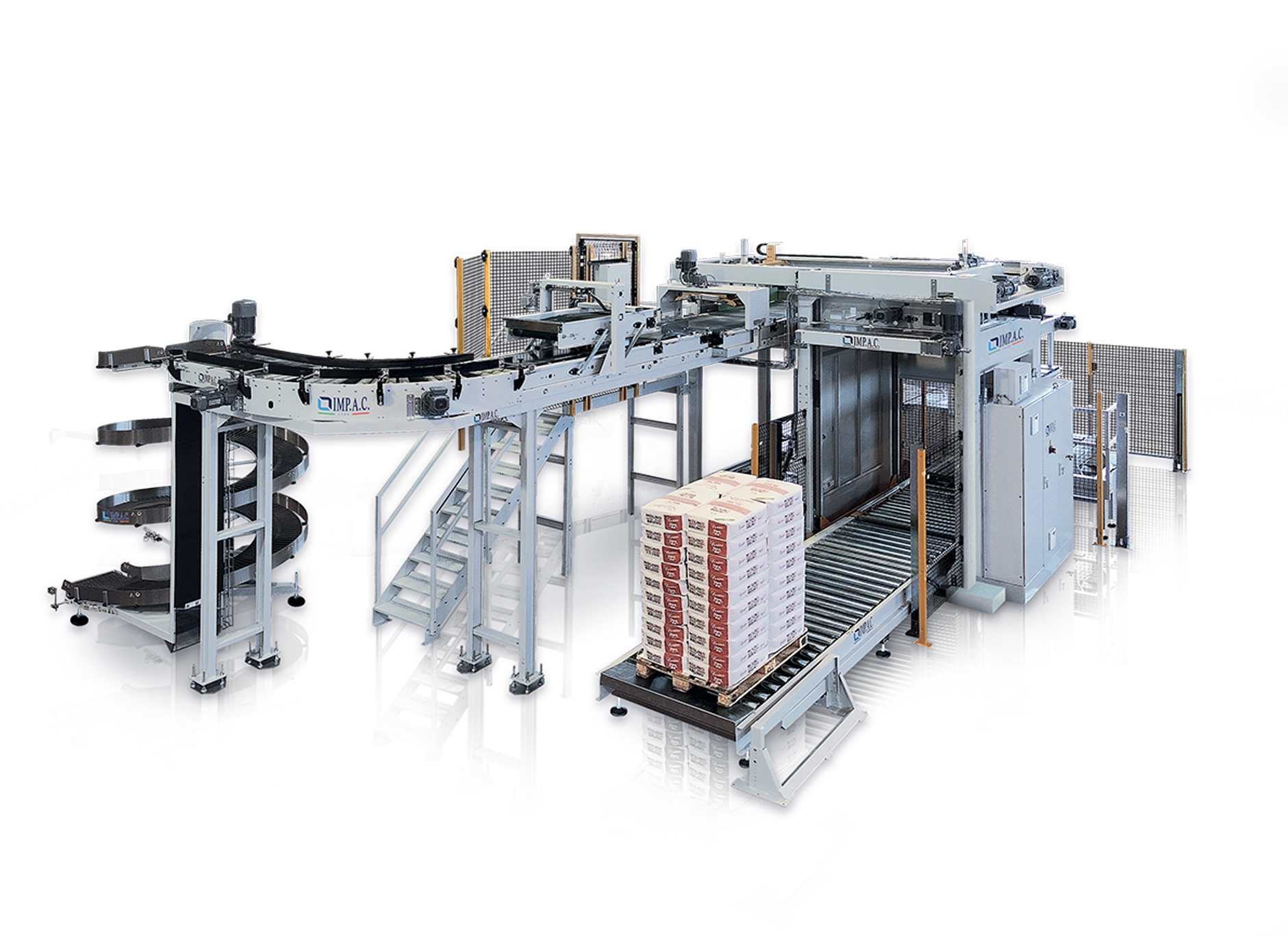

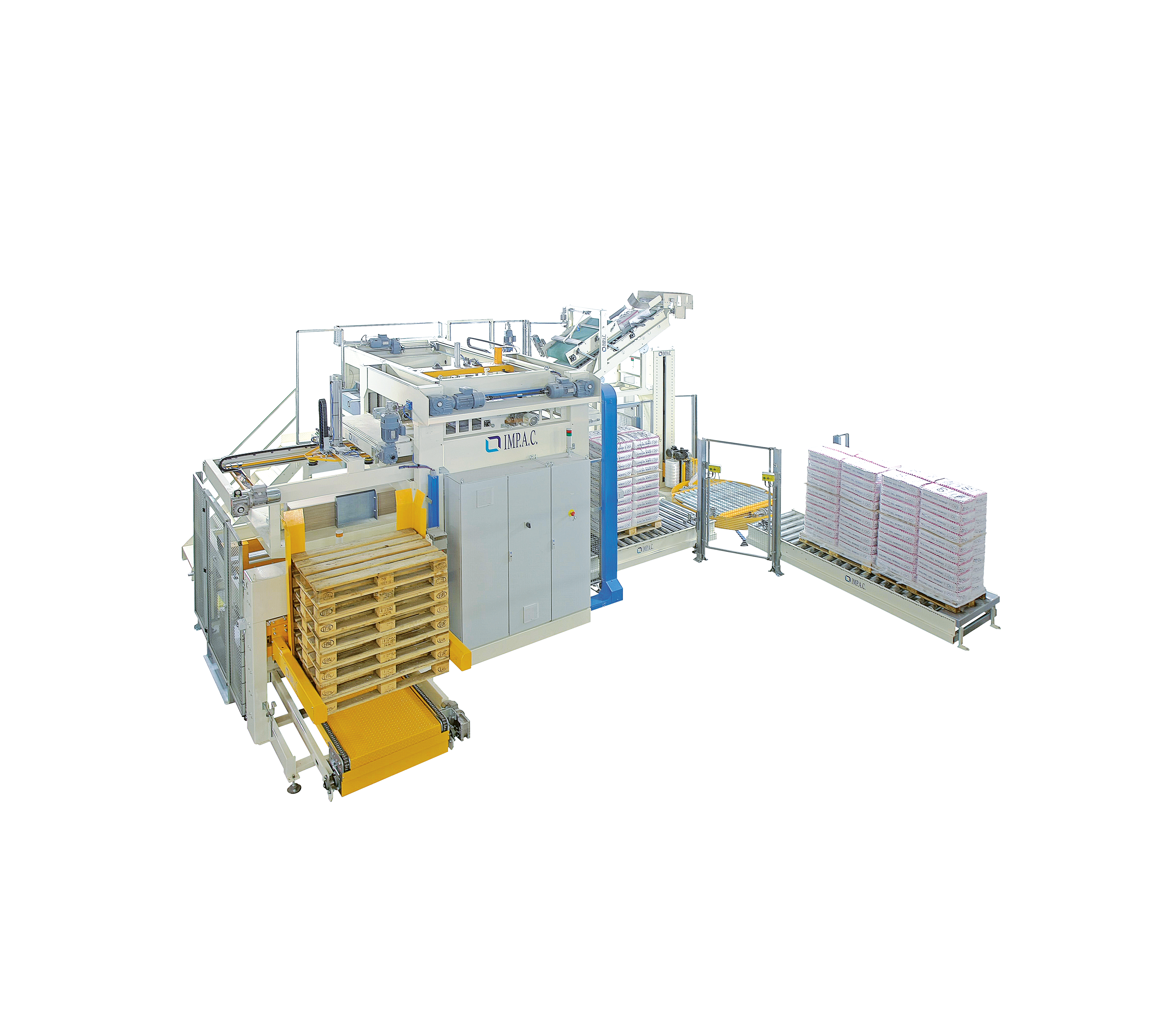

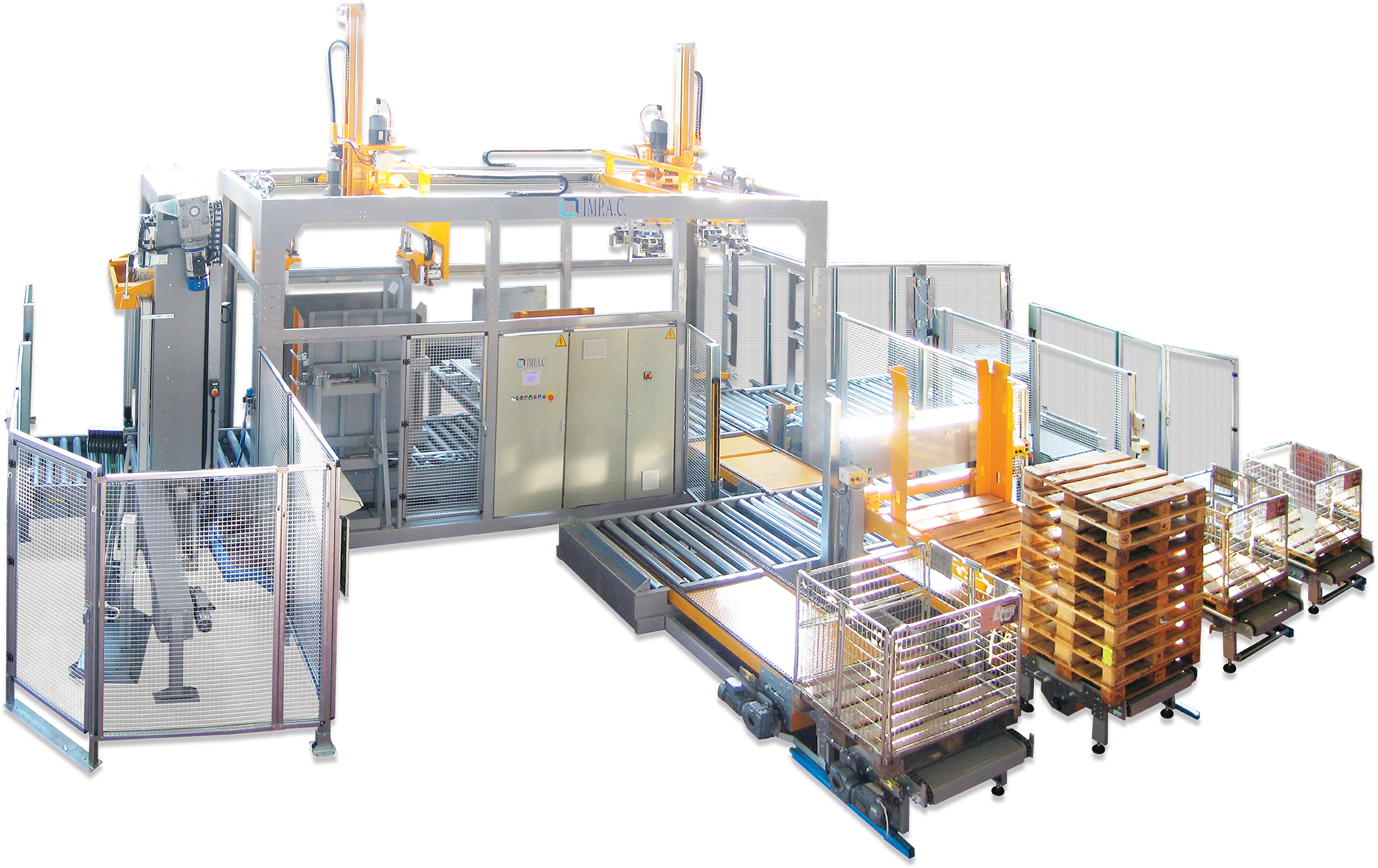

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

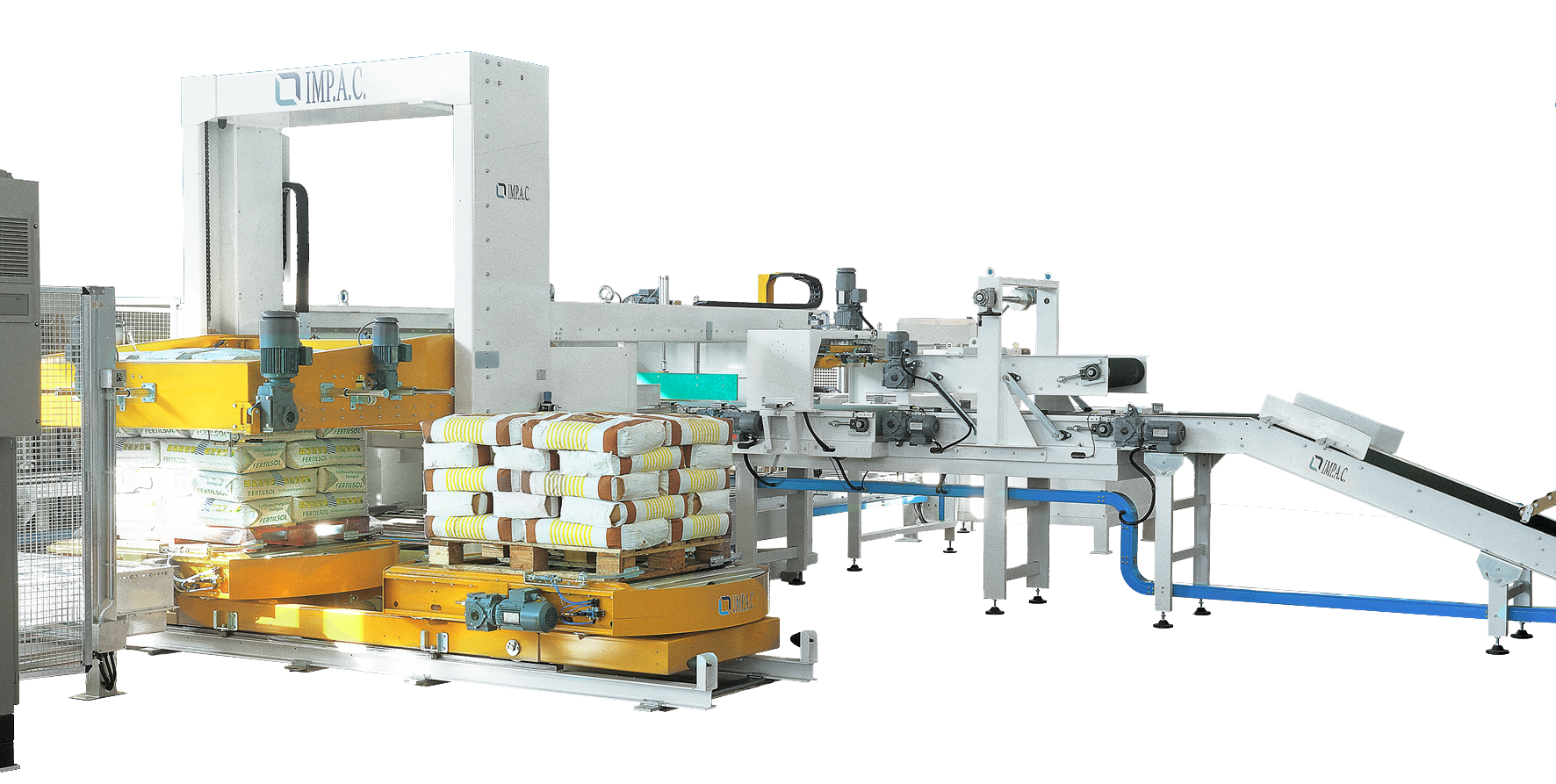

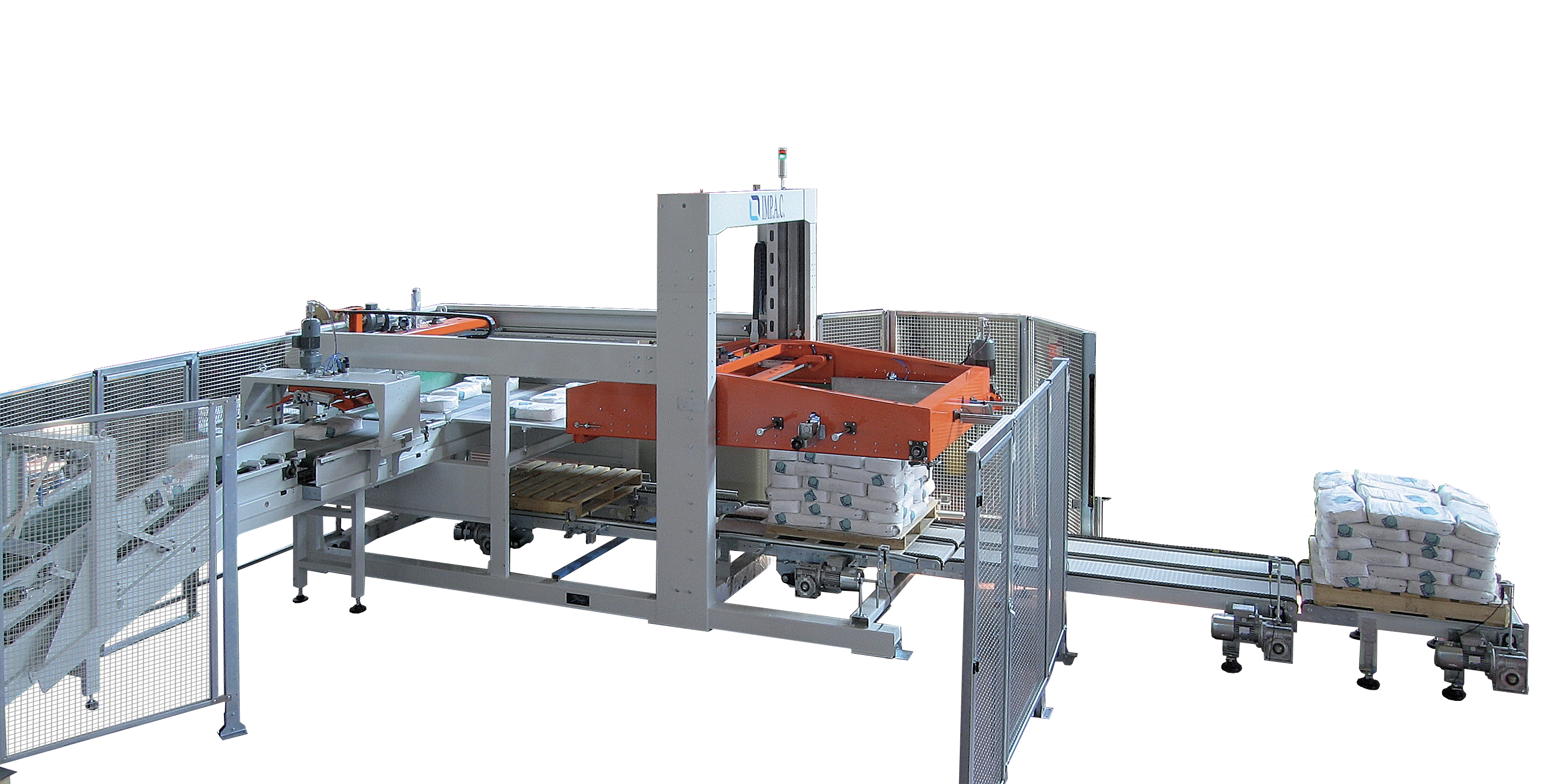

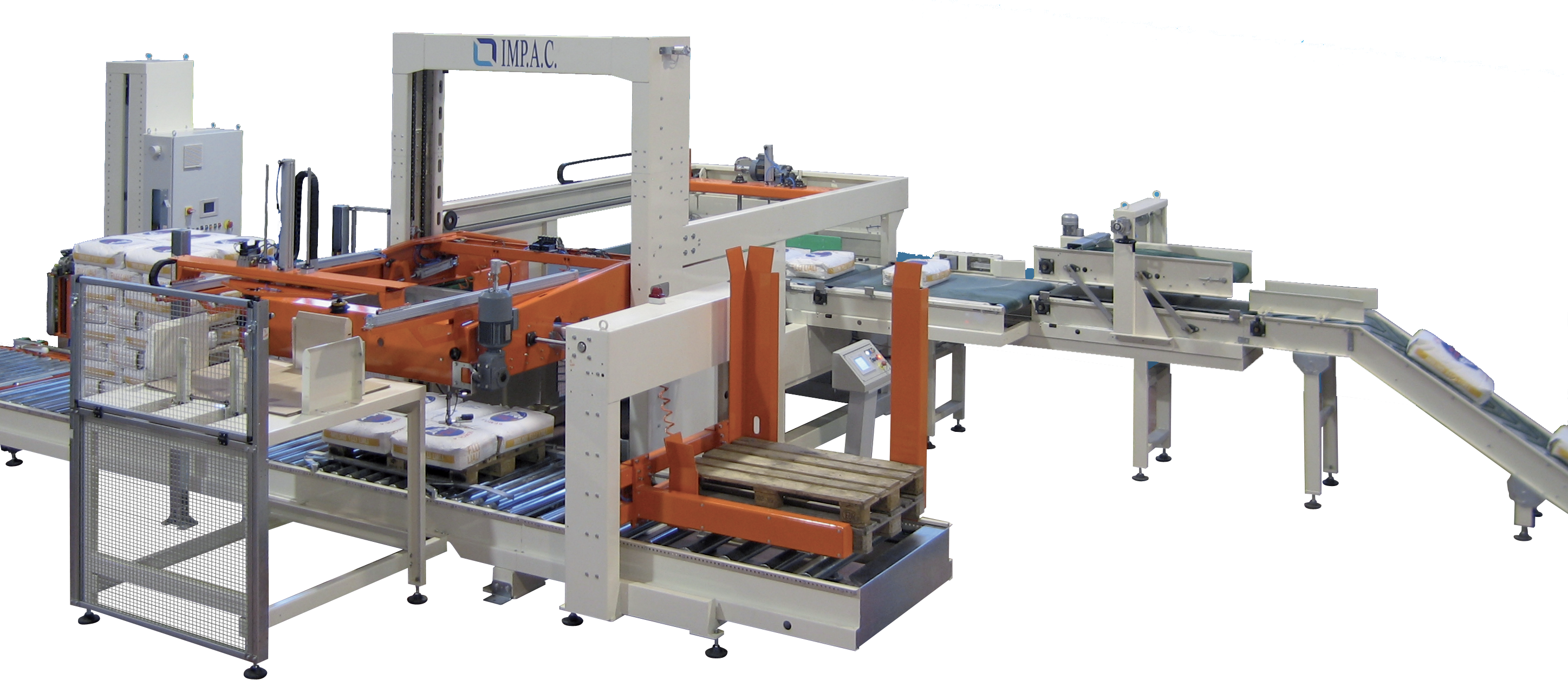

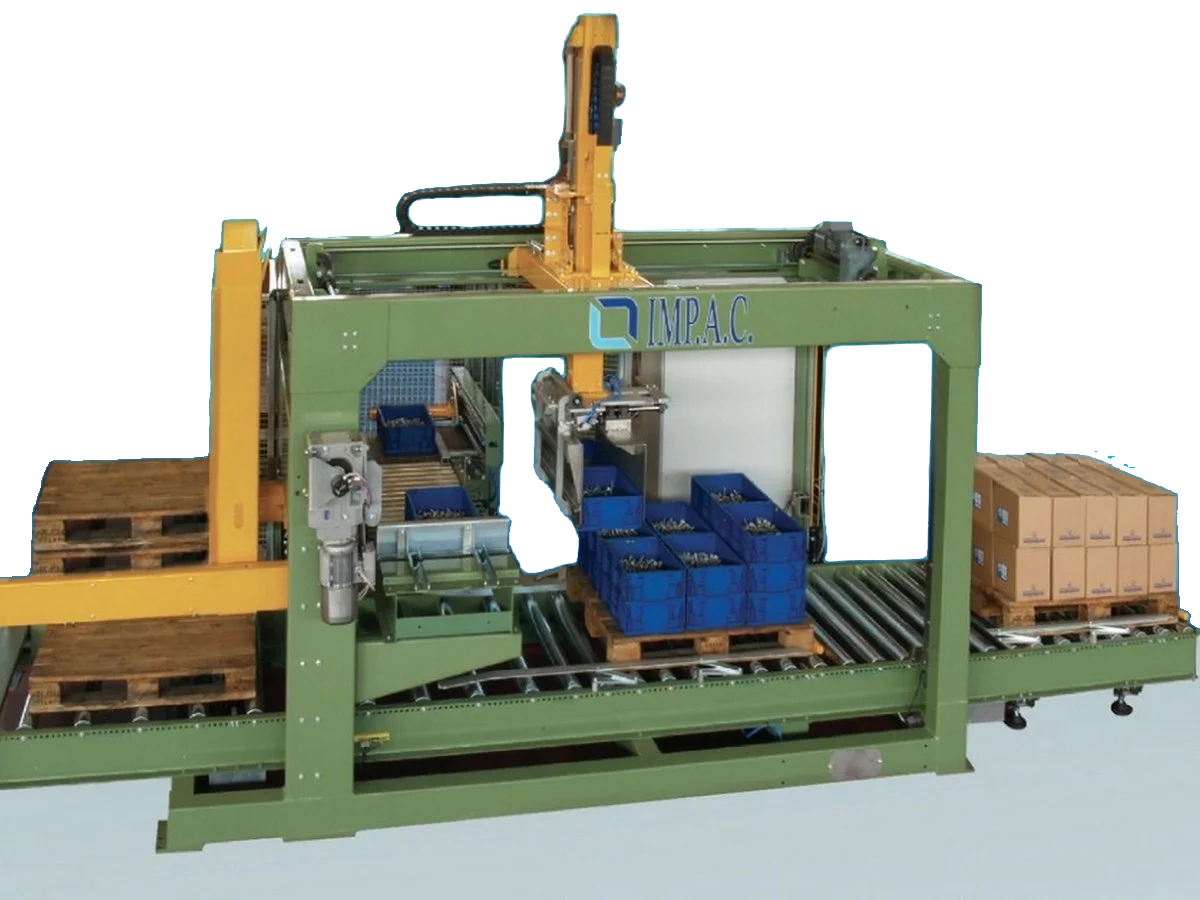

- High level paletizing system for box and bundles

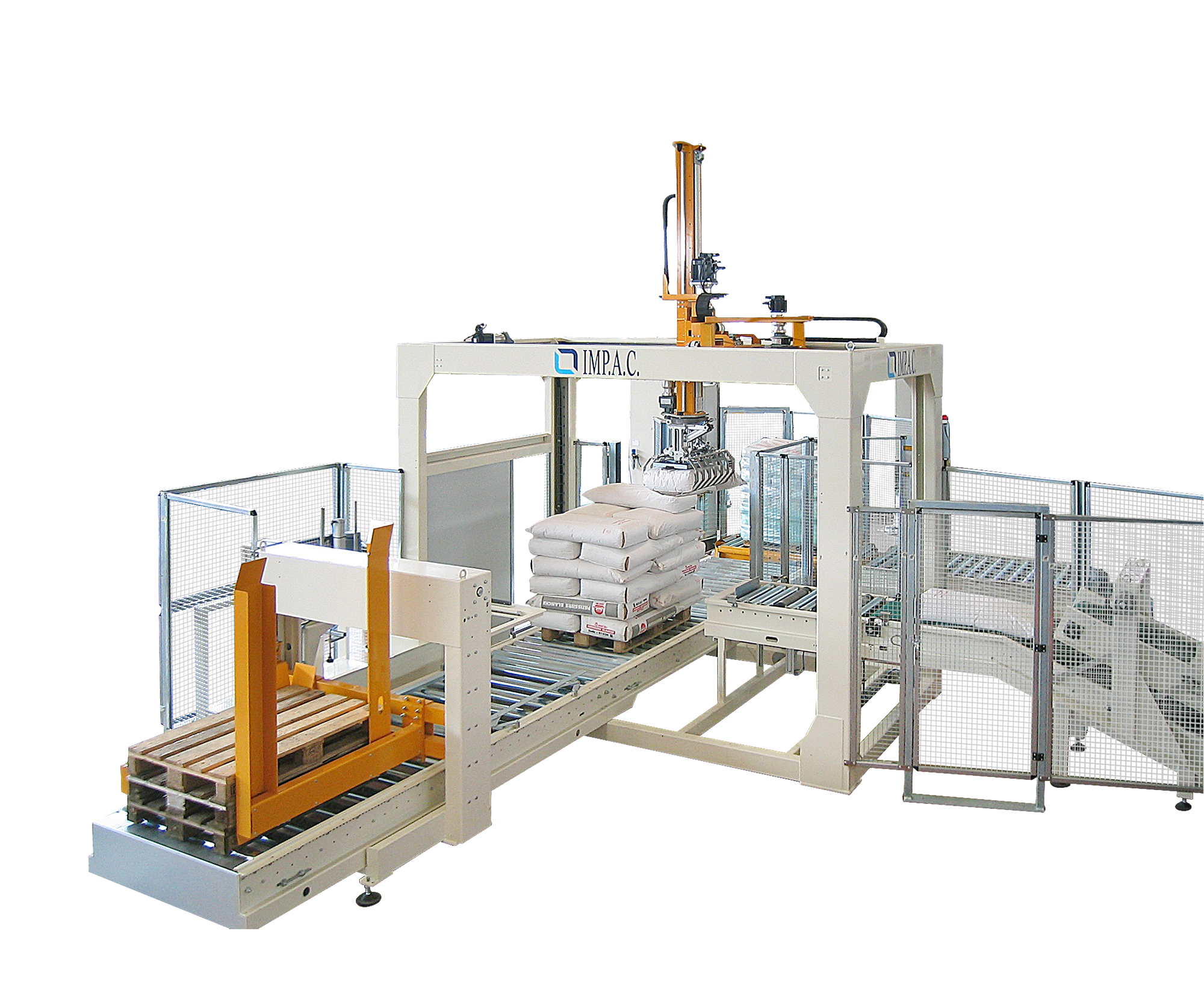

- High-Level palletizer for bags

- Low-Level Palletizer for boxes and bundles

- Low level palletizer for bags

- Low level palletizer for bags

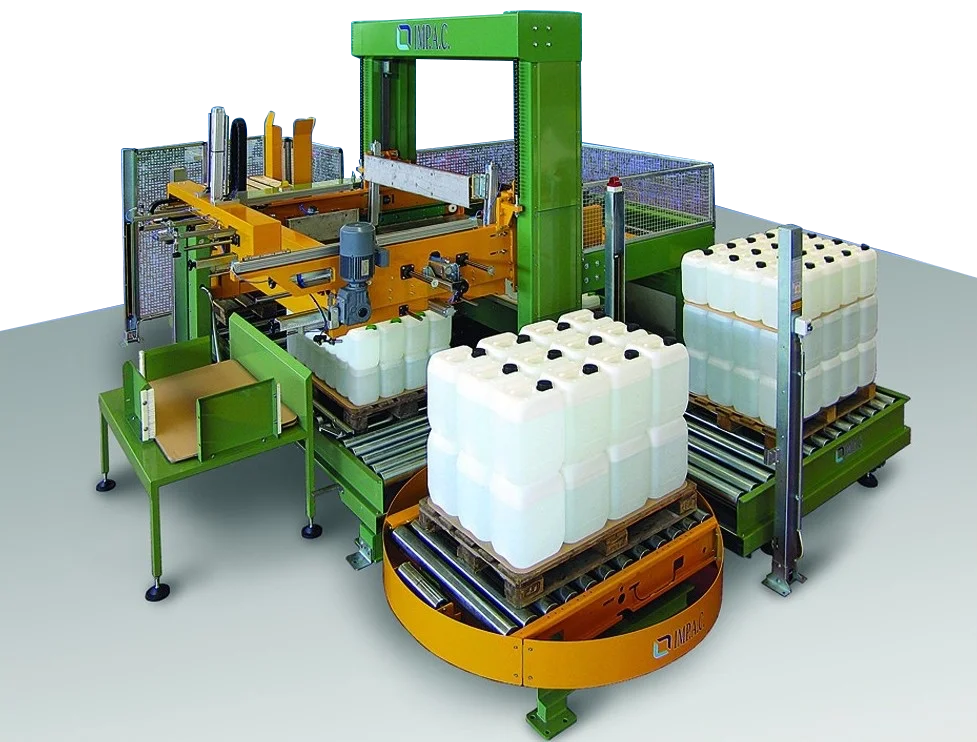

- Low-Level Palletizer for cans

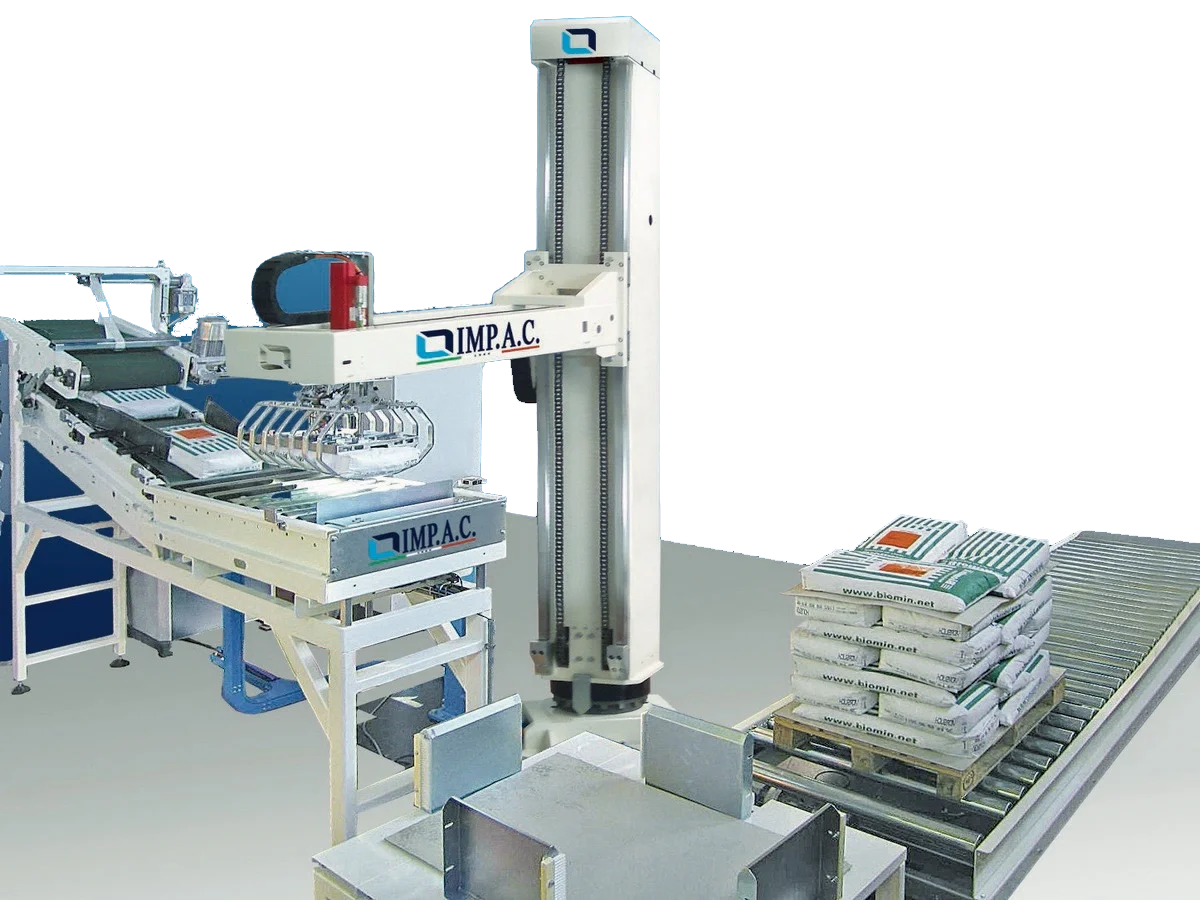

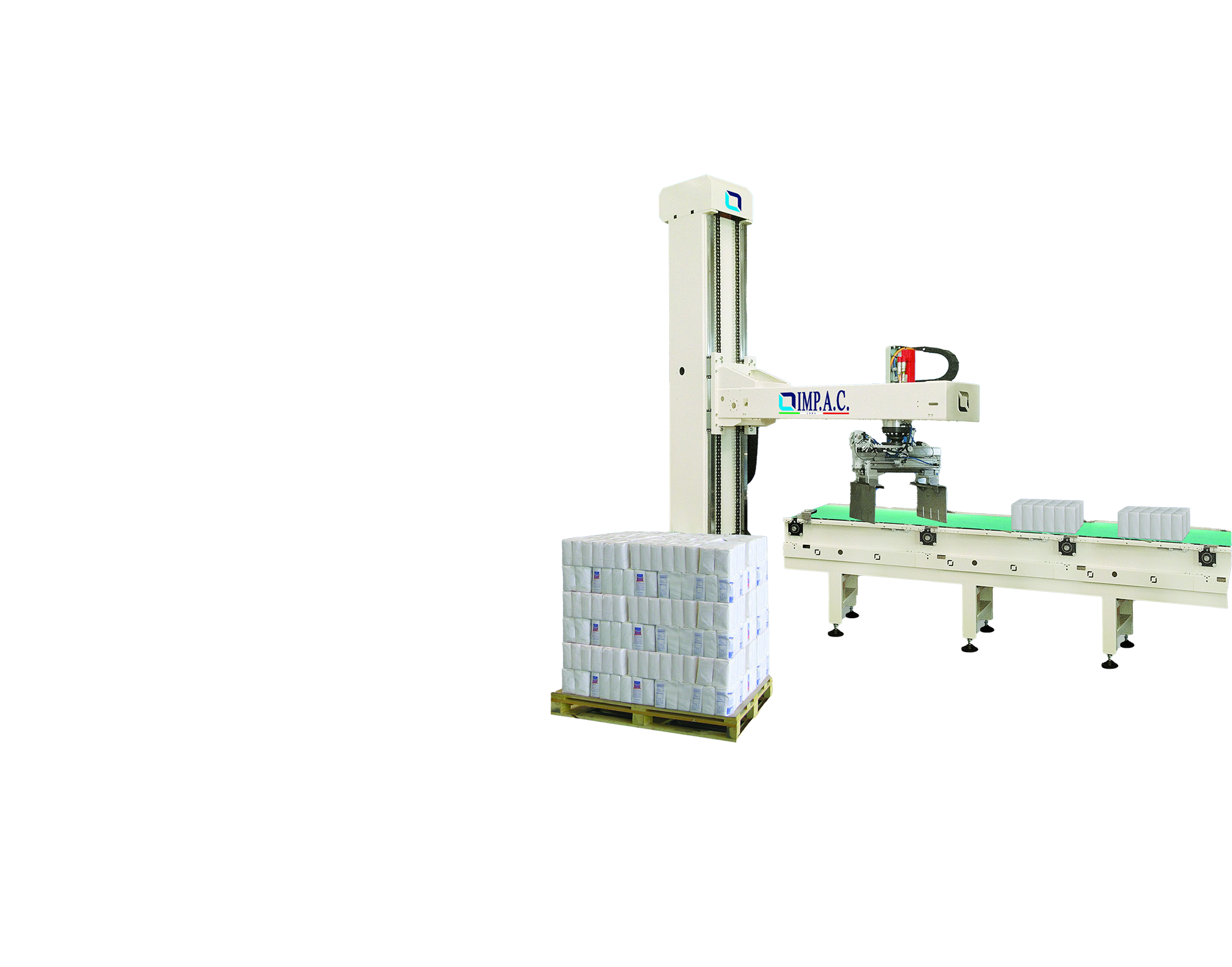

- Cartesian Robot palletizer for bags

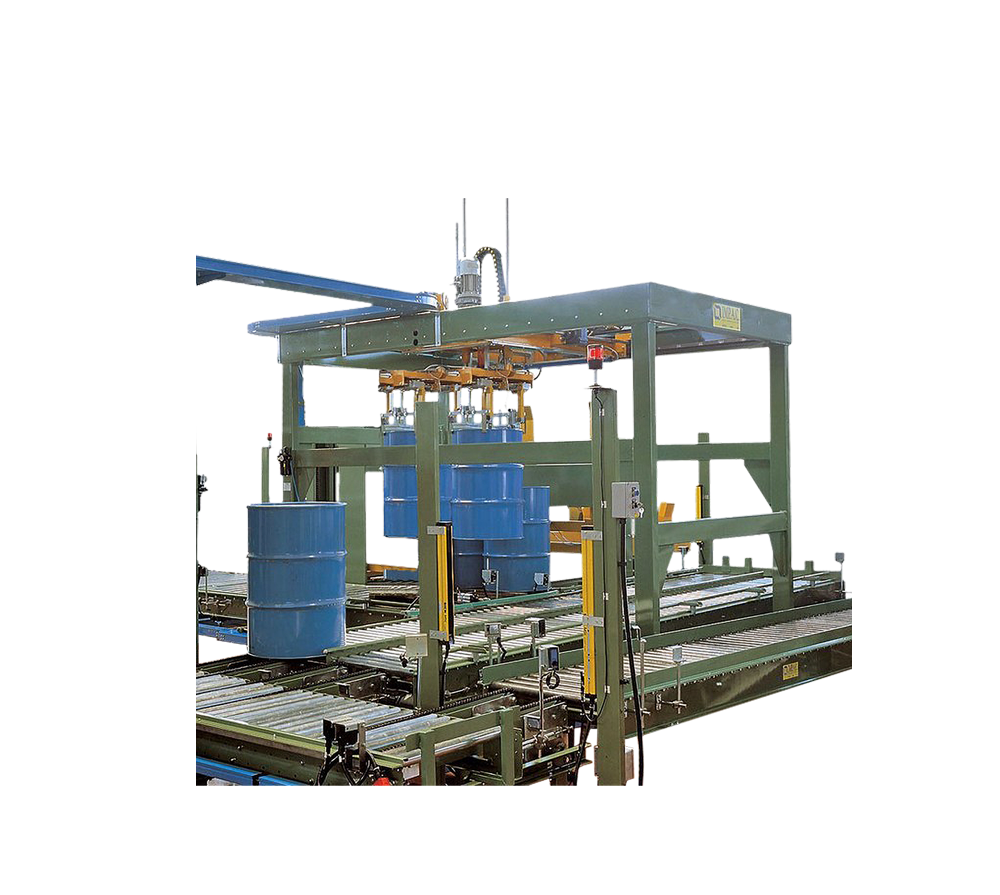

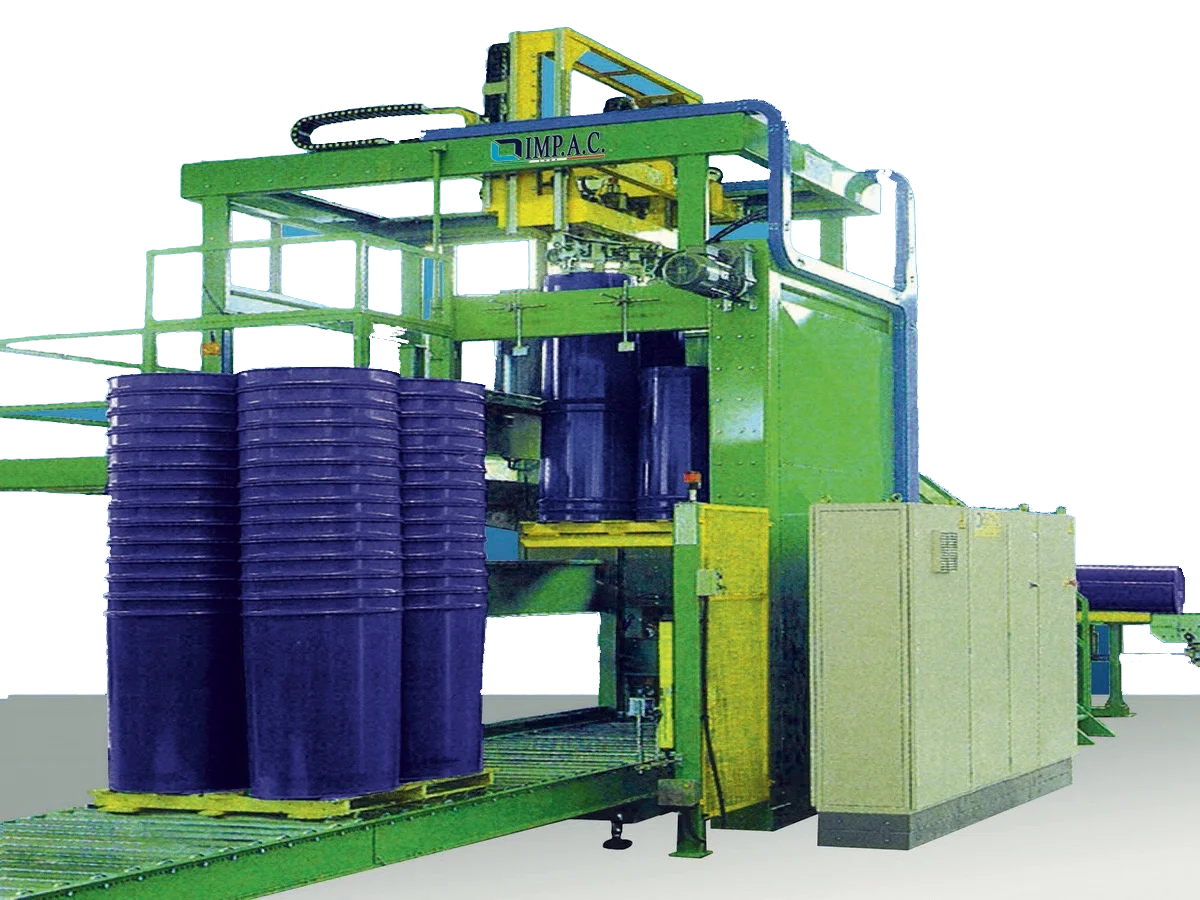

- Cartesian robots for drums, jerrycans and pails

- Cartesian Robot palletizer for boxes and bundles

- Monocolumn Robot Palletizer and Depalletizer for cans pails and drums

- Monocolumn Robot Palletizer for bags

- Mono-column pallettizing system for box and bundles

- High level robot palletizing system for bags

- High level Robotic palletizer for conical drums

- High level Robotic palletizer for boxes and bundles

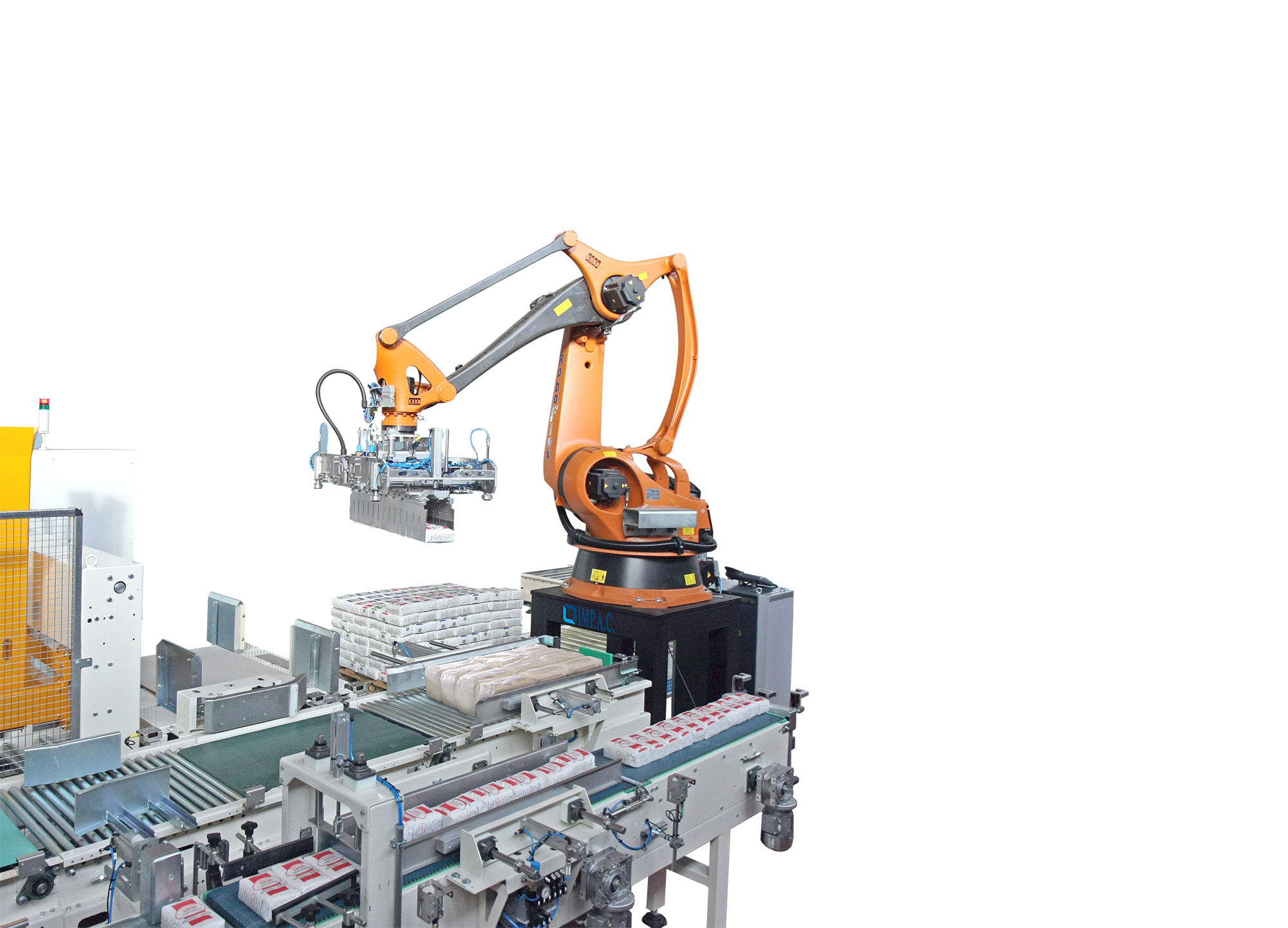

- Anthropomorphic Robot palletizer for boxes and bundles

- Anthropomorphic Robot Palletizer and Depalletizer for cans, pails and drums

- Anthropomorphic Robot palletizer for bags