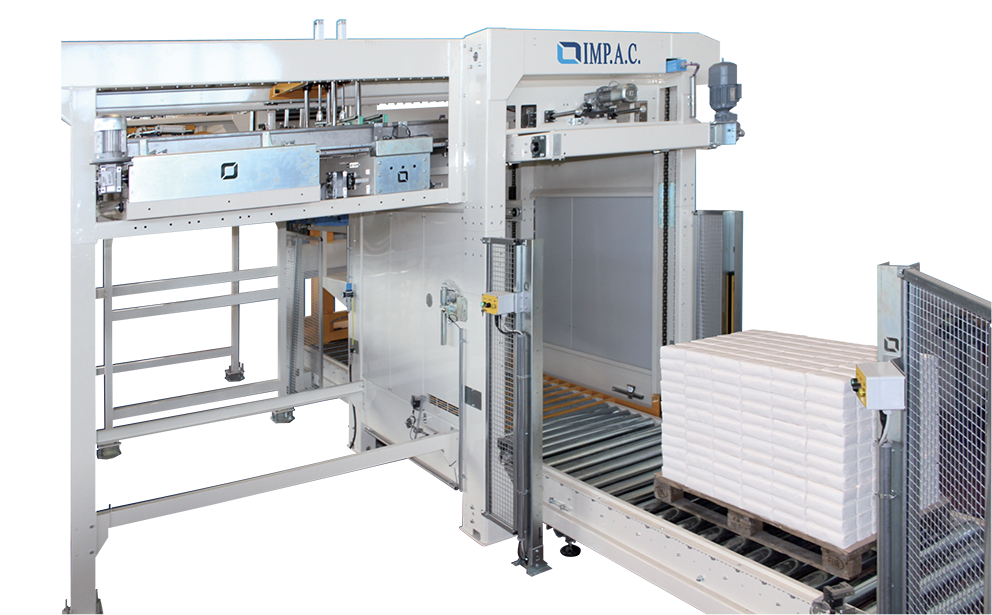

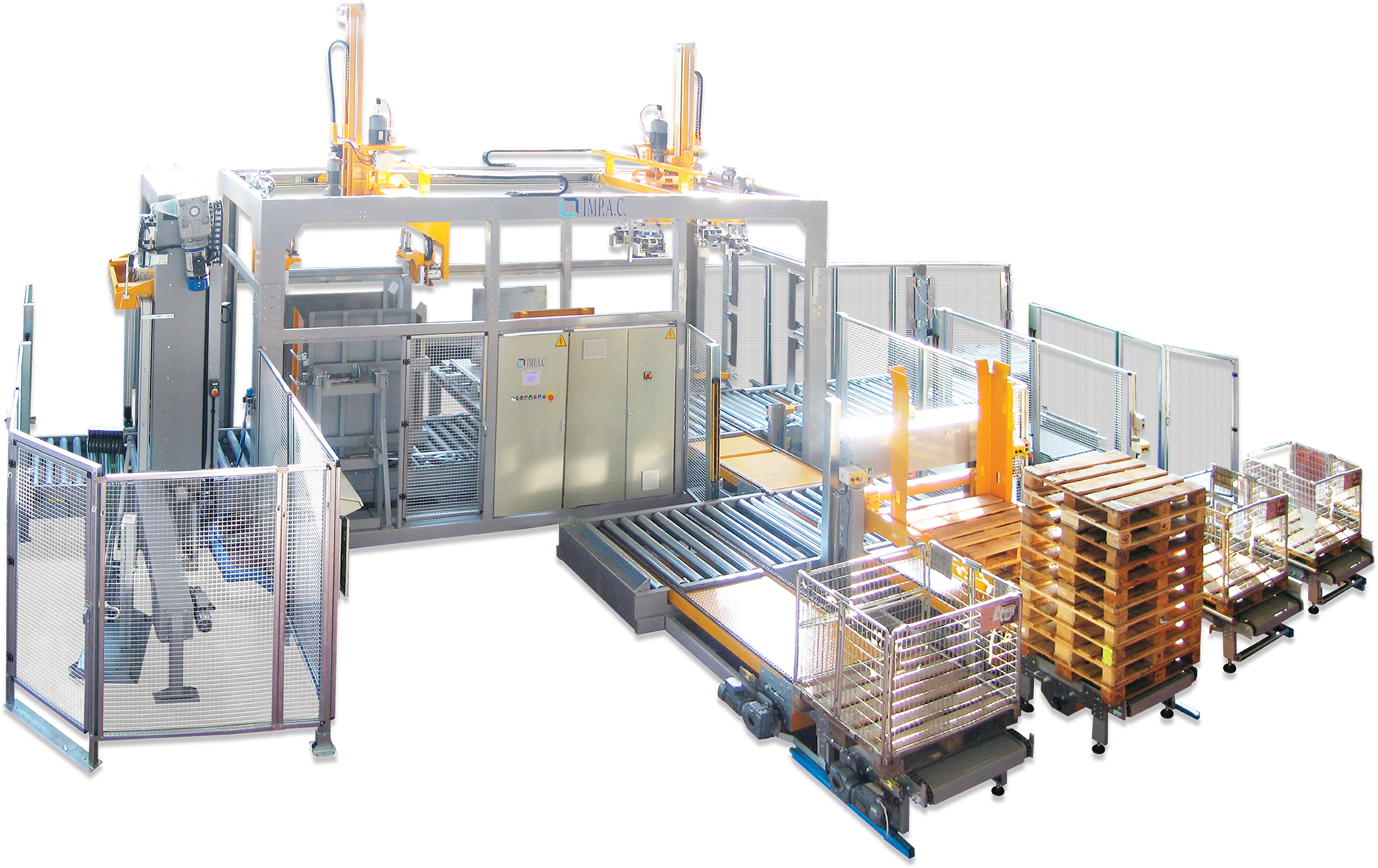

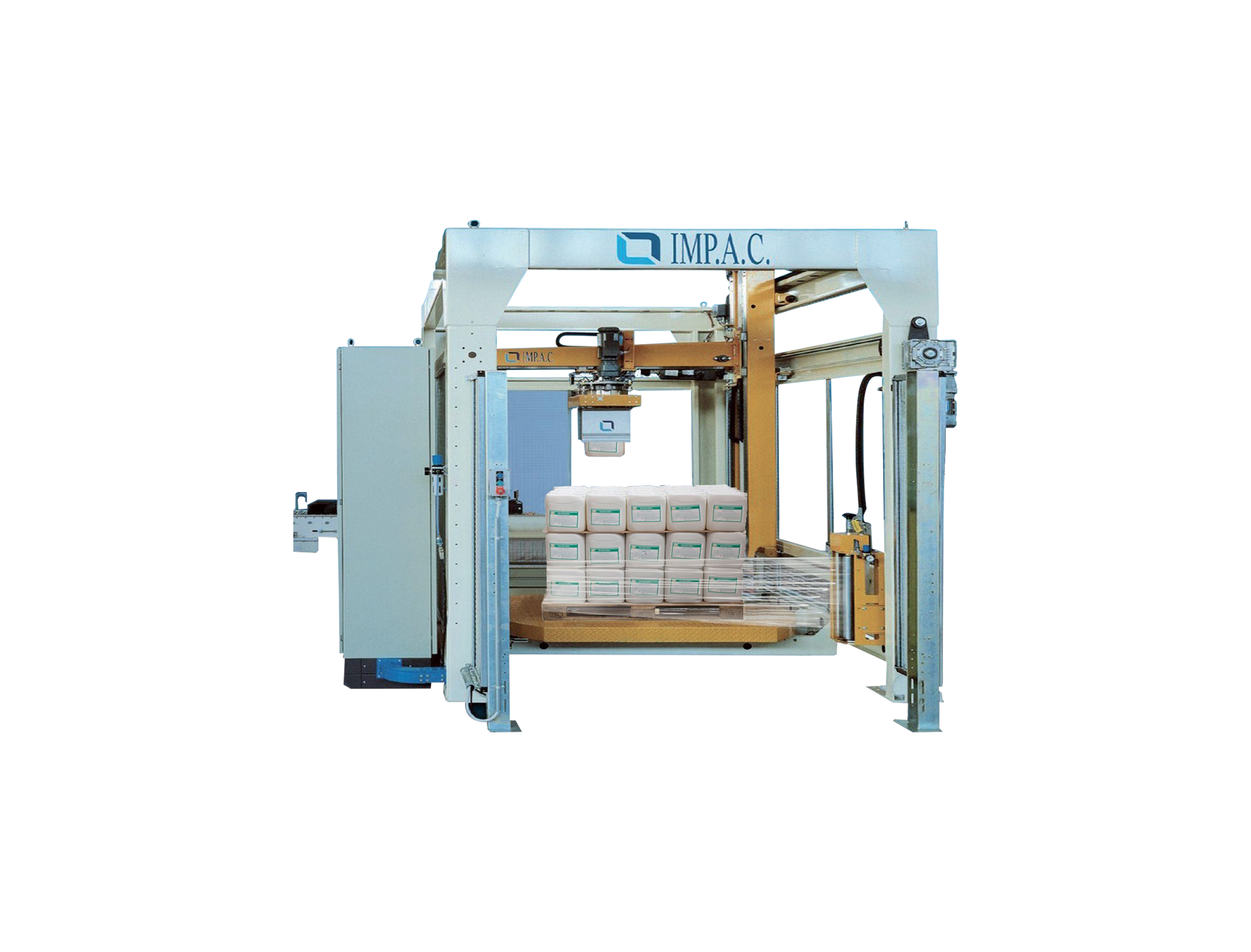

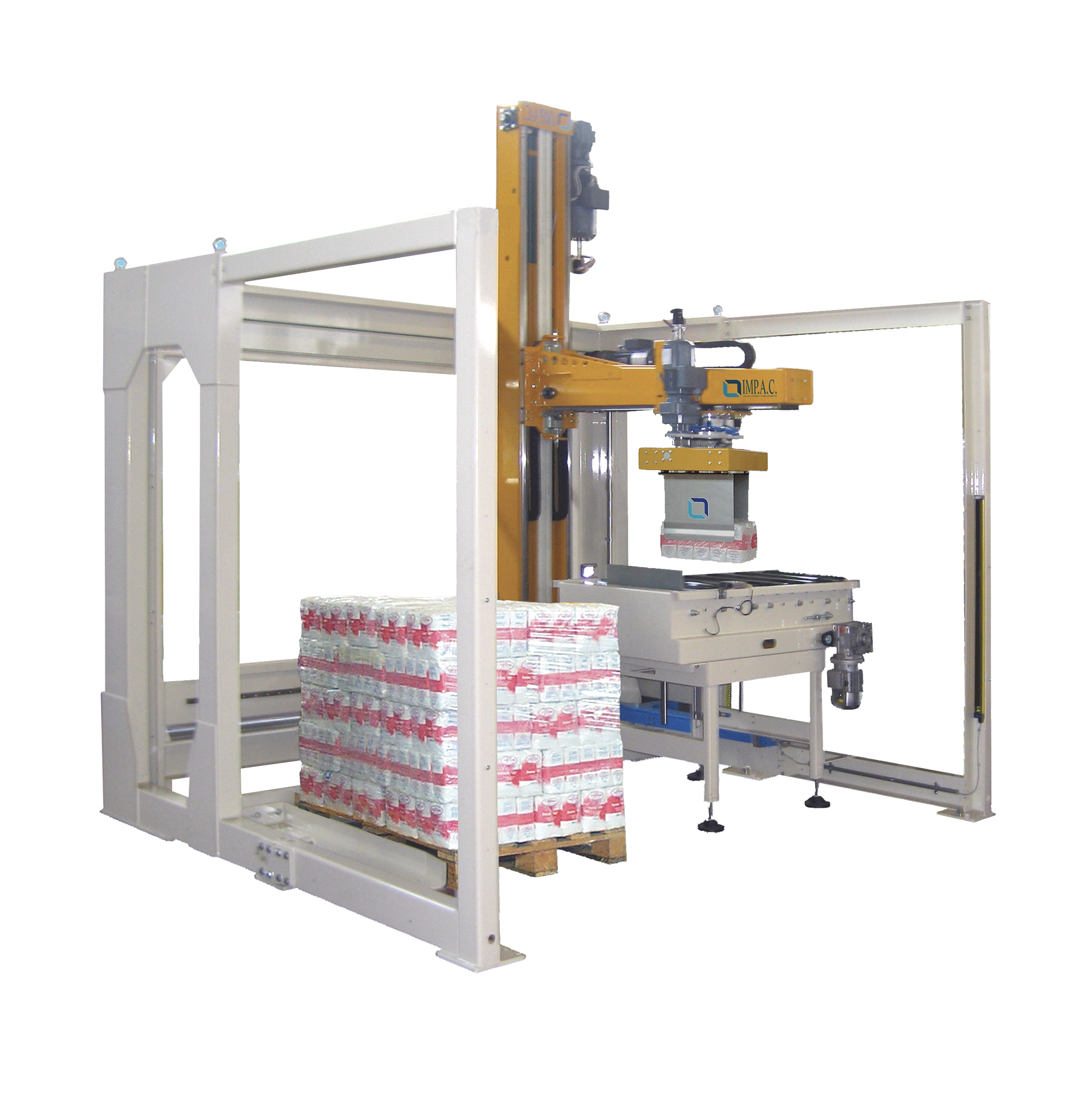

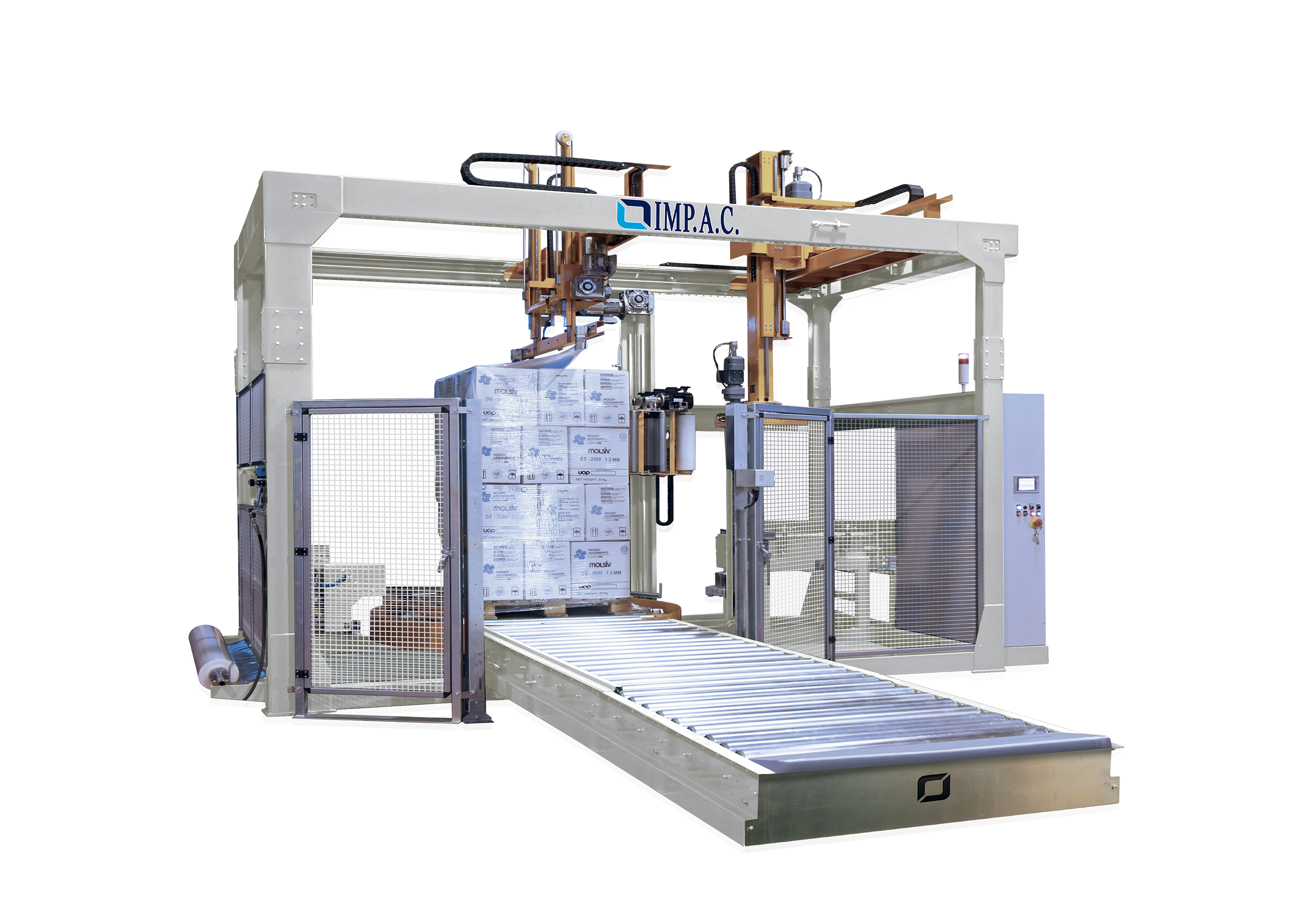

The IMP.A.C. BR 4A+TOP is a high-performance automatic wrapper, designed for spiral wrapping of palletized units with variable heights.

Thanks to the rotating arm system, the pallet remains stationary throughout the entire cycle, ensuring stability and safety even for unstable or large loads.

With a production capacity of up to 52 pallets/hour, this machine is ideal for high-production industrial lines. The TOP cover device ensures airtight sealing of the load, protecting it from dust, moisture, and external agents.

Technology and Operation

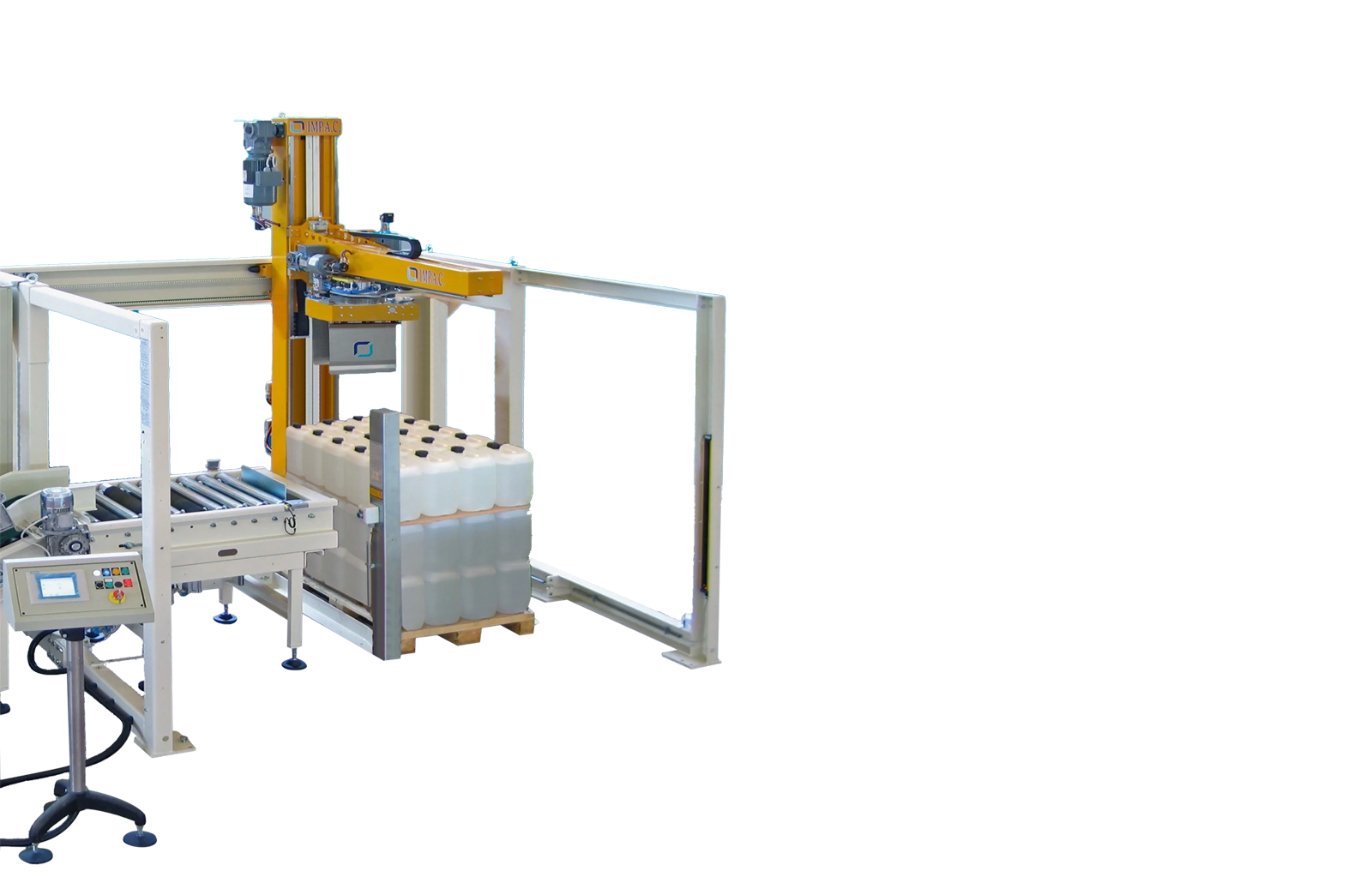

Rotating arm with fixed pallet

The rotating arm wrapping system allows pallets to be wrapped without moving them, reducing the risk of load instability and optimizing operational safety.

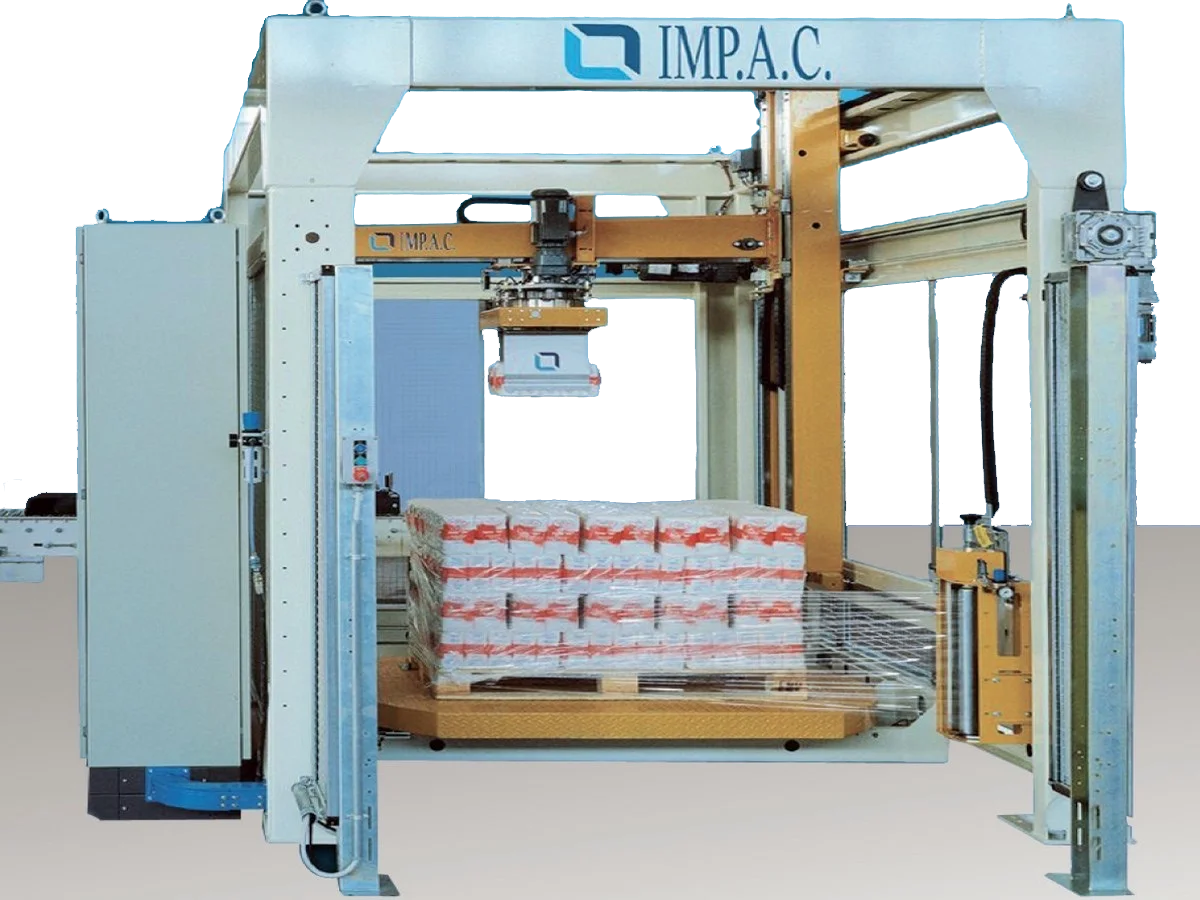

Spiral wrapping with film pre-stretch

The wrapping is done with a spiral system, adapting to pallets of varying heights, while the film pre-stretch optimizes material consumption, reducing costs and ensuring an effective wrap.

TOP cover device

The TOP system applies a top cover to the pallet, making it airtight and protected from weather, dust, and contamination.

Upper pressing option

Available as an option, the top press ensures greater load stability during wrapping, particularly useful for light or irregular pallets.

Optional accessories:

- Strapping/film cordonatura device to ventilate/stabilize the palletized product.

- Welding and film cutting device.

- Dispositivo di pre-stiro film 300%.

TheIMP.A.C. BR 4A+TOP is the ideal choice for companies needing a reliable, high-performance automatic winder capable of fast, protective and efficient winding, perfect for high-intensity industrial environments.

Turning arm stretch wrapping machine with top covering device

Max Production: 52 Palettes/h

Max pallet dimensions.

Max. 1300 x 1200 mm

Compressed air consumption

150 Nl/min

Auxiliary voltage

24 V

Max weight of full pallet

2000 Kg

Standard full pallet height

1600 mm

Operational capacity

52 paddles/h

Potenza installata

5,1 KW

Operating pressure

6 bar

Peso indicativo

4600 Kg

Product benefits

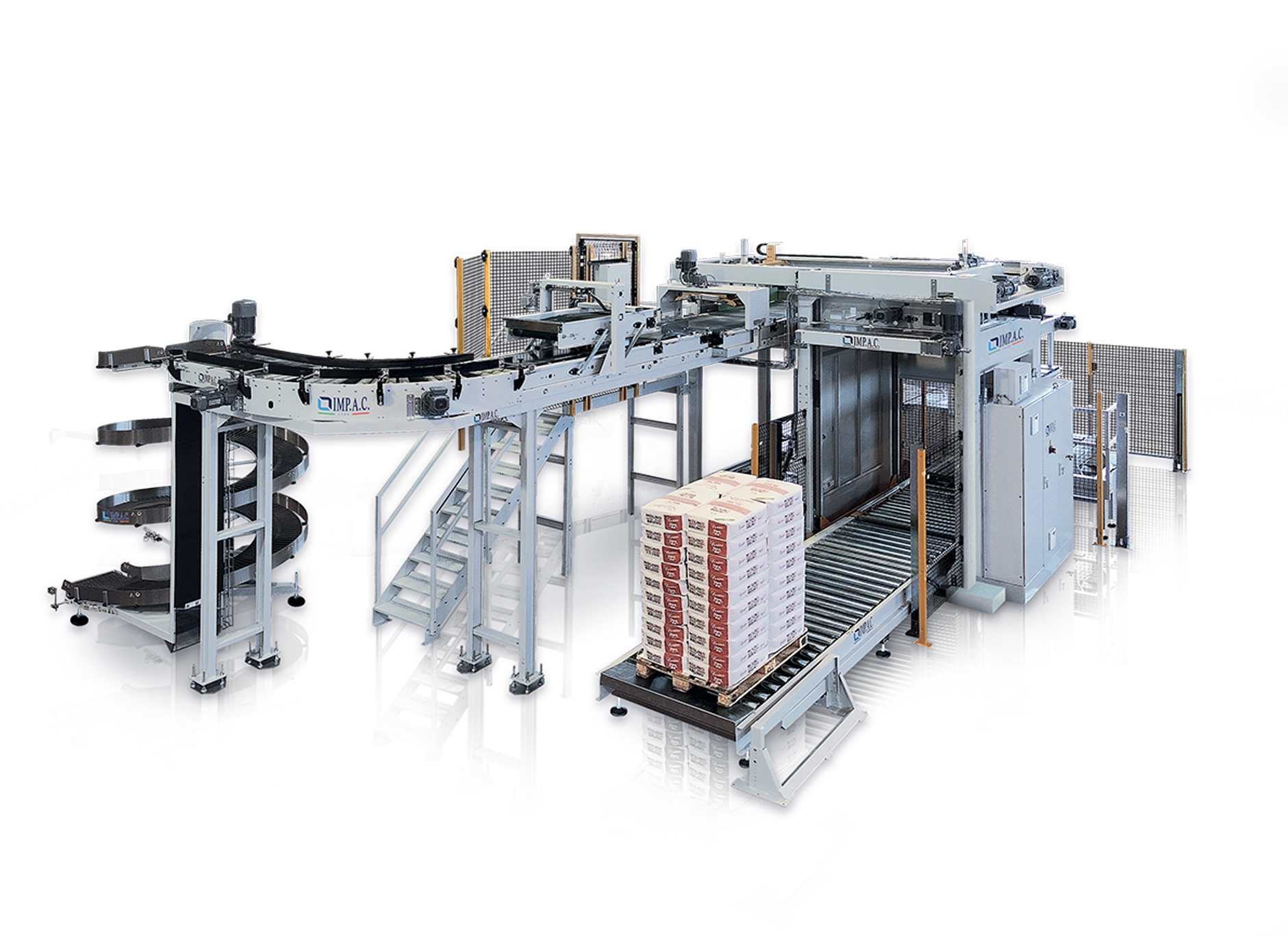

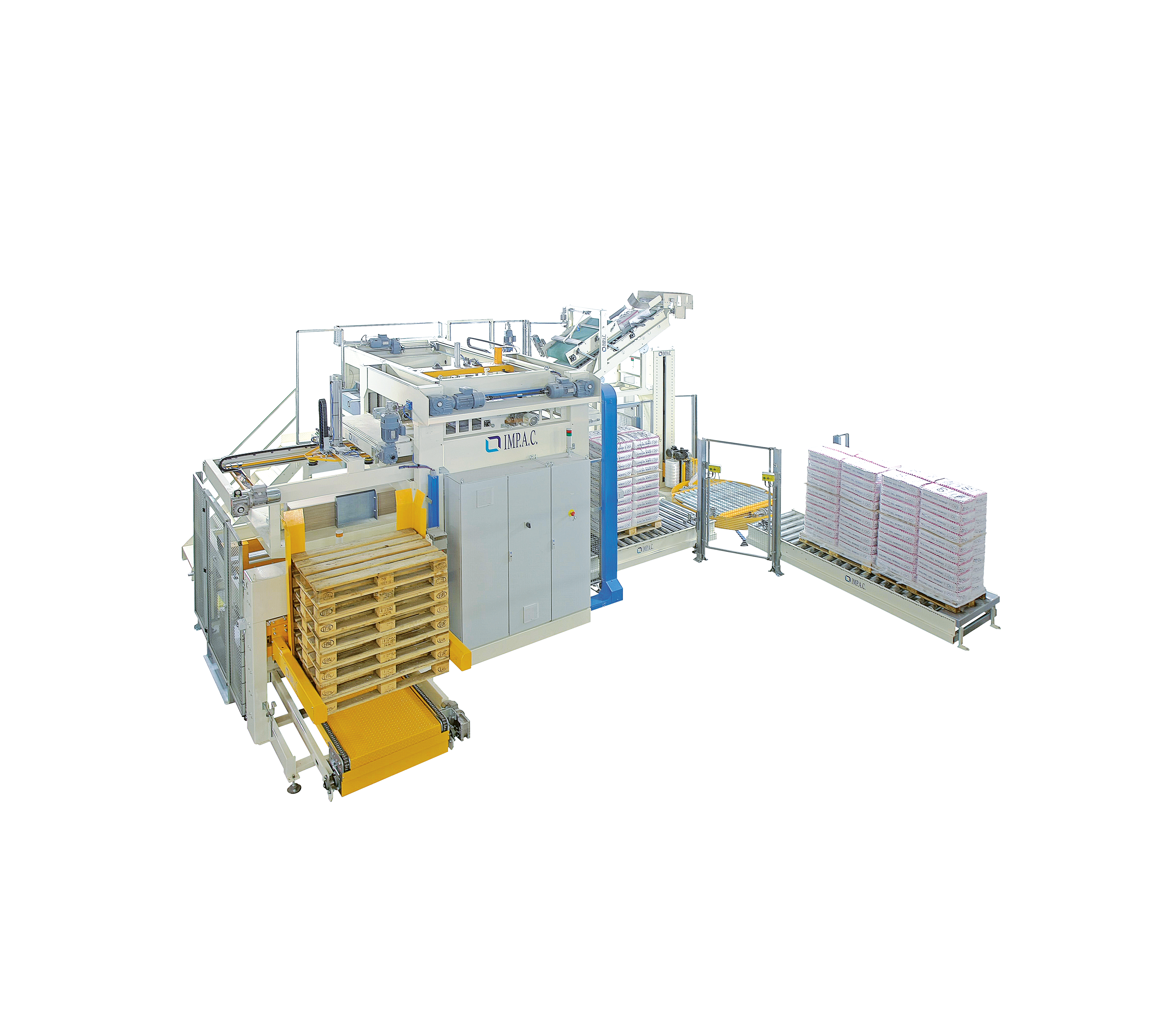

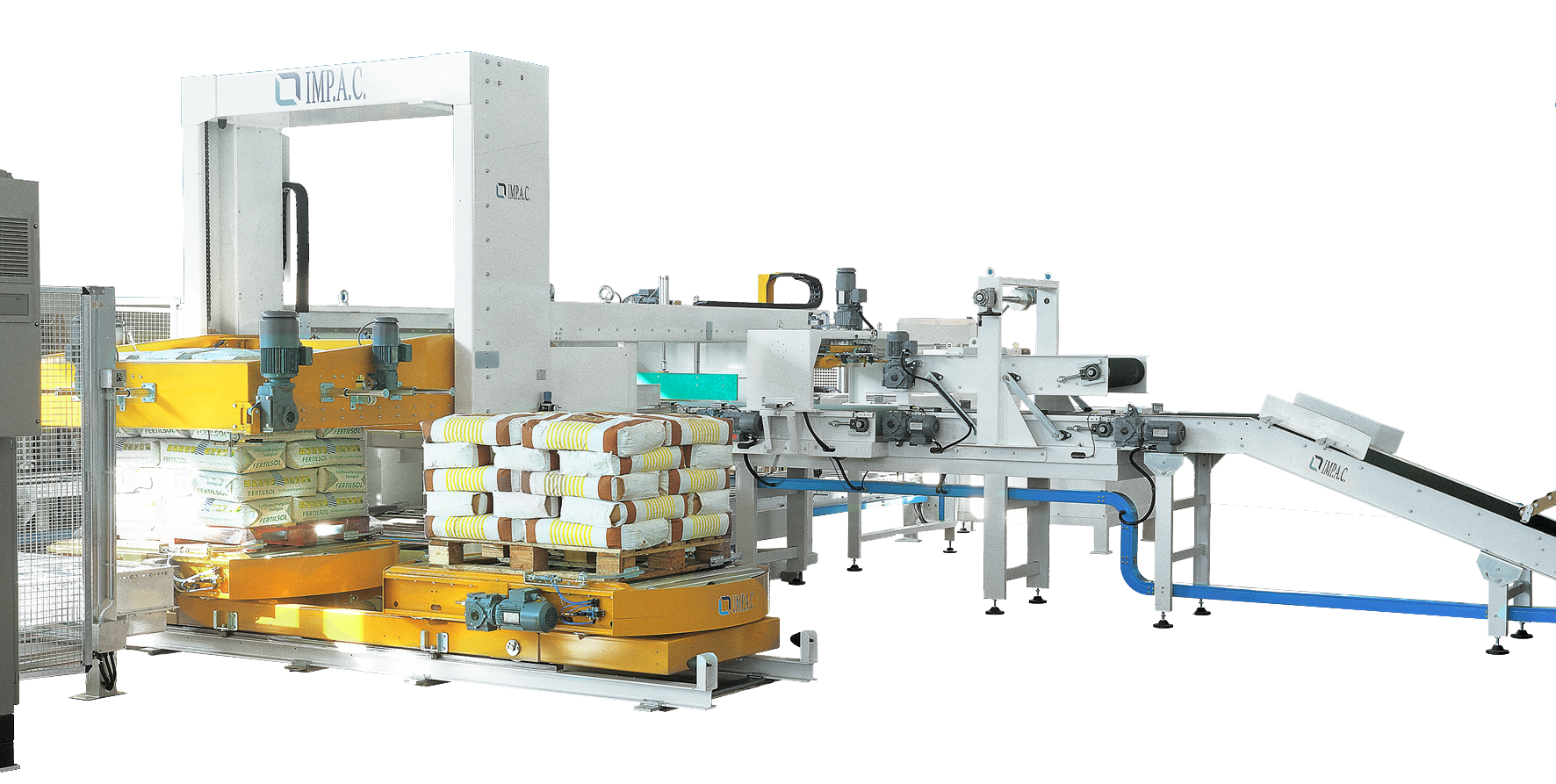

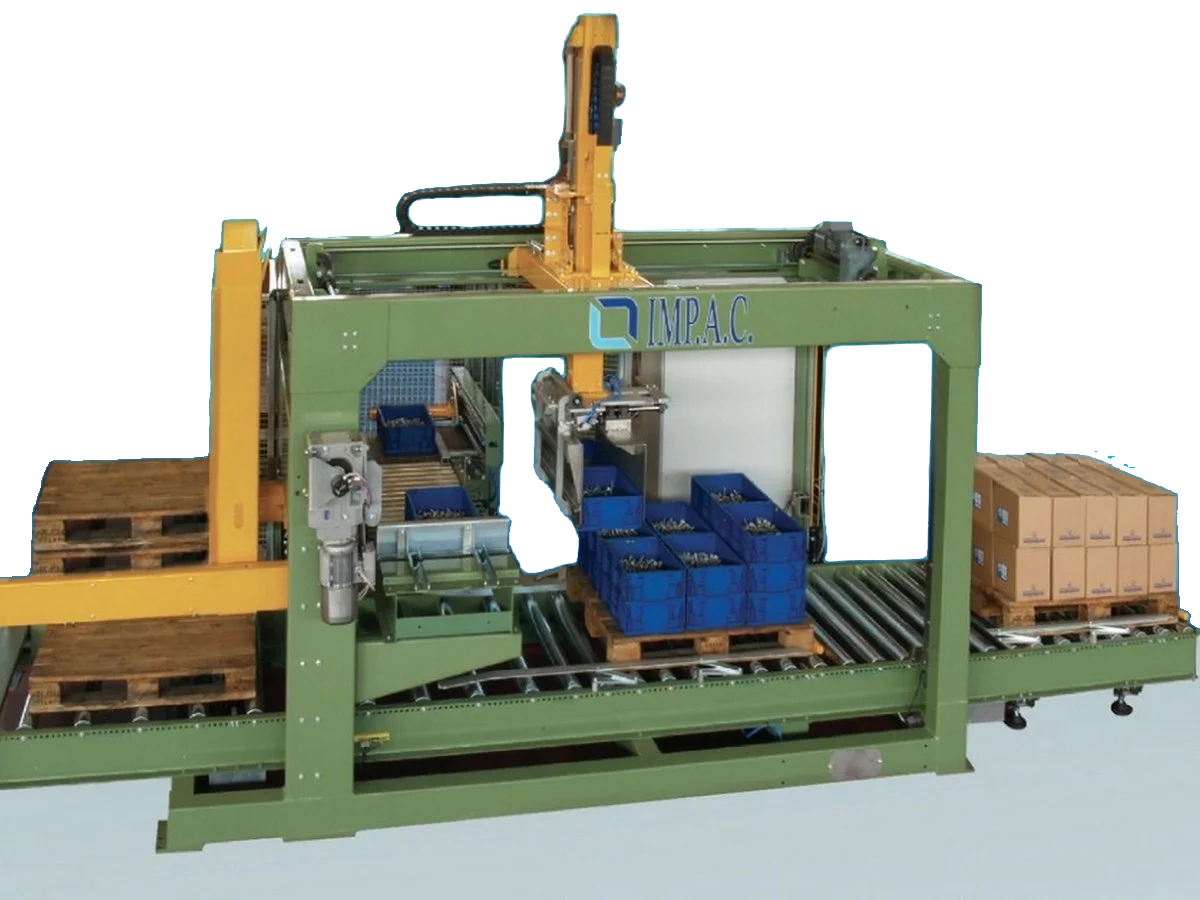

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

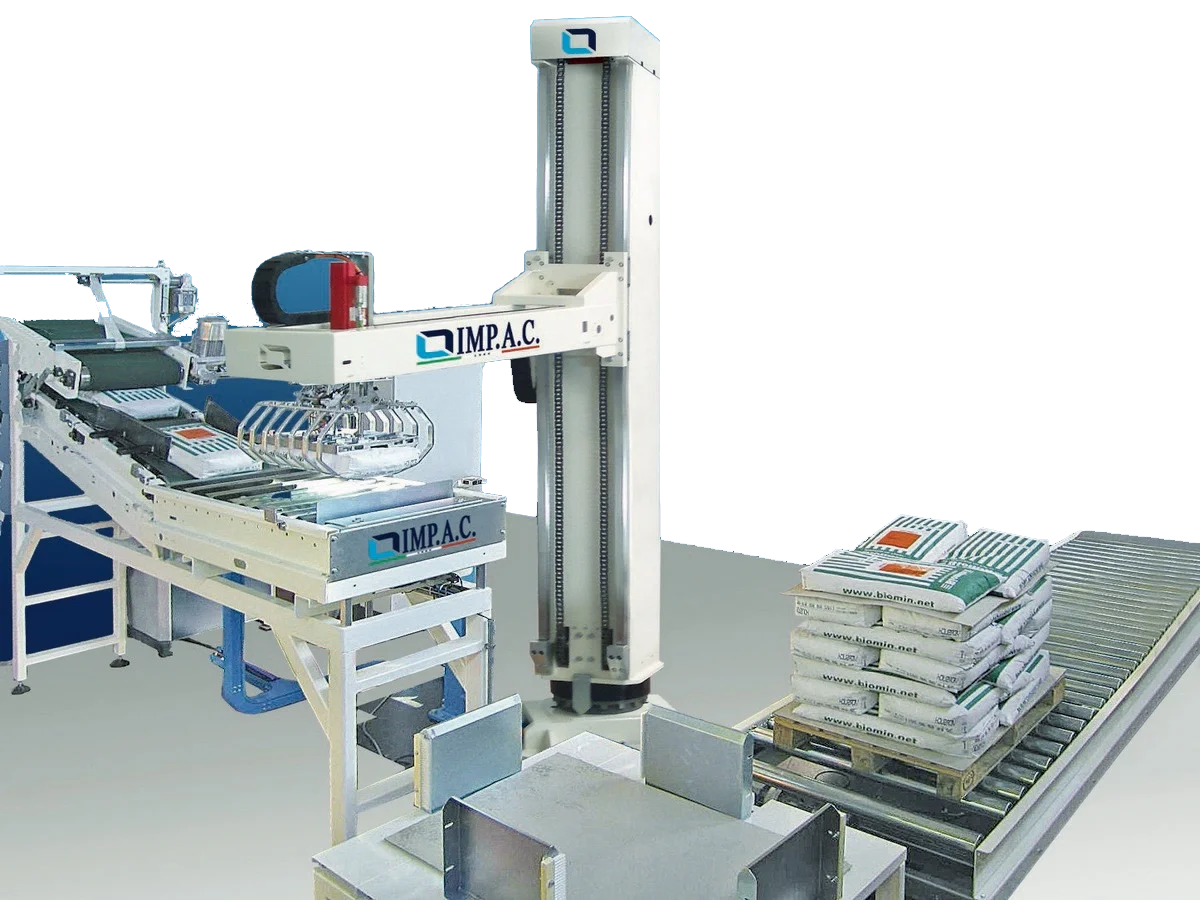

- High level paletizing system for box and bundles

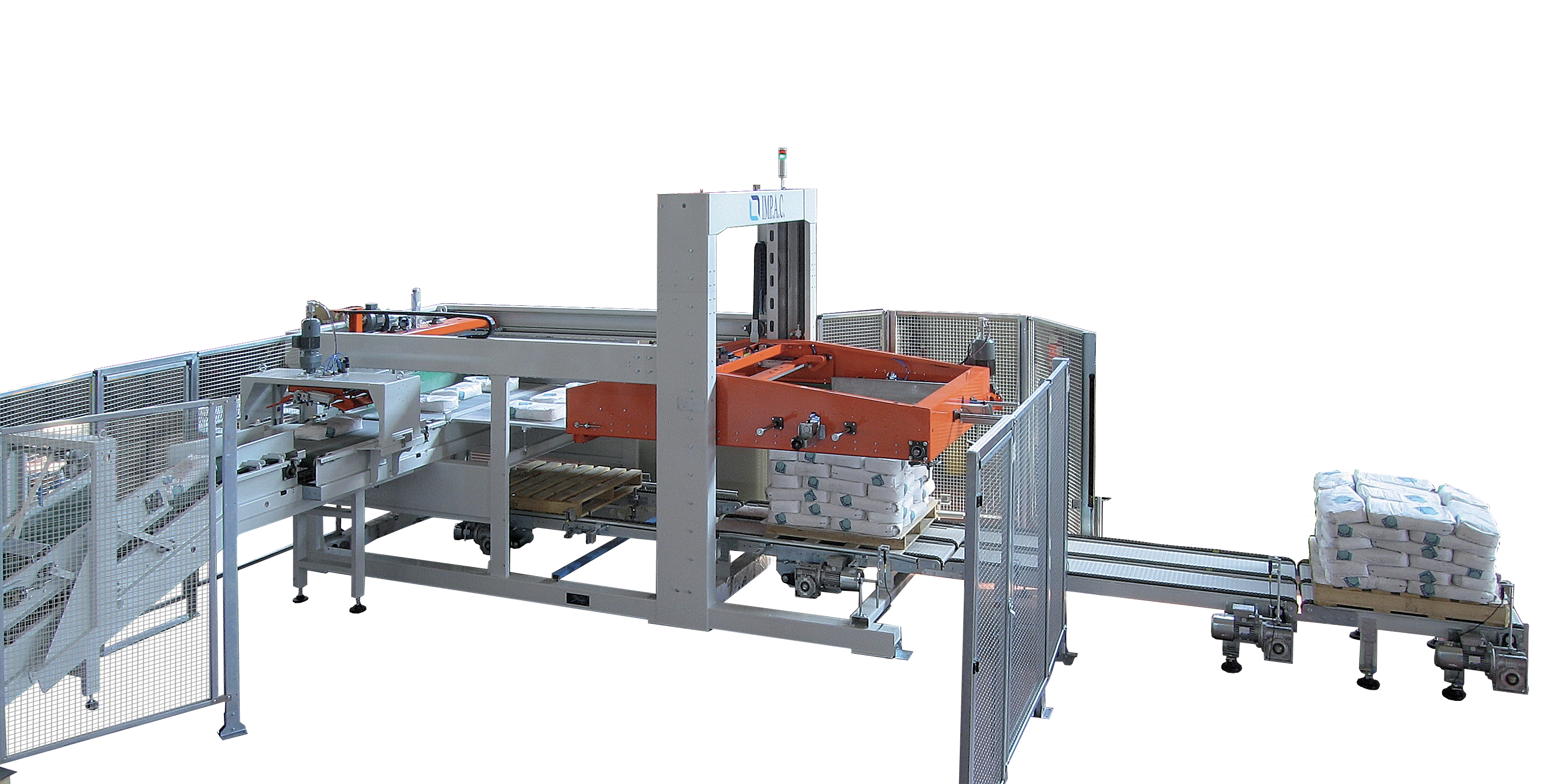

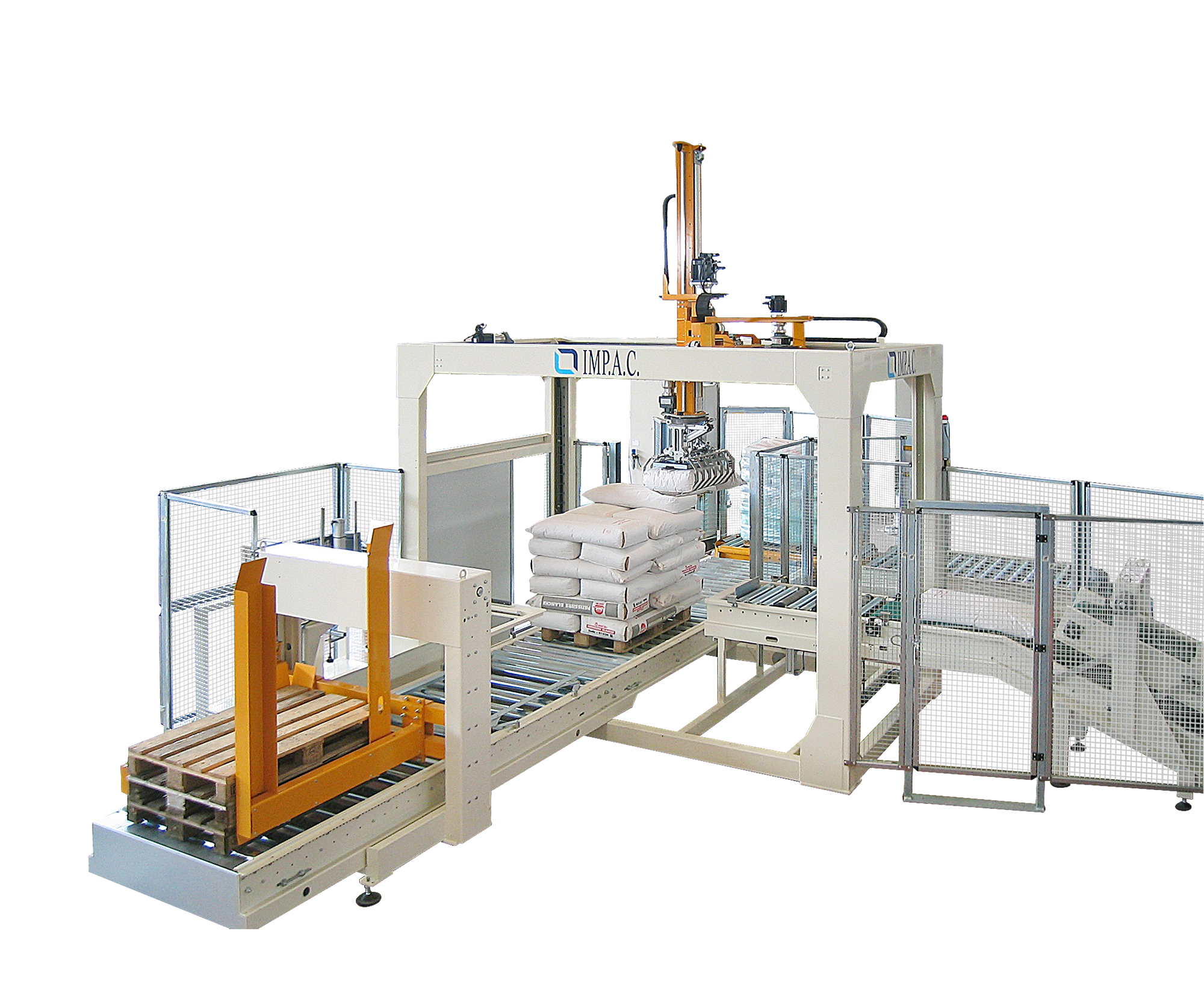

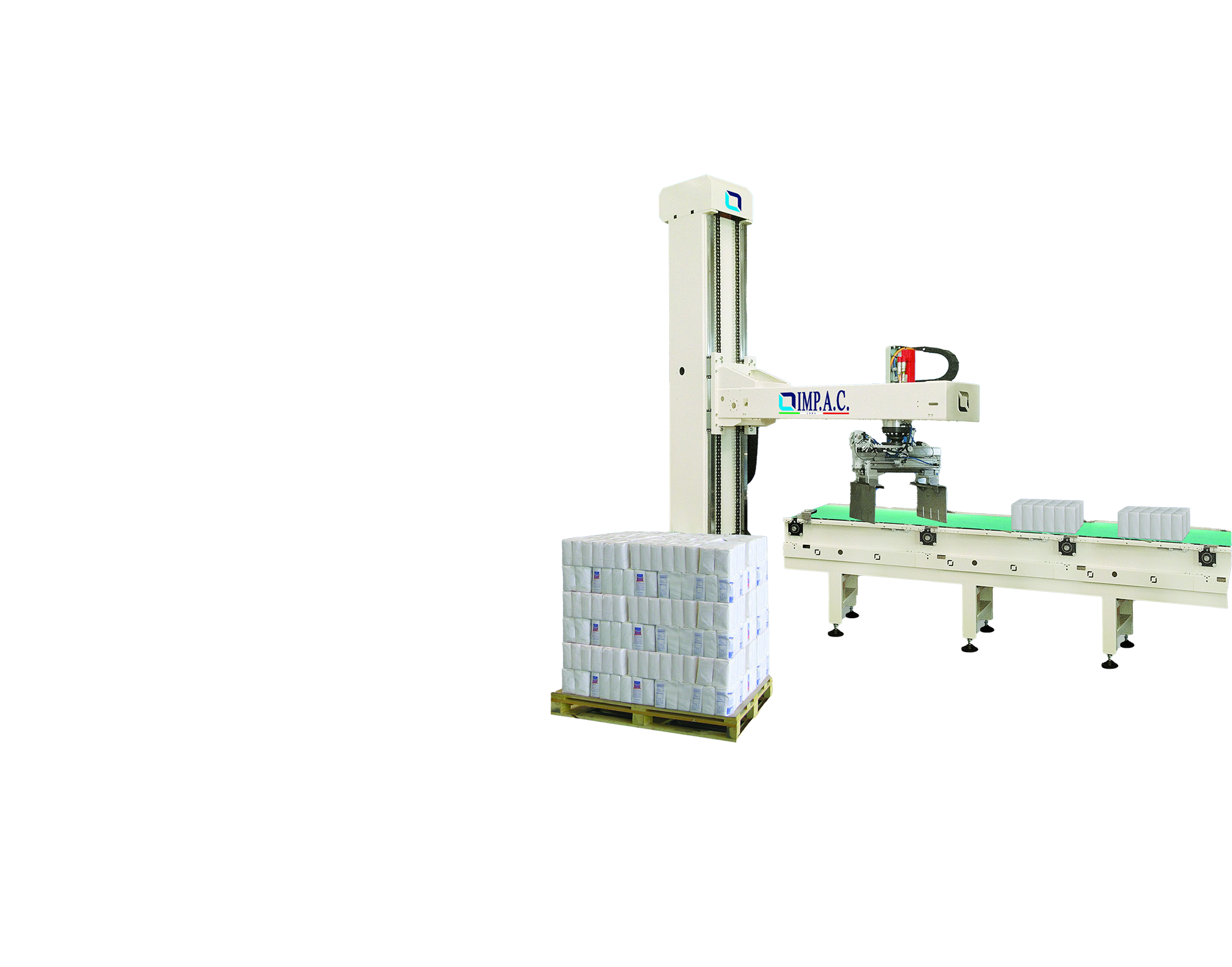

- High-Level palletizer for bags

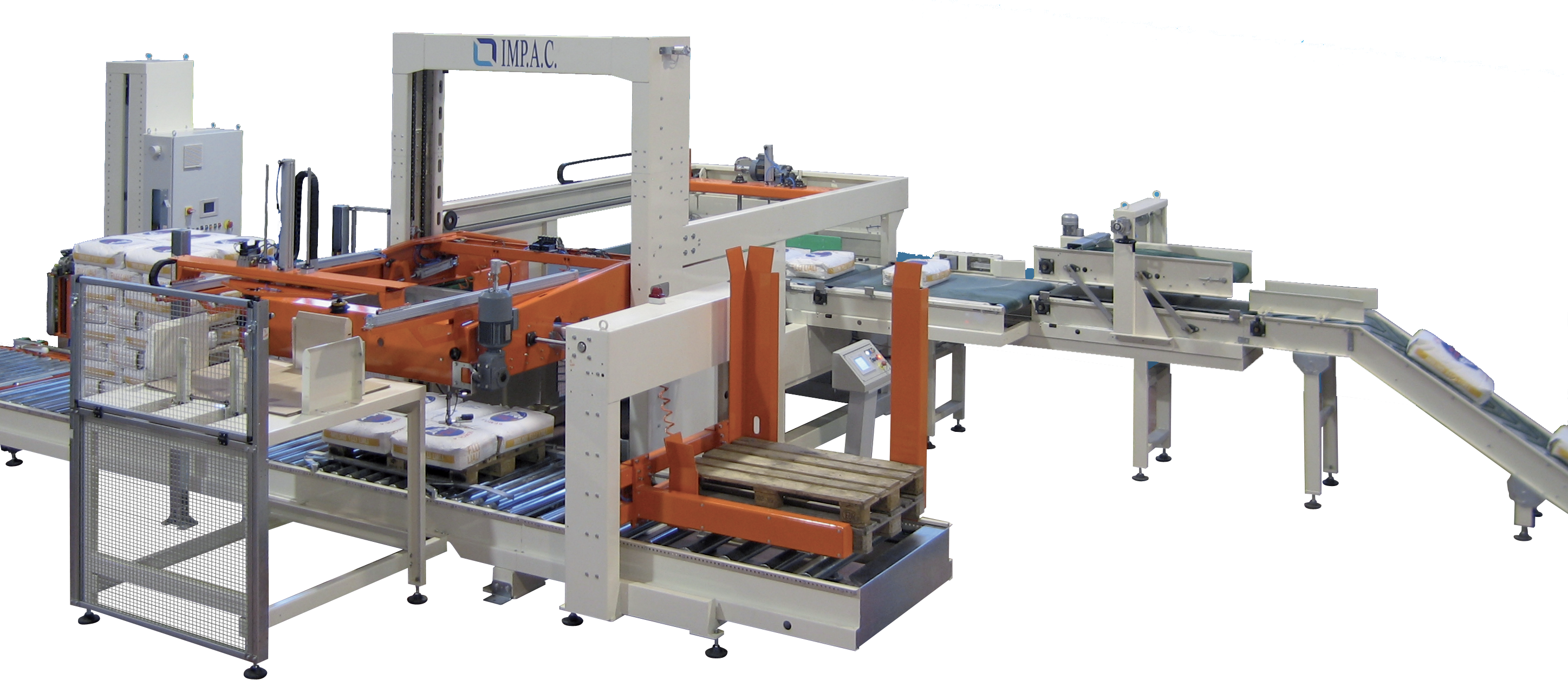

- Low-Level Palletizer for boxes and bundles

- Low level palletizer for bags

- Low level palletizer for bags

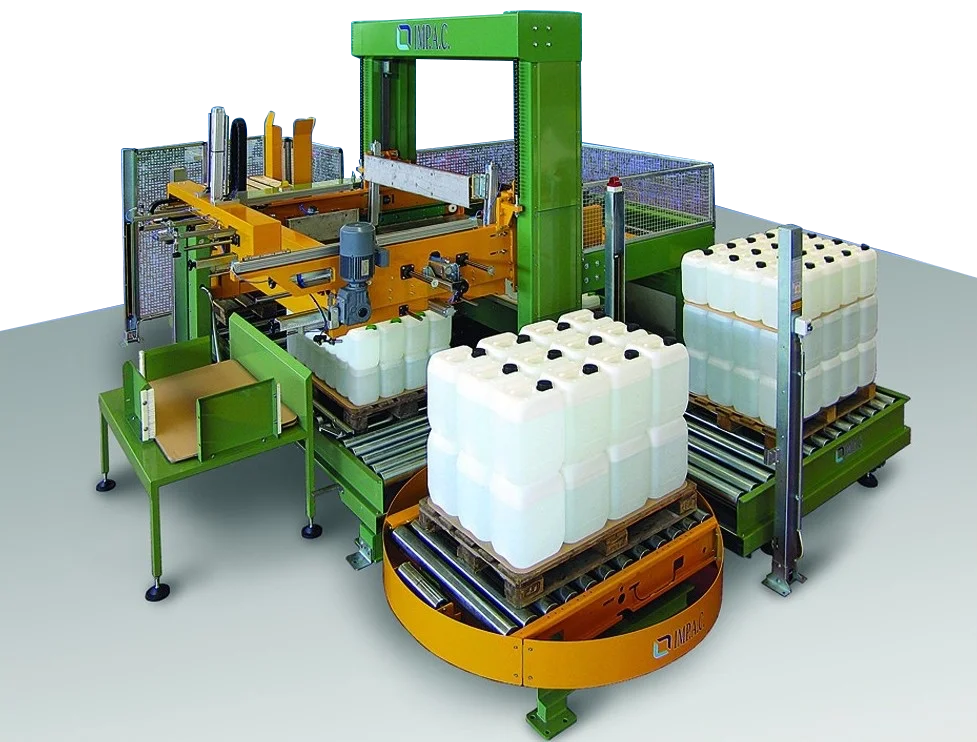

- Low-Level Palletizer for cans

- Cartesian Robot palletizer for bags

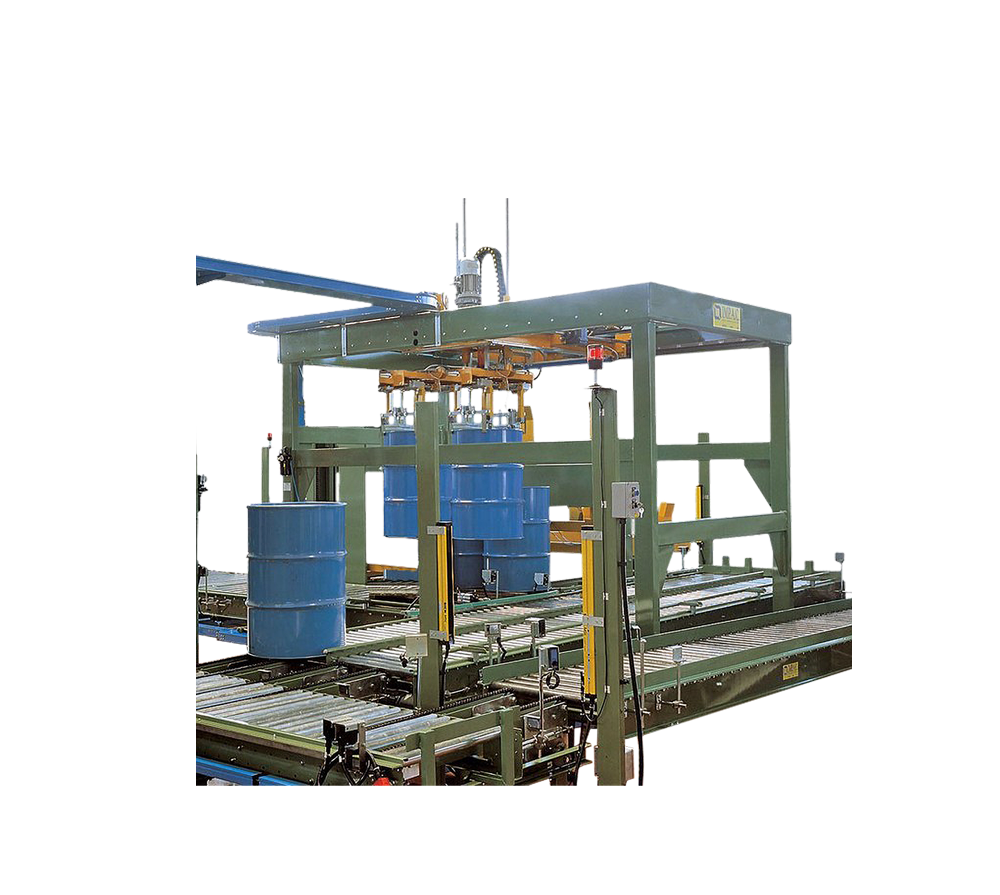

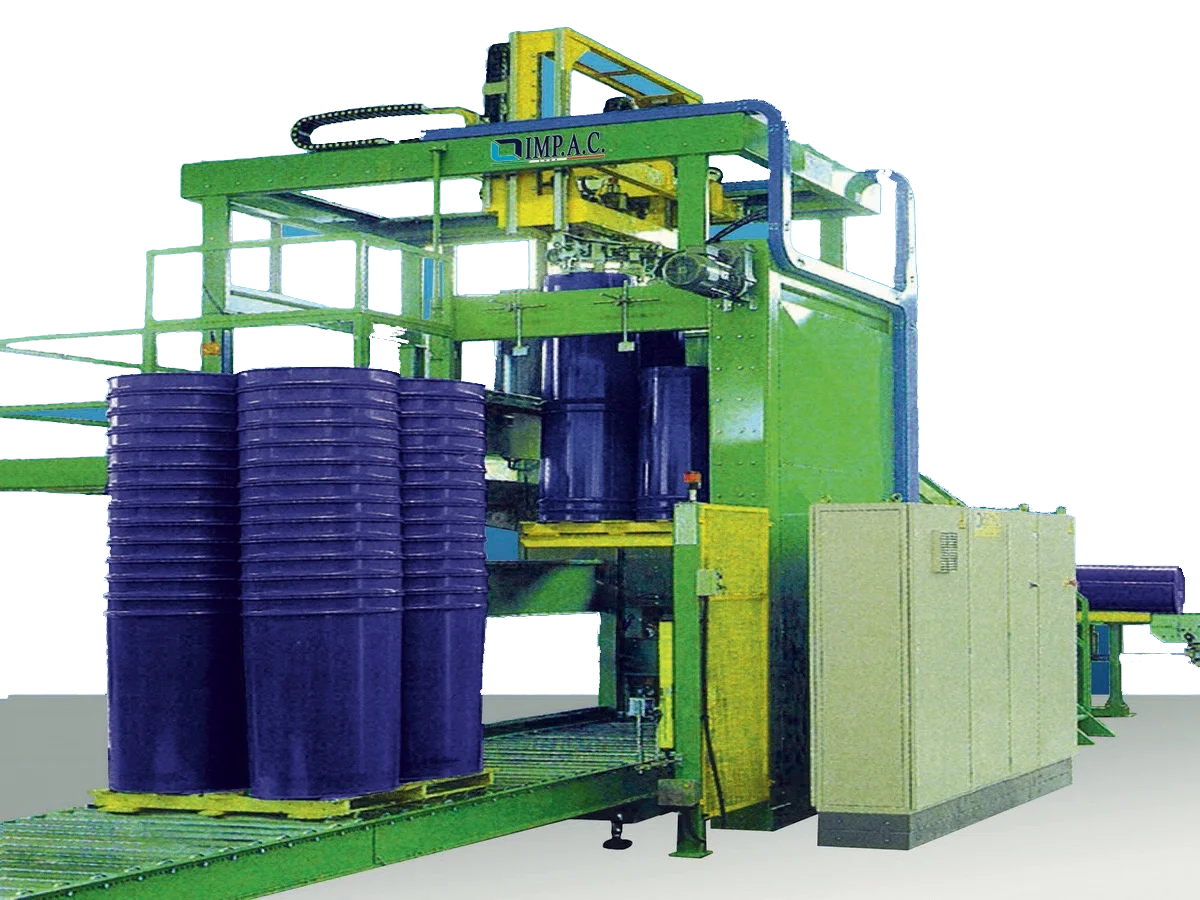

- Cartesian robots for drums, jerrycans and pails

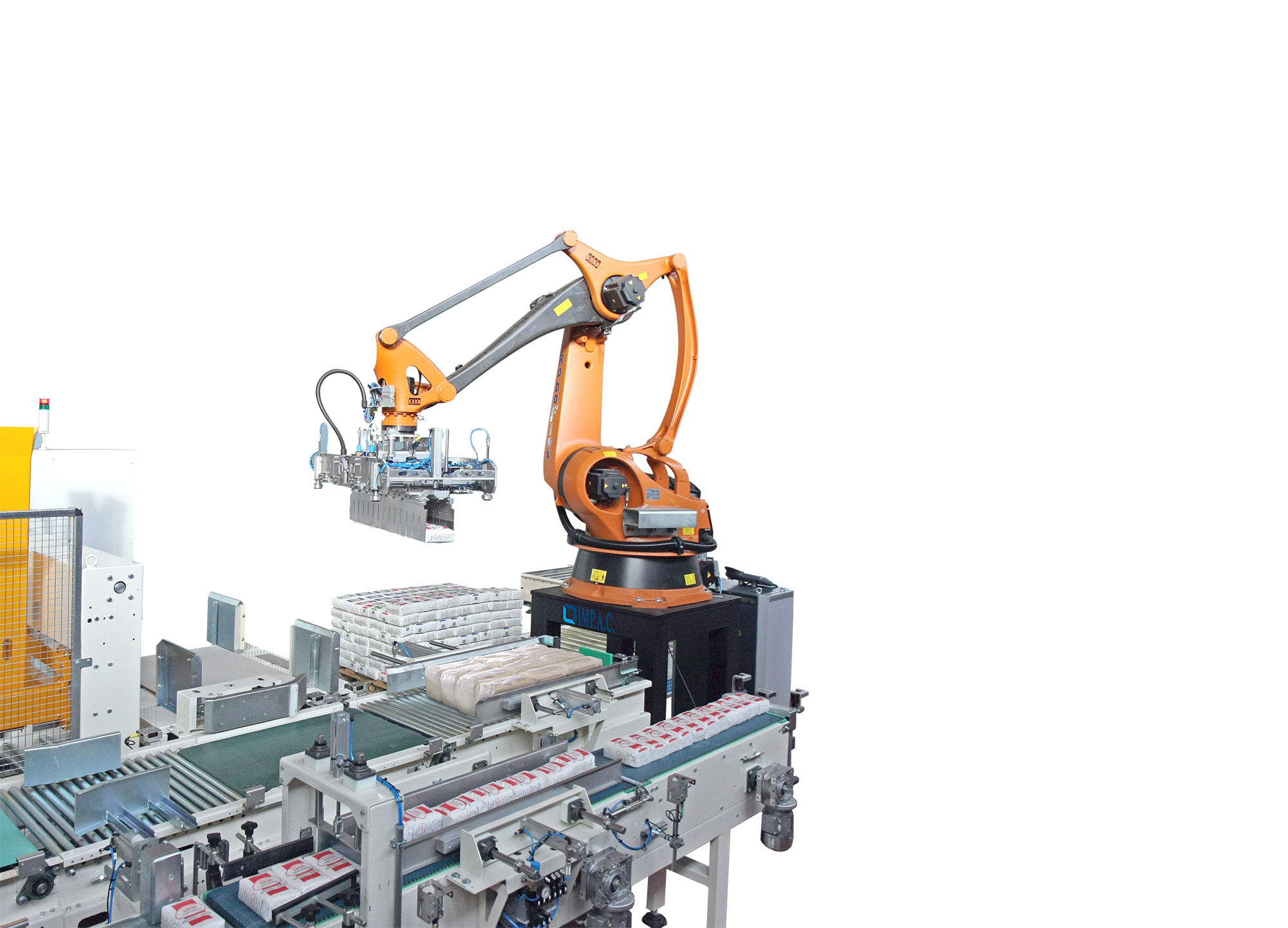

- Cartesian Robot palletizer for boxes and bundles

- Monocolumn Robot Palletizer and Depalletizer for cans pails and drums

- Monocolumn Robot Palletizer for bags

- Mono-column pallettizing system for box and bundles

- High level robot palletizing system for bags

- High level Robotic palletizer for conical drums

- High level Robotic palletizer for boxes and bundles

- Anthropomorphic Robot palletizer for boxes and bundles

- Anthropomorphic Robot Palletizer and Depalletizer for cans, pails and drums

- Anthropomorphic Robot palletizer for bags