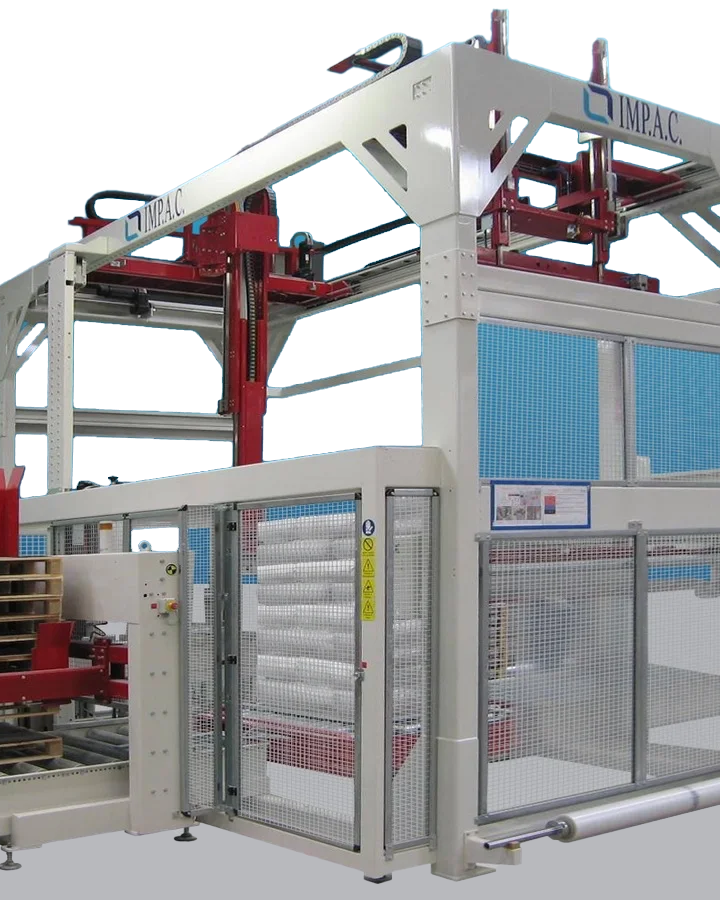

IMP.A.C. ROBOTEX 226 A-PR+TOP

Cartesian bundle palletising robot with automatic wrapper and built-in cover top

Cartesian bundle palletising robot with automatic wrapper and built-in cover top

Max. output

230 carton-bags/hour basic solution

400 carton-bags/hour fast solution

Bag dimensions

Max. 1000 x 500 x h. 250 mm<br>Min. 300 x 200 x h. 60 mm

Bundle size

Max. 1300 x 1200 x h. 140 mm<br>Min. 800 x 600 x h. 100 mm

Maximum layer size

Max. 1400 x 1250 mm

Standard full pallet height

1600 mm

Compressed air consumption

100 Nl/min

Control voltage

24 V

Max. full pallet weight

2000 Kg

Operational capacity

230-400 cartons-bundles/h

Installed power

8,1 KW

Operating pressure

6 bar

Indicative weight

6000 Kg

The ROBOTEX 226 A-PR+TOP is a state-of-the-art, fully automatic palletising solution designed to optimise end-of-line processes.

With integrated roller conveyors for handling empty and full pallets, it offers complete automation without the need for manual intervention.

The integration of an automatic winder and a top cover system provides stable and protected loads, ideal for safe handling and storage. Perfect for small spaces thanks to its compact dimensions, it can handle a maximum production capacity of 400 bundle-cartons/hour, adapting to different industrial requirements.

Key features

- Full wrapping gripper: allows handling of sacks and bundles of different materials and formats, with weights from 5 to 50 kg, guaranteeing precision even under difficult conditions (e.g. half-empty sacks or sacks containing liquids).

- Pressing and compacting system: ensures uniformity and stability of the load on the pallet.

- Built-in automatic winder: wraps loads during palletising to ensure safety.

- Top cover: protects the load from moisture, dust and damage during transport or storage.

- Compact design: optimal for installation in confined spaces.

- Full automation: designed for unmanned operation, ideal for high-efficiency production lines.

Advanced technology

- Cartesian motion: ensures high precision through encoder position control.

- Programmable modular system (PLC): manages movements and synchronises all phases of the operating cycle.

- Customisable programming: allows pallet formations, sizes and layers to be configured according to production needs.

Operation

- Receipt of the sack or bundle: the material coming from the production line is pressed to uniform its shape.

- Picking and placing: the full wrapping gripper picks, orients, positions and presses the sack or bundle onto the pallet according to the set programme.

- Wrapping and top cover: the load is automatically wrapped and protected with a top cover, ensuring stability and safety during transport.

- Evacuation: the completed pallet is evacuated and replaced automatically, ready for a new cycle.

The ROBOTEX 226 A-PR+TOP is an ideal choice for those looking for a complete, reliable and high-tech palletising solution, capable of improving production efficiency and ensuring maximum load protection.