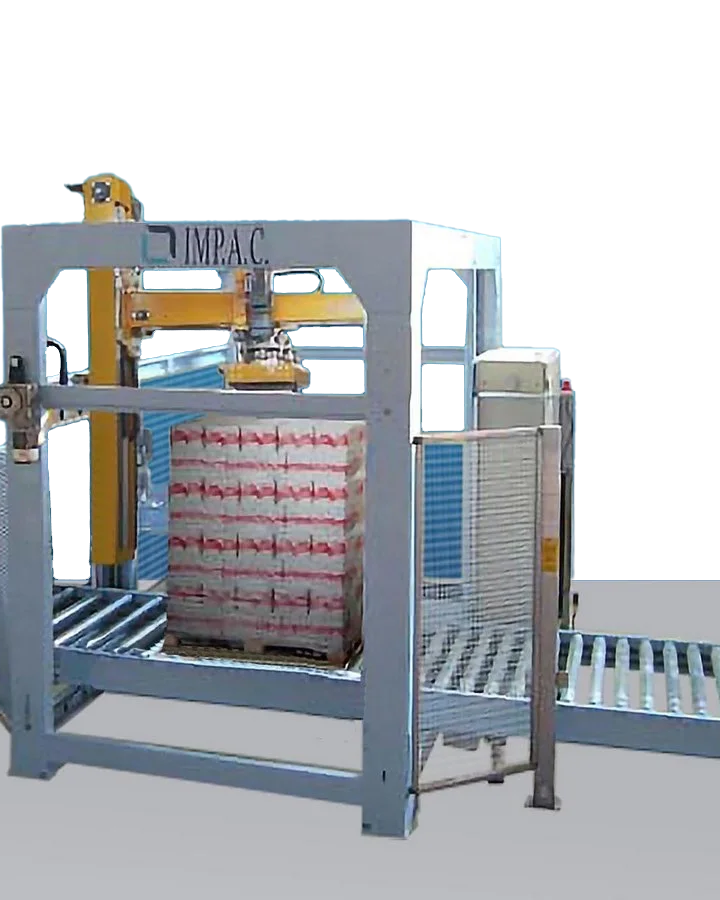

IMP.A.C. ROBOTEX 226 A-PR

Cartesian bundle palletising robot with built-in automatic winder

Cartesian bundle palletising robot with built-in automatic winder

Production Max:

270 carton-bags/hour basic solution

450 carton-bags/hour fast solution

Bag dimensions

Max. 1000 x 500 x h. 250 mm<br>Min. 300 x 200 x h. 80 mm

Bundle size

Max. 1300 x 1200 x h. 140 mm<br>Min. 800 x 600 x h. 100 mm

Maximum layer size

Max. 1400 x 1250 mm

Standard full pallet height

1600 mm

Compressed air consumption

100 Nl/min

Control voltage

24 V

Max. full pallet weight

2000 Kg

Operational capacity

270-450 sacks/h

Installed power

8,1 KW

Operating pressure

6 bar

Indicative weight

6000 Kg

The ROBOTEX 226 A-PR is an innovative automatic palletiser designed to meet the needs of the most advanced production lines.

Complete with roller conveyors for automatic handling of empty and full pallets, it is ideal for optimising production processes without requiring the presence of operators.

Thanks to its compact design and the possibility of simultaneous palletising and wrapping, the ROBOTEX 226 APR guarantees load stability, even for unstable or slippery bags. It is perfect for integration into fully automated lines with a maximum throughput of 450 bundle-cartons/hour.

Key features

- Full wrapping gripper: allows the handling of bundles and sacks of any material and format, even under difficult conditions (e.g. half-empty sacks or sacks containing liquids).

- Integrated pressing device: ensures that the bags are compacted on the pallet, improving load stability.

- Built-in automatic winder: ensures optimal packing directly during palletising.

- Compact design: ideal for installation in small spaces.

- Versatility: designed to handle bundles and cartons with weights between 10 and 15 kg.

Advanced technology

- Cartesian motion: precision assured thanks to positioning control via encoder.

- Programmable modular system (PLC): manages movement synchronisms for smooth and customised palletising.

- Customisable programming: suitable for pallet configurations with different formats, layers and layouts.

Operation

- The sacks or bundles, coming from the upstream production line, are pressed and made uniform to ensure load stability.

- Subsequently, they are transferred to the positioning station and picked up by the total clamp, which ensures a firm and precise grip.

- Each unit is oriented, positioned and pressed on the pallet according to the configured programme.

- Once the cycle is complete, the pallet is automatically evacuated and replaced, ready for the start of a new cycle.

The ROBOTEX 226 A-PR is the ideal choice for automated production lines, offering an advanced palletising and wrapping system. Reliability, precision and flexibility make it an optimal solution for improving production efficiency.