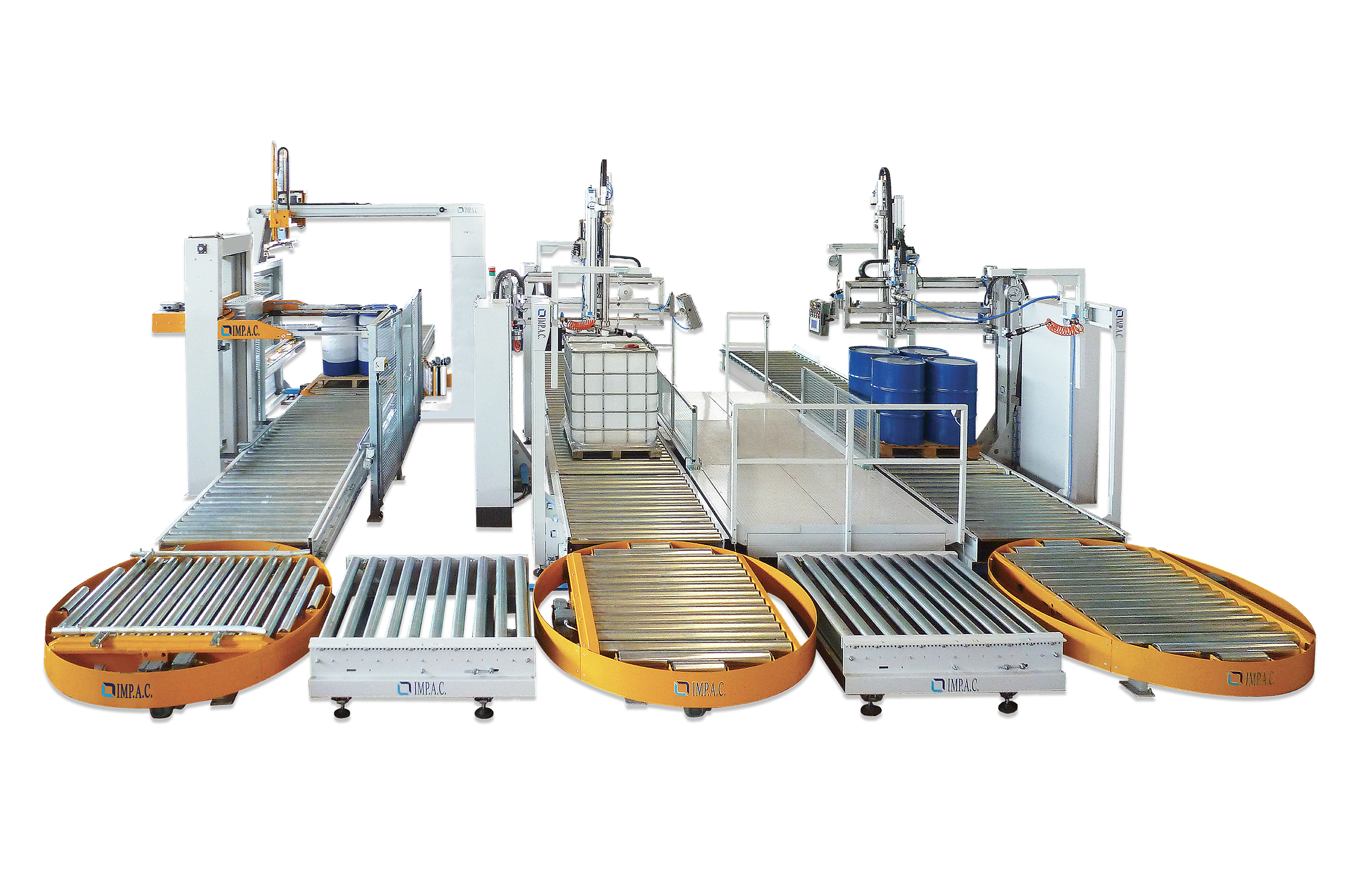

Semi-automatic drum filling machine on pallet and IBC IMP.A.C. 56 SA 4P 1500

The IMP.A.C. 56 SA 4P 1500 is a semi-automatic filling machine designed for filling chemicals and related products in 220-litre and 60-litre drums on pallets as well as in 1000-litre IBCs.

With its adjustable nozzle arm and weighing platform with load cells, it guarantees high precision and reliability throughout the entire filling cycle.

Production capacity

• 28 drums/hour (220 or 60 litres)

• 8 IBCs/hour (from 1000 litres)

Operating Cycle

Pallet positioning with drums or IBCs on the weighing platform.

Automatic nozzle adjustment to avoid splashes and leaks.

Start of filling with weight monitoring via load cells.

Automatic interruption of filling when the preset weight is reached.

Manual removal of the pallet for subsequent packaging.

Available options and accessories

Fume and vapour extraction system – For improved environmental safety.

ATEX version – For filling in explosion-hazardous environments.

Customisable configurations – Can be adapted to specific needs.

Industrial applications

Chemical industry – For solvents, paints, adhesives and hazardous products.

Agrochemicals – For liquid fertilisers, pesticides and agricultural products.

Industrial Lubricants and Oils – For motor oils, technical fluids and additives.

The IMP.A.C. 56 SA 4P 1500 is the ideal solution for companies needing flexibility, precision and safety when filling drums and IBCs.

Semi-automatic drum filling machine on pallet and IBC

Production Max:

28 drums/h

8 IBC/h

Type container

Drums, Drums, IBCs

Paddle size

1200 x 1200 mm

Weight tolerance

500 g

Compressed air consumption

90 Nl/min

Container handling

Manual or Motorised

Installed power

400 V

Total empty weight

1300 Kg

Container weight

Max. 1000 l

Min. 50 l

Nozzle height adjustment

800 mm

Filling nozzle stroke

1000 mm

Production time = cycle time + Filling time (TR)

25 s + TR

Air pressure

6 bar

Product benefits

__ Suitable for drums and tanks

__ Suitable for drums and tanks

Compatible with 220 litre drums, 60 litre drums on pallet and 1000 litre IBCs.

__ 3-axis movable nozzle arm

__ 3-axis movable nozzle arm

It allows precise positioning for each container.

__ Real-time weight control

__ Real-time weight control

Platform with load cells to ensure accurate dosing.

__ Semi-automatic operation

__ Semi-automatic operation

The operator positions the container and starts the cycle with a button.

__ Compact and robust construction

__ Compact and robust construction

Perfect for industrial environments with limited space.

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

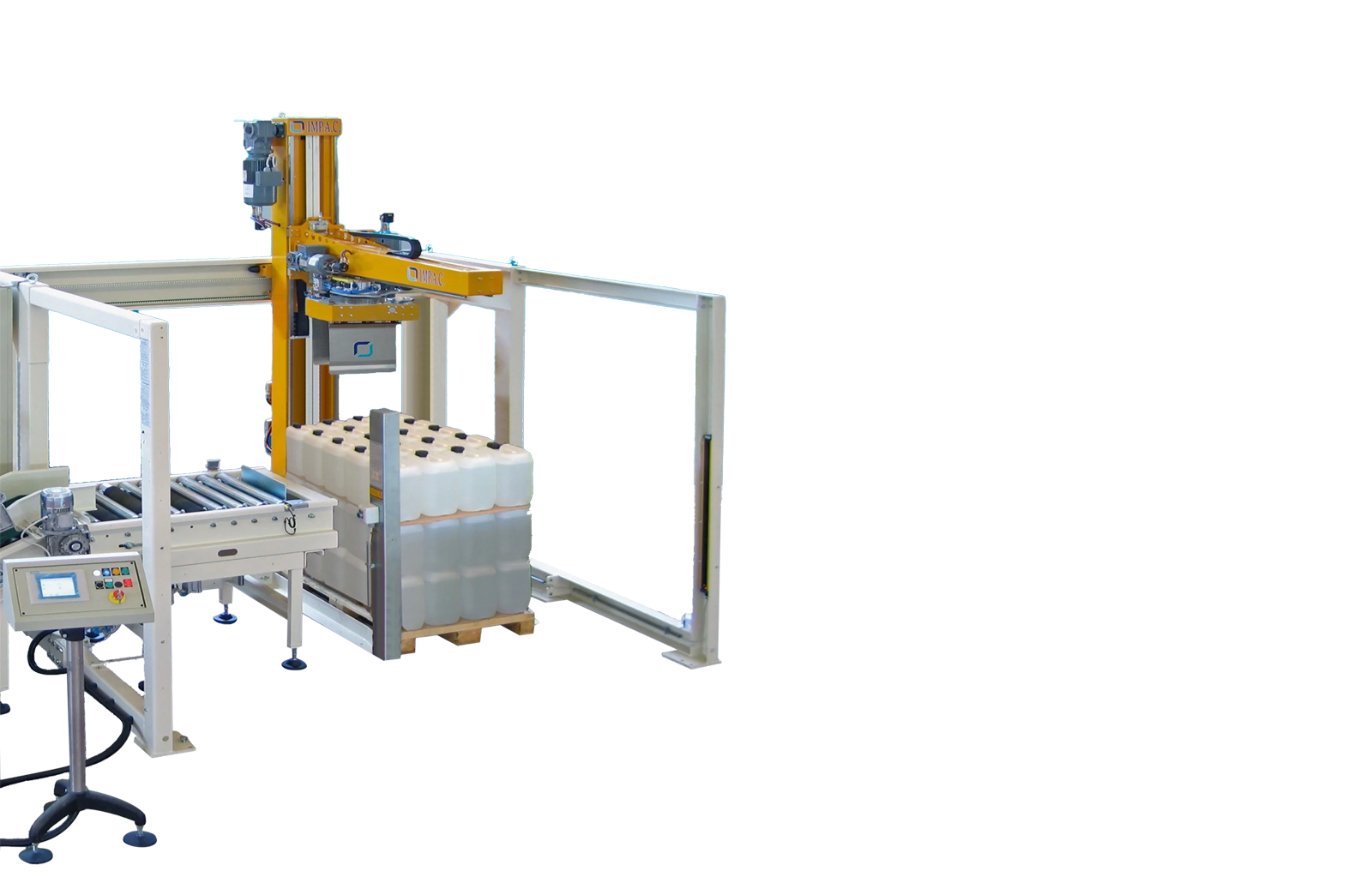

- Stretch wrapping machines

- Stretch hood machines

- Low-Level Palletizer for cans

- Cartesian robots for drums, jerrycans and pails

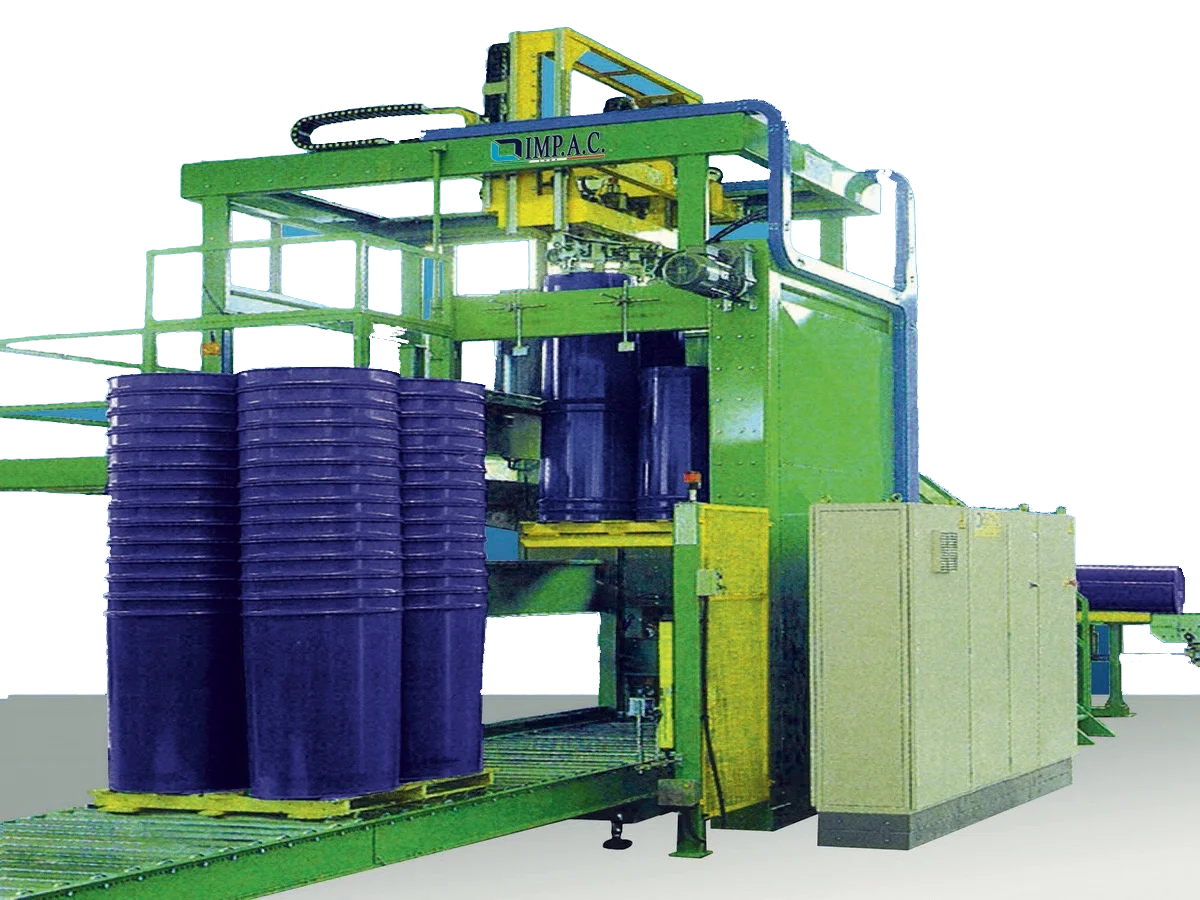

- Monocolumn Robot Palletizer and Depalletizer for cans pails and drums

- High level Robotic palletizer for conical drums

- Anthropomorphic Robot Palletizer and Depalletizer for cans, pails and drums

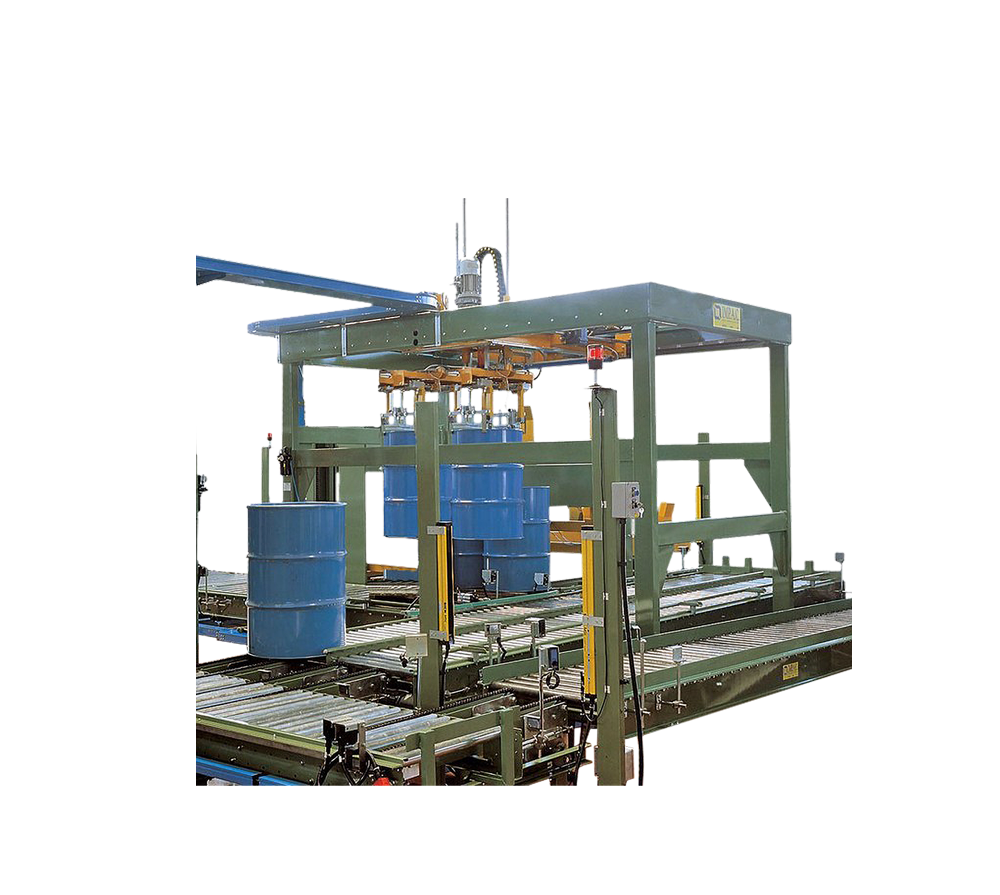

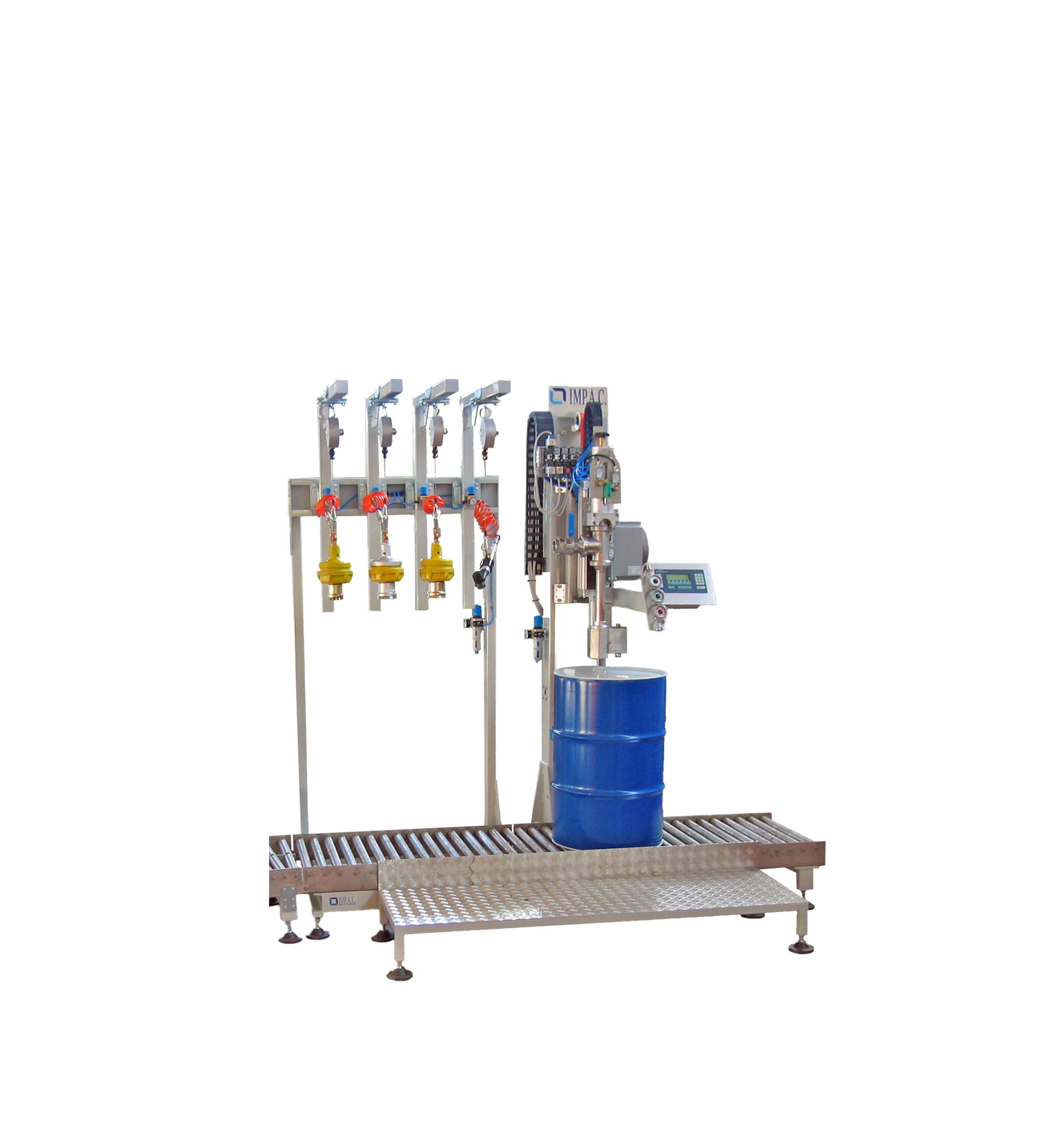

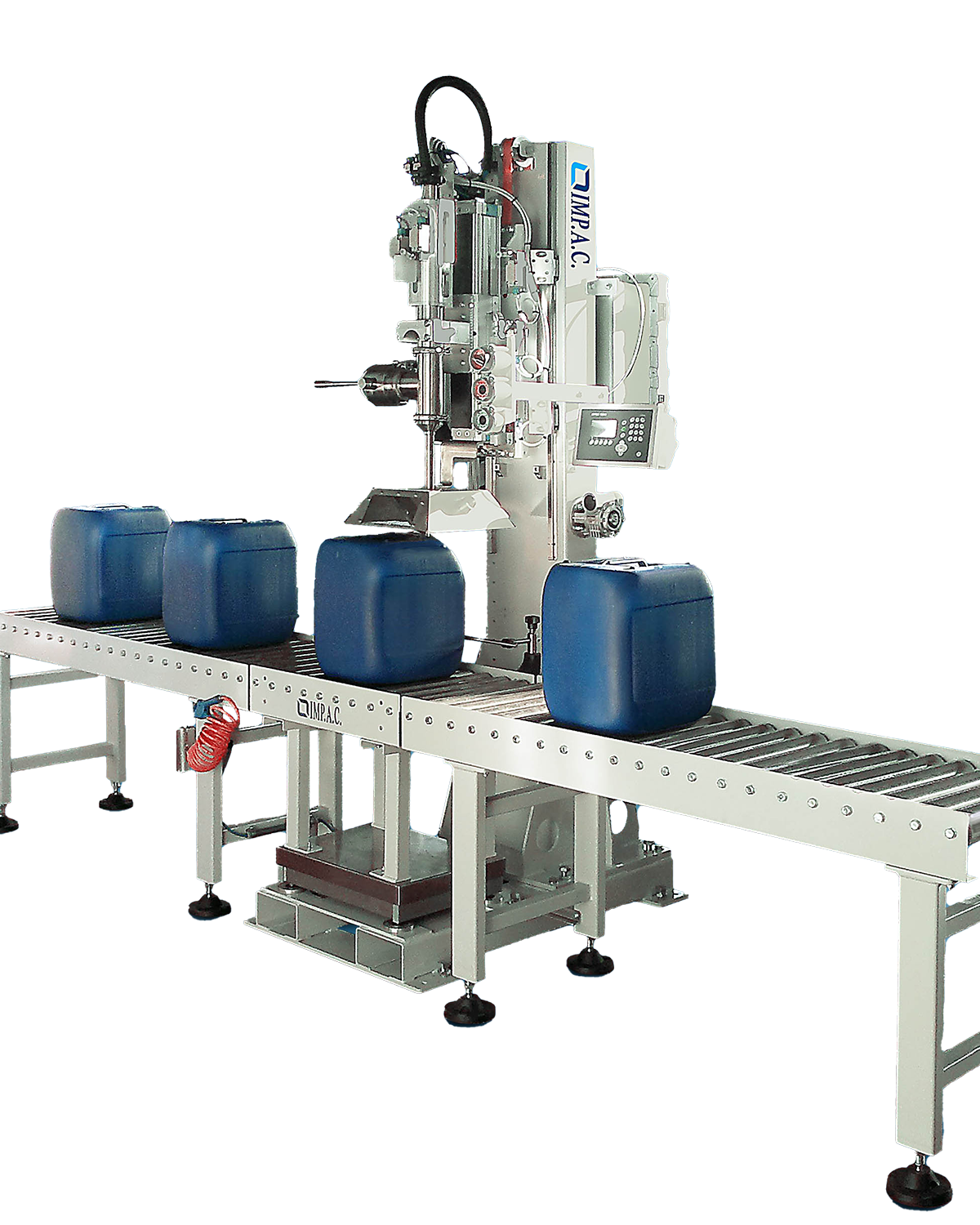

Semi-automatic drum and single drum filling machine IMP.A.C. 56 SA 300

The IMP.A.C. 56 SA 300 is a semi-automatic filling machine designed for filling chemicals and related products in 220-litre drums and 60-litre drums.

With its integrated weighing system and height-adjustable nozzle, it ensures accurate dosing and reduces the risk of waste and contamination.

Production capacity

• 40 drums/hour (220 litres)

• 60 drums/hour (60 litres)

Operating Cycle

Positioning of the drum or drum under the filling nozzle.

Automatic nozzle height adjustment to prevent splashes and leaks.

Start of filling with weight monitoring via load cells.

Automatic filling interruption when the preset weight is reached.

Manual removal of container for subsequent packaging.

Available options and accessories

Fume and vapour extraction system – For improved environmental safety.

ATEX version – For filling in explosion-hazardous environments.

Customisable configurations – Can be adapted to specific needs.

Industrial applications

Chemical industry – For solvents, paints, adhesives and hazardous products.

Agrochemicals – For liquid fertilisers, pesticides and agricultural products.

Industrial Lubricants and Oils – For motor oils, technical fluids and additives.

The IMP.A.C. 56 SA 300 is the ideal solution for companies looking for a flexible, precise and safe system for filling single drums and drums.

Semi-automatic drum and canister filling machine

Max. production: 40 drums/h

Type container

Drums, Drums

Container size

Ø 600 mm

Weight tolerance

50 g

Compressed air consumption

60 Nl/min

Container handling

Manual or Motorised

Installed power

400 V

Container weight

Max. 300 l

Min. 50 l

Nozzle height adjustment

450 mm

Production time = cycle time + Filling time (TR)

20 s + TR

Air pressure

6 bar

Total empty weight

700 Kg

Product benefits

__ Suitable for different formats

__ Suitable for different formats

Compatible with 220 litre drums and 60 litre drums.

__ Automatic nozzle adjustment

__ Automatic nozzle adjustment

It adapts to the height of the container for optimal filling.

__ Real-time weight control

__ Real-time weight control

Base with load cells for precise weighing during filling.

__ Semi-automatic operation

__ Semi-automatic operation

The operator positions the container and starts the cycle with a button.

__ Compact and robust construction

__ Compact and robust construction

Perfect for industrial environments with limited space.

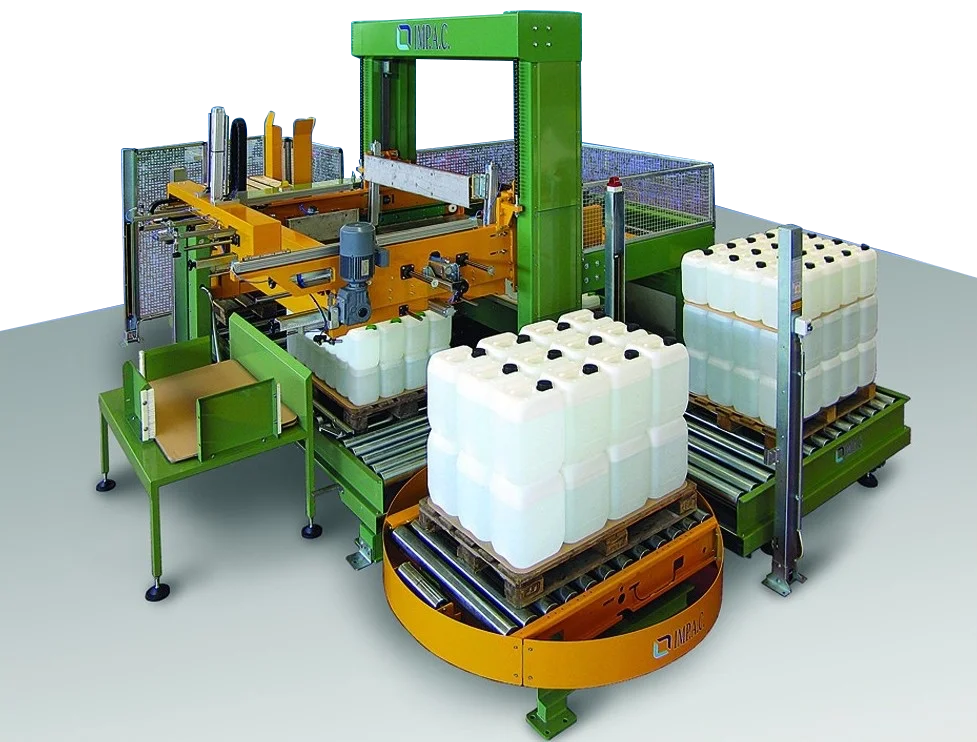

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

- Stretch wrapping machines

- Stretch hood machines

- Low-Level Palletizer for cans

- Cartesian robots for drums, jerrycans and pails

- Monocolumn Robot Palletizer and Depalletizer for cans pails and drums

- High level Robotic palletizer for conical drums

- Anthropomorphic Robot Palletizer and Depalletizer for cans, pails and drums

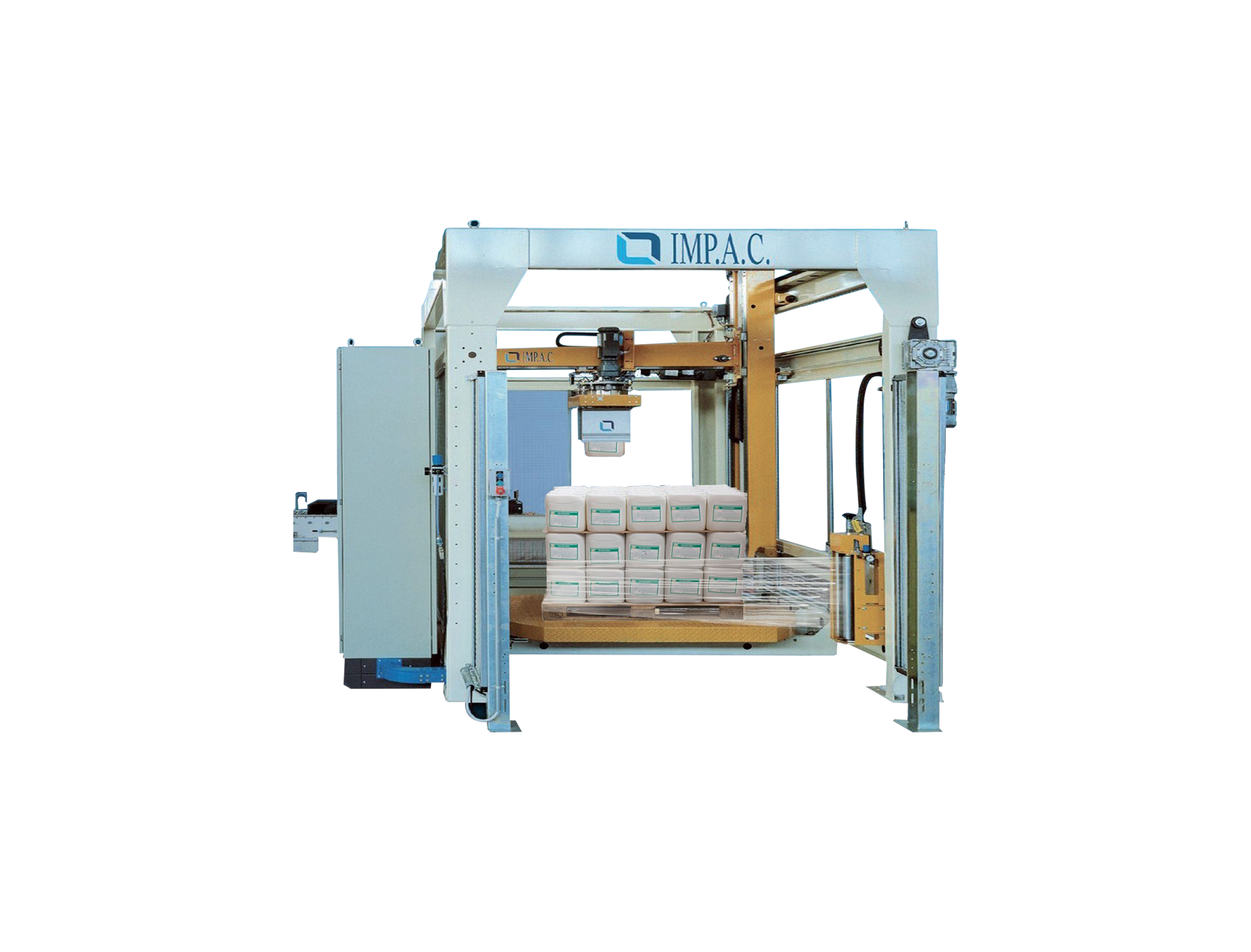

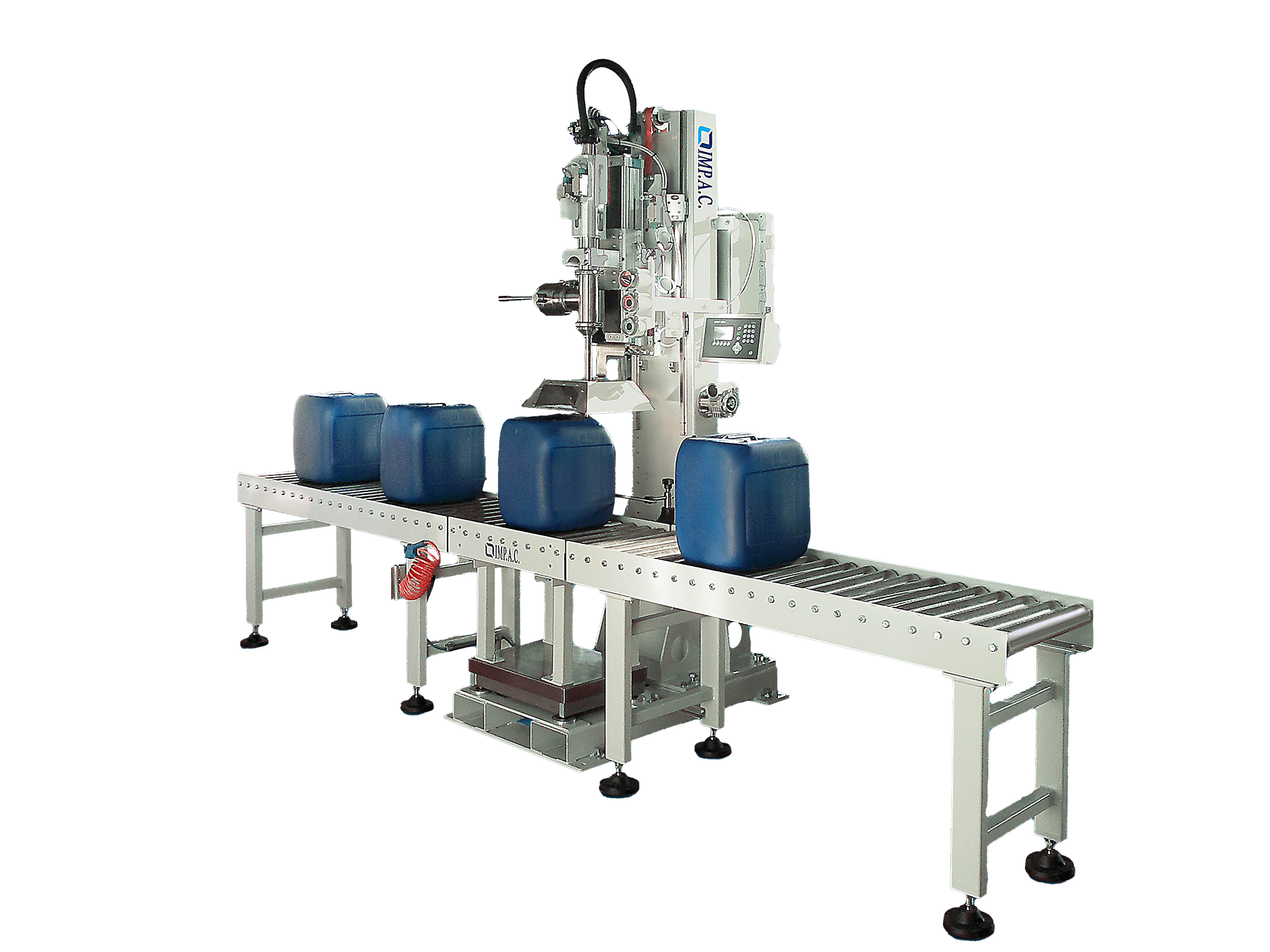

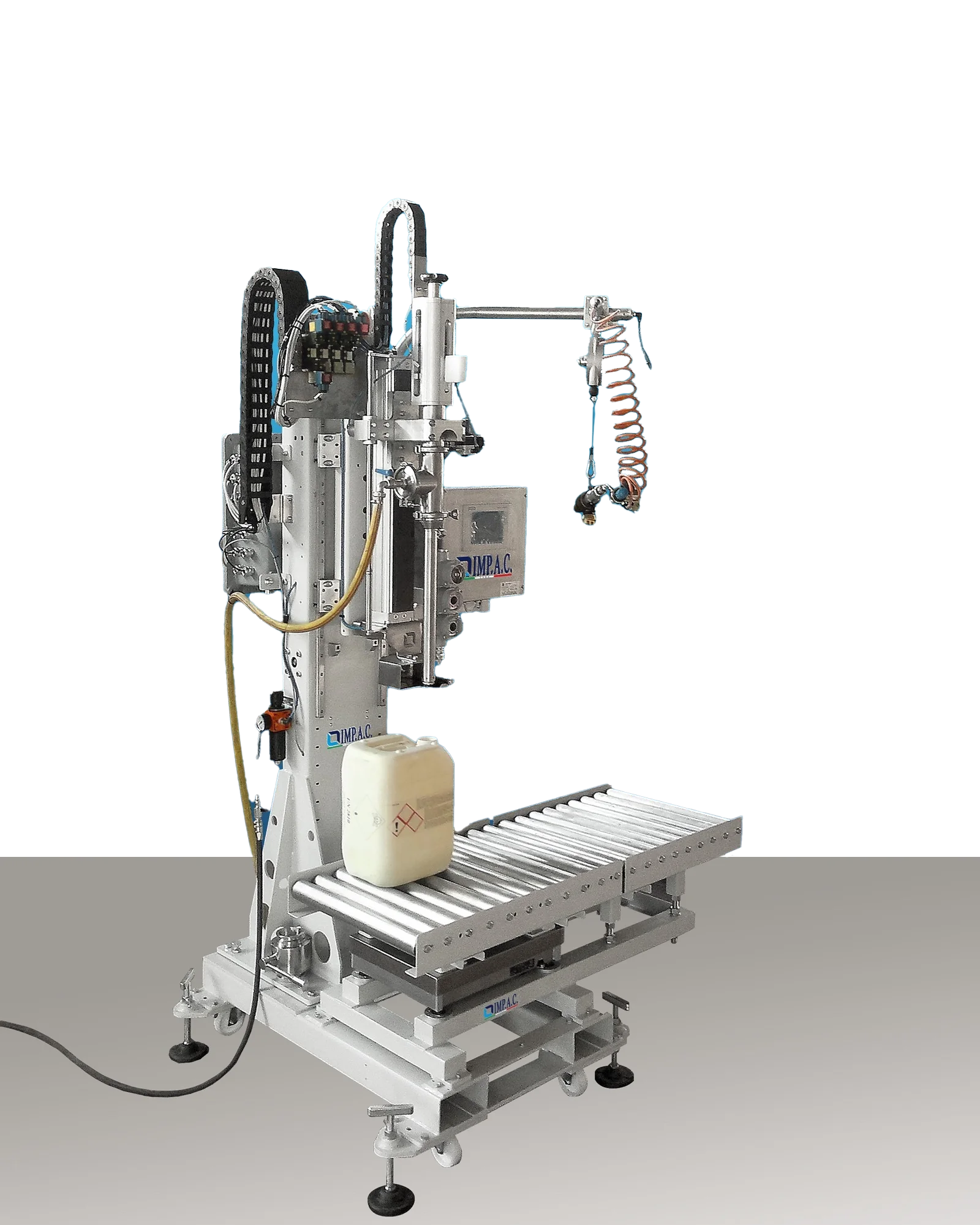

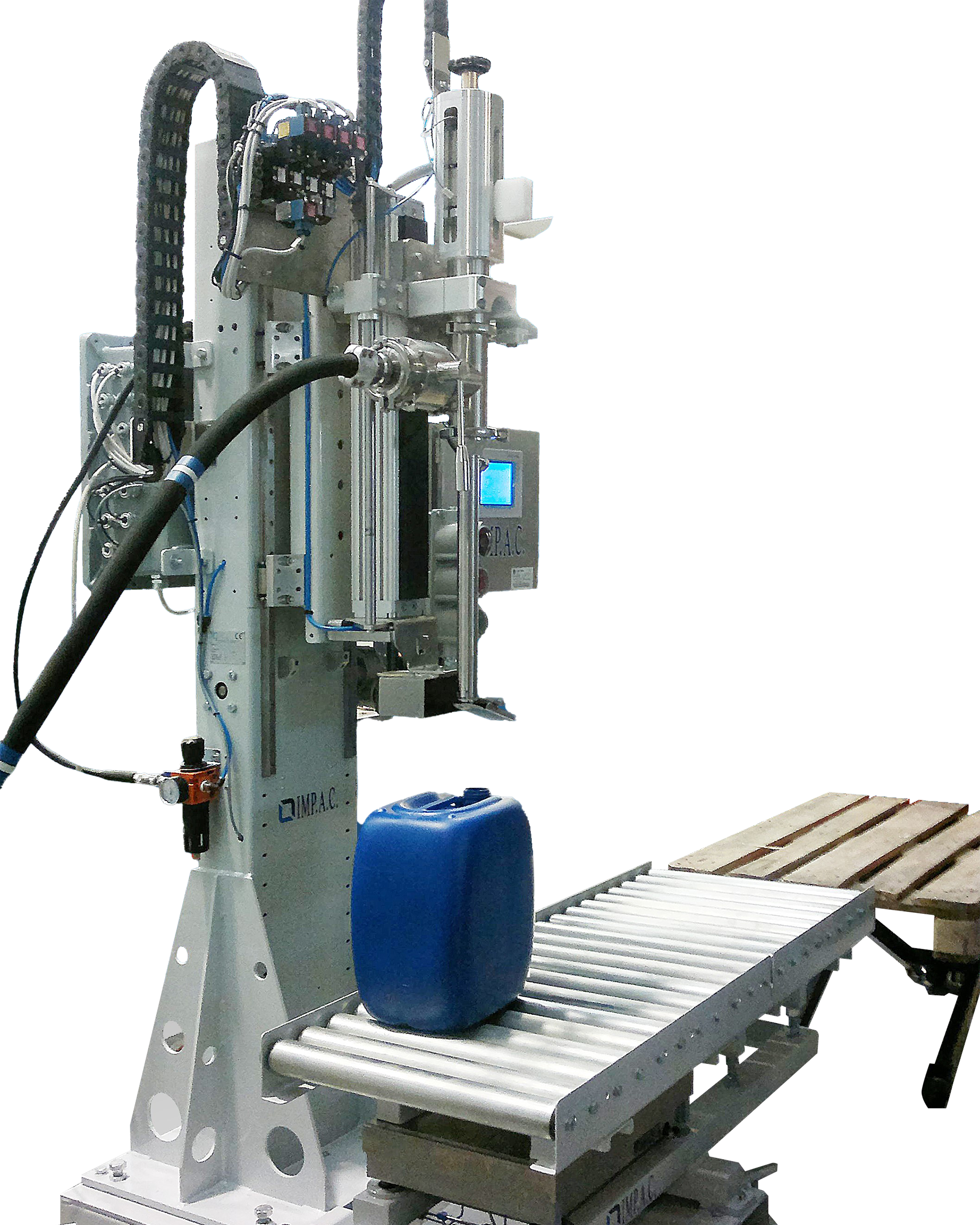

Semi-automatic single tank filling machine IMP.A.C. 56 SA 100

The IMP.A.C. 56 SA 100 is a semi-automatic filling machine designed for filling chemical and related products for jerry cans and drums of various capacities.

With its height-adjustable nozzle and integrated weighing system, it allows accurate control of the filling process, ensuring efficiency and safety.

Production capacity

• 80 cans/hour (5 litres)

• 50 cans/hour (25 litres)

Operating Cycle

Positioning of the canister/canister under the filling nozzle.

Automatic adjustment of nozzle height according to container.

Filling start with real-time weight control via load cells.

Automatic interruption when the desired weight is reached.

Manual removal of the canister/canister for subsequent packaging.

Available options and accessories

Fume and vapour extraction system – For a safer working environment.

ATEX version – For operation in explosion-hazardous environments.

Customisations on request – To adapt to specific production requirements.

Industrial applications

Chemical Industry – Filling of solvents, detergents and hazardous products.

Agrochemicals – Filling of fertilisers and liquid solutions for agriculture.

Lubricants and Automotive – Filling of oils, technical fluids and additives.

The IMP.A.C. 56 SA 100 is the ideal solution for companies needing a compact, precise and reliable system for filling jerry cans and drums.

Semi-automatic filling machine for jerry cans and drums

Max. production

80 jerrycans/h 5-litre jerrycans

50 jerry cans/hour 25-litre jerry cans

Type container

Tanks, Drums

Container size

Tanks 300 x 350 x 600 mm, diameter 400 mm

Weight tolerance

20 g

Compressed air consumption

60 Nl/min

Container handling

Manual or Motorised

Installed power (in case of IP 55 protection)

0.3 KW - 220 V

Container weight

Max. 60 l

Min. 2 l

Nozzle height adjustment

450 mm

Production time = cycle time + Filling time (TR)

20 s + TR

Air pressure

6 bar

Total empty weight

600 Kg

Product benefits

__ Flexibility

__ Flexibility

Suitable for 5, 10, 25 litre cans and 60 litre drums.

__ Height adjustment

__ Height adjustment

The filling nozzle automatically adapts to the container.

__ Weight control

__ Weight control

Base with load cells to ensure dosing accuracy.

__ Semi-automatic operation

__ Semi-automatic operation

The operator positions the container, starts the filling and manages the removal.

__ Compactness

__ Compactness

Small footprint for optimal integration into existing production lines.

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

- Stretch wrapping machines

- Stretch hood machines

- Low-Level Palletizer for cans

- Cartesian robots for drums, jerrycans and pails

- Monocolumn Robot Palletizer and Depalletizer for cans pails and drums

- High level Robotic palletizer for conical drums

- Anthropomorphic Robot Palletizer and Depalletizer for cans, pails and drums