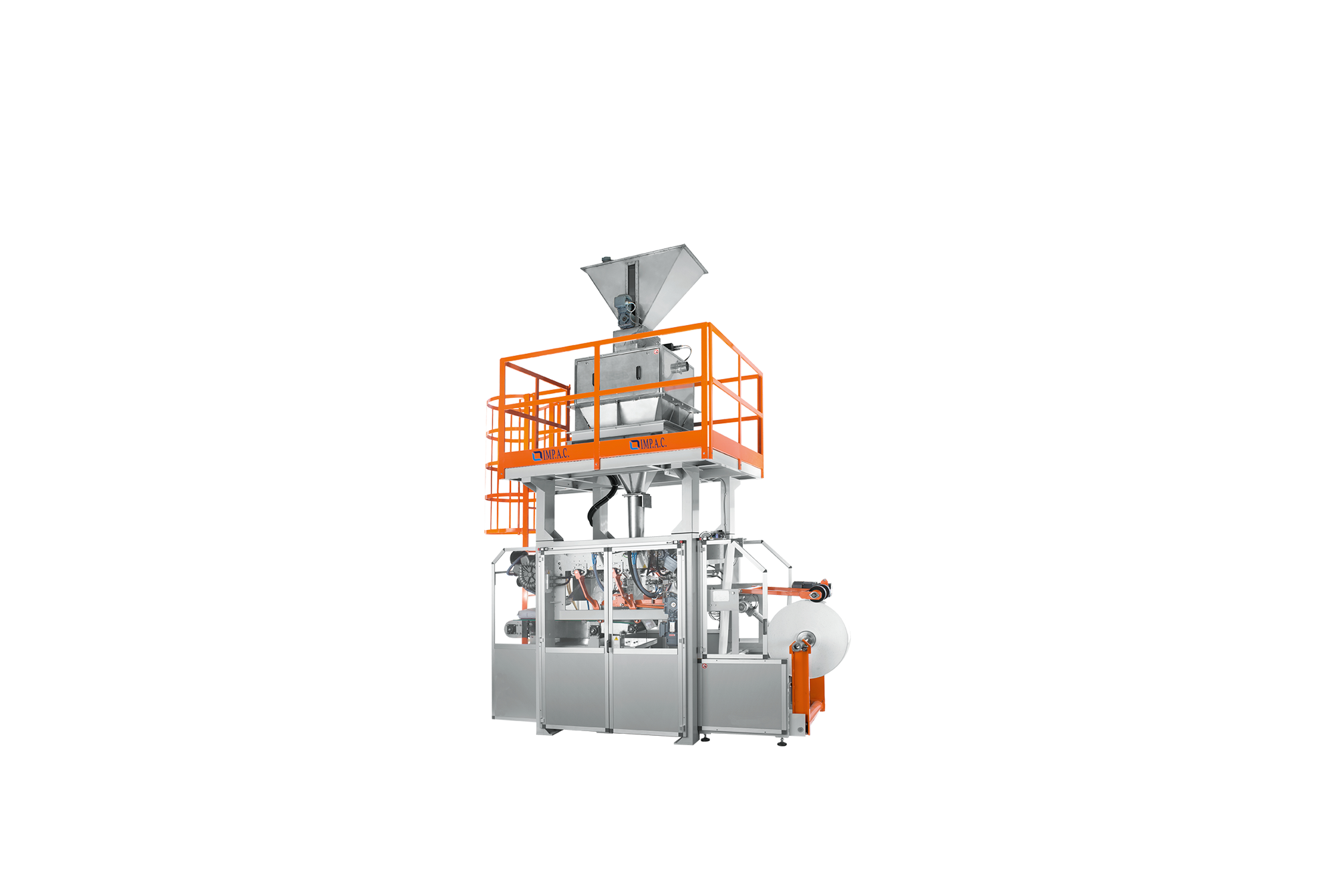

IMP.A.C. ROBOTEX 11 A

Bag palletizer robot with conventional compacting system, create square and sturdy pallets

The ROBOTEX 11 A is a state-of-the-art robotic palletizer designed to meet complex palletizing needs, with a production capacity of up to 550 sacks/hour.

Thanks to the layer palletizing system and the compaction mechanism on all four sides, it ensures stable and uniform loads, even when handling difficult-to-manage sacks.

Its advanced features make it the ideal solution in production environments where traditional palletizers or standard robots are not sufficient.

Key features

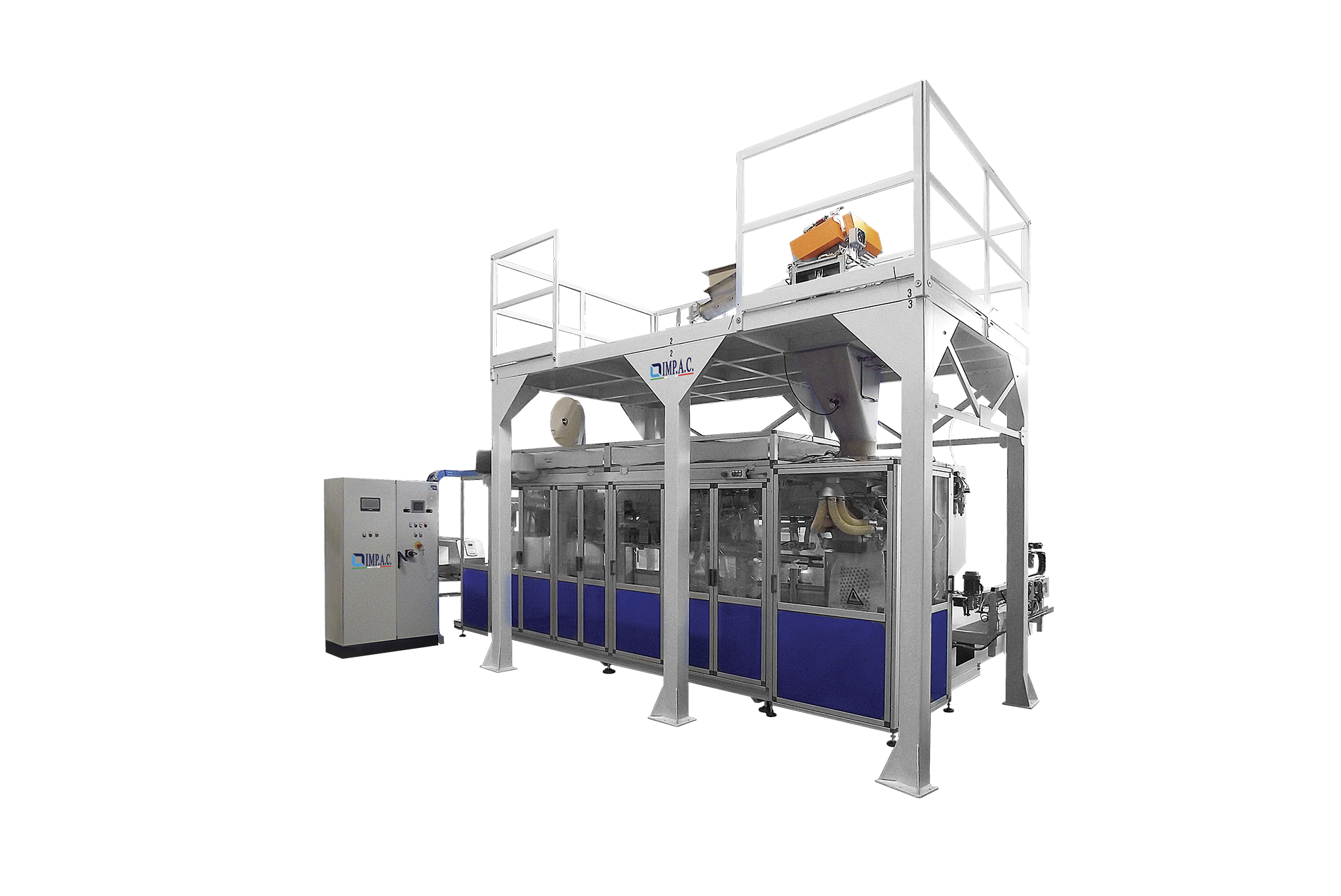

- Advanced handling: the bag is picked up with a total wrapping gripper, ideal for various materials and formats (paper, jute, plastic, sewn, electro-welded, or valve bags).

- Compaction on 4 sides: ensures precise layer formation, enhancing load stability.

- Mobile pallet: the lifter positions the pallet optimally, thanks to a detection system with photoelectric barrier.

- Top feeding: enables a continuous flow of bags, improving production line efficiency.

- Versatile design: can be used with bags containing difficult materials, such as half-empty bags or bags with liquid or viscous products.

Advanced technology

- 3-axis movement system: rotary, transverse and longitudinal movements allow total mobility in the horizontal plane, guaranteeing precision at every stage of the cycle.

- Customisable mechanical hand: designed to transfer bags gently and position them precisely on the pre-forming platform.

- PLC control: the programmable modular system coordinates and optimises all movements, providing flexibility to adapt to different pallet sizes and configurations.

Operation

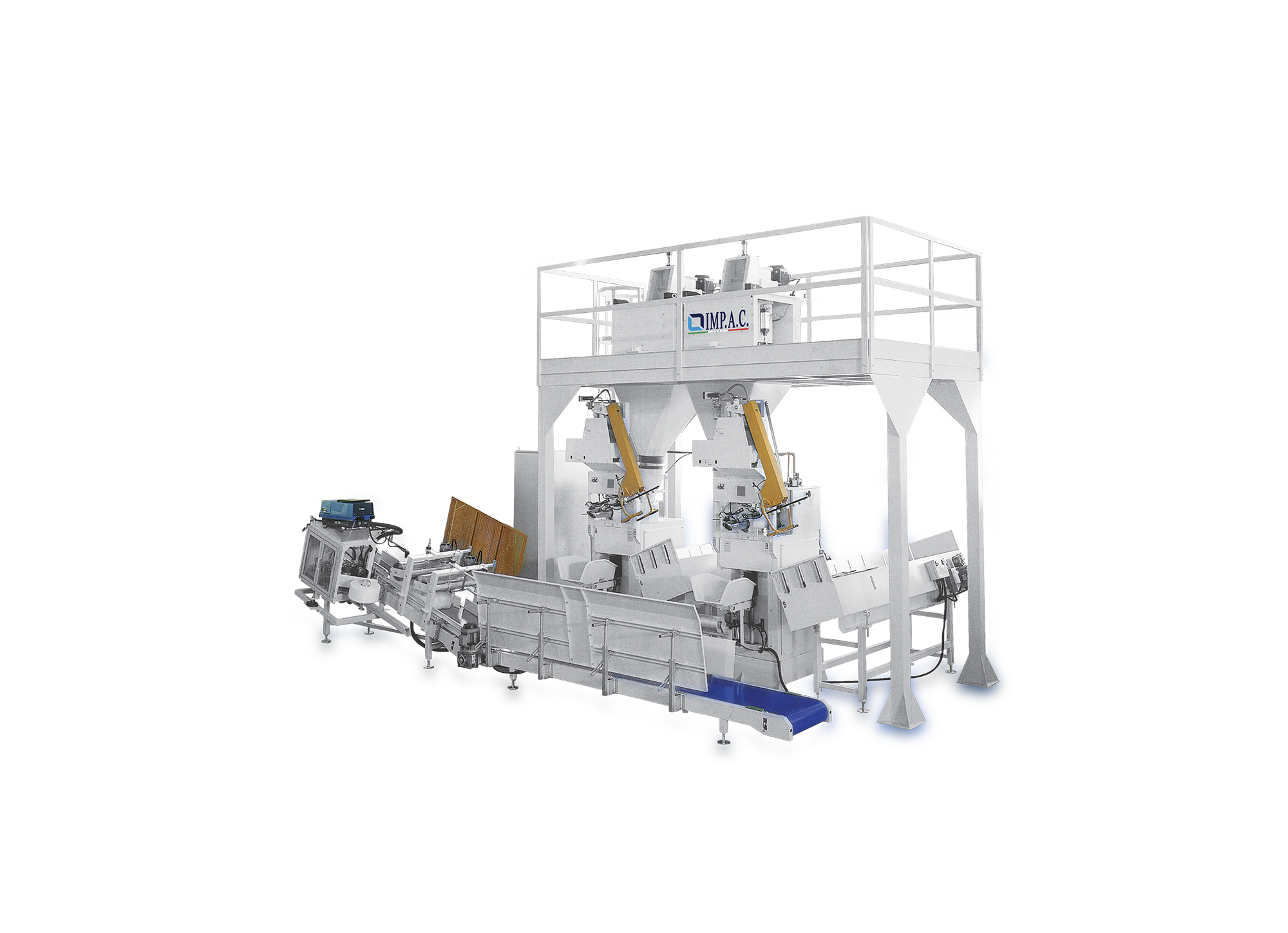

- Picking and compacting: the bag from the upstream line is pressed to ensure it is compact and transferred to the pre-forming station.

- Layer positioning: the movable mechanical hand orients and positions the bag on the layer, completing the arrangement according to the set programme.

- Transfer and compaction: the formed layer is transferred onto the moving pallet and compacted on all four sides to ensure stability.

- Pallet evacuation: once completed, the pallet is automatically evacuated and replaced, allowing a new cycle to begin.

The ROBOTEX 11 A is a technologically advanced solution designed to ensure efficiency, flexibility and quality in bag palletising, adapting to any production context with precision and reliability.

Bag palletizer robot with conventional compacting system, create square and sturdy pallets

Max. production: 550 bags/h

Bag dimensions

Max. 1000 x 500 x h. 250 mm

Min. 300 x 200 x h. 60 mm

Paddle size

Max. 1200 x 1000 x h. 140 mm

Min. 800 x 600 x h. 100 mm

Maximum layer size

Max. 1300 x 1100 mm

Standard full pallet height

1600 mm

Compressed air consumption

100 Nl/min

Control voltage

24 V

Max. full pallet weight

2000 Kg

Operational capacity

550 bags/h

Installed power

12 KW

Operating pressure

6 bar

Indicative weight

8000 Kg

Product benefits

__ Ultra-fast handling

__ Ultra-fast handling

With a total wrapping gripper to ensure precision and speed.

__ Layer preforming and compaction

__ Layer preforming and compaction

Stable and uniform pallet

__ Gripper with integrated pressing system

__ Gripper with integrated pressing system

Ideal for difficult and unstable sacks

__ Three-dimensional movements

__ Three-dimensional movements

Maximum flexibility and precision

__ Total automation

__ Total automation

Management via programmable PLC