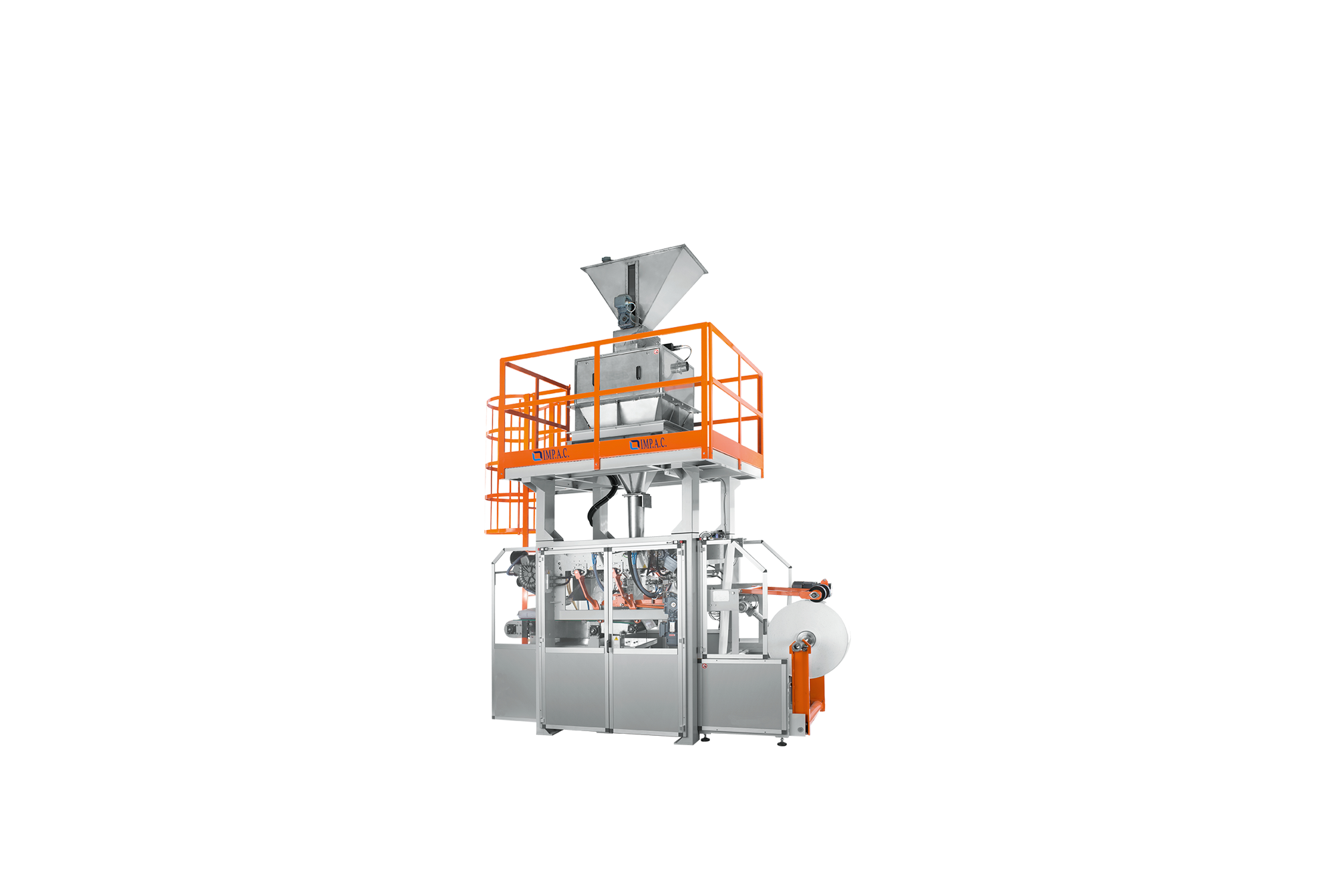

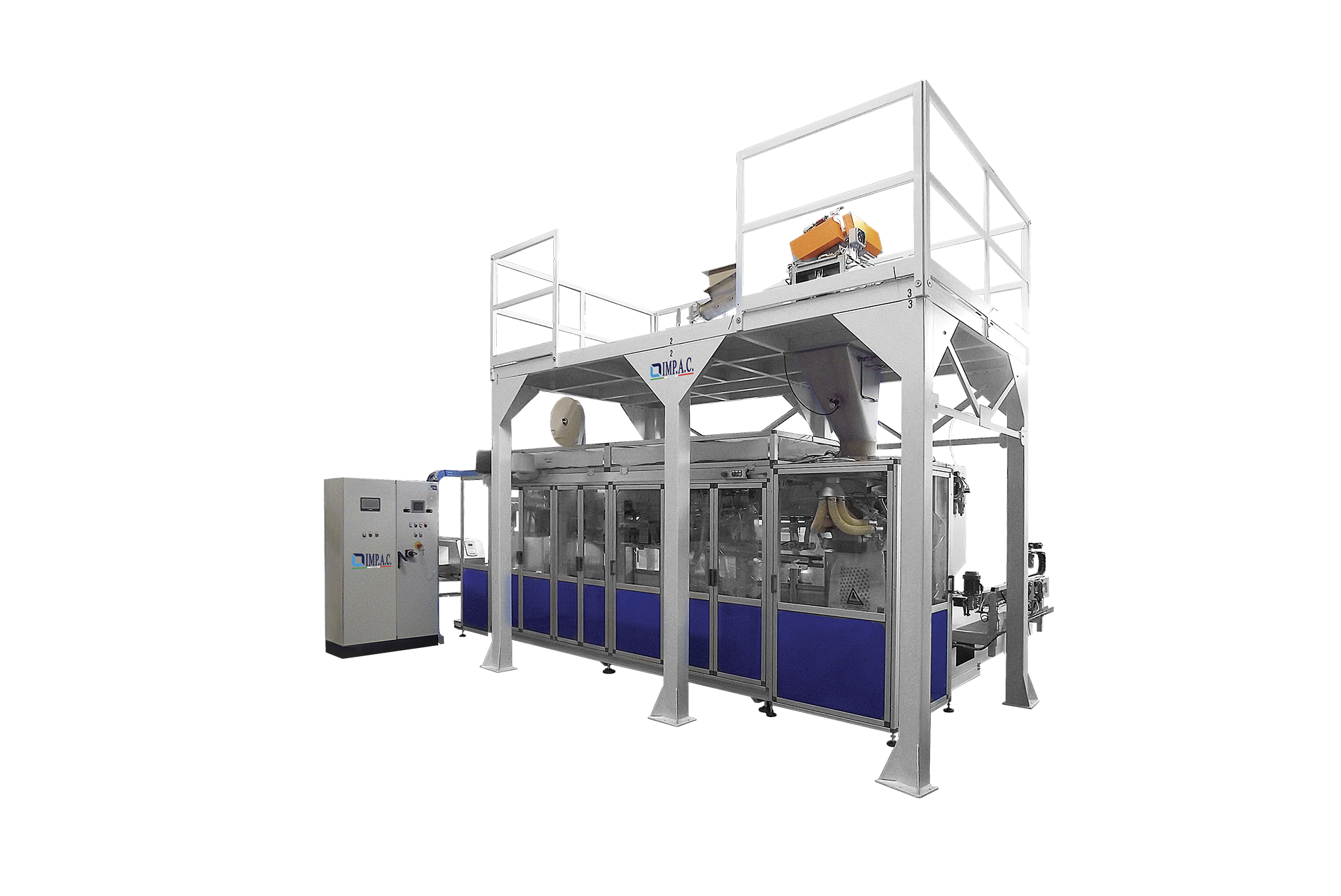

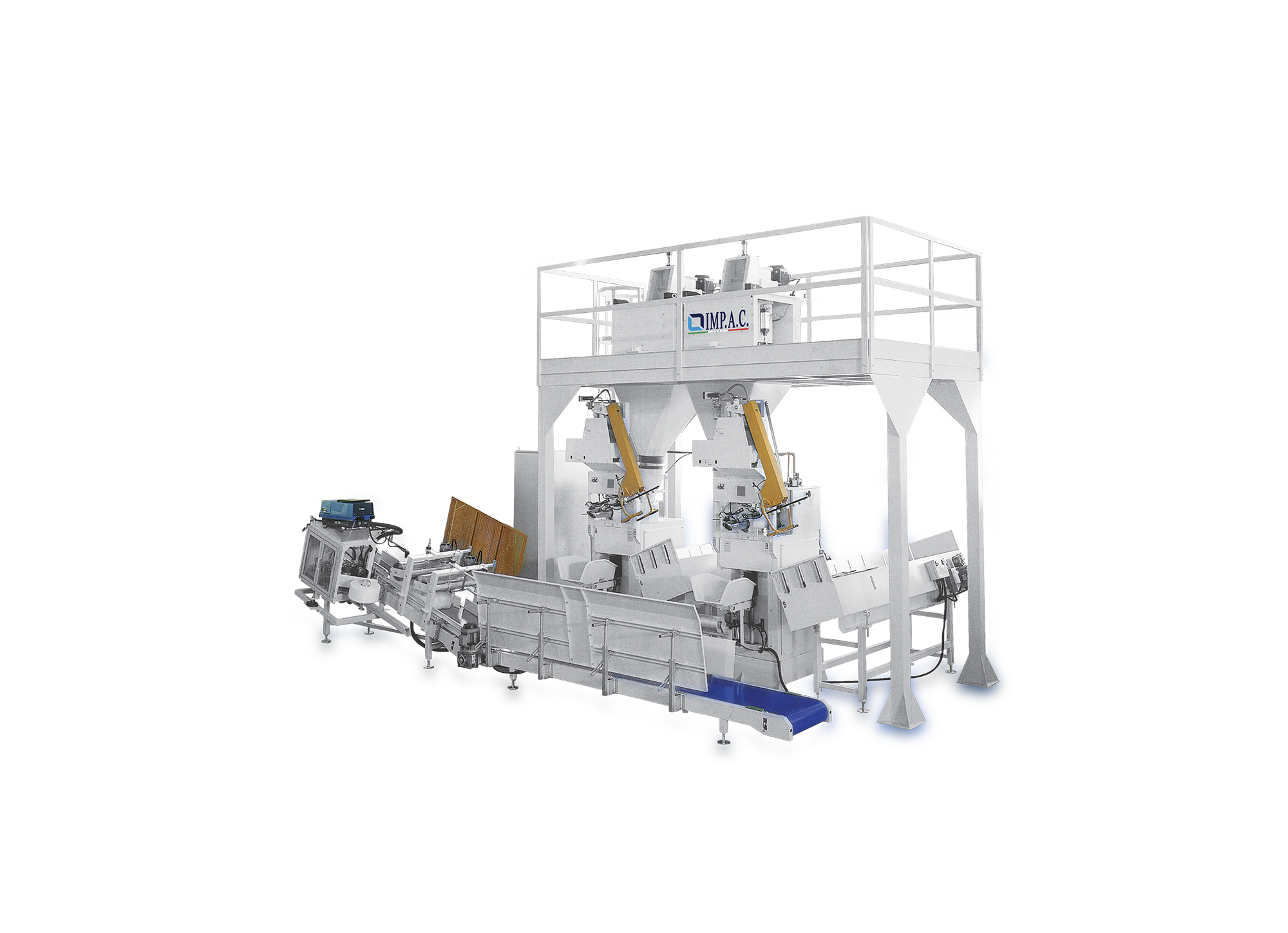

The IMP.A.C. ROBOTEX A is a single-column automatic palletiser with a bag transport system, empty and full pallets, designed for automated handling of bags of various types with a production capacity of 550 cycles/hour.

Thanks to its flexibility, precision and efficiency, it is the ideal solution for companies needing a reliable and versatile palletising system.

Its strong point is its gripper system with full wrapping, which allows the safe and efficient handling of any type of bag, including:

• Paper

• Jute

• Plastic

• Valve, sewn or electro-welded sacks

This technology is particularly useful for handling difficult bags, such as those that are half-empty or contain products with low viscosity (e.g. water).

Technology and Operation

Intelligent pressing and gripping system

- The bag, coming from the production line, is pressed to ensure compactness and uniformity.

- The wrap-around clamp wraps the bag completely, ensuring a secure and stable grip.

Advanced handling

- The movable mechanical arm is equipped with rotating and translating movements, ensuring total mobility in all axes.

- The system is mounted on a rotating column, which allows smooth and precise movements.

Intelligent automation

- Modular programmable PLC, managing all machine movements.

- Customisable programming to palletise bags of different sizes, formations and number of layers.

Main advantages

High productivity: up to 550 cycles/h, perfect for high capacity lines

Precise positioning: thanks to synchronised movements and stable grip

Total adaptability: compatible with bags of any material and format

Complete automation: advanced management with programmable PLC

Compact and versatile design: the rotating column system allows installation in small spaces

The IMP.A.C. ROBOTEX A is the perfect solution for anyone looking for a highly efficient, precise and adaptable palletiser that optimises production processes and ensures reliable and safe bag handling.

Monocolumn robot palletizer for boxes and bundles

Max. production: 550 cycles/h

Bag size

Max. 1000 x 500 x h. 250 mm

Min. 500 x 300 x h. 80 mm

Paddle size

Max. 1200 x 1000 mm x h 140

Min. 1000 x 800 mm x h 80

Maximum layer size

Max. 1300 x 1100 mm

Standard full pallet height

1600 mm

Control voltage

24 V

Max. full pallet weight

2000 Kg

Operational capacity

550 cycles/h

Installed power

15 KW

Operating pressure

6 bar

Indicative weight

4000 Kg

Product benefits

__ Advanced gripping system

__ Advanced gripping system

With full-band clamp

__ Pressing device

__ Pressing device

To even out and compact the sacks on the pallet

__ Arm with rotating and translating movements

__ Arm with rotating and translating movements

For flexible burden management

__ Synchronized movements

__ Synchronized movements

On all axes, ensuring maximum precision

__ Advanced control

__ Advanced control

Via PLC, for optimised palletising management

__ Total adaptability

__ Total adaptability

In bags of different sizes and materials