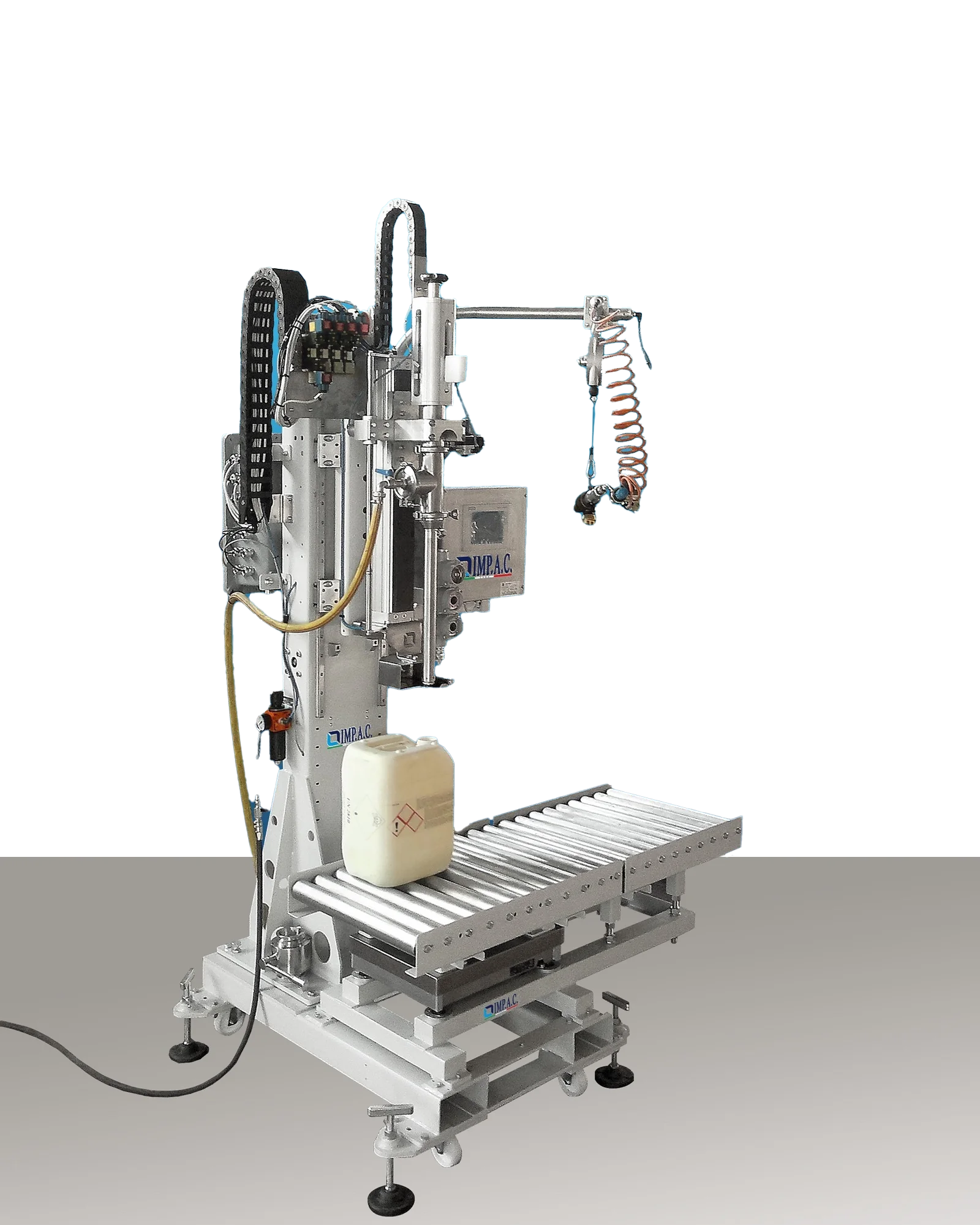

The IMP.A.C. 56 SA 100 is a semi-automatic filling machine designed for filling chemical and related products for jerry cans and drums of various capacities.

With its height-adjustable nozzle and integrated weighing system, it allows accurate control of the filling process, ensuring efficiency and safety.

Production capacity

• 80 cans/hour (5 litres)

• 50 cans/hour (25 litres)

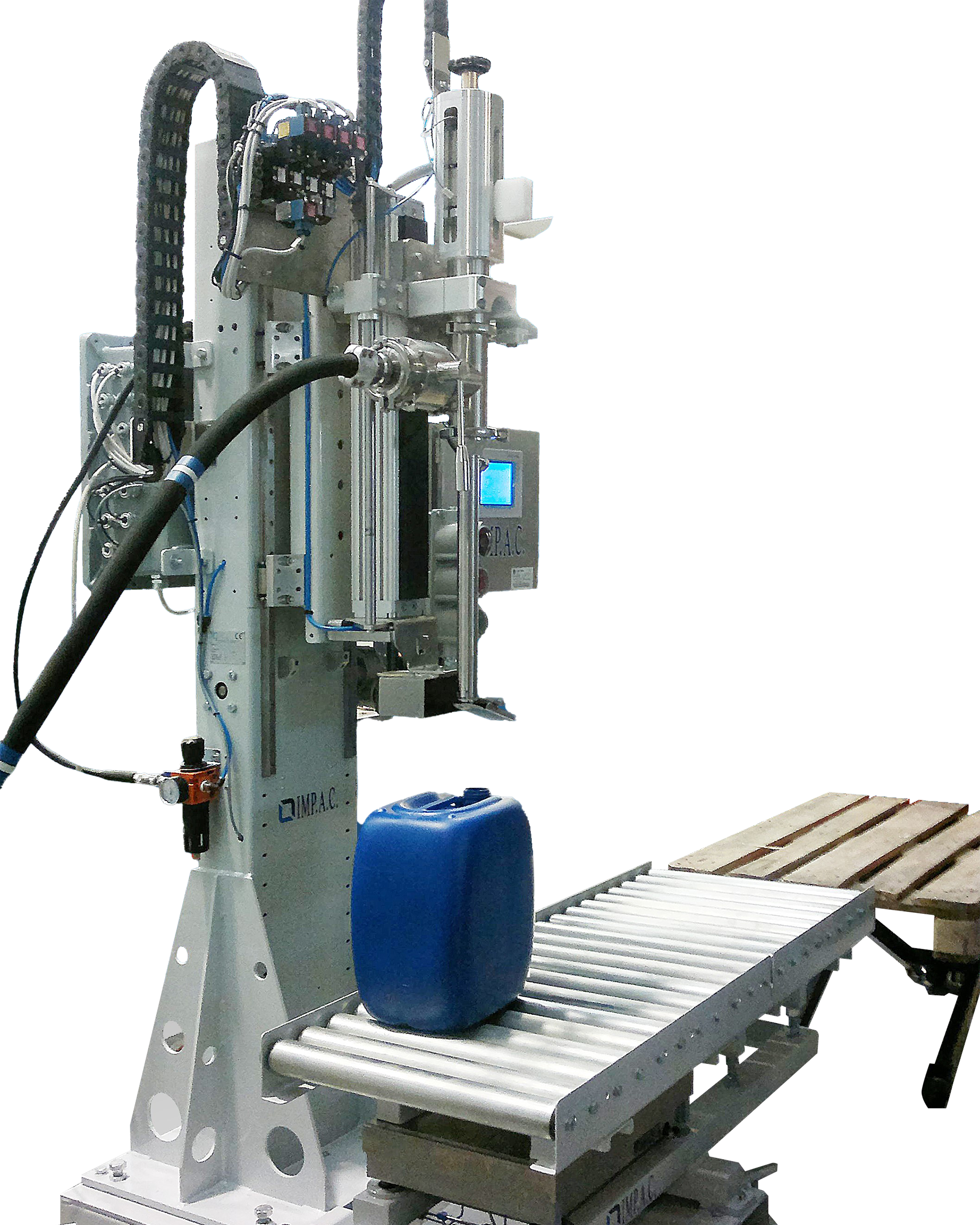

Operating Cycle

Positioning of the canister/canister under the filling nozzle.

Automatic adjustment of nozzle height according to container.

Filling start with real-time weight control via load cells.

Automatic interruption when the desired weight is reached.

Manual removal of the canister/canister for subsequent packaging.

Available options and accessories

Fume and vapour extraction system – For a safer working environment.

ATEX version – For operation in explosion-hazardous environments.

Customisations on request – To adapt to specific production requirements.

Industrial applications

Chemical Industry – Filling of solvents, detergents and hazardous products.

Agrochemicals – Filling of fertilisers and liquid solutions for agriculture.

Lubricants and Automotive – Filling of oils, technical fluids and additives.

The IMP.A.C. 56 SA 100 is the ideal solution for companies needing a compact, precise and reliable system for filling jerry cans and drums.

Semi-automatic filling machine for jerry cans and drums

Max. production80 jerrycans/h 5-litre jerrycans50 jerry cans/hour 25-litre jerry cans

Type container

Tanks, Drums

Container size

Tanks 300 x 350 x 600 mm, diameter 400 mm

Weight tolerance

20 g

Compressed air consumption

60 Nl/min

Container handling

Manual or Motorised

Installed power (in case of IP 55 protection)

0.3 KW - 220 V

Container weight

Max. 60 l

Min. 2 l

Nozzle height adjustment

450 mm

Production time = cycle time + Filling time (TR)

20 s + TR

Air pressure

6 bar

Total empty weight

600 Kg

Product benefits

__ Flexibility

__ Flexibility

Suitable for 5, 10, 25 litre cans and 60 litre drums.

__ Height adjustment

__ Height adjustment

The filling nozzle automatically adapts to the container.

__ Weight control

__ Weight control

Base with load cells to ensure dosing accuracy.

__ Semi-automatic operation

__ Semi-automatic operation

The operator positions the container, starts the filling and manages the removal.

__ Compactness

__ Compactness

Small footprint for optimal integration into existing production lines.

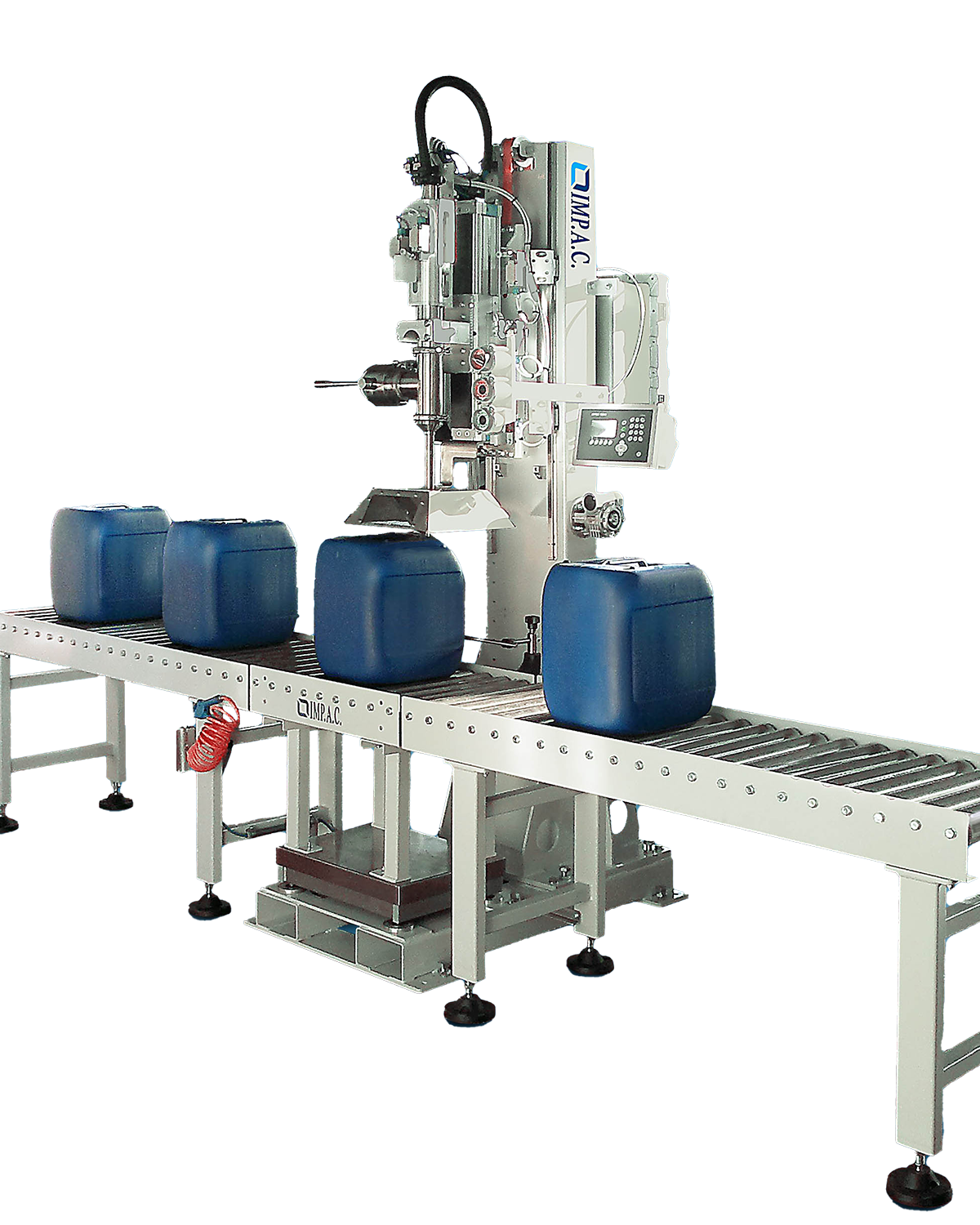

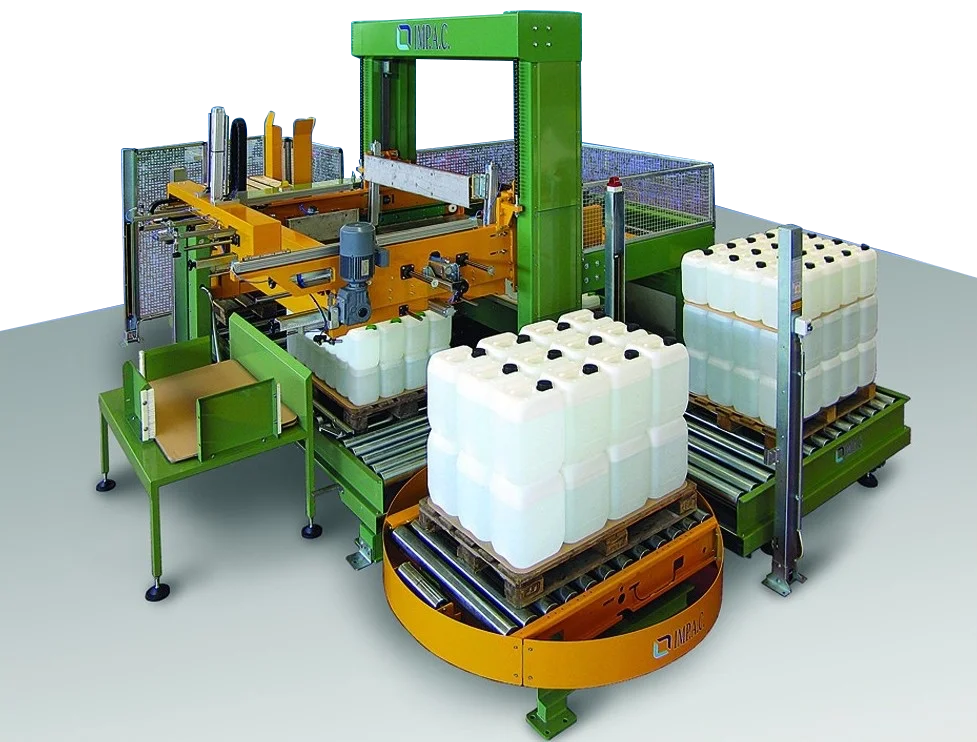

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

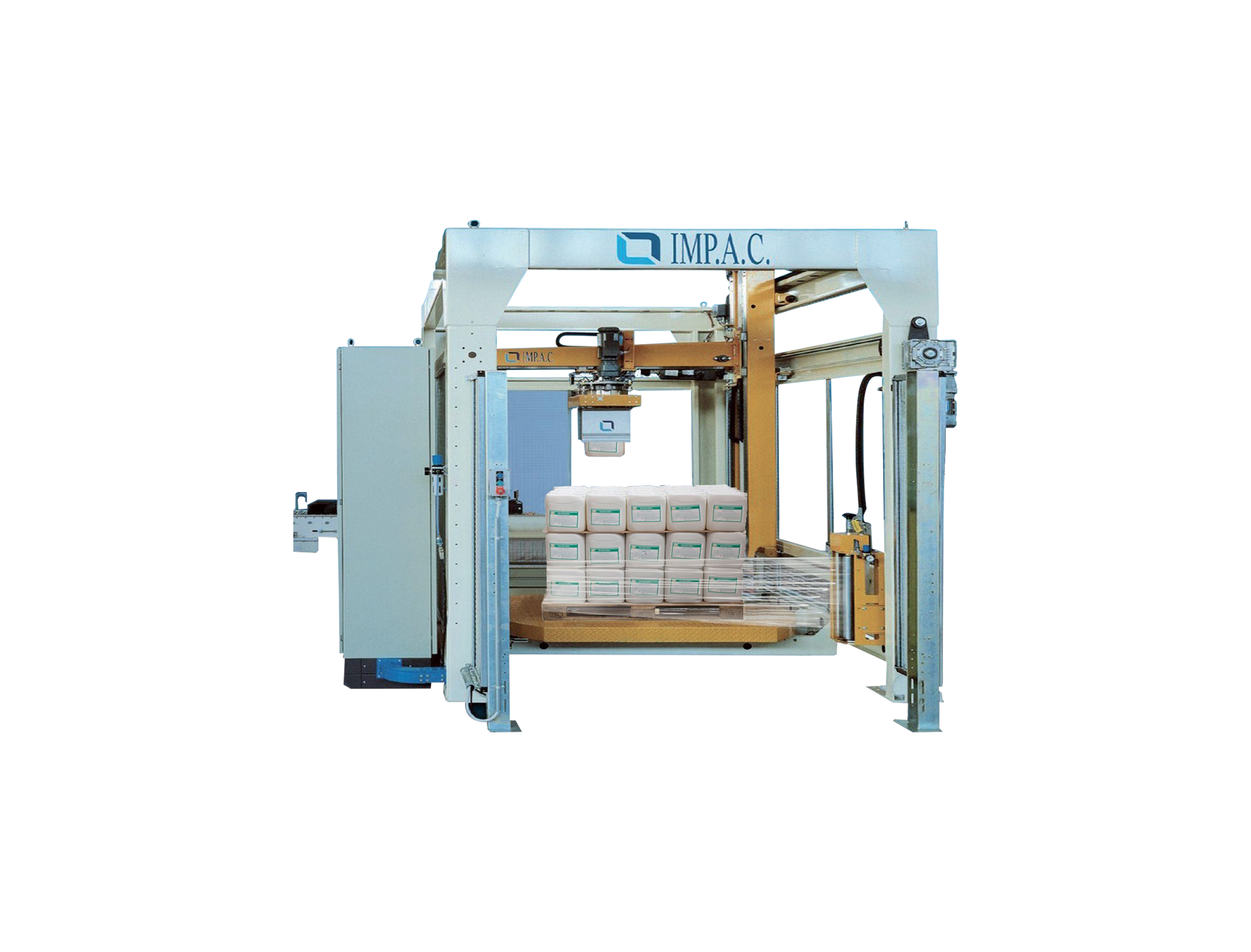

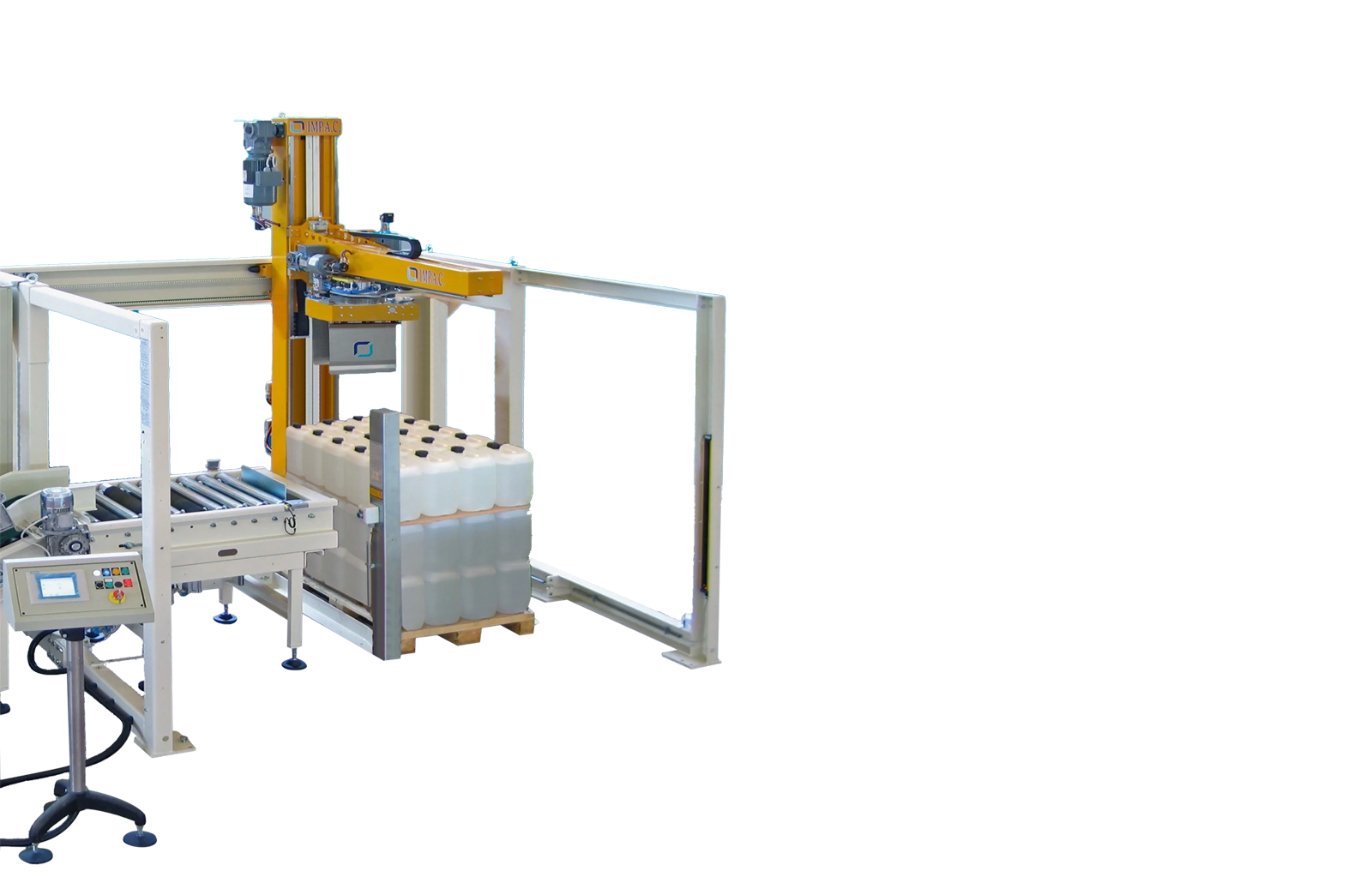

- Stretch wrapping machines

- Stretch hood machines

- Low-Level Palletizer for cans

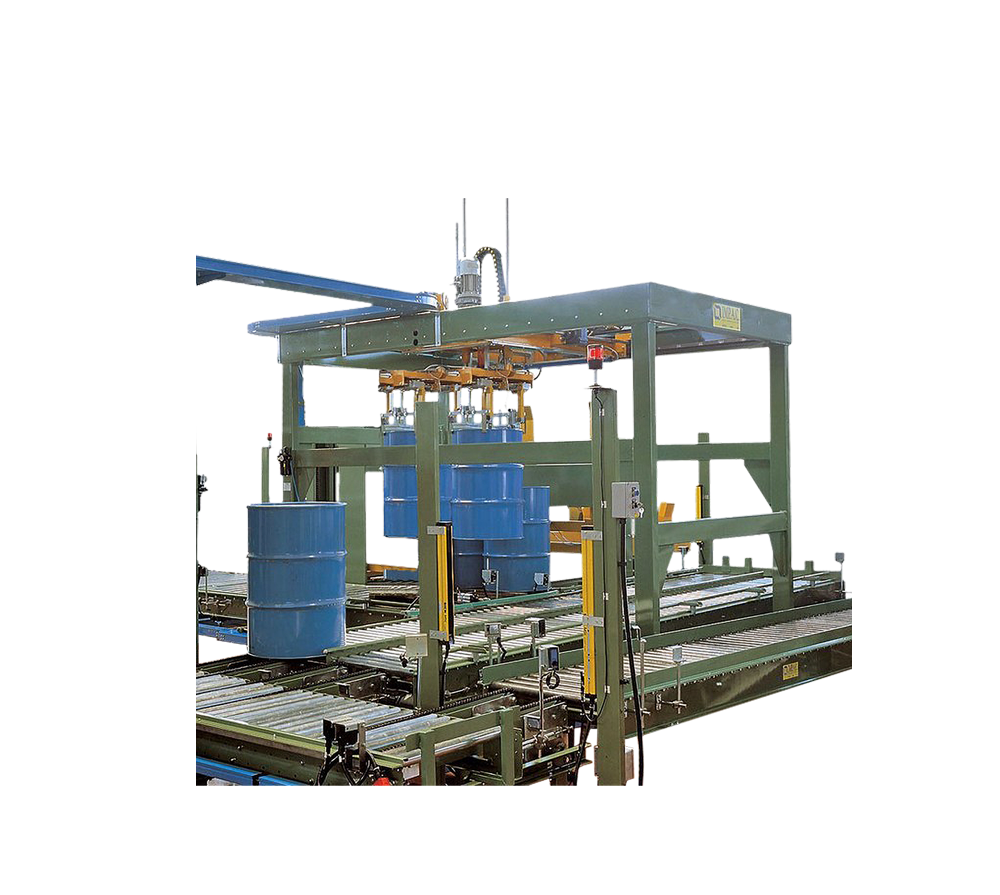

- Cartesian robots for drums, jerrycans and pails

- Monocolumn Robot Palletizer and Depalletizer for cans pails and drums

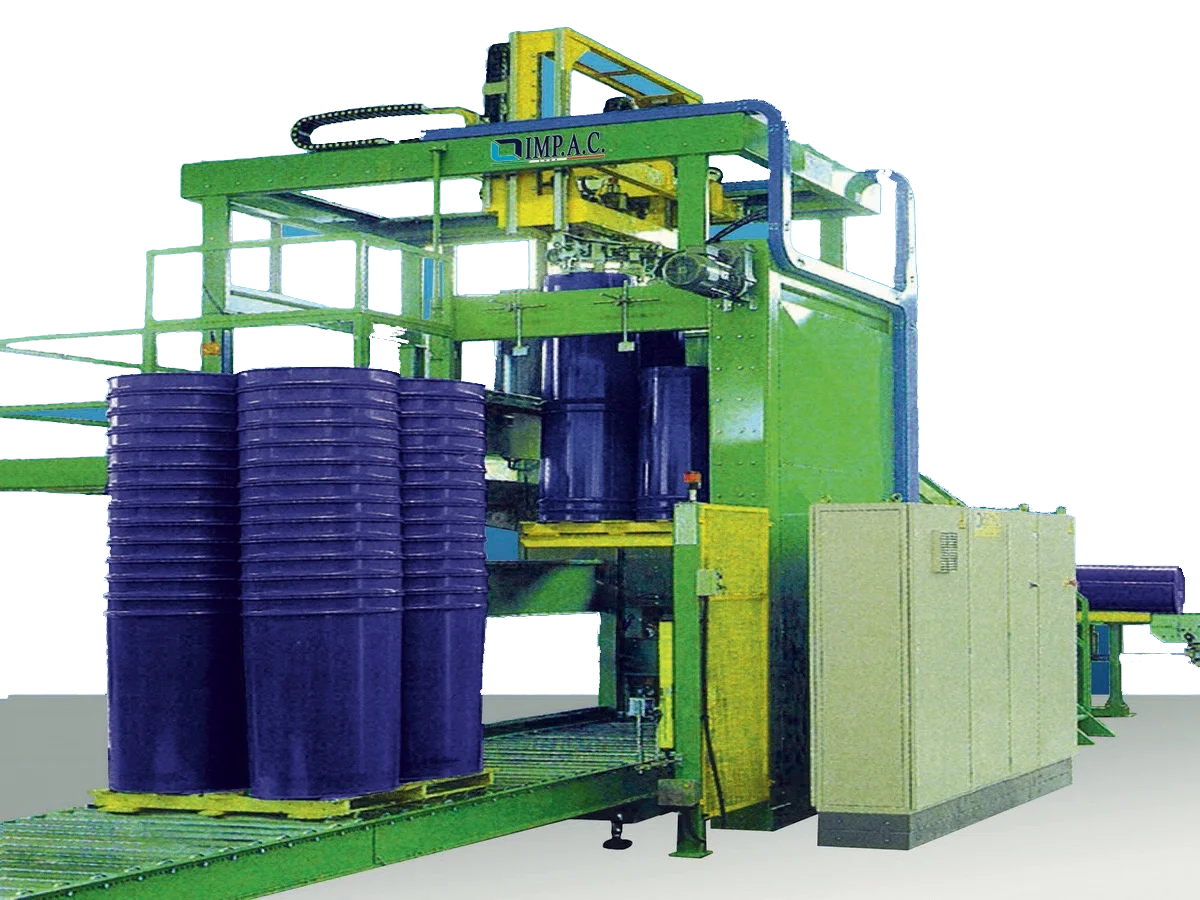

- High level Robotic palletizer for conical drums

- Anthropomorphic Robot Palletizer and Depalletizer for cans, pails and drums