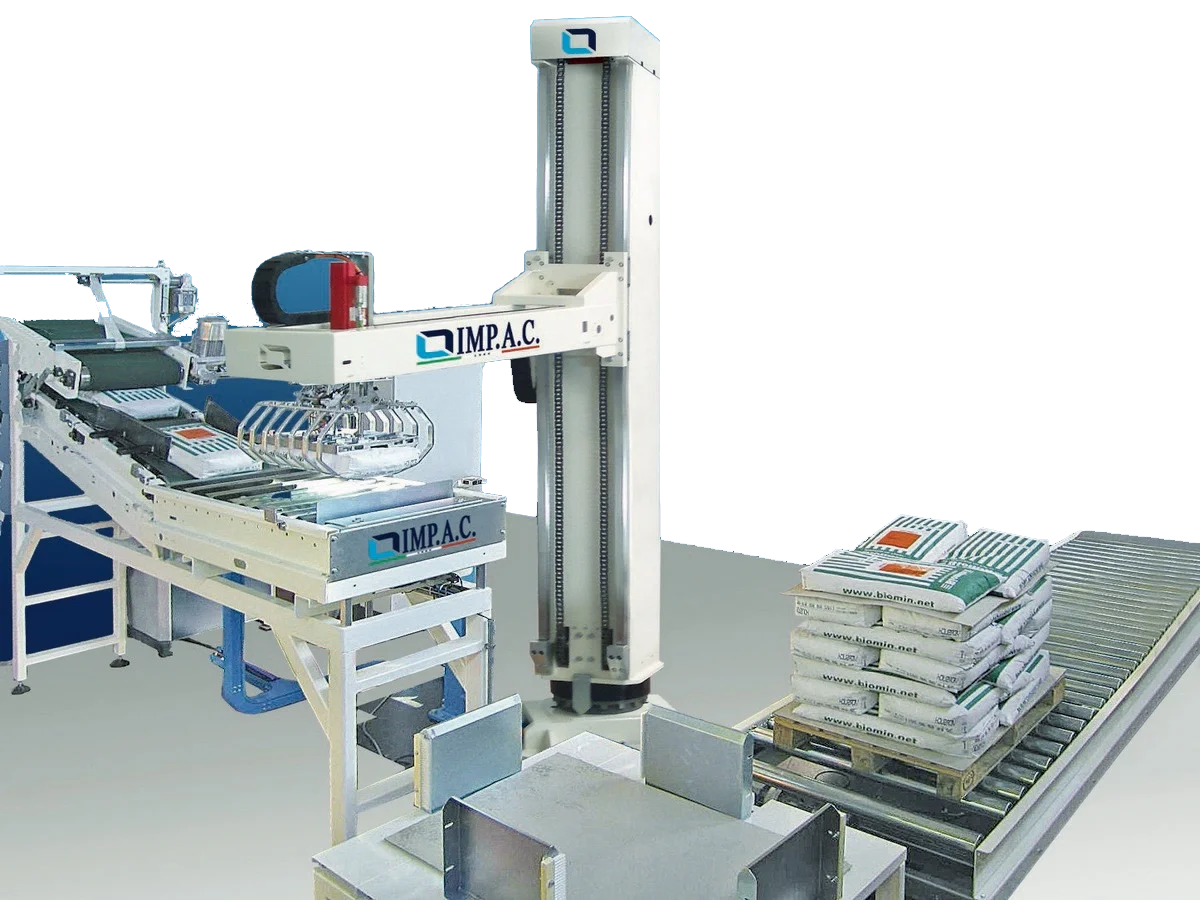

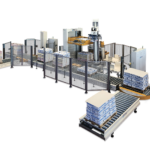

IMP.A.C. ROBOTEX 127 A rotating column robot for bag palletising

The IMP.A.C. ROBOTEX A is a single-column automatic palletiser with a bag transport system, empty and full pallets, designed for automated handling of bags of various types with a production capacity of 550 cycles/hour.

Thanks to its flexibility, precision and efficiency, it is the ideal solution for companies needing a reliable and versatile palletising system.

Its strong point is its gripper system with full wrapping, which allows the safe and efficient handling of any type of bag, including:

• Paper

• Jute

• Plastic

• Valve, sewn or electro-welded sacks

This technology is particularly useful for handling difficult bags, such as those that are half-empty or contain products with low viscosity (e.g. water).

Technology and Operation

Intelligent pressing and gripping system

- The bag, coming from the production line, is pressed to ensure compactness and uniformity.

- The wrap-around clamp wraps the bag completely, ensuring a secure and stable grip.

Advanced handling

- The movable mechanical arm is equipped with rotating and translating movements, ensuring total mobility in all axes.

- The system is mounted on a rotating column, which allows smooth and precise movements.

Intelligent automation

- Modular programmable PLC, managing all machine movements.

- Customisable programming to palletise bags of different sizes, formations and number of layers.

Main advantages

High productivity: up to 550 cycles/h, perfect for high capacity lines

Precise positioning: thanks to synchronised movements and stable grip

Total adaptability: compatible with bags of any material and format

Complete automation: advanced management with programmable PLC

Compact and versatile design: the rotating column system allows installation in small spaces

The IMP.A.C. ROBOTEX A is the perfect solution for anyone looking for a highly efficient, precise and adaptable palletiser that optimises production processes and ensures reliable and safe bag handling.

Monocolumn robot palletizer for boxes and bundles

Max. production: 550 cycles/h

Bag size

Max. 1000 x 500 x h. 250 mm

Min. 500 x 300 x h. 80 mm

Paddle size

Max. 1200 x 1000 mm x h 140

Min. 1000 x 800 mm x h 80

Maximum layer size

Max. 1300 x 1100 mm

Standard full pallet height

1600 mm

Control voltage

24 V

Max. full pallet weight

2000 Kg

Operational capacity

550 cycles/h

Installed power

15 KW

Operating pressure

6 bar

Indicative weight

4000 Kg

Product benefits

__ Advanced gripping system

__ Advanced gripping system

With full-band clamp

__ Pressing device

__ Pressing device

To even out and compact the sacks on the pallet

__ Arm with rotating and translating movements

__ Arm with rotating and translating movements

For flexible burden management

__ Synchronized movements

__ Synchronized movements

On all axes, ensuring maximum precision

__ Advanced control

__ Advanced control

Via PLC, for optimised palletising management

__ Total adaptability

__ Total adaptability

In bags of different sizes and materials

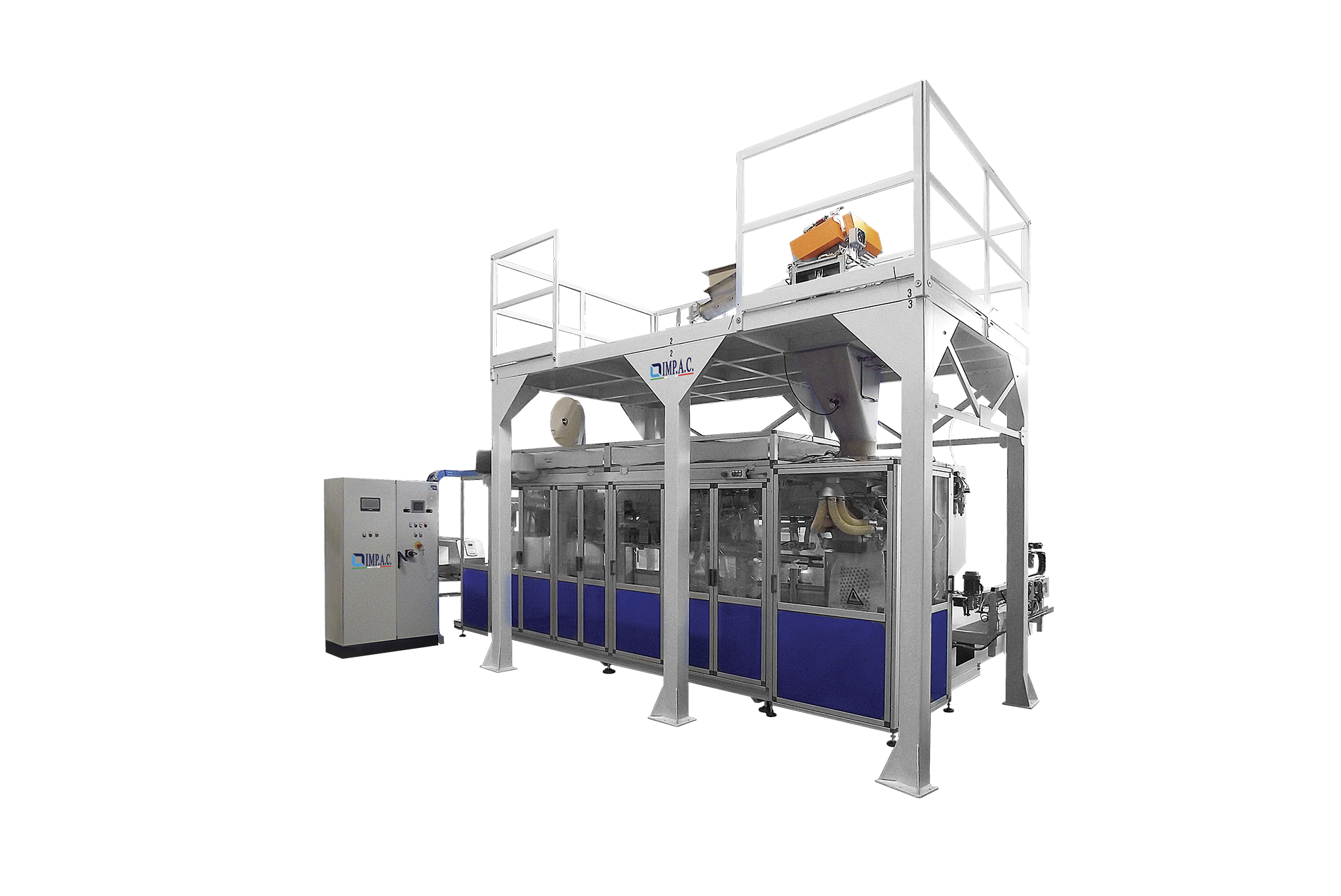

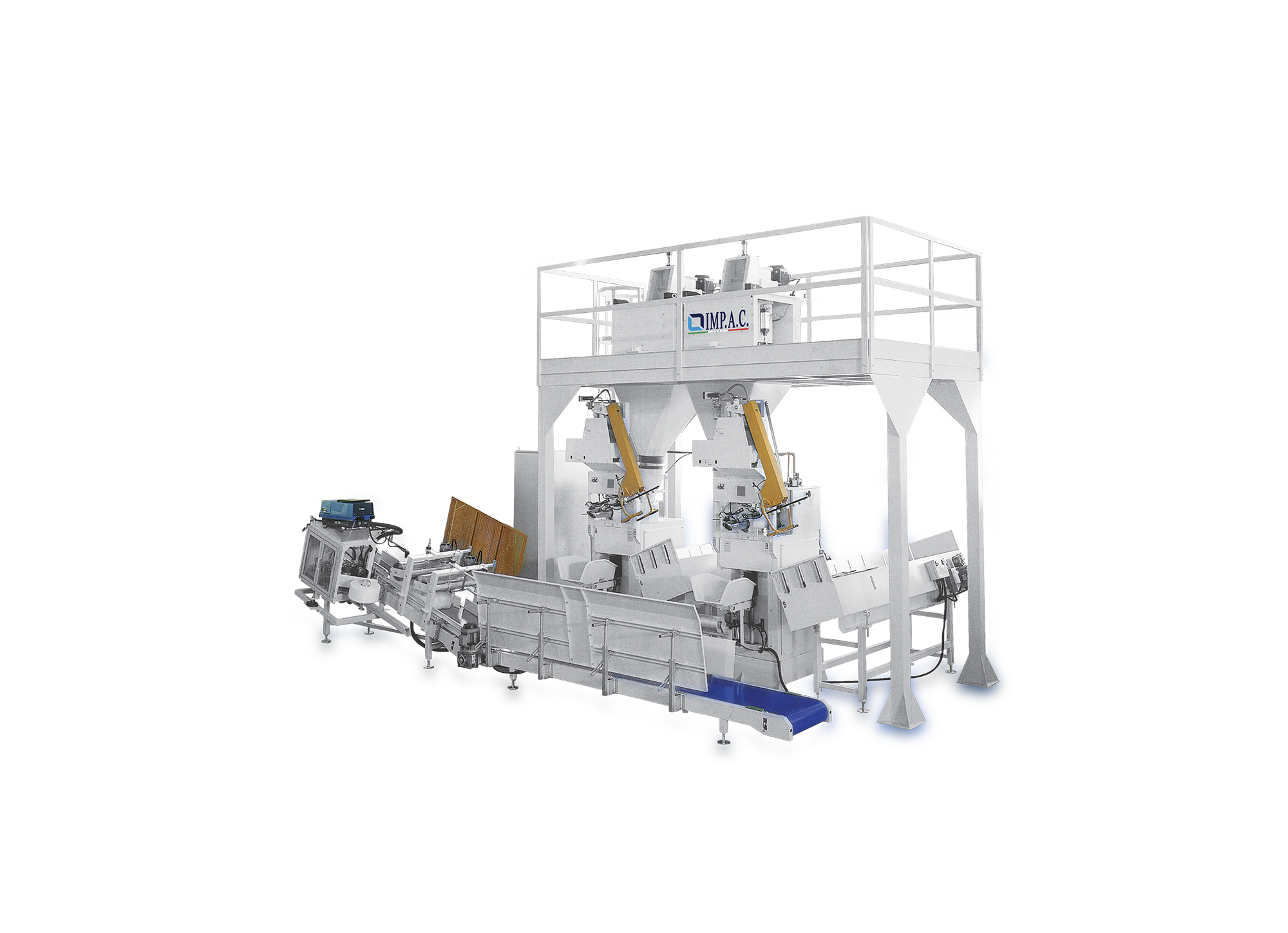

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

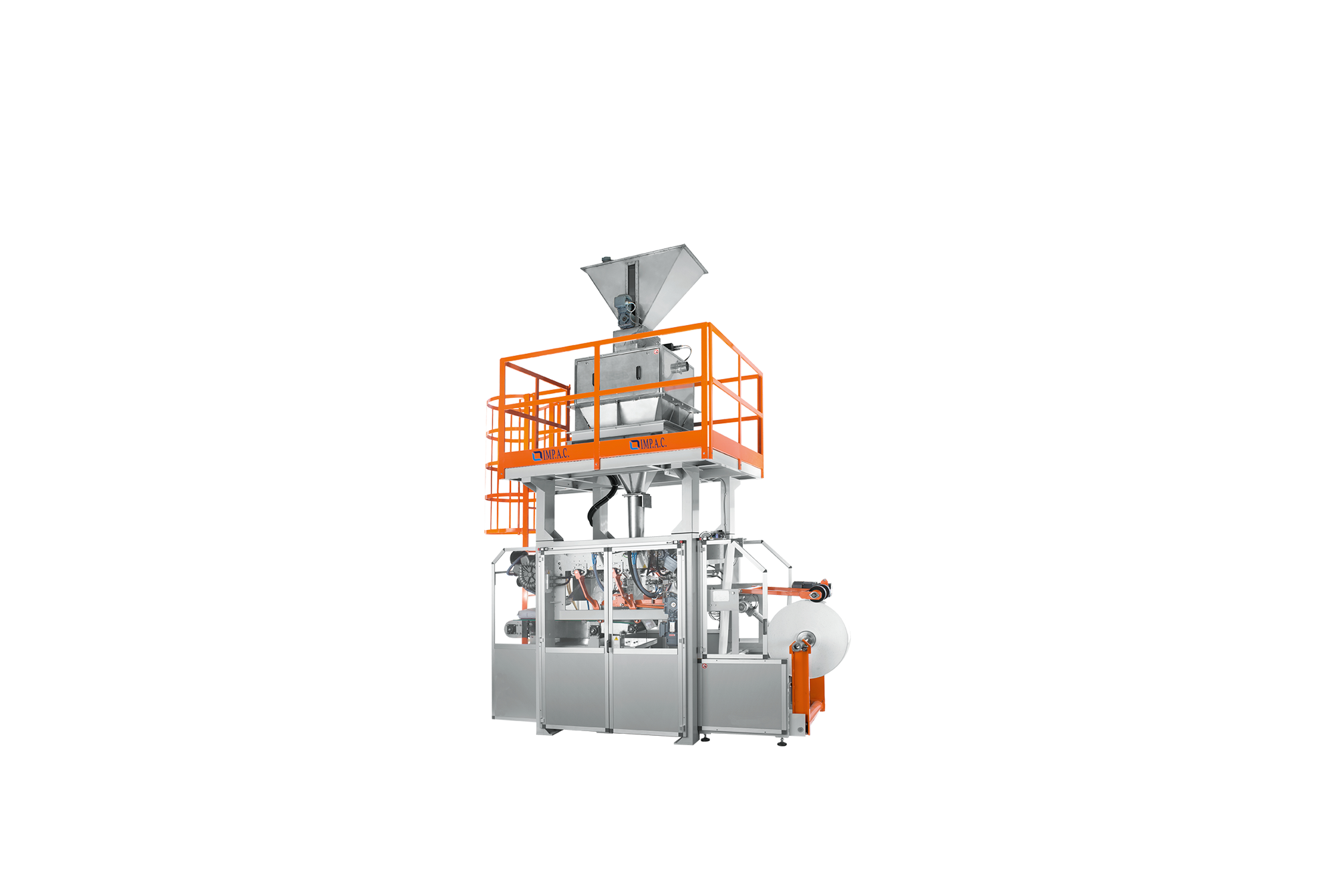

IMP.A.C. ROBOTEX 127 APT rotating column bag palletising robot

IMP.A.C. ROBOTEX 127 APT monocolumn robot palletizer for boxes and bundles on the pallet at the ground

The IMP.A.C. ROBOTEX A-PT is an automatic single-column palletiser with a floor pallet, designed for automated bag handling with a throughput capacity of 400 cycles/hour.

Due to its flexibility and precision, it is ideal for production lines that require palletising efficiency and versatility.

The key element of this machine is its gripper system with full wrap gripper, which allows safe handling of any type of bag, including:

• Paper

• Jute

• Plastic

• Valve, sewn or electro-welded sacks

This system is particularly advantageous for handling difficult bags, such as those that are half-empty or contain products with low viscosity (e.g. water).

Technology and Operation

Intelligent pressing and gripping system

- The bag, coming from the production line, is pressed to ensure compactness and uniformity.

- The wrap-around clamp wraps the bag completely, ensuring a secure and stable grip.

Advanced handling

- The movable mechanical arm is equipped with rotating and translating movements, ensuring total mobility in all axes.

- The system is mounted on a rotating column, which allows smooth and precise movements.

Intelligent automation

- Modular programmable PLC, managing all machine movements.

- Customisable programming to palletise bags of different sizes, formations and number of layers.

Main advantages

High productivity: up to 400 cycles/h, perfect for medium capacity lines

Precise positioning: thanks to synchronised movements and stable grip

Total adaptability: compatible with bags of any material and format

Complete automation: advanced management with programmable PLC

Compact and versatile design: the rotating column system allows installation in small spaces

The IMP.A.C. ROBOTEX A-PT is the ideal choice for anyone looking for a reliable, precise and highly adaptable palletiser that optimises production processes and ensures efficient bag handling.

Monocolumn robot palletizer for boxes and bundles on the pallet at the ground

Max. production: 400 cycles/h

Bag size

Max. 1000 x 500 x h. 250 mm

Min. 500 x 300 x h. 80 mm

Paddle size

Max. 1200 x 1000 mm x h 140

Min. 1000 x 800 mm x h 80

Maximum layer size

Max. 1300 x 1100 mm

Standard full pallet height

1600 mm

Control voltage

24 V

Max. full pallet weight

2000 Kg

Operational capacity

400 cycles/h

Installed power

12 KW

Operating pressure

6 bar

Indicative weight

3500 Kg

Product benefits

__ Advanced gripping system

__ Advanced gripping system

With full-band clamp

__ Pressing device

__ Pressing device

To even out and compact the sacks on the pallet

__ Arm with rotating and translating movements

__ Arm with rotating and translating movements

For flexible burden management

__ Synchronized movements

__ Synchronized movements

On all axes, ensuring maximum precision

__ Advanced control

__ Advanced control

Via PLC, for optimised palletising management

__ Total adaptability

__ Total adaptability

In bags of different sizes and materials