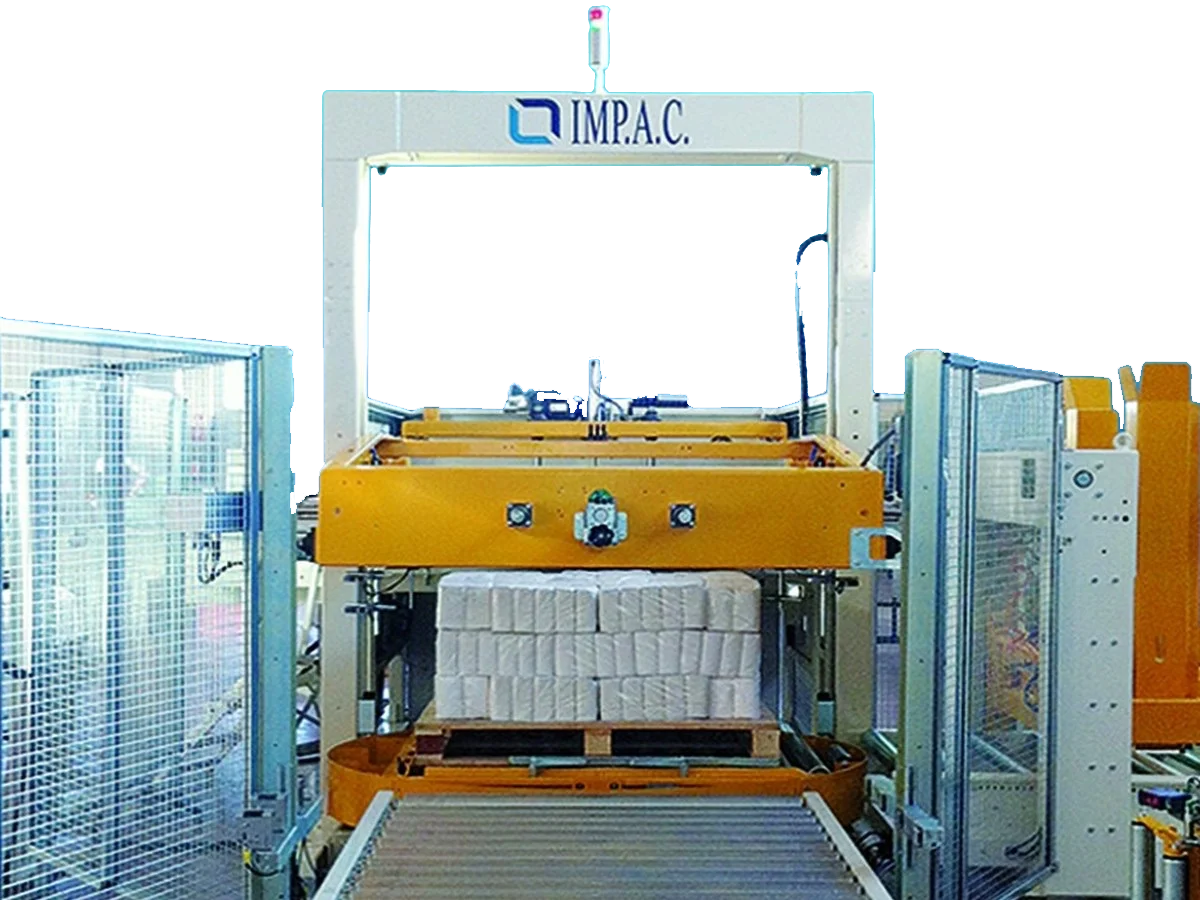

Multilayer automatic palletiser with 2 or more IMP.A.C. 23 AMY pallets

The IMP.A.C. 22 AL automatic palletizer represents a versatile and reliable solution for medium production, optimizing palletizing management.

Designed to adapt to a wide range of production needs, it allows palletizing cartons of different sizes, layer patterns, and configurations, ensuring precise and consistent results.

/With a production capacity of up to 1000 cartons/hour, the IMP.A.C. 22 AL model stands out for its operational efficiency and ability to meet the needs of diverse industrial sectors.

Low level palletizer for boxes and bundles

Max Production: 1000 cartons/hour

Cardboard dimensions

Max. 500 x 400 x h. 300

Min. 200 x 150 x h. 25

Pallet dimensions

Max. 1200 x 1000 x h. 140

Min. 1000 x 800 x h. 100

Layer dimensions

Max. 1300 x 1100

Standard full pallet height

1600 mm

Compressed air consumption

120 Nl/min

Max. full pallet weight

1500 Kg

Operational capacity

2 layers per minute with a limit of 15 cartons per minute

Installed power

8,5 KW

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

7500 Kg

Product benefits

__ Optimised movements

__ Optimised movements

Equipped with a platform with vertical and horizontal movements for proper positioning and transfer of the layer onto the pallet.

__ Total automation

__ Total automation

Each phase of the cycle is managed by a programmable modular system (PLC), ensuring synchronization and complete control.

__ Operational flexibility

__ Operational flexibility

It can be configured to handle cartons of various sizes and layering patterns, addressing the specific needs of each production.

__ Efficiency without compromise

__ Efficiency without compromise

The work cycle is continuous, with an automatic pallet replacement system to minimize downtime.

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

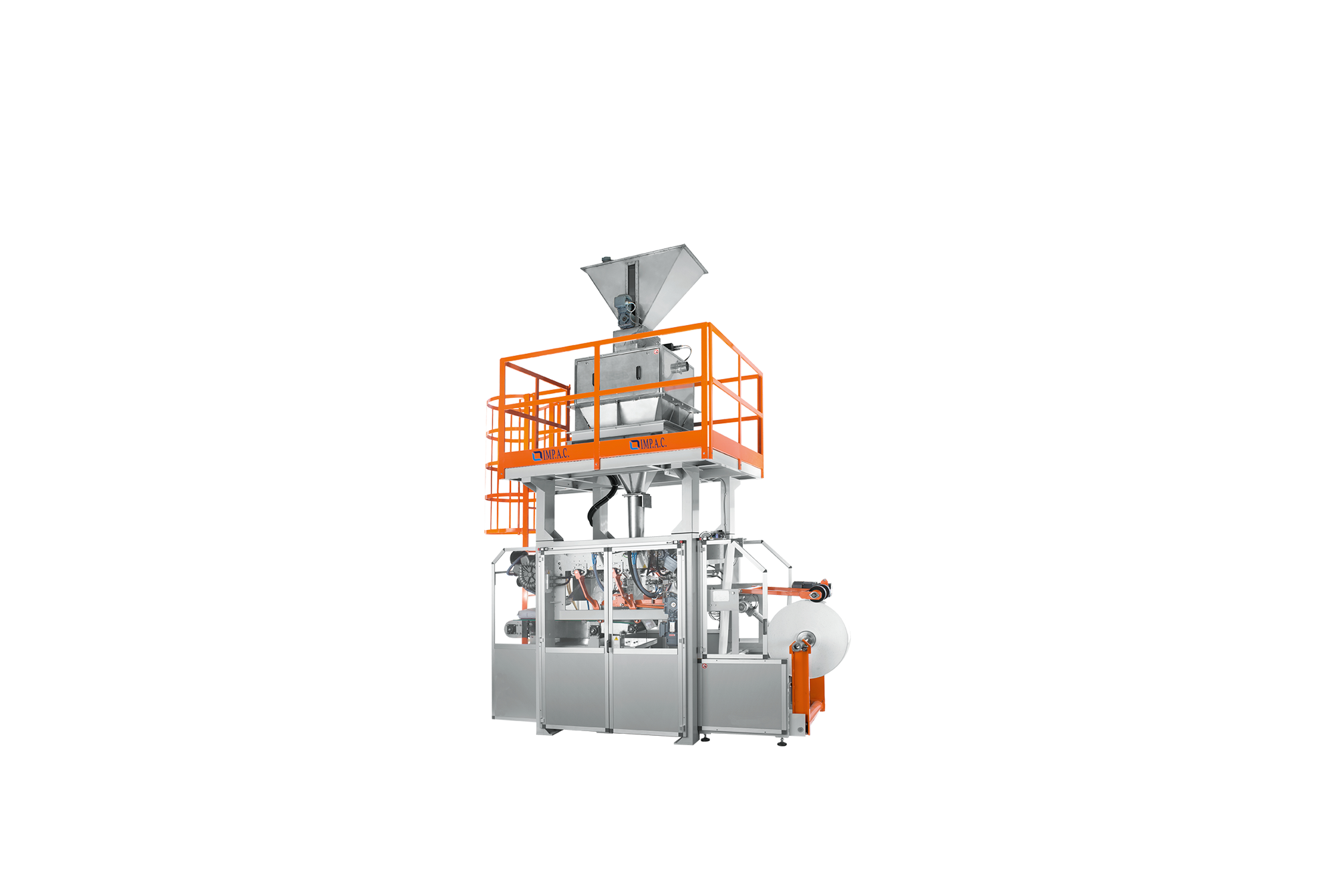

Palletizer/packaging machine for 1 kg vertical bags and bundles with bottom feed – IMP.A.C. 22-32 AVC

The IMP.A.C. 22-32 AVC palletizer/packaging machine is the ideal choice for industrial operations requiring high performance and flexibility in handling 1-5 kg vertical bags and 10-15 kg bundles.

Thanks to the combination of high speed and precision, this machine ensures optimal productivity in every industrial sector.

Reliability and innovation

The IMP.A.C. 22-32 AVC model represents a technologically advanced solution for optimizing packaging and palletizing processes, ensuring efficiency and precision in every operational cycle. Perfect for meeting the most complex production needs.

Palletizer/packaging machine for 1 kg vertical bags and bundles with bottom feed

Max Production: 180 bags per minute

6 bundles per minute

Bag and bundle dimensions

Max. 180 x 110 x h. 80 mm

Pallet dimensions

Max. 1300 x 1200 x h. 140 mm

Min. 1000 x 800 x h. 100 mm

Layer dimensions

Max. 1400 x 1250 mm

Standard full pallet height

1600 mm

Max. full pallet weight

2000 Kg

Compressed air consumption

100 Nl/min

Installed power

13,5 KW

Operational capacity

6 layers per minute with a limit of 180 bags per minute

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

12000 Kg

Product benefits

__ Operational versatility

__ Operational versatility

It efficiently palletizes both light bags (1-5 kg) and heavier bundles (10-15 kg), adapting to different configurations.

__ High productivity

__ High productivity

Designed to handle up to 1700 bags-bundles per hour, with a speed of 180 bags per minute and 15 bundles per minute.

__ Layer optimization

__ Layer optimization

The bags and bundles are compressed, made uniform, and oriented according to the predefined formation, ensuring a stable and precise arrangement.

__ Central opening mechanism

__ Central opening mechanism

The dedicated platform enables fast and accurate layer placement onto the pallet.

__ Advanced automation

__ Advanced automation

All movements are synchronized through a programmable modular PLC, ensuring smooth operation and adaptability to different needs.

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

Automatic stationary palletiser IMP.A.C. 22 A

Low level palletizer for boxes and bundles on the pallet at the ground

Max Production: 600 cartons/bundles per hour

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

IMP.A.C. 22 A – Automatic palletizer with fixed pallet system

The IMP.A.C. 22 A palletiser is the ideal solution for tasks requiring a smooth and precise palletising process, guaranteeing versatility and reliable performance in any production environment.

Designed to handle cartons coming from an upstream line, the system automatically orients the cartons and bundles according to the predefined formation, transferring them to the layer preformation area. Each layer is then moved by a platform with vertical and horizontal movements.

- Vertical movement for precise positioning of the layer drain.

- Horizontal movement to transfer the layer onto the pallet.

The cycle automatically repeats until the pallet is complete, which is then evacuated and replaced with an empty pallet, ready for a new cycle. All synchronizations are managed by a programmable modular system (PLC), ensuring precise and reliable operation.

Thanks to its advanced technology, the machine can be configured to palletize cartons of different sizes, formats, and layer counts, offering extraordinary operational flexibility.

Low level palletizer for boxes and bundles High capacity

Max. production: 2000 cardboard/h

Cardboard dimensions

Max. 500 x 400 x h. 300 mm

Min. 200 x 150 x h. 25 mm

Pallet dimensions

Max. 1200 x 1000 x h. 140 mm

Min. 1000 x 800 x h. 100 mm

Layer dimensions

Max. 1300 x 1100 mm

Standard full pallet height

1600 mm

Compressed air consumption

150 Nl/min

Max. full pallet weight

1500 Kg

Operational capacity

3.5 states at the limit of 35 carboards/min

Installed power

11,5 KW

Operating pressure

6 bar

Indicative weight

8000 Kg

Product benefits

__ Operational flexibility

__ Operational flexibility

Support for cartons of various sizes, patterns and layers.