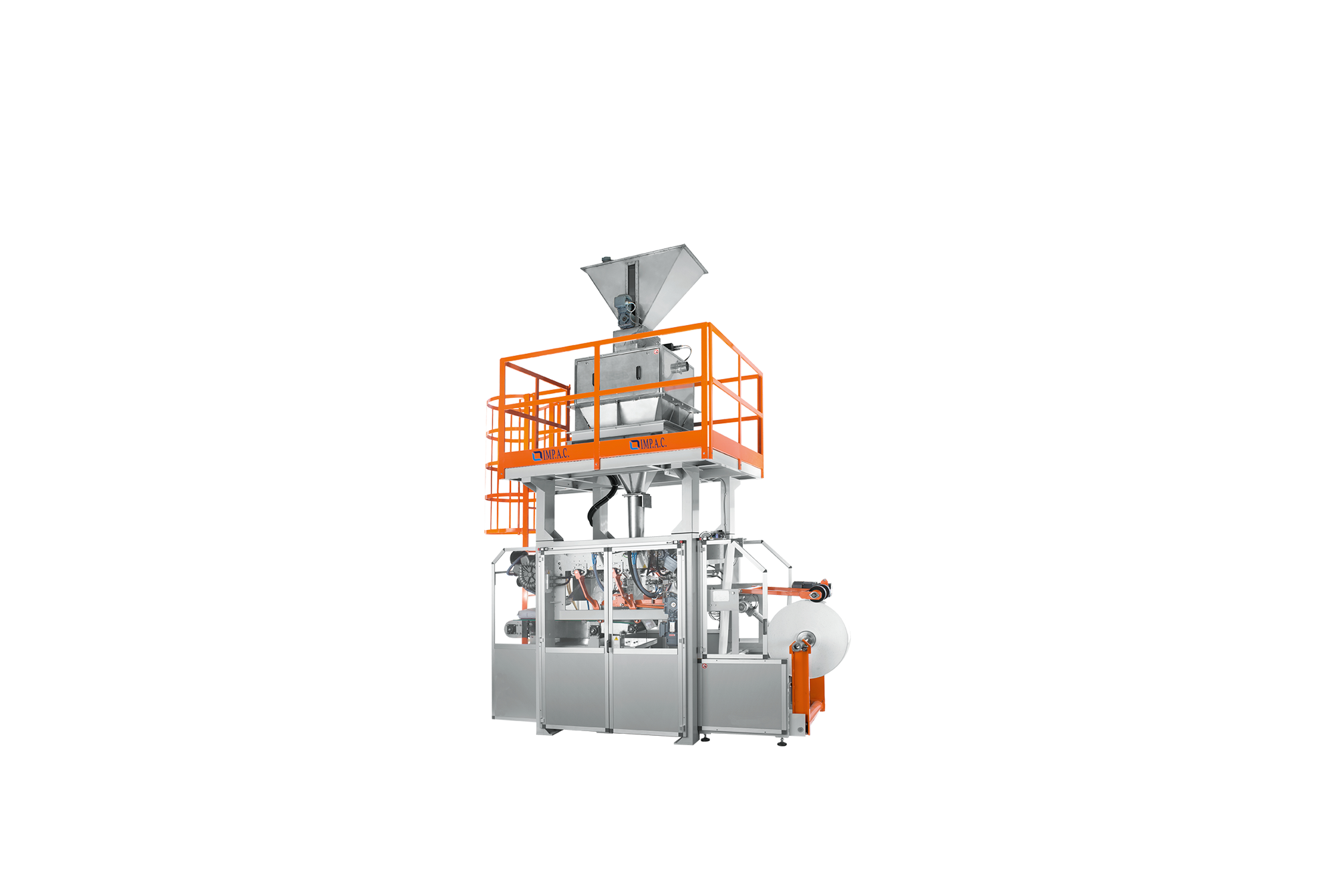

Layered bundle palletising robot with movable pallet and top infeed for high output IMP.A.C. ROBOTEX 11-21 AV

IMP.A.C. ROBOTEX 11-21 AV

Bags,boxes and bundle palletizer robot with conventional compacting system, create square and sturdy pallets. High speed

The ROBOTEX 11-21 AV is a high-speed robotic palletiser designed to handle up to 1,000 carton-bags per hour with maximum efficiency and stability.

Thanks to the top feeding and the layer compaction system, it ensures optimal load placement, improving safety and logistics.

This palletiser is the ideal solution for high-speed production lines, especially when other conventional palletisers or robots cannot operate as effectively.

Advanced technology

- High-precision gripping system: the handling gripper allows any type of bag, carton or bundle to be handled, including those of variable size and weight.

- Automatic compaction: each layer is pressed and levelled for stable and uniform palletisation.

- Dynamic handling: thanks to its rotary, transverse and longitudinal movements, the robot provides total mobility across the horizontal plane.

- Moving pallet: the lifter positions the pallet by photoelectric sensing, ensuring maximum operational precision.

- Automated control (PLC): all movements are synchronized to optimize productivity and efficiency.

Operation

- Picking and pressing: the cardboard-bundle arriving from the line is pressed for uniformity and transferred to the pre-forming station.

- Layer formation: the movable mechanical hand positions the cardboard-bundles according to the set pattern.

- Compaction and transfer: the layer is compacted on all four sides and placed on the mobile pallet.

- Evacuation and replacement: the completed pallet is evacuated and replaced to start a new cycle.

Main advantages

High speed: up to 1000 carton-bags/hour, ideal for intensive productions

Maximum precision: each layer is pre-formed and compacted for optimal stability

Handles bundles and cartons of various sizes: perfect for unstable or lightweight packaging

Advanced automation: intelligent control with programmable PLC

Total adaptability: configurable for different sizes, formations and number of layers

The ROBOTEX 11-21 AV is the perfect solution for anyone looking for a fast, reliable and efficient robot palletiser, providing flexibility and operational precision in any production environment.

Bags,boxes and bundle palletizer robot with conventional compacting system, create square and sturdy pallets. High speed

Max. production: 1000 bags-cartons/h

Bag and box dimensions

Max. 1000 x 500 x h. 250 mm

Min. 500 x 300 x h. 80 mm

Paddle size

Max. 1200 x 1000 x h. 140 mm

Min. 1000 x 800 x h. 100 mm

Maximum layer size

Max. 1300 x 1100 mm

Standard full pallet height

1600 mm

Compressed air consumption

100 Nl/min

Control voltage

24 V

Max. full pallet weight

2000 Kg

Operational capacity

1000 sacks-bags-cartons/hour

Installed power

15 KW

Operating pressure

6 bar

Indicative weight

9500 Kg

Product benefits

__ Precise handling

__ Precise handling

With bundle and carton gripper, which allows overlapping placement in pre-formed layer

__ Layered pallet formation

__ Layered pallet formation

With compaction on all four sides to ensure load stability

__ Universal gripper

__ Universal gripper

Suitable for any type of carton or bundle

__ Three-dimensional movements

__ Three-dimensional movements

(rotating, transverse, longitudinal) for maximum flexibility and precision

__ Total automation

__ Total automation

With management via programmable PLC

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

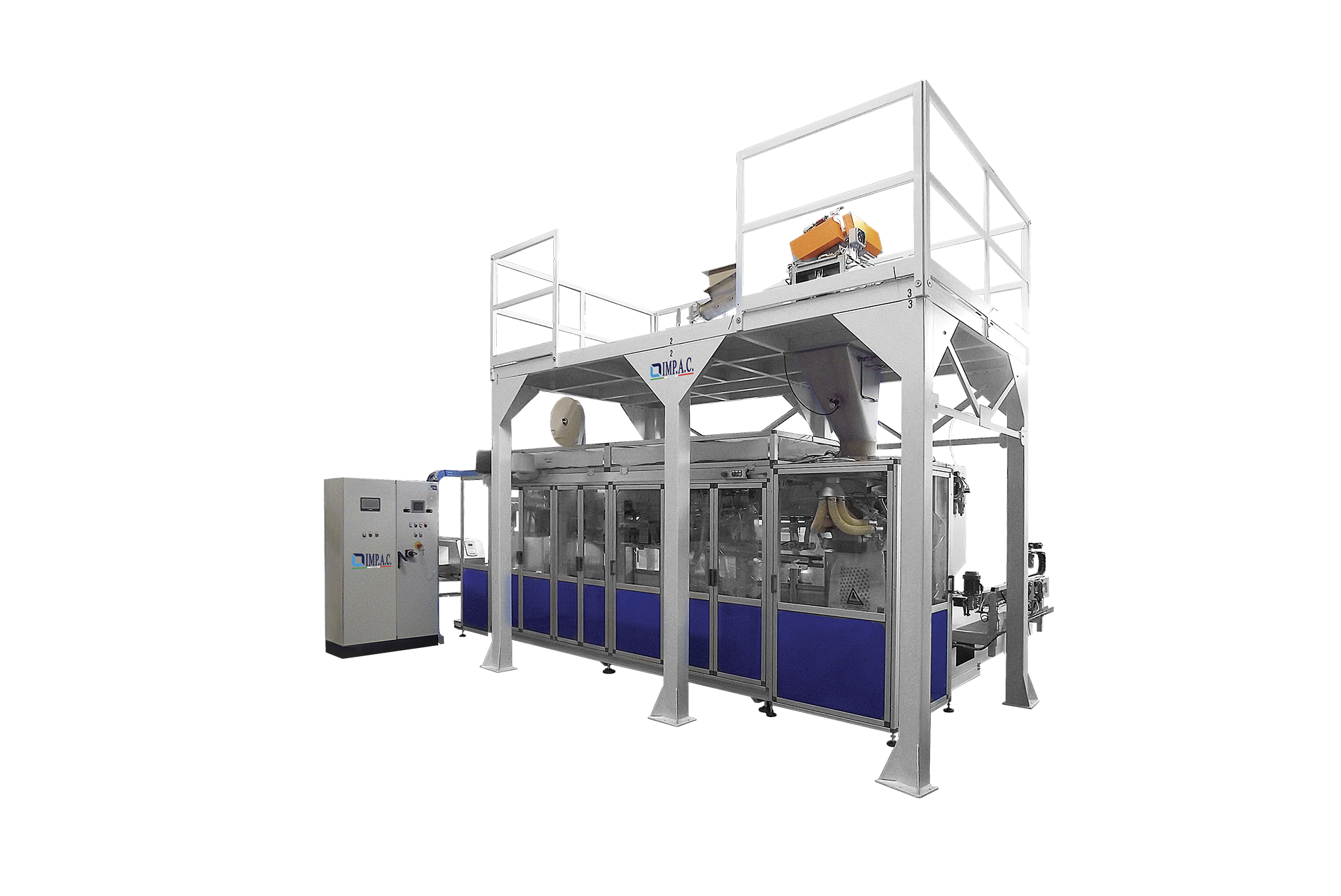

Layered bundle palletising robot with moving pallet and top infeed for high output IMP.A.C. ROBOTEX 21 AV

IMP.A.C. ROBOTEX 21 AV

Boxes and bundle palletizer robot with conventional compacting system, create square and sturdy pallets. High speed

The ROBOTEX 21 AV is a high-speed robotic palletiser designed to handle up to 1100 carton packs/hour with maximum accuracy and stability.

Thanks to the top feeding and the layered compaction system, it ensures a stable load arrangement by optimising the space on the pallet.

This palletiser is ideal for production environments with high processing speeds, especially when other conventional palletisers or robots cannot operate as efficiently.

Advanced technology

- High-precision gripping system: the handling gripper allows the handling of any type of bundle or box, including those of variable size and weight.

- Automatic compaction: each layer is pressed and levelled for stable and uniform palletisation.

- Dynamic handling: thanks to its rotary, transverse and longitudinal movements, the robot provides total mobility across the horizontal plane.

- Moving pallet: the lifter positions the pallet by photoelectric sensing, ensuring maximum operational precision.

- Automated control (PLC): all movements are synchronized to optimize productivity and efficiency.

Operation

- Picking and pressing: the incoming bundle or box from the line is pressed for uniformity and transferred to the pre-forming station.

- Layer formation: the mechanical moving hand positions the bundles according to the set pattern.

- Compaction and transfer: the layer is compacted on all four sides and placed on the mobile pallet.

- Evacuation and replacement: the completed pallet is evacuated and replaced to start a new cycle.

Main advantages

High speed: up to 1100 carton-bags/h, ideal for intensive productions

Maximum precision: each layer is pre-formed and compacted for optimal stability

Handles bundles and boxes of various sizes: perfect for unstable or lightweight packaging

Advanced automation: intelligent control with programmable PLC

Total adaptability: configurable for different sizes, formations and number of layers

The ROBOTEX 21 AV is the perfect solution for anyone looking for a fast, reliable and efficient robot palletiser, providing flexibility and operational precision in any production environment.

Boxes and bundle palletizer robot with conventional compacting system, create square and sturdy pallets. High speed

Max. production: 1100 carton-bags/hour

Box dimensions - bundles

Max. 600 x 500 x h. 300 mm

Min. 300 x 200 x h. 80 mm

Paddle size

Max. 1200 x 1000 x h. 140 mm

Min. 1000 x 800 x h. 100 mm

Maximum layer size

Max. 1300 x 1100 mm

Standard full pallet height

1600 mm

Compressed air consumption

100 Nl/min

Control voltage

24 V

Max. full pallet weight

2000 Kg

Operational capacity

1100 carton-bags/h

Installed power

15 KW

Operating pressure

6 bar

Indicative weight

9500 Kg

Product benefits

__ Precise handling

__ Precise handling

With bundle and box gripper, which allows overlapping placement in pre-formed layer

__ Layered pallet formation

__ Layered pallet formation

With compaction on all four sides to ensure load stability

__ Universal gripper

__ Universal gripper

Suitable for any type of box or bundle

__ Three-dimensional movements

__ Three-dimensional movements

(rotating, transverse, longitudinal) for maximum flexibility and precision

__ Total automation

__ Total automation

With management via programmable PLC

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

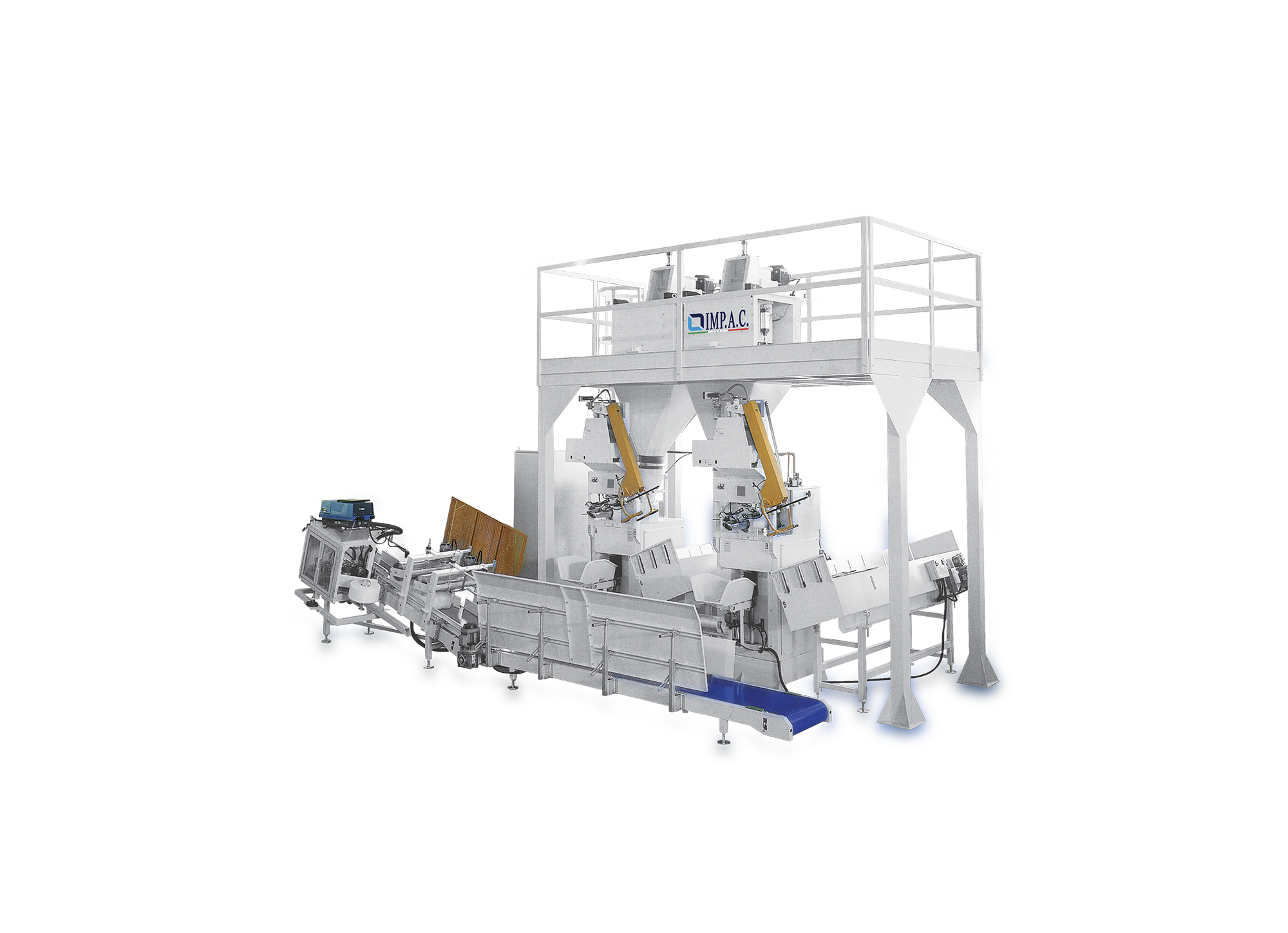

Layered bundle palletising robot with moving pallet and top feeding for high output IMP.A.C. ROBOTEX 21 A

IMP.A.C. ROBOTEX 21 A

Boxes and bundle palletizer robot with conventional compacting system, create square and sturdy pallets

The ROBOTEX 21 A is a high-speed robotic palletiser, capable of handling up to 600 carton packs/hour.

Thanks to its top feeding and four-sided compaction system, it ensures a stable and safe load placement, optimising pallet space.

Its advanced features make it ideal in contexts where conventional palletisers or other robots cannot operate with the same efficiency and flexibility.

Advanced technology

- High-precision gripping system: the full wrapping gripper allows handling of all types of bundles (paper, jute, plastic, valve bags, sewn, electro-welded) and complex materials such as half-empty bundles or those with fluid contents.

- Automatic compaction: each layer is pressed and leveled for stable palletizing.

- Dynamic handling: thanks to rotary, transversal, and longitudinal movements, the robot has full mobility across the entire horizontal plane.

- Paletta mobile: il sollevatore porta il pallet in posizione tramite rilevamento fotoelettrico, garantendo precisione e continuità operativa.

- Automated control (PLC): all movements are synchronized to optimize productivity and efficiency.

Operation

- Picking and pressing: the incoming bundle from the line is pressed for uniformity and transferred to the pre-forming station.

- Layer formation: the mechanical moving hand positions the bundle according to the set pattern.

- Compaction and transfer: the layer is compacted on all four sides and placed on the mobile pallet.

- Evacuation and replacement: the completed pallet is evacuated and replaced to start a new cycle.

Main advantages

Extreme speed: up to 600 carton-bags/h, perfect for intensive productions

Maximum precision: each layer is pre-formed and compacted for superior stability

Handling of complex bundles: perfect even for light bundles or difficult contents

Advanced automation: total optimisation with programmable PLC

Total adaptability: configurable for different sizes, formations and number of layers

The ROBOTEX 21 A is the ideal solution for those looking for a fast and reliable robotic palletiser, ensuring efficiency, precision and flexibility in any production environment.

Boxes and bundle palletizer robot with conventional compacting system, create square and sturdy pallets

Max. production: 600 carton-bags/hour

Box dimensions - bundles

Max. 600 x 500 x h. 300 mm

Min. 300 x 200 x h. 80 mm

Dimensione paletta

Max. 1200 x 1000 x h. 140 mm

Min. 1000 x 800 x h. 100 mm

Maximum layer size

Max. 1300 x 1100 mm

Standard full pallet height

1600 mm

Compressed air consumption

100 Nl/min

Control voltage

24 V

Max. full pallet weight

2000 Kg

Operational capacity

600 boxes-bundles/hour

Potenza installata

15 KW

Operating pressure

6 bar

Peso indicativo

9500 Kg

Product benefits

__ Ultra-fast handling

__ Ultra-fast handling

With a total wrapping gripper to ensure precision and speed.

__ Layer preforming and compaction

__ Layer preforming and compaction

For a stable and uniform pallet

__ Gripper with integrated pressing system

__ Gripper with integrated pressing system

Ideal for unstable or light burdens

__ Three-dimensional movements

__ Three-dimensional movements

Maximum flexibility and precision

__ Total automation

__ Total automation

Management via programmable PLC