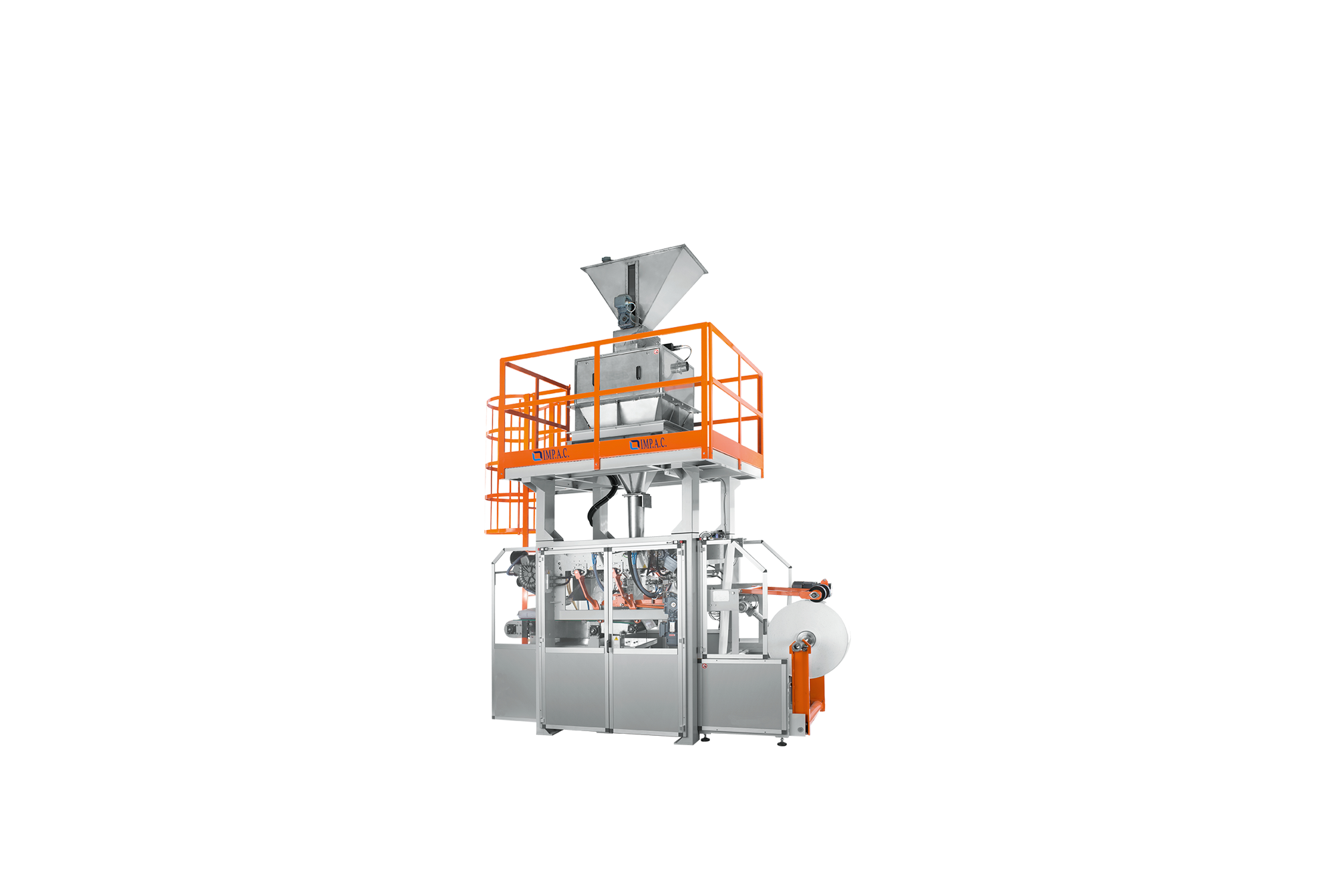

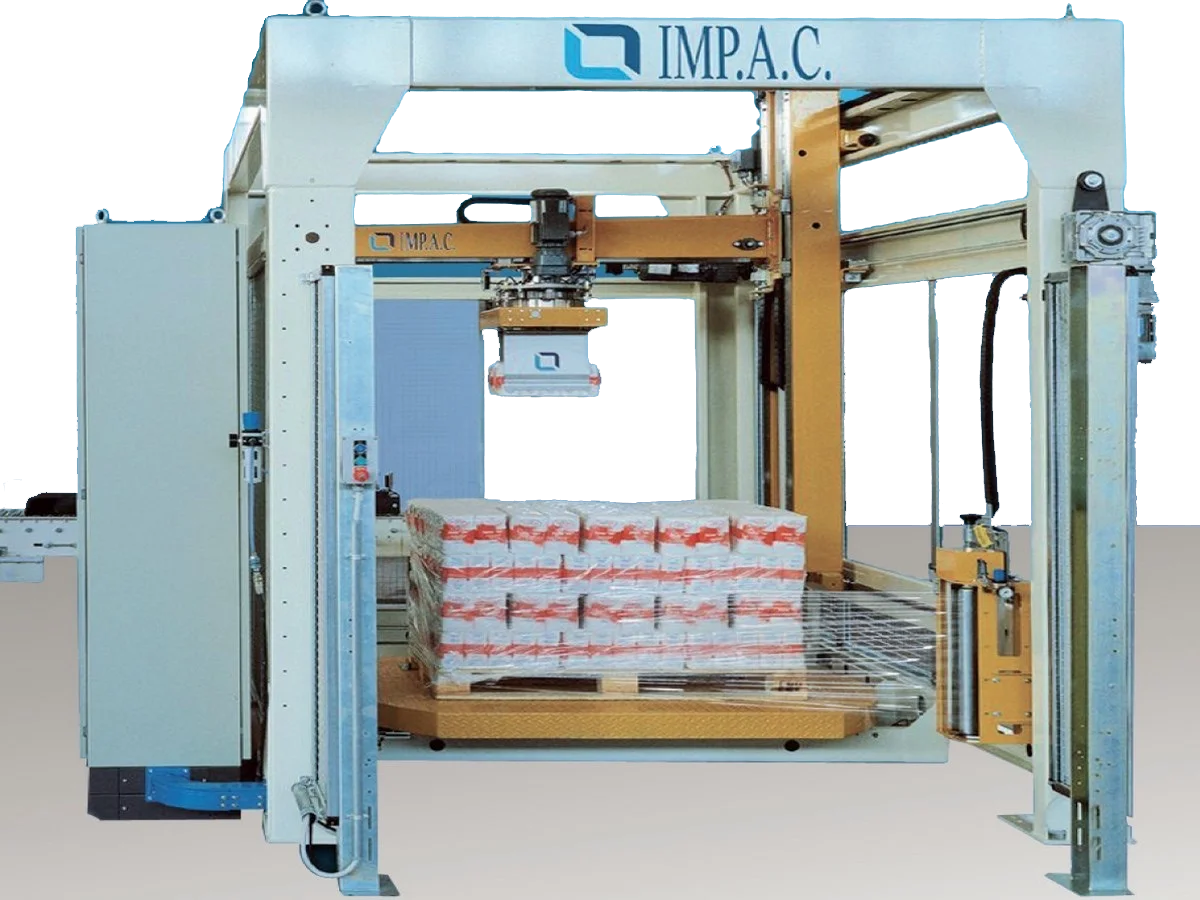

Automatic Cartesian axis palletiser with built-in semi-automatic winder IMP.A.C. ROBOTEX 226 A-SA

IMP.A.C. ROBOTEX 226 A-SA

Automatic Cartesian-axis palletiser with built-in semi-automatic winder

The ROBOTEX 226 A-SA is an innovative automatic palletiser designed to meet the common challenges of palletising and packaging processes.

Thanks to the integration of a semi-automatic winder, this machine allows simultaneous palletising and wrapping of loads, providing greater stability and safety for unstable cartons, bundles and packages.

Its compact design, with a small footprint area of only 4000×2400 mm, makes it ideal for installation in confined spaces, adapting to both mass production lines and production niches, with a capacity of up to 400 cycles/hour.

Key features

- Universal gripper: allows handling of packages of different shapes and weights, from 1 to 50 kg.

- Built-in semi-automatic winder: ensures load stability directly during the palletising process.

- Compact dimensions: ideal for tight spaces thanks to optimised footprint area.

- Production versatility: designed to handle standard or niche production lines, providing flexibility for different package configurations.

Advanced technology

- Cartesian motion: high positioning accuracy thanks to encoder control.

- Programmable modular system (PLC): coordinates movement synchronisms for a smooth and customisable operating cycle.

- Advanced programming: customisable configurations to palletise packages of various sizes, formations and layers.

Operation

The packages, coming from the upstream production line, are directed to the positioning station, where the universal gripper picks them up to orient and position the cartons on the pallet according to the set programme.

During palletisation, the built-in semi-automatic winder ensures that each layer is stabilised, guaranteeing the safety of the load. The cycle repeats until the pallet is completed, which is evacuated and replaced to start a new cycle.

The ROBOTEX 226 A-SA is a technologically advanced and flexible solution, perfect for optimising palletising processes and ensuring maximum efficiency in any production environment.

Automatic Cartesian axis palletiser with built-in semi-automatic winder

Cycles: 400 cartons/h

Cardboard dimensions

Max. 800 x 400 x h. 600<br>Min. 200 x 100 x h. 50

Paddle size

Max. 1300 x 1200 x h. 140<br>Min. 800 x 600 x h. 100

Maximum layer size

Max. 1400 x 1250 mm

Standard full pallet height

1600 mm

Compressed air consumption

100 Nl/min

Control voltage

24 V

Max. full pallet weight

2000 Kg

Operational capacity

400 cycles/h

Installed power

6,5 KW

Operating pressure

6 bar

Indicative weight

4500 Kg

Product benefits

__ Production up to 400 cycles/h

__ Production up to 400 cycles/h

__ Simultaneous palletising and winding for stable loads

__ Simultaneous palletising and winding for stable loads

__ Handling of packages from 1 to 50 kg

__ Handling of packages from 1 to 50 kg

__ Customisable programming for different configurations and formats

__ Customisable programming for different configurations and formats

__ Compact design for small spaces (4000×2400 mm)

__ Compact design for small spaces (4000×2400 mm)

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

Automatic Cartesian-axis palletiser with ground pallet (also available in multi-pallet version) IMP.A.C. ROBOTEX 226 A-PT

IMP.A.C. ROBOTEX 226 A-PT

Pallettizzatore automatico ad assi cartesiani con paletta a terra

(Disponibile anche in versione multipaletta)

The IMP.A.C. ROBOTEX 226 A-PT is an innovative palletiser designed for efficiency and versatility.

Thanks to its compact design, it is ideal for use in small spaces, offering high performance even in multi-pallet configurations.

Key features

- High operating capacity: the multi-pallet system allows simultaneous operation on 1, 2, 3 or 4 pallets, achieving a total output of 500 cycles/hour.

- Universal gripper system: equipped with a versatile gripper, it can handle packages of various shapes and weights up to 50 kg.

- Flexible handling: can be programmed for different sizes, formations and number of layers, adapting to specific production requirements.

- Compact dimensions: the optimised design makes this machine perfect for production facilities with space constraints.

Advanced technology

- Cartesian movement with encoder: guarantees precision and synchronisation in positioning.

- Programmable PLC: allows customised programme management, optimising cycle times and palletising configurations.

Operation

The packages from the production lines are directed to a positioning station, where they are picked up by the universal gripper. Each package is oriented and positioned on the selected pallet according to the set programme. Once completed, the pallet is automatically evacuated and replaced, ensuring continuity in the production cycle.

The IMP.A.C. ROBOTEX 226 A-PT is the ideal solution for anyone looking for a reliable, precise and highly adaptable automatic machine.

Automatic Cartesian-axis palletiser with roller conveyors (also available in multi-pallet version)

Cycles: 500 cartons/h

Cardboard dimensions

Max. 800 x 400 x h. 600

Min. 200 x 100 x h. 50

Paddle size

Max. 1200 x 1000 x h. 140

Min. 1000 x 800 x h. 100

Maximum layer size

Max. 1400 x 1250 mm

Standard full pallet height

1600 mm

Compressed air consumption

100 Nl/min

Control voltage

24 V

Max. full pallet weight

2000 Kg

Operational capacity

400 cartons/hour

Installed power

5 KW

Operating pressure

6 bar

Indicative weight

3500 Kg

Product benefits

__ Up cycles to 500 cartons/h

__ Up cycles to 500 cartons/h

__ Simultaneous multi-pallet machining

__ Simultaneous multi-pallet machining

__ Handling of packages up to 50 kg

__ Handling of packages up to 50 kg

__ Flexibility in programming for different formats and configurations

__ Flexibility in programming for different formats and configurations

__ Compact design, ideal for limited spaces

__ Compact design, ideal for limited spaces

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

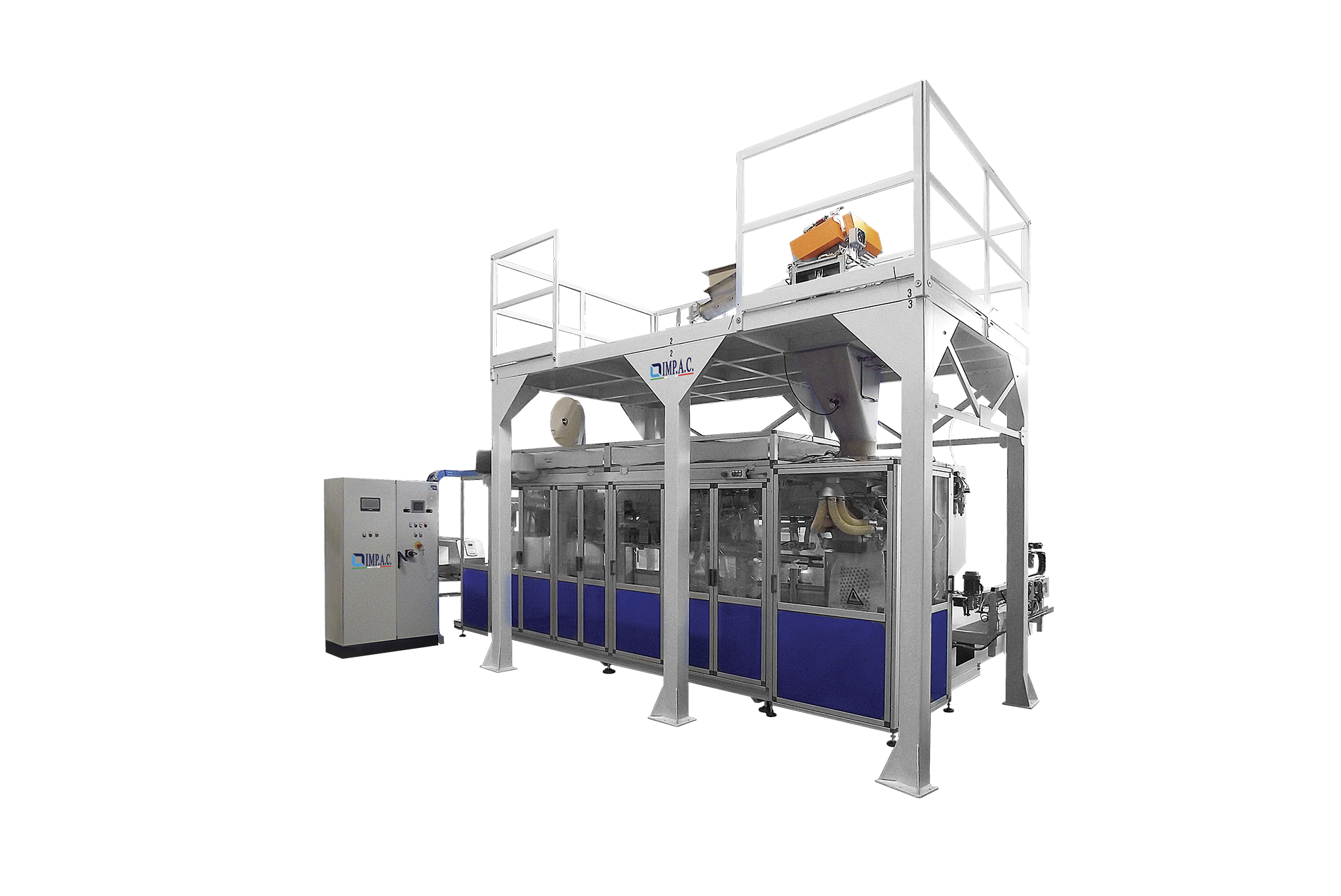

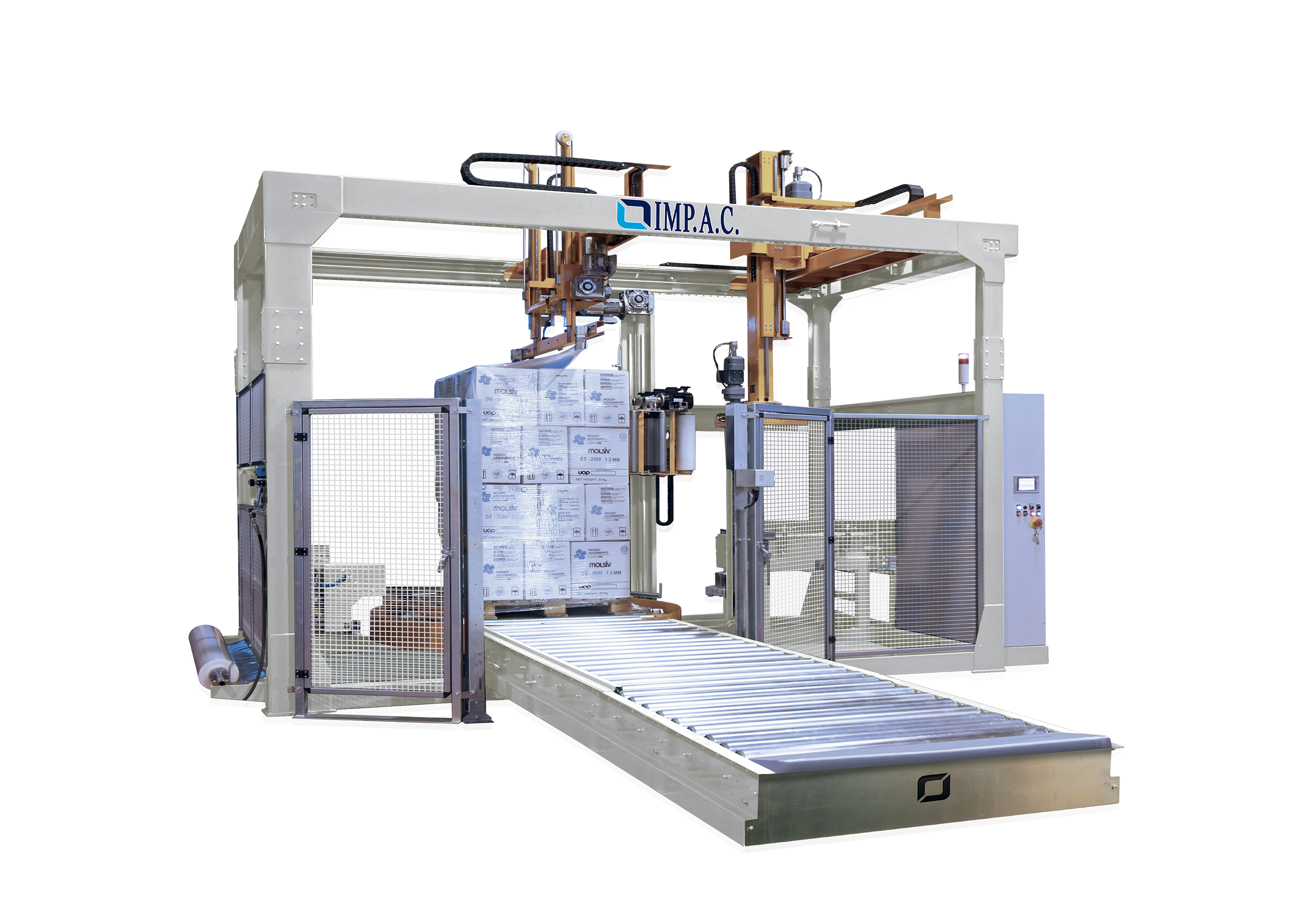

Automatic Cartesian-axis palletiser with roller conveyor (also available in multi-pallet version) IMP.A.C. ROBOTEX 226 A

IMP.A.C. ROBOTEX 226 A

Pallettizzatore automatico ad assi cartesiani con rulliere

(Disponibile anche in versione multipaletta)

The IMP.A.C. ROBOTEX 226 A is an innovative palletiser designed for efficiency and versatility.

Thanks to its compact design, it is ideal for use in small spaces, offering high performance even in multi-pallet configurations.

Key features

- High operating capacity: the multi-pallet system allows simultaneous operation on 1, 2, 3 or 4 pallets, achieving a total output of 500 cartons/hour.

- Universal gripper system: equipped with a versatile gripper, it can handle packages of various shapes and weights up to 50 kg.

- Flexible handling: can be programmed for different sizes, formations and number of layers, adapting to specific production requirements.

- Compact dimensions: the optimised design makes this machine perfect for production facilities with space constraints.

Advanced technology

- Cartesian movement with encoder: guarantees precision and synchronisation in positioning.

- Programmable PLC: allows customised programme management, optimising cycle times and palletising configurations.

Operation

The packages from the production lines are directed to a positioning station, where they are picked up by the universal gripper. Each package is oriented and positioned on the selected pallet according to the set programme. Once completed, the pallet is automatically evacuated and replaced, ensuring continuity in the production cycle.

The IMP.A.C. ROBOTEX 226 A is the ideal solution for anyone looking for a reliable, precise and highly adaptable automatic machine.

Automatic Cartesian-axis palletiser with roller conveyors (also available in multi-pallet version)

Max. production: 500 cartons/h

Cardboard dimensions

Max. 800 x 400 x h. 600

Min. 200 x 100 x h. 50

Paddle size

Max. 1200 x 1000 x h. 140

Min. 1000 x 800 x h. 100

Maximum layer size

Max. 1400 x 1250 mm

Standard full pallet height

1600 mm

Compressed air consumption

100 Nl/min

Control voltage

24 V

Max. full pallet weight

2000 Kg

Operational capacity

400 cartons/hour

Installed power

7 KW

Operating pressure

6 bar

Indicative weight

3500 Kg

Product benefits

__ Production up to 500 cartons/h

__ Production up to 500 cartons/h

__ Simultaneous multi-pallet machining

__ Simultaneous multi-pallet machining

__ Handling of packages up to 50 kg

__ Handling of packages up to 50 kg

__ Flexibility in programming for different formats and configurations

__ Flexibility in programming for different formats and configurations

__ Compact design, ideal for limited spaces

__ Compact design, ideal for limited spaces

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

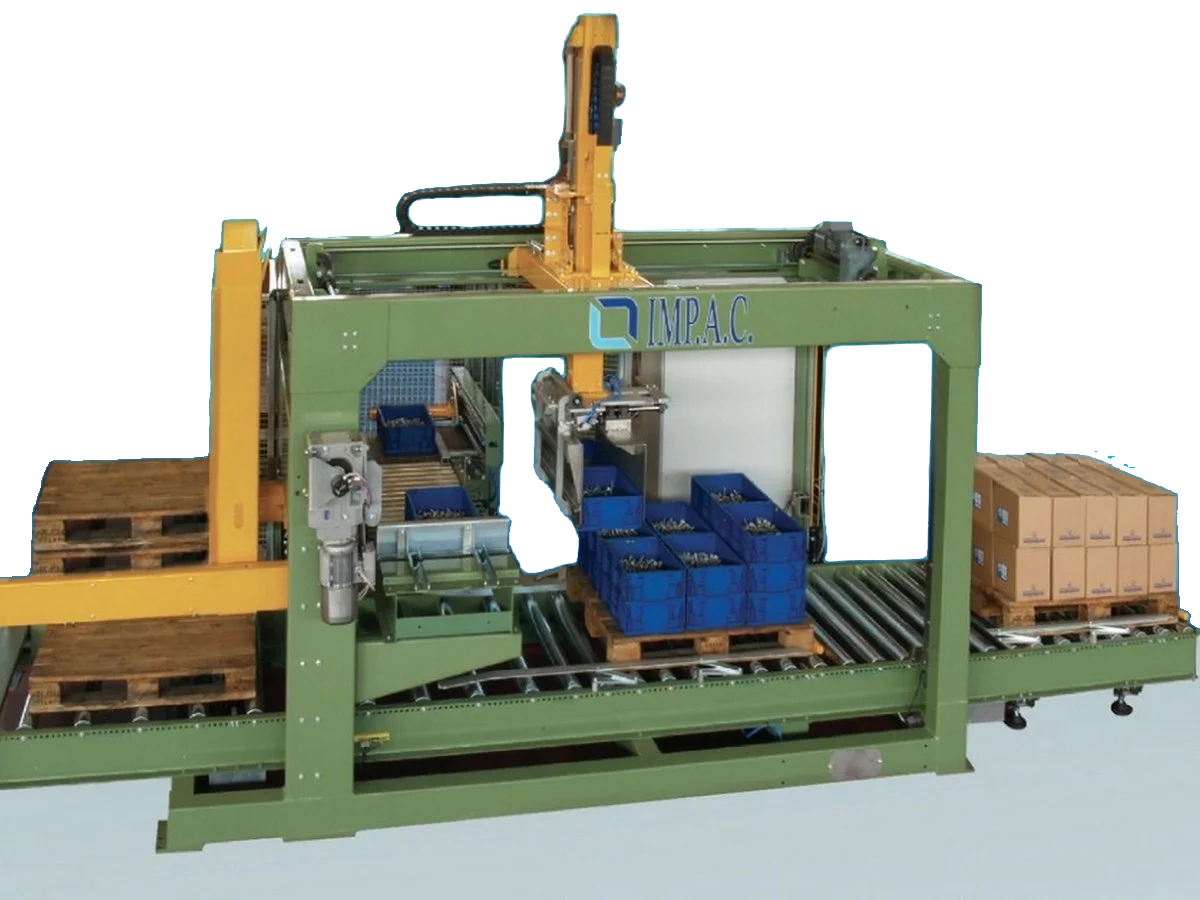

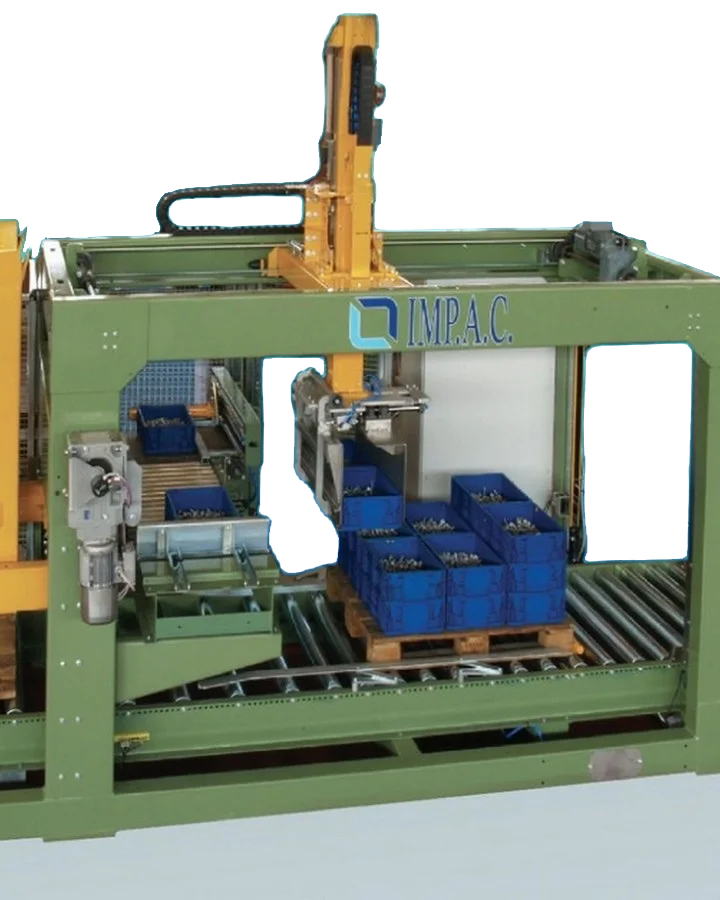

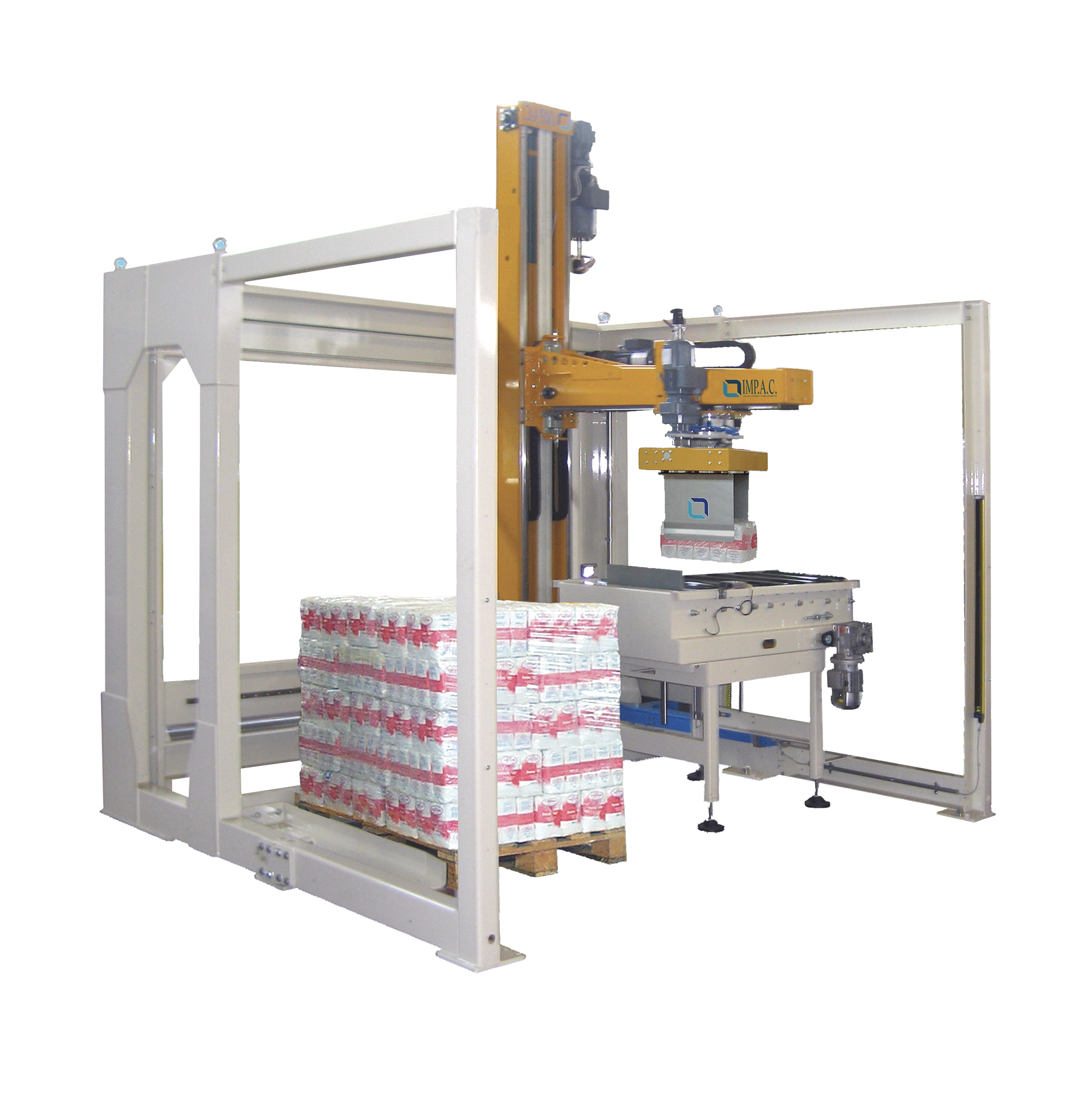

Cartesian bundle and carton palletising robot with built-in semi-automatic winder IMP.A.C. ROBOTEX 225 A-SA

IMP.A.C. ROBOTEX 225 A-SA / 226 A-SA

Robotic palletizer for boxes,klt and bundles with semi automatic wrapping system integrated

The IMP.A.C. ROBOTEX 225 A-SA / 226 A-SA is an innovative palletiser designed to meet the demands of versatility, load stability and space optimisation.

Ideal for serial or niche production lines, with a maximum capacity of 300 cycles/h, it offers a reliable solution for end-of-line automation.

Key features

- Versatility in formats and weights: it allows bundles of 10 to 15 kg and cartons of various sizes to be palletised using the same equipment.

- Load stability: thanks to the built-in semi-automatic winder, it guarantees safe palletising even for unstable or slippery bundles.

- Compactness: designed for installation in small spaces, with a minimum footprint of 4000×2400 mm.

- Pressing and uniformity: the pressing device makes the bags pressed and uniform before palletising, improving load stability.

- Complete automation: the Cartesian system, controlled by encoders, allows precise positioning and a fully automatic cycle, from gripping to positioning on the pallet.

- Programmable handling: the modular PLC allows the machine to be easily configured for different sizes, formations and number of layers.

The ROBOTEX 225 A-SA / 226 A-SA IMP.A.C. is a modern and reliable solution for optimising end-of-line operations, combining efficiency, precision and versatility.

Robotic palletizer for boxes,klt and bundles with semi automatic wrapping system integrated

Cycles: 300 carton-bags/hour

Cardboard dimensions

Max. 450 x 400 x h. 300 mm

Min. 200 x 100 x h. 50 mm

Pallet Size

Max. 1200 x 1100 x h. 300 mm

Min. 800 x 600 x h. 100 mm

Maximum layer size

Max. 1300 x 1100 mm

Standard full pallet height

1600 mm

Compressed air consumption

100 Nl/min

Control voltage

24 V

Max. full pallet weight

2000 Kg

Operational capacity

240-300 cycles/h

Installed power

6,5 KW

Operating pressure

6 bar

Indicative weight

4000 Kg

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

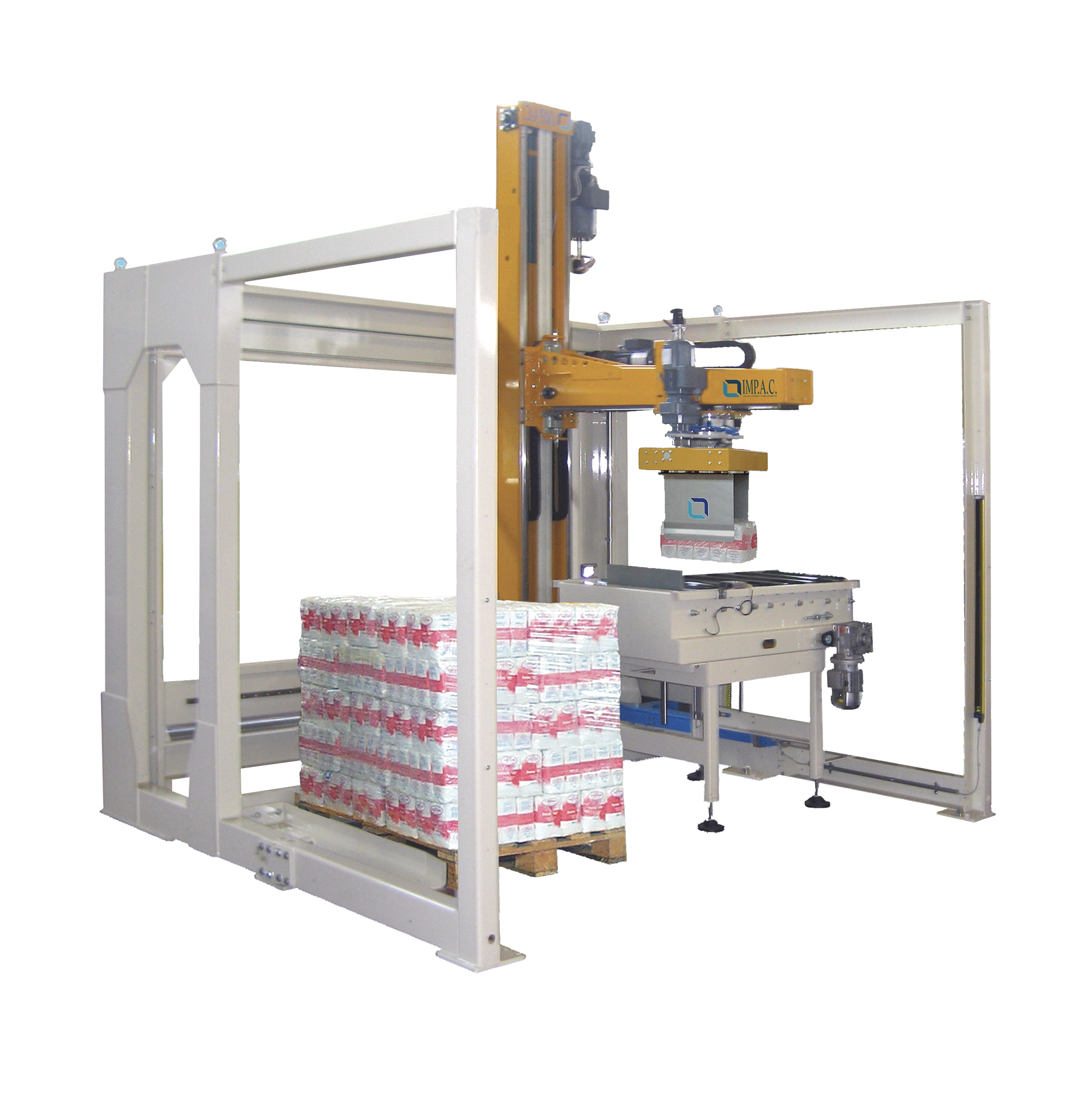

Cartesian palletising robot for cartons with floor pallet (also available as multi-pallet version) IMP.A.C. ROBOTEX 225 A-PT

IMP.A.C. ROBOTEX 225 A-PT / 226 A-PT

Robotic palletizer for boxes,klt and bundles on the pallet at the ground

The IMP.A.C. ROBOTEX 225 A-PT / 226 A-PT is a Cartesian palletiser designed for low throughputs.

Maximum capacity of 300 cycles/h, ideal for production lines with limited space thanks to compact dimensions of 4000×2400 mm.

Key features

- Innovative gripping system: the full wrap gripper allows handling of all types of bags, including paper, jute, plastic, valve, sewn or electro-welded bags.

- Handling of complex sacks: designed for difficult sacks, such as half-empty sacks or sacks containing products with low viscosity, ensuring stability and uniformity thanks to the pressing device.

- Optimised operations: the sack is pressed to make it uniform and compact, then sent to the positioning station to be picked up, oriented and placed on the pallet with precision.

- Automatic cycle: the machine runs the process until the pallet is completed, which is evacuated and automatically replaced for a new cycle.

- High-precision control: the Cartesian axis movement system is controlled by encoders, while synchronisms are managed by a programmable modular system (PLC).

- Format versatility: it can be configured to palletise bags of different sizes, formations and number of layers.

The ROBOTEX 225 A-PT / 226 A-PT IMP.A.C. is the ideal choice for optimising end-of-line operations, ensuring reliability, precision and compactness even in the most complex production environments.

Robotic palletizer for boxes,klt and bundles on the pallet at the ground

Cycles: 250/h

Carton size

Max. 450 x 400 x h. 300 mm

Min. 200 x 100 x h. 50 mm

Pallet Size

Max. 1200 x 800 x h. 300 mm

Min. 800 x 600 x h. 100 mm

Maximum layer size

Max. 1300 x 1100 mm

Standard full pallet height

1600 mm

Compressed air consumption

100 Nl/min

Control voltage

24 V

Max. full pallet weight

1500 Kg

Operational capacity

250 cycles/h

Installed power

5 KW

Operating pressure

6 bar

Indicative weight

3500 Kg

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

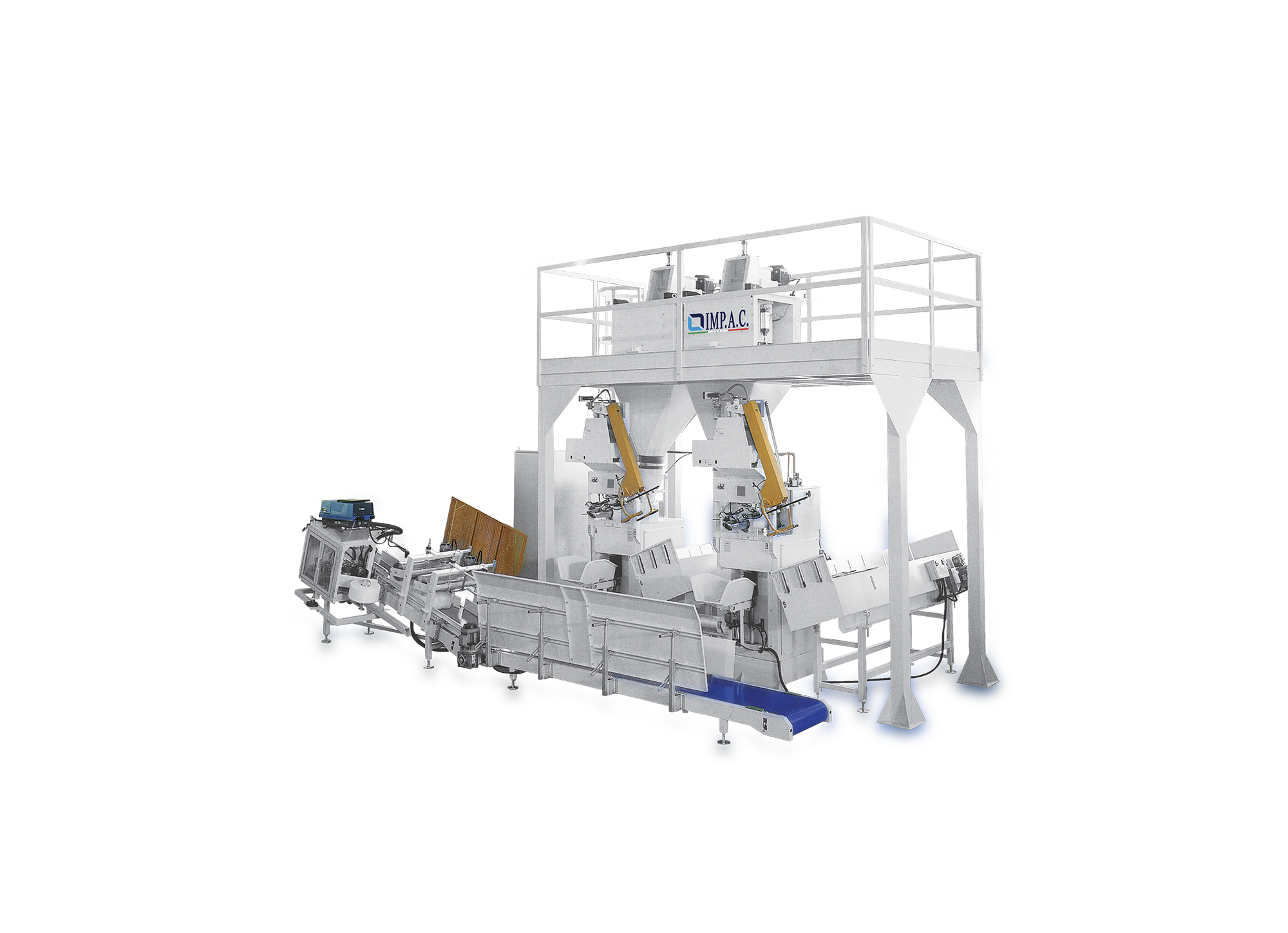

Automatic Cartesian axis palletiser for cartons and KLT IMP.A.C. ROBOTEX 225 A

The IMP.A.C. ROBOTEX 225 A / 226 A is an automatic Cartesian-axis palletiser, designed to efficiently handle cartons, KLTs and bundles, distinguished by its compact design and high operating performance.

Ideal for optimising end-of-line operations, it guarantees reliability and precision even in high-intensity production environments.

Key features

- Row preparation on the preformer: each row is prepared entirely on the preformer, ensuring a continuous and orderly flow.

- Row palletising: the robot gripper picks up one complete row at a time, reaching a maximum speed of 300 cycles/h, with actual production varying according to the number of packs per row.

- Automatic format changeover: thanks to PLC control, the machine allows versatile and fully automatic handling of different formats, reducing set-up times.

- Compact design: small footprint for easy installation even in confined spaces.

The IMP.A.C. ROBOTEX 225 A / 226 A is the ideal choice for companies requiring a compact, versatile and highly efficient solution for automatic palletising, ensuring a smooth process and quality results.

Robotic palletizer for boxes,klt and bundles

Cycles: 300/h

Carton, KLT and bundle dimensions

Max. 450 x 400 x h. 300<br>Min. 200 x 100 x h. 50

Paddle size

1200 x 800 x h. 140<br>1300 x 900 mm

Standard full pallet height

1600 mm

Compressed air consumption

100 Nl/min

Control voltage

24 V

Max. full pallet weight

1500 Kg

Operational capacity

300 cycles/h

Installed power

7 KW

Operating pressure

6 bar

Indicative weight

400 Kg