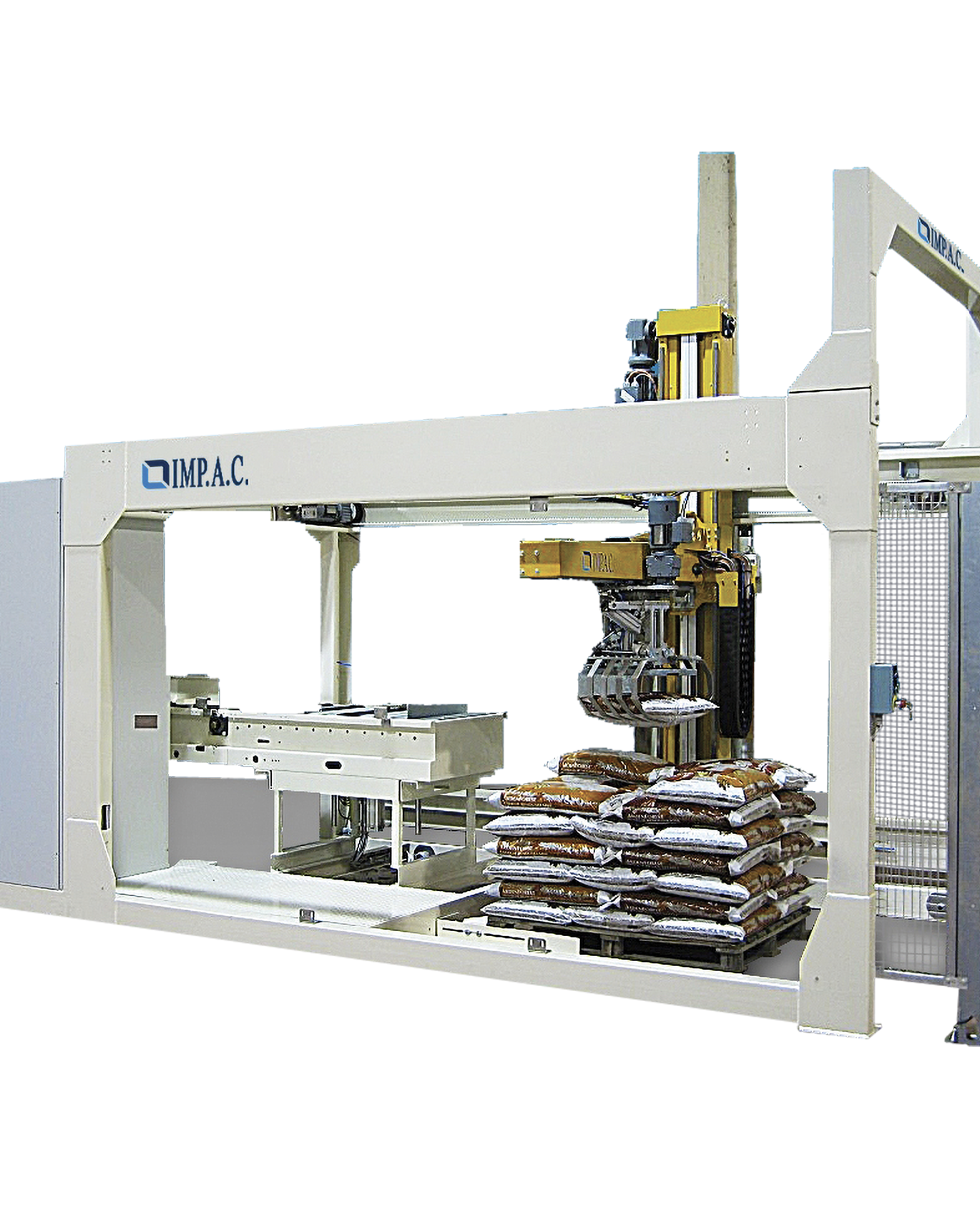

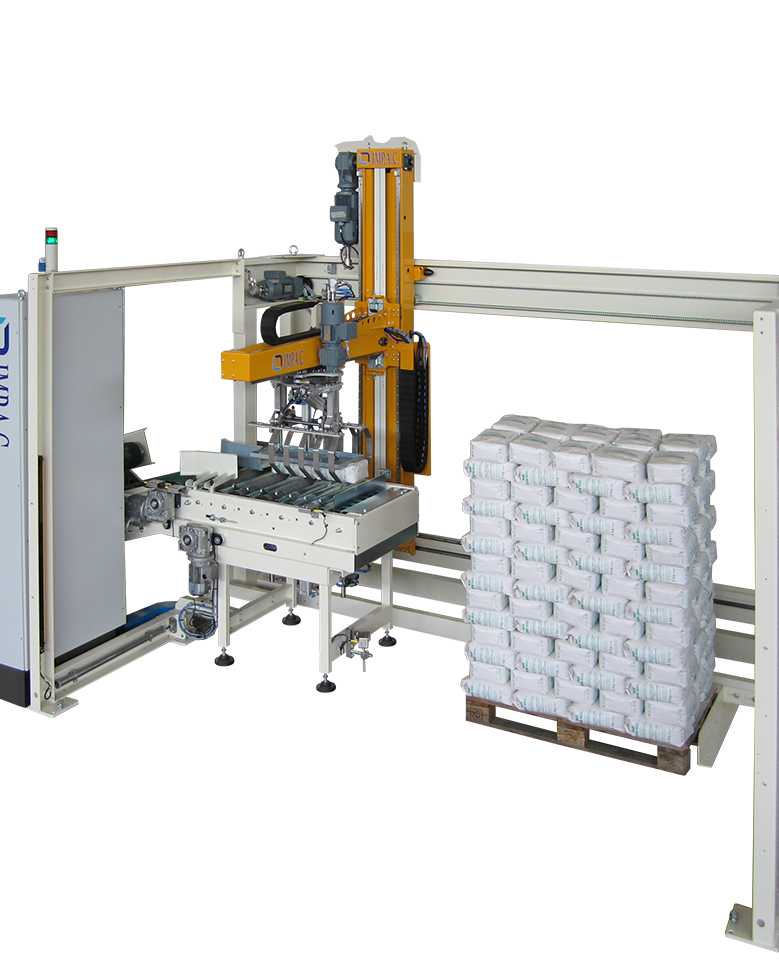

The ROBOTEX 126 A-PT IMP.A.C. palletiser is the ideal solution for low throughputs, with a maximum capacity of 300 bags/hour and compact dimensions of just 4000x2400 mm, making it perfect for small and very low spaces

Operation

- Bag pressing: the incoming bag from the upstream line is pressed for uniformity and compactness.

- Transfer to the gripper: the pressed sack is oriented and fed to the positioning station.

- Picking and placing: the gripper picks up the sack, orients it and places it on the pallet according to the set programme.

- Continuous cycle: once a pallet is completed, it is manually evacuated and replaced with an empty one to start a new cycle.

Advantages

- High accuracy and reliability thanks to the Cartesian system.

- Suitable for all types of sacks, even those difficult to handle.

- Compact and versatile, ideal for small spaces.

- Low energy consumption and simplified maintenance.

The ROBOTOEX 126 A-PT model is an excellent choice for optimising low production rates, ensuring quality, efficiency and maximum adaptability to different bag formats.

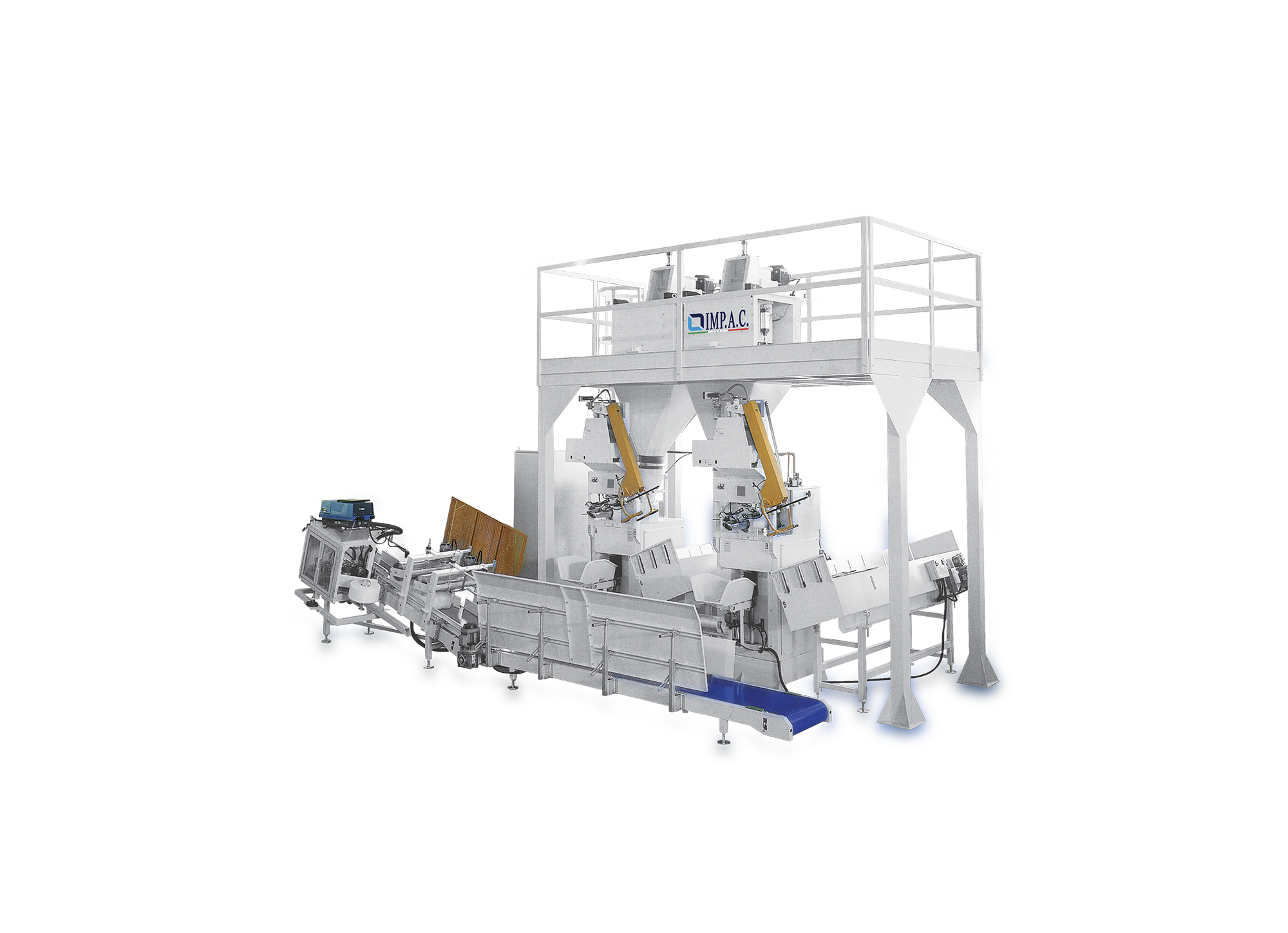

Compact Cartesian bag palletizer on the pallet at the ground

Cycles: 300 bags/h

Bag dimensions

Max. 1000 x 500 x h. 250 mm

Min. 300 x 200 x h. 80 mm

Pallet Size

Max. 1200 x 1000 x h. 140 mm

Min. 1000 x 800 x h. 80 mm

Maximum layer size

Max. 1300 x 1100 mm

Standard full pallet height

1600 mm

Compressed air consumption

100 Nl/min

Max. full pallet weight

2000 Kg

Operational capacity

300 sacks/hour

Installed power

5 KW

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

3500 Kg

Product benefits

__ Total wrapping pliers

__ Total wrapping pliers

It provides a secure and stable grip for all types of sacks (paper, jute, plastic, valve, sewn or electro-welded), even for difficult sacks such as those that are partially empty or contain viscous materials.

__ Pressing device

__ Pressing device

It ensures optimal compaction of the bag on the pallet for stable and safe palletising.

__ Cartesian movement

__ Cartesian movement

The Cartesian axis system, controlled by encoders, guarantees precise positioning and operational versatility.

__ Advanced automation

__ Advanced automation

Synchronisations and operations coordinated by a programmable modular PLC, which allows bags of different sizes, formations and number of layers to be handled.