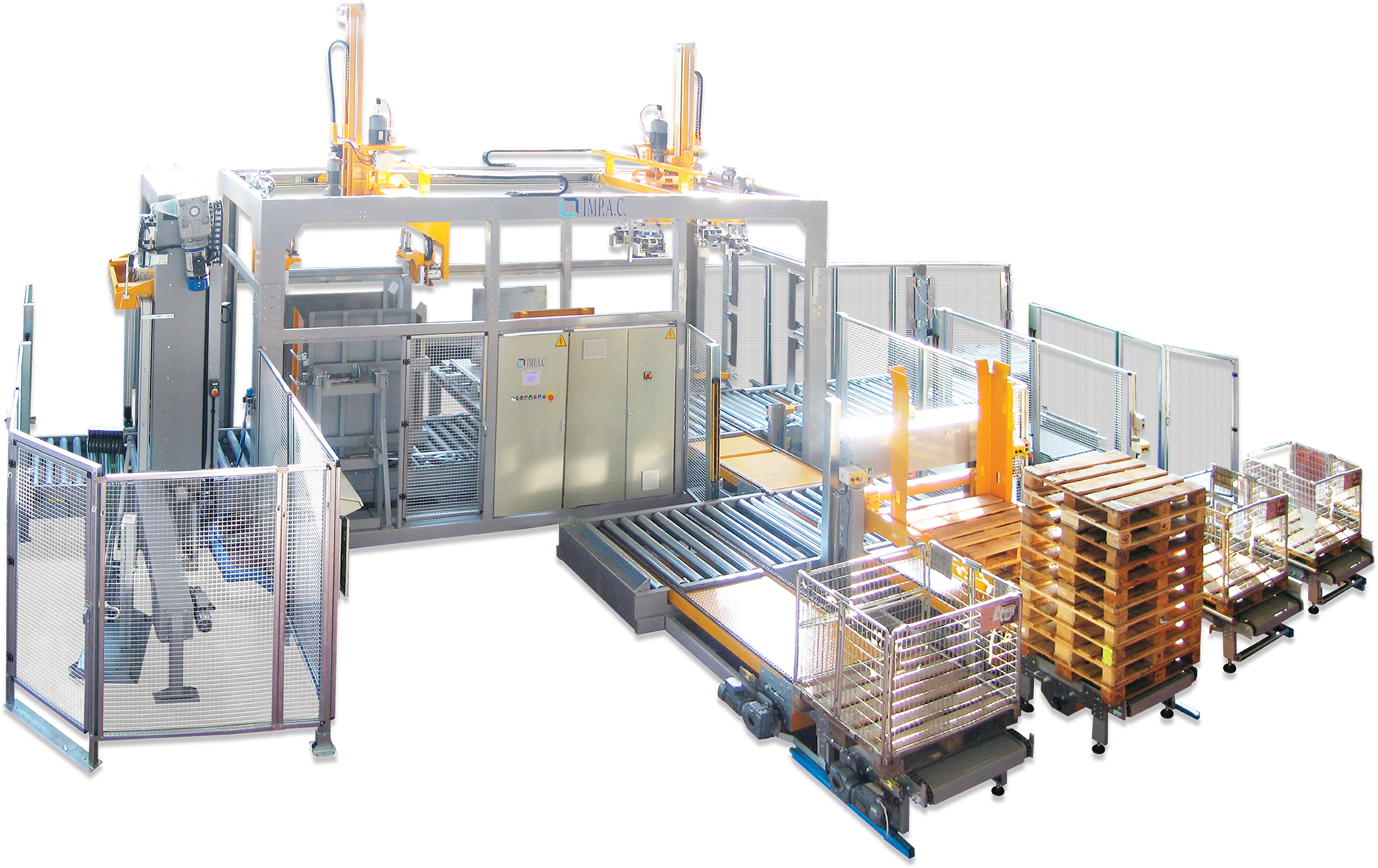

The IMP.A.C. ROBOTEX 126 A palletiser is a fully automatic machine, designed to ensure high efficiency and adaptability in fully automatic production plants, even in reduced height spaces in the absence of an operator.

Operation

- Feeding and positioning:

The bag coming from the upstream line is pressed to be made uniform and compact. - Positioning station:

The sack is started at the positioning station to be picked up by the gripper. - Cartesian handling:

The gripper orients, positions and presses the bag onto the pallet according to the set programme. - Palletising cycle:

The process continues until the pallet is completed, which is automatically evacuated and replaced.

Advanced technology

- Cartesian axis movement:

Controlled by encoders to ensure precision and reliability. - Programmable modular system (PLC):

Synchronises all movements for smooth and customisable operation.

Operational flexibility

The machine is programmable to handle:

- Sacks of different sizes and formats

- Multiple palletising configurations

- Different numbers of layers on the pallet.

Ideal applications

Perfect for fully automated industrial production lines, where high precision, reliability and flexibility in bag handling is required even under critical conditions.

IMP.A.C. ROBOTEX 126 A is the optimal solution for companies requiring efficient and compact palletising with high production performance.

Compact Cartesian bag palletizer

Cycles:

300 sacks/hour basic solution

500 sacks/hour fast solution

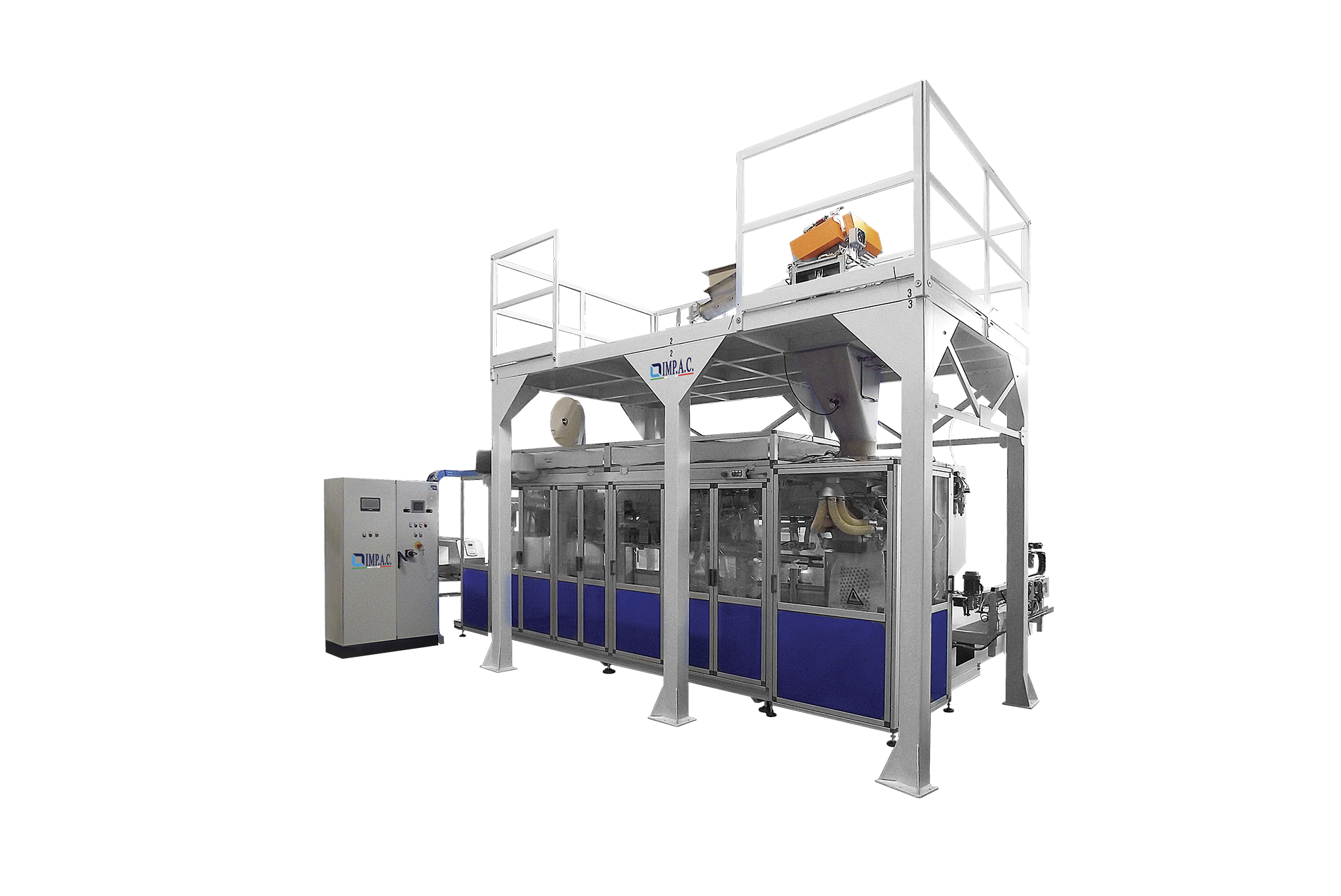

Bag dimensions

Max. 1000 x 500 x h. 250 mm

Min. 300 x 200 x h. 80 mm

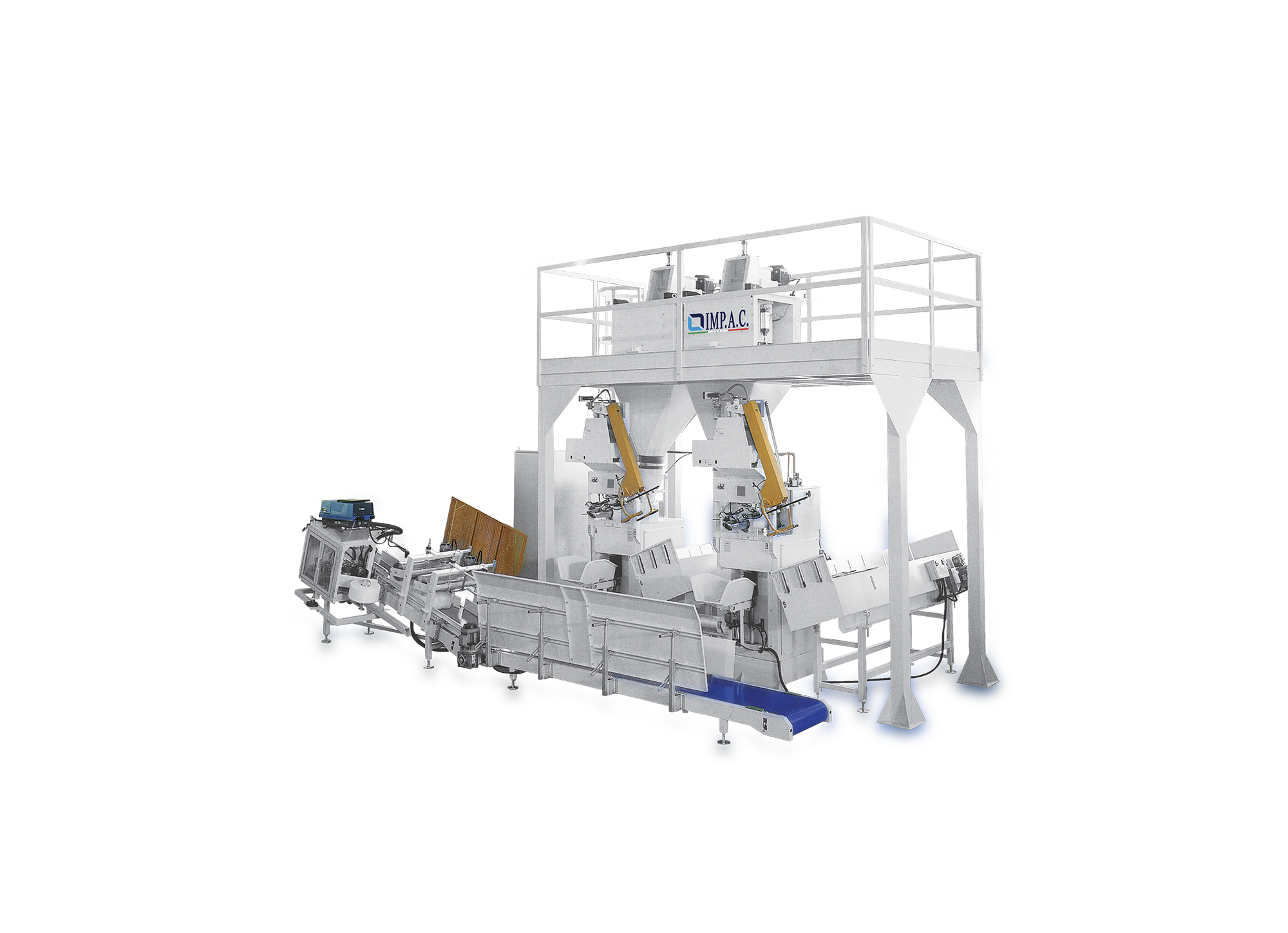

Pallet Size

Max. 1200 x 1000 x h. 140 mm

Min. 1000 x 800 x h. 80 mm

Maximum layer size

Max. 1300 x 1100 mm

Standard full pallet height

1600 mm

Compressed air consumption

100 Nl/min

Max. full pallet weight

2000 Kg

Operational capacity

300-500 sacks/h

Potenza installata

7 KW

Operating pressure

6 bar

Control voltage

24 V

Peso indicativo

5000 Kg

Product benefits

__ High production capacity

__ High production capacity

Up to 500 sacks/h in the fast configuration.

__ Compact design

__ Compact design

Optimised for small spaces.

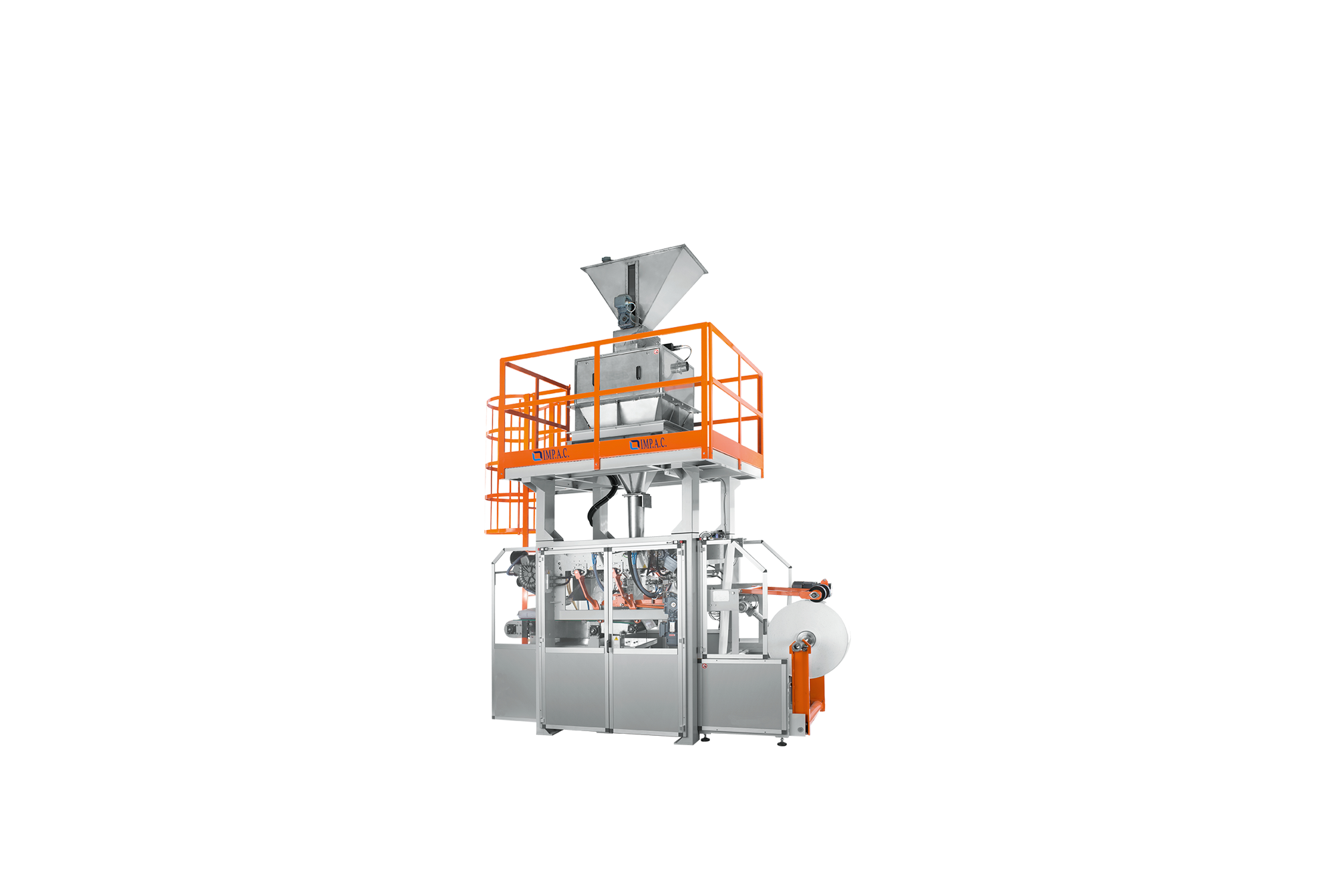

__ Advanced gripping system

__ Advanced gripping system

Full wrapping gripper for handling sacks of all types:<br>- Paper, jute, plastic<br>- Valve, sewn or electro-welded sacks<br>Half-empty sacks or sacks containing products at the viscosity limit (e.g. water).

__ Pressing device

__ Pressing device

It ensures uniform and compact sacks.