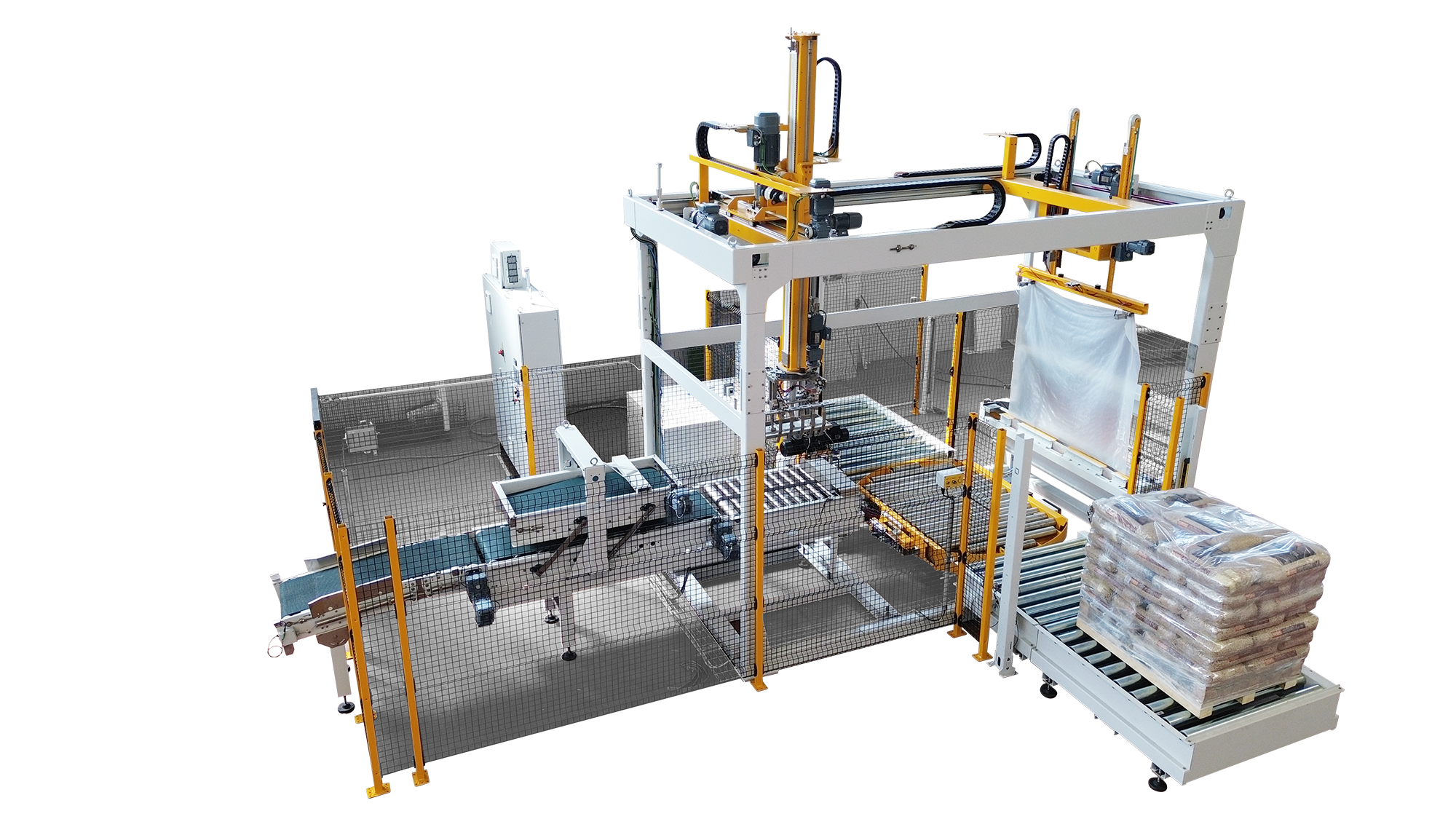

IMP.A.C. ROBOTEX 125 A-PR+TOP

Cartesian bag palletizer with integrated automatic wrapping system + top cover

The IMP.A.C. ROBOTEX 125 A-PR+TOP palletiser is an innovative, fully automatic solution equipped with roller conveyors for handling empty and full pallets.

Designed to meet the needs of a wide range of users, it offers the following distinctive features.

Operation

The bag coming from the production line is:

- Pressed to be made uniform and compact.

- Started at a positioning station where it is picked up by the gripper.

- Oriented, positioned and pressed on the pallet according to the set programme.

The cycle repeats until the pallet is completed, which is automatically evacuated and replaced to start a new cycle.

Programmazione e controllo

- Sincronismi dei movimenti coordinati da un sistema modulare programmabile (PLC).

- Possibilità di programmare la macchina per diverse dimensioni dei sacchi, configurazioni e numero di strati.

Il IMP.A.C. ROBOTEX 125 A-PR+TOP è la scelta ideale per chi necessita di una soluzione affidabile, compatta e versatile per la pallettizzazione e l’avvolgimento automatico, garantendo la protezione completa del carico anche in condizioni operative complesse.

Cartesian bag palletizer with integrated automatic wrapping system + top cover

Cycles:

230 sacks/hour basic solution

400 bags/hour fast solution

Bag dimensions

Max. 1000 x 500 x h. 250 mm

Min. 300 x 200 x h. 60 mm

Pallet Size

Max. 1200 x 1000 x h. 140 mm

Min. 1000 x 800 x h. 80 mm

Maximum layer size

Max. 1300 x 1100 mm

Standard full pallet height

1600 mm

Compressed air consumption

200 Nl/min

Max. full pallet weight

2000 Kg

Operational capacity

230-400 sacks/h

Installed power

9 KW

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

6000 Kg

Product benefits

__ Total versatility

__ Total versatility

Palletising of all types of sacks (paper, jute, plastic, valve, sewn or electro-welded).<br>Compatibility with sizes and weights from 5 to 50 kg using the same equipment.

__ Load stability and protection

__ Load stability and protection

Automatic pallet winding for maximum stability.<br>Integrated top cover system for additional protection.

__ Compactness

__ Compactness

Compact design ideal for limited spaces, with small overall dimensions.

__ Full automation

__ Full automation

Suitable for fully automatic, unmanned production lines.<br>Production capacity up to 400 bags/h in the fast version.

__ Advanced gripping system

__ Advanced gripping system

Full wrapping gripper for safe handling of complex sacks, including semi-empty sacks or sacks containing viscous materials.<br>Pressing device for uniform positioning of the sack on the pallet.

__ Precision in movements

__ Precision in movements

Cartesian motion system with encoder control to ensure accurate positioning.