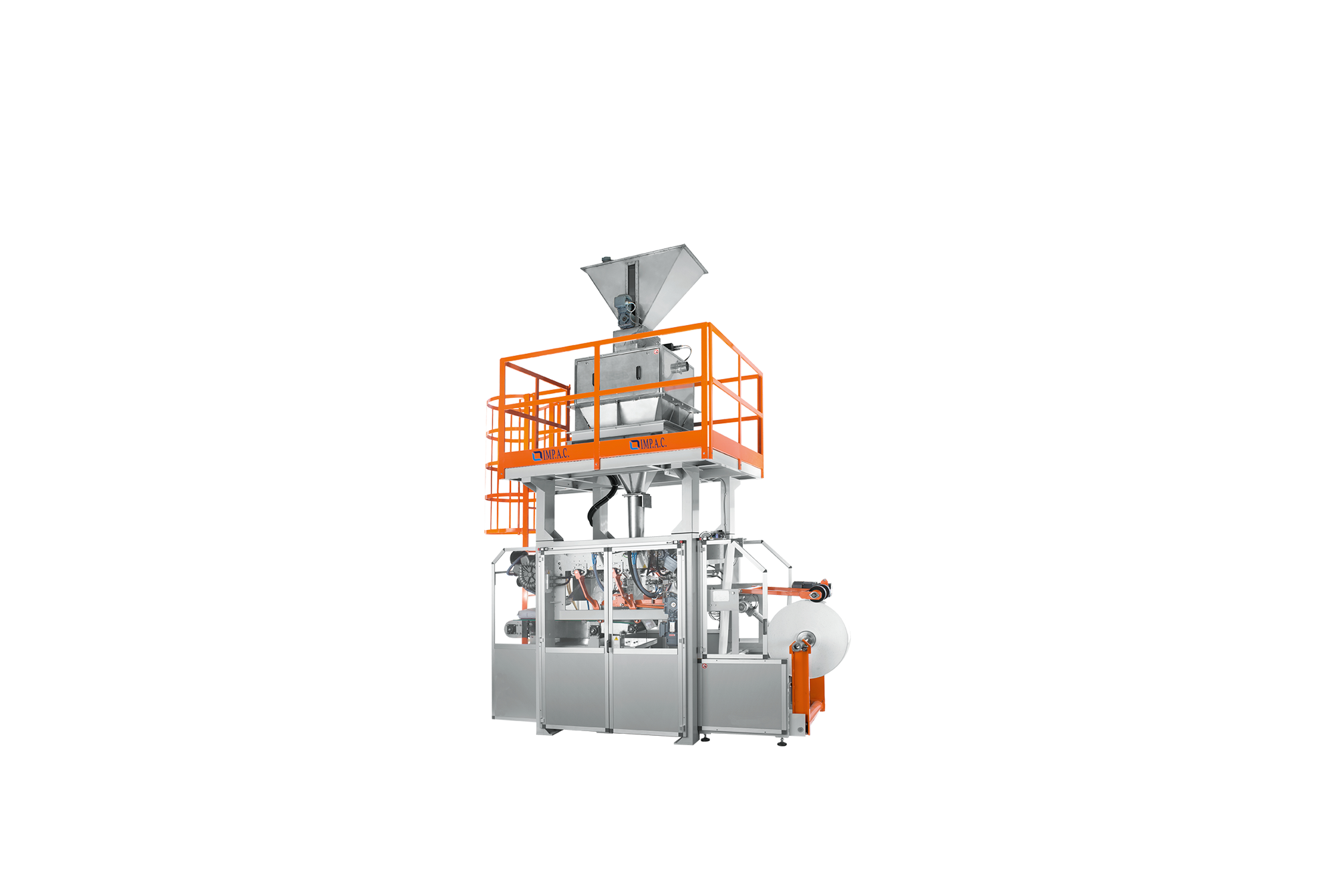

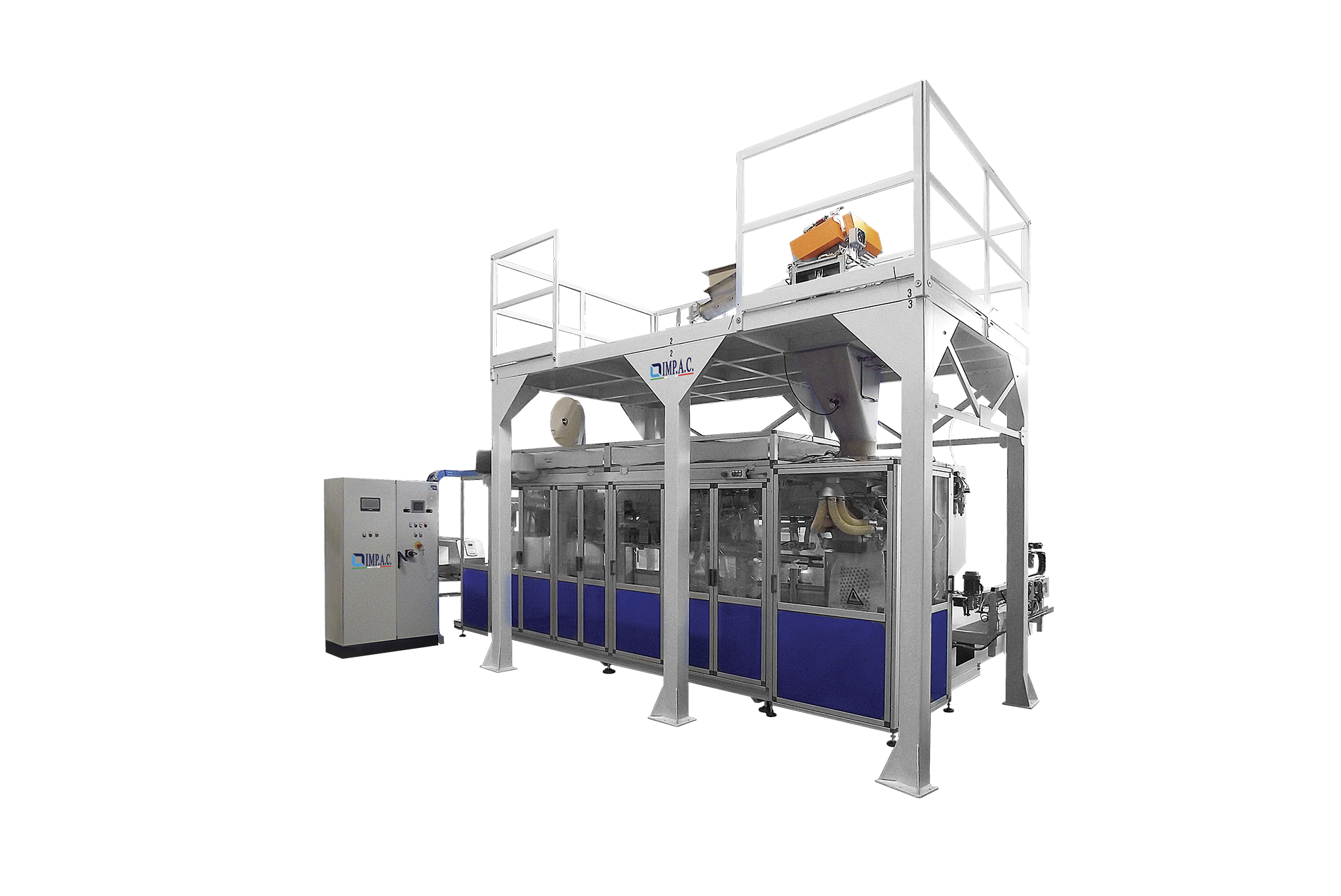

IMP.A.C. ROBOTEX 125 A-PR

Cartesian bag palletizer with integrated automatic wrapping system

The ROBOTEX 125 A-PR IMP.A.C. palletiser represents a technologically advanced, fully automatic solution designed to meet palletising and wrapping requirements in an efficient and versatile manner.

Main advantages

- Versatility:

Handles bags with different sizes and weights, from 5 to 50 kg, with one equipment. - Load stability:

Integrates an automatic winding system to ensure the stability of slippery or unstable bags. - Compactness:

Ideal for installation in small spaces due to its compact footprint. - Complete automation:

Designed to work without supervision in automated production plants.

Ideal applications

Designed for fully automated production lines with capacities of up to 450 bags/hour, the ROBOTEX 125 A-PR is the ideal choice for those requiring efficiency, load stability and space optimisation.

Cartesian bag palletizer with integrated automatic wrapping system

Cycles:

270 bags/hour basic solution

450 sacks/hour fast solution

Bag dimensions

Max. 1000 x 500 x h. 250 mm

Min. 300 x 200 x h. 80 mm

Pallet Size

Max. 1200 x 1000 x h. 140 mm

Min. 1000 x 800 x h. 80 mm

Maximum layer size

Max. 1300 x 1100 mm

Standard full pallet height

1600 mm

Compressed air consumption

150 Nl/min

Max. full pallet weight

2000 Kg

Operational capacity

270-450 sacks/h

Installed power

8,5 KW

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

6000 Kg

Product benefits

__ Advanced gripping system

__ Advanced gripping system

The full wrapping gripper allows the handling of paper, jute, plastic, sewn or electro-welded sacks, ensuring optimal handling even for half-empty sacks or sacks containing viscous materials.

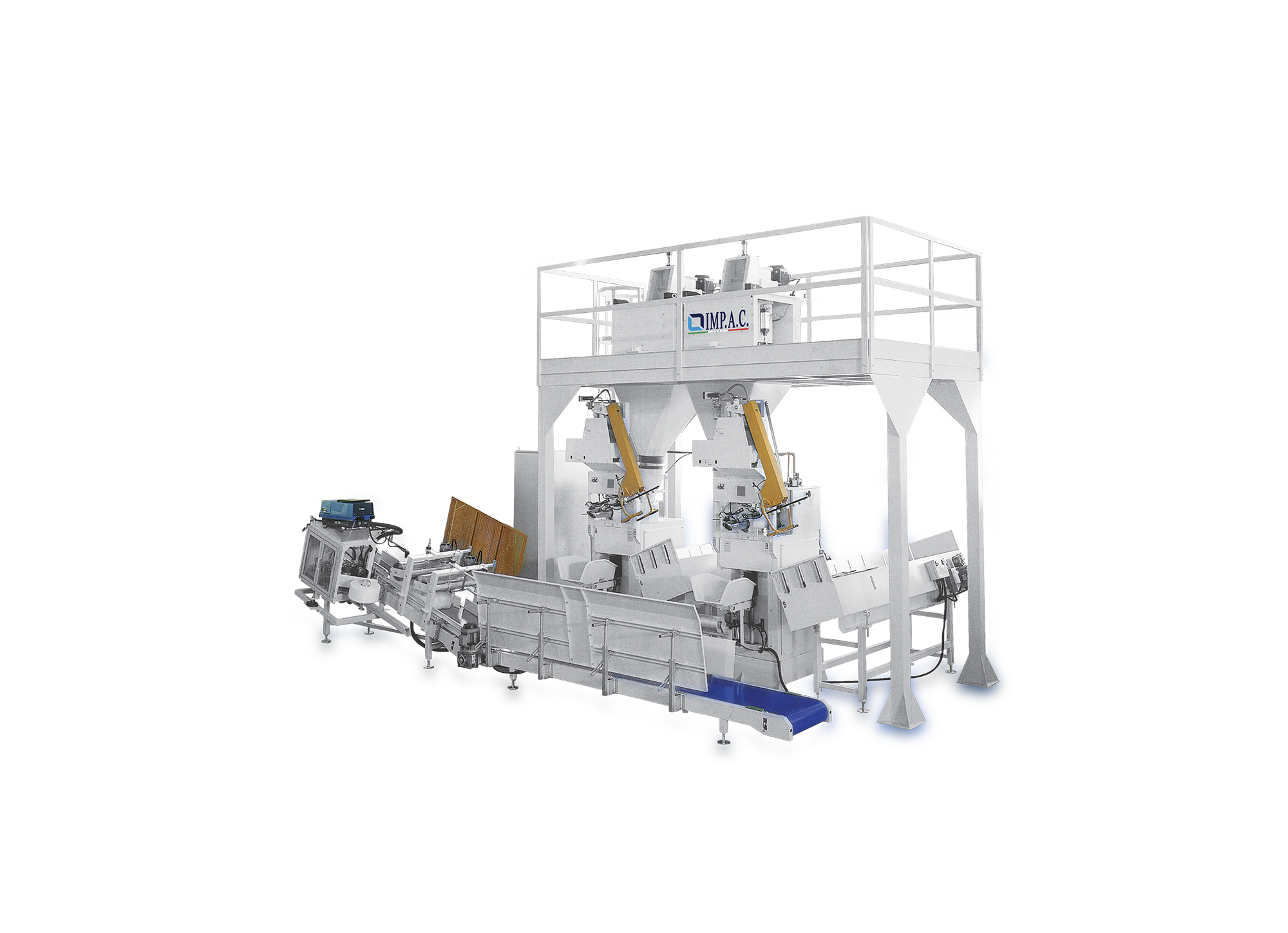

__ Automatic palletising

__ Automatic palletising

The bags are pressed for uniformity, oriented and placed on the pallet according to the preset programme.

__ Cartesian movement

__ Cartesian movement

Precise Cartesian axes, controlled by encoders, ensure accurate positioning.

__ Intuitive management

__ Intuitive management

All movements and synchronisms are coordinated by a programmable modular PLC, which can be customised for various bag sizes and formations.

__ Continuous cycle

__ Continuous cycle

Once completed, the pallet is evacuated and automatically replaced to start a new cycle.