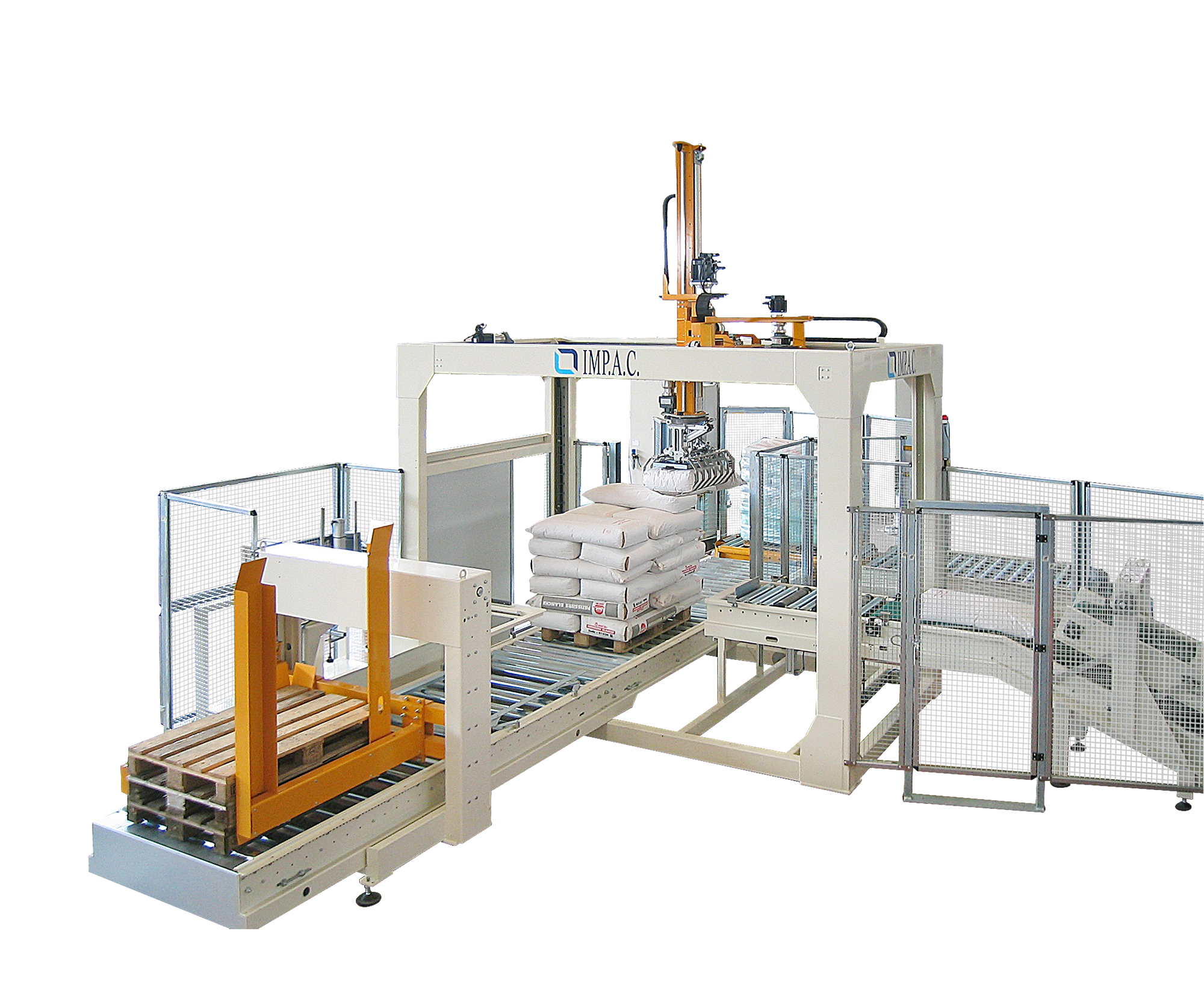

The IMP.A.C. ROBOTEX 125 A palletiser is a fully automatic solution designed for production lines where there is no operator presence.

Thanks to its configuration with integrated roller conveyors for handling empty and full pallets, it integrates perfectly as an end-of-line unit in highly automated plants.

Cycles:

- 300 bags/hour (basic solution)

- 500 sacks/h (fast solution)

Advantages

- High productivity: capacity up to 500 bags/h with the fast solution.

- Operational versatility: ideal for bags that are difficult to handle and for multiple formats.

- Unmanned reliability: perfect for fully automated systems.

IMP.A.C. ROBOTEX 125 A offers a combination of precision, flexibility and automation, making it an optimal choice for companies looking for a modern and efficient solution for bag palletising.

Cartesian bag palletizer

Cycles:

300 sacks/hour basic solution

500 sacks/hour fast solution

Bag dimensions

Max. 1000 x 500 x h. 250 mm

Min. 300 x 200 x h. 80 mm

Pallet dimensions

Max. 1200 x 1000 x h. 140 mm

Min. 1000 x 800 x h. 80 mm

Maximum layer size

Max. 1300 x 1100 mm

Standard full pallet height

1600 mm

Compressed air consumption

100 Nl/min

Max. full pallet weight

2000 Kg

Operational capacity

300-500 sacks/h

Installed power

8,5 KW

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

5000 Kg

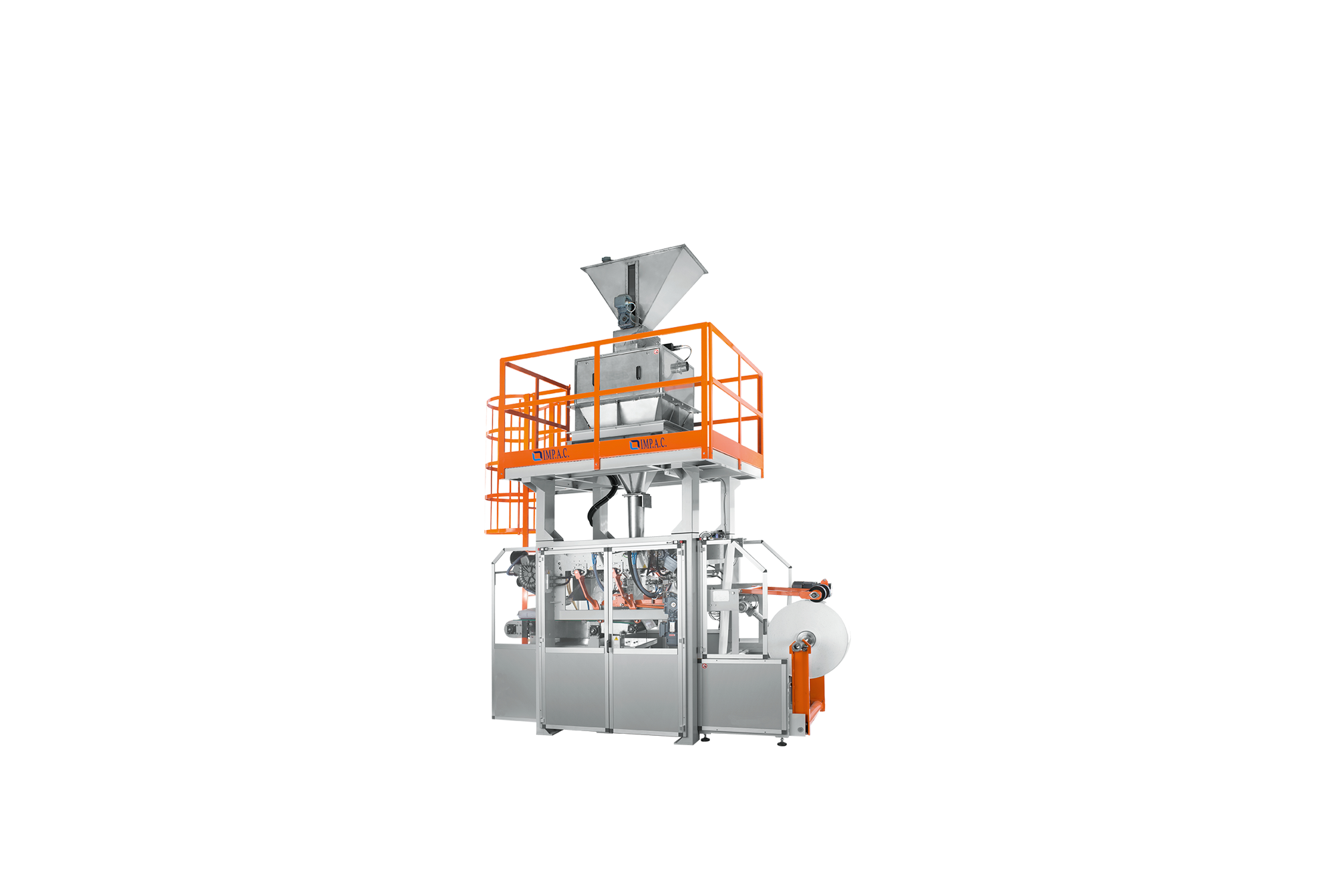

Product benefits

__ Maximum grip flexibility

__ Maximum grip flexibility

The full wrapping gripper ensures safe handling of any type of bag, including paper, jute, plastic, valve, sewn or electro-welded bags, as well as half-empty bags or bags containing materials with high viscosity.

__ Optimum pressing

__ Optimum pressing

Integrated pressing device to ensure stability of the bag on the pallet.

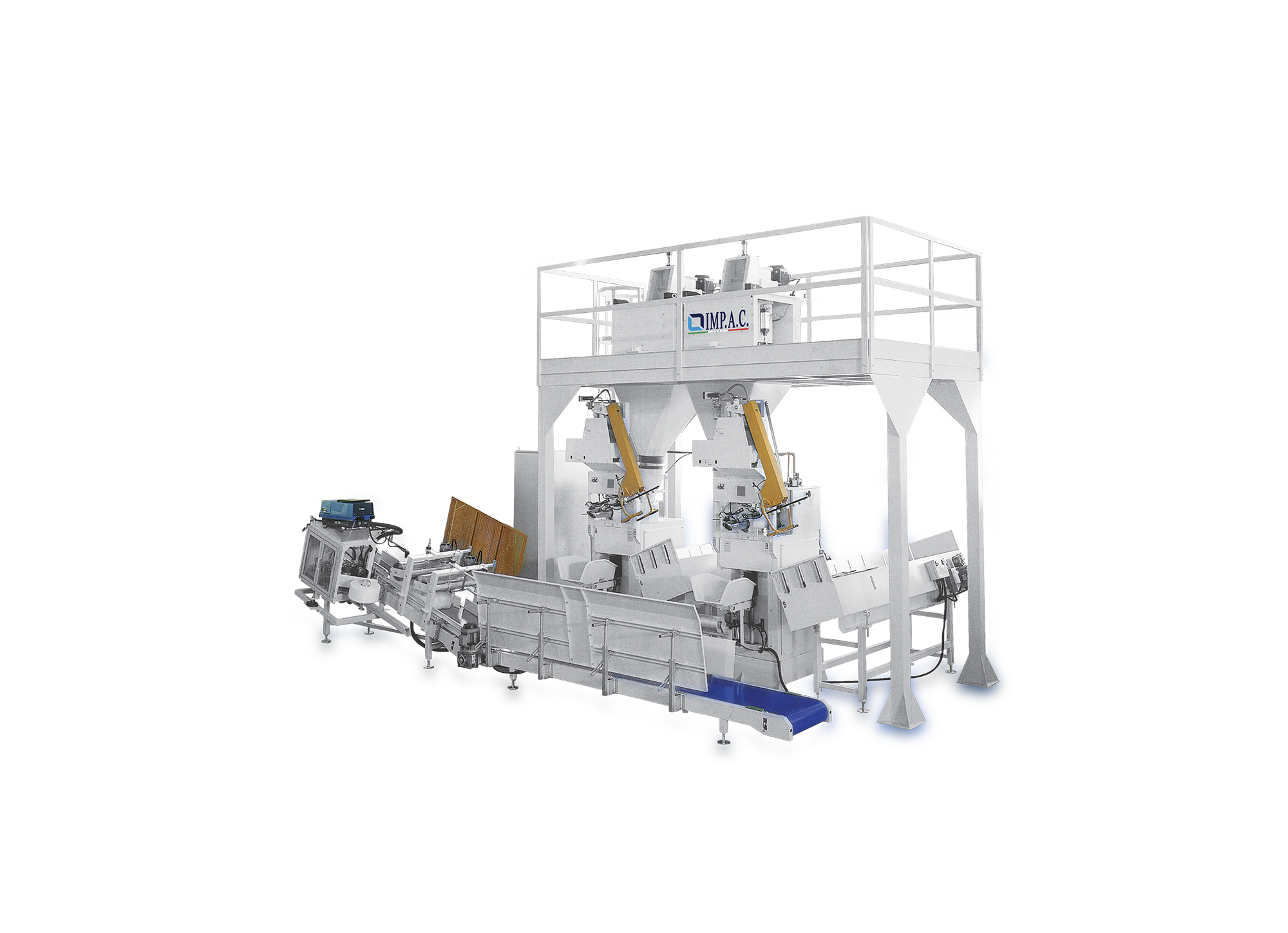

__ Cartesian movement

__ Cartesian movement

Cartesian axis system for precise positioning, controlled by encoder.

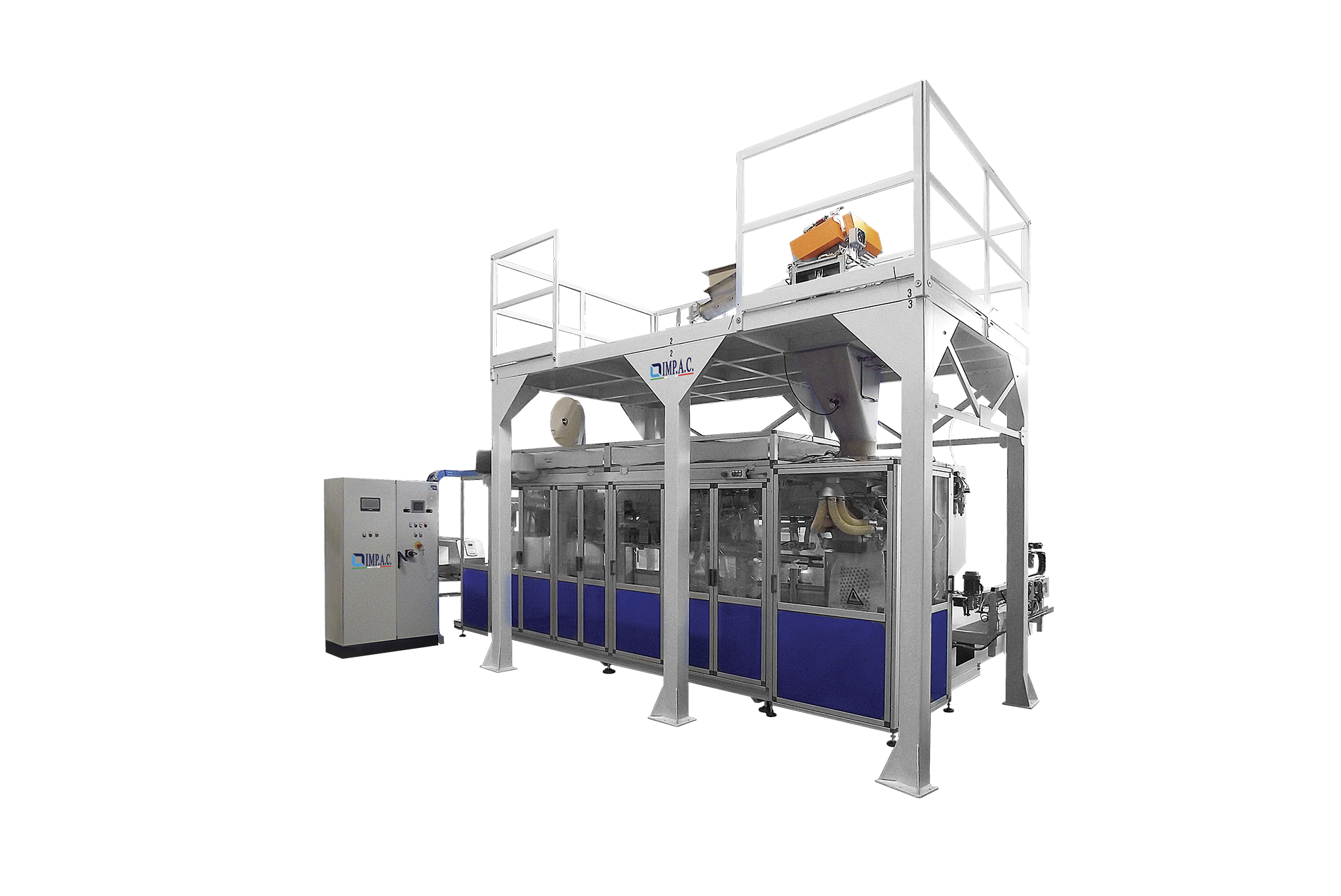

__ Full automation

__ Full automation

All synchronisms are managed by a programmable modular system (PLC), with the possibility of customising programmes for different bag sizes, configurations and number of layers.