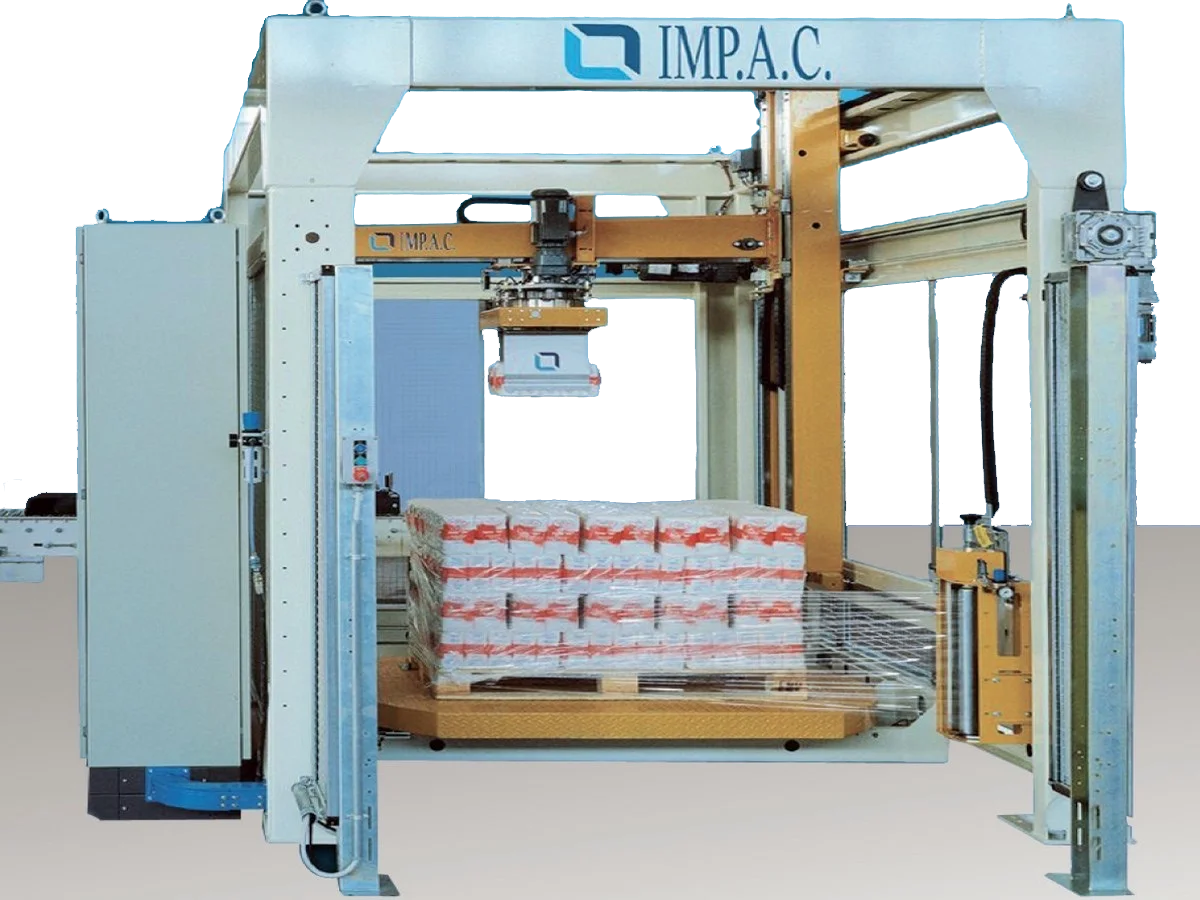

IMP.A.C. ROBOTEX 225 A-SA / 226 A-SA

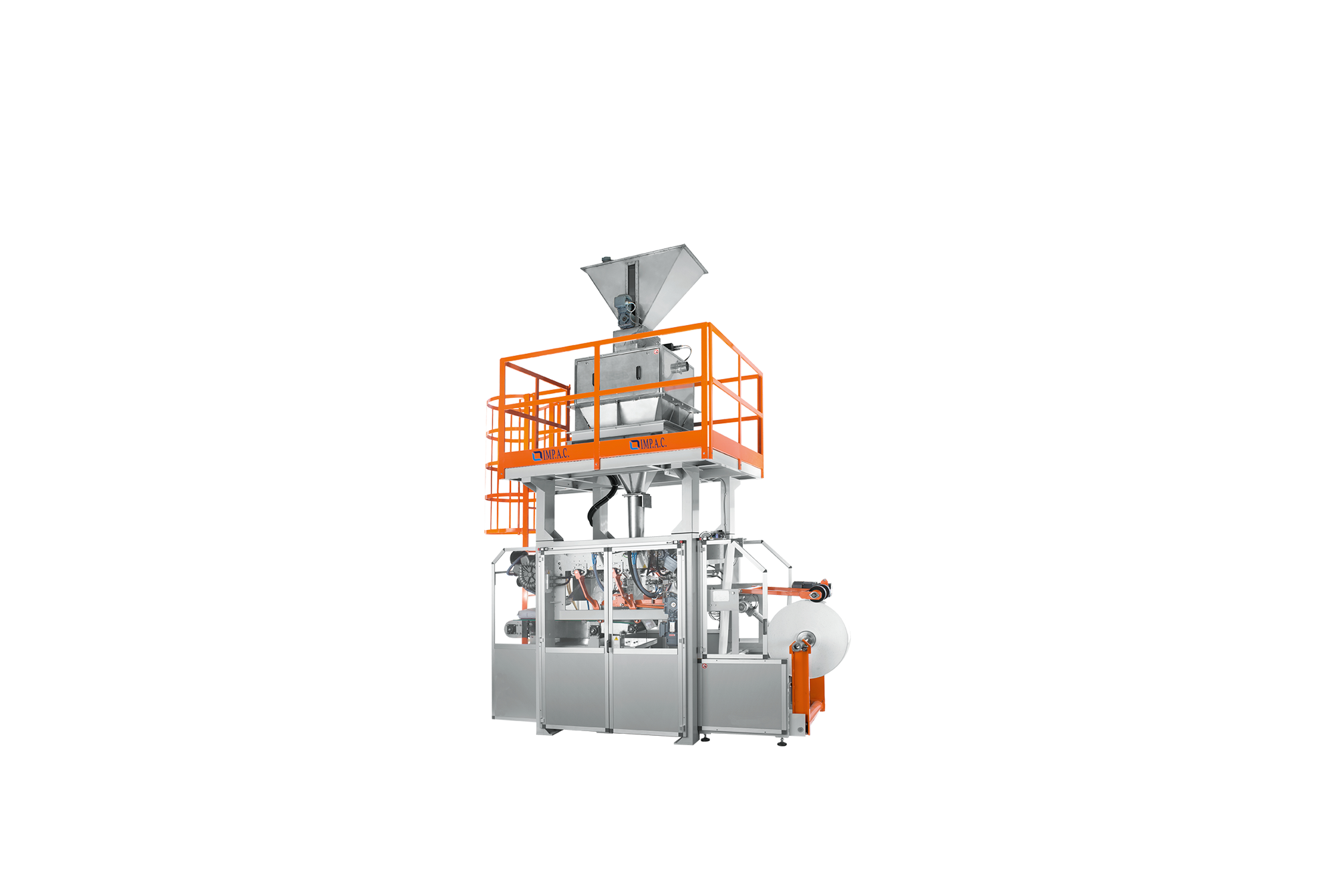

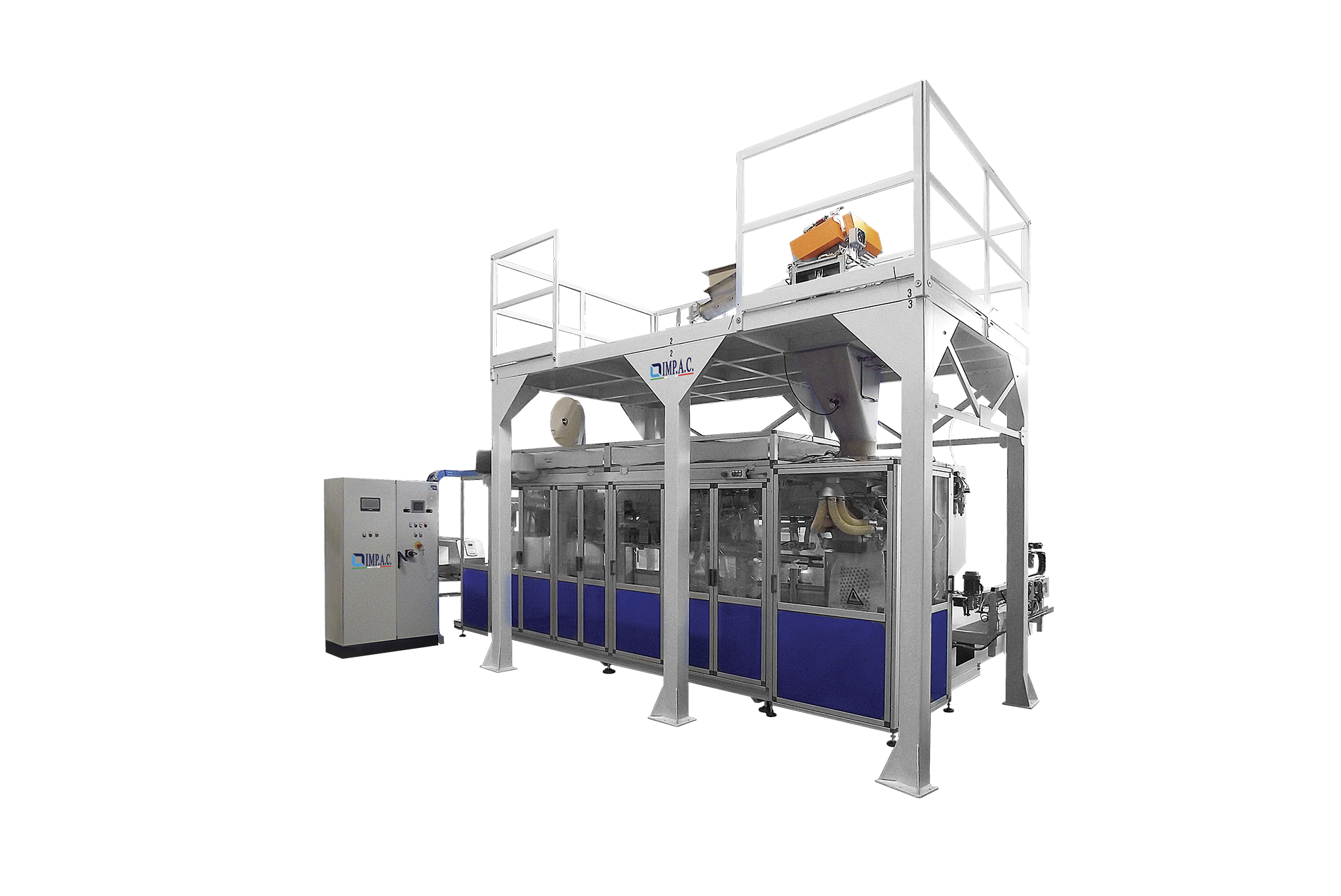

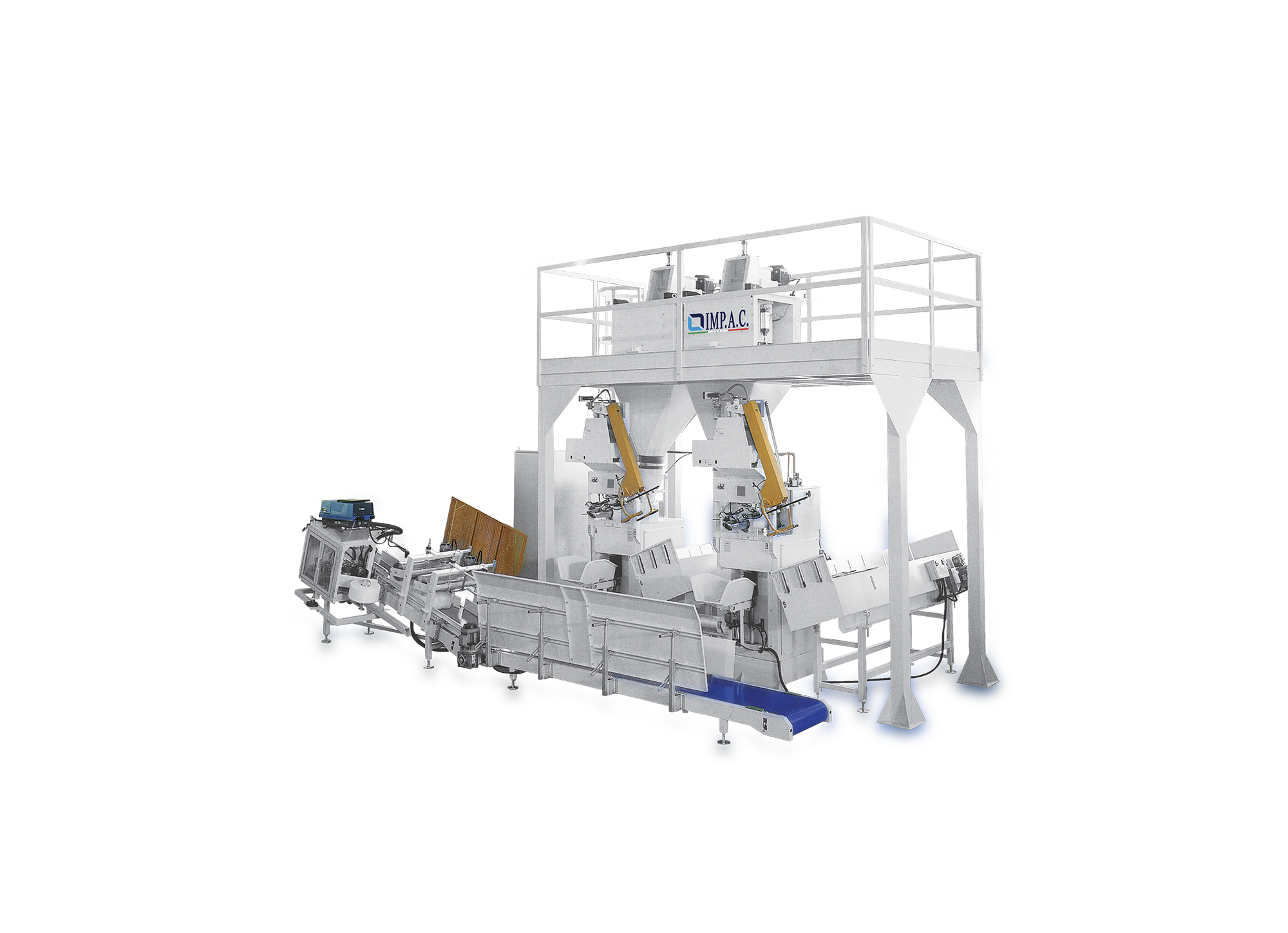

Robotic palletizer for boxes,klt and bundles with semi automatic wrapping system integrated

The IMP.A.C. ROBOTEX 225 A-SA / 226 A-SA is an innovative palletiser designed to meet the demands of versatility, load stability and space optimisation.

Ideal for serial or niche production lines, with a maximum capacity of 300 cycles/h, it offers a reliable solution for end-of-line automation.

Key features

- Versatility in formats and weights: it allows bundles of 10 to 15 kg and cartons of various sizes to be palletised using the same equipment.

- Load stability: thanks to the built-in semi-automatic winder, it guarantees safe palletising even for unstable or slippery bundles.

- Compactness: designed for installation in small spaces, with a minimum footprint of 4000×2400 mm.

- Pressing and uniformity: the pressing device makes the bags pressed and uniform before palletising, improving load stability.

- Complete automation: the Cartesian system, controlled by encoders, allows precise positioning and a fully automatic cycle, from gripping to positioning on the pallet.

- Programmable handling: the modular PLC allows the machine to be easily configured for different sizes, formations and number of layers.

The ROBOTEX 225 A-SA / 226 A-SA IMP.A.C. is a modern and reliable solution for optimising end-of-line operations, combining efficiency, precision and versatility.

Robotic palletizer for boxes,klt and bundles with semi automatic wrapping system integrated

Cycles: 300 carton-bags/hour

Cardboard dimensions

Max. 450 x 400 x h. 300 mm

Min. 200 x 100 x h. 50 mm

Pallet Size

Max. 1200 x 1100 x h. 300 mm

Min. 800 x 600 x h. 100 mm

Maximum layer size

Max. 1300 x 1100 mm

Standard full pallet height

1600 mm

Compressed air consumption

100 Nl/min

Control voltage

24 V

Max. full pallet weight

2000 Kg

Operational capacity

240-300 cycles/h

Installed power

6,5 KW

Operating pressure

6 bar

Indicative weight

4000 Kg