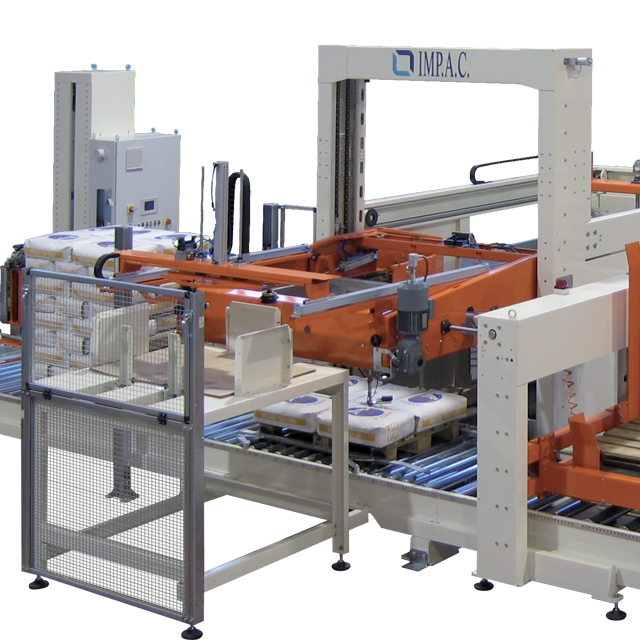

Designed to meet medium to high capacity requirements, the IMP.A.C. 12 A palletiser guarantees reliable performance up to 1100 bags/hour.

Thanks to its advanced technology, the bag is:

- Pressed to achieve uniformity and compactness.

- Orientated according to the predefined formation.

- Started in the pre-forming zone of the layer.

The layer thus composed is transferred to a platform equipped with movements:

- Vertical, to locate and position the discharge area.

- Horizontal, to transfer the layer onto the stationary pallet.

The cycle is repeated automatically until the pallet is completed, which is then evacuated and replaced to start a new cycle.

IMP.A.C. 12 A is the ideal solution for tasks requiring productivity of up to 1100 bags/hour.

Low level palletizer for bags High capacity

Max production: 1100 bags/h

Bag dimensions

Max. 900 x 500 x h. 250 mm

Min. 300 x 200 x h. 80 mm

Pallet dimensions

Max. 1200 x 1000 x h. 140 mm

Min. 1000 x 800 x h. 100 mm

Layer dimensions

Max. 1300 x 1100 mm

Standard full pallet height

1600 mm

Operating pressure

6 bar

Compressed air consumption

150 Nl/min

Max. full pallet weight

2000 Kg

Operational capacity

3.5 layers/min with a limit of 1100 bags/h

Installed power

13 KW

Control voltage

24 V

Electric voltage

400 V / 50 Hz

Indicative weight

9500 Kg

Product benefits

__ Advanced automation

__ Advanced automation

Precise and synchronised management via programmable modular system (PLC).

__ Operational reliability

__ Operational reliability

Designed to ensure continuous and stable cycles.