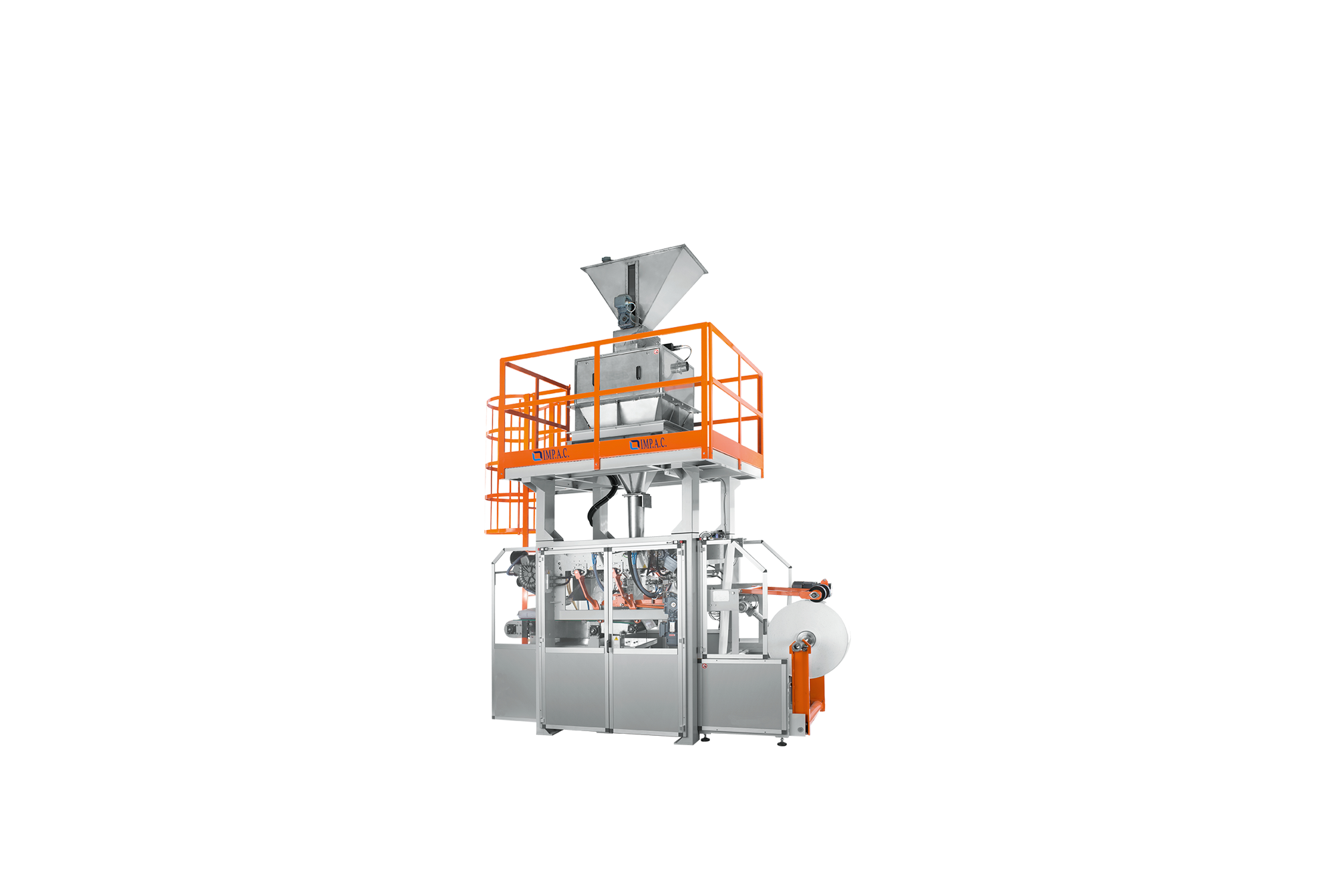

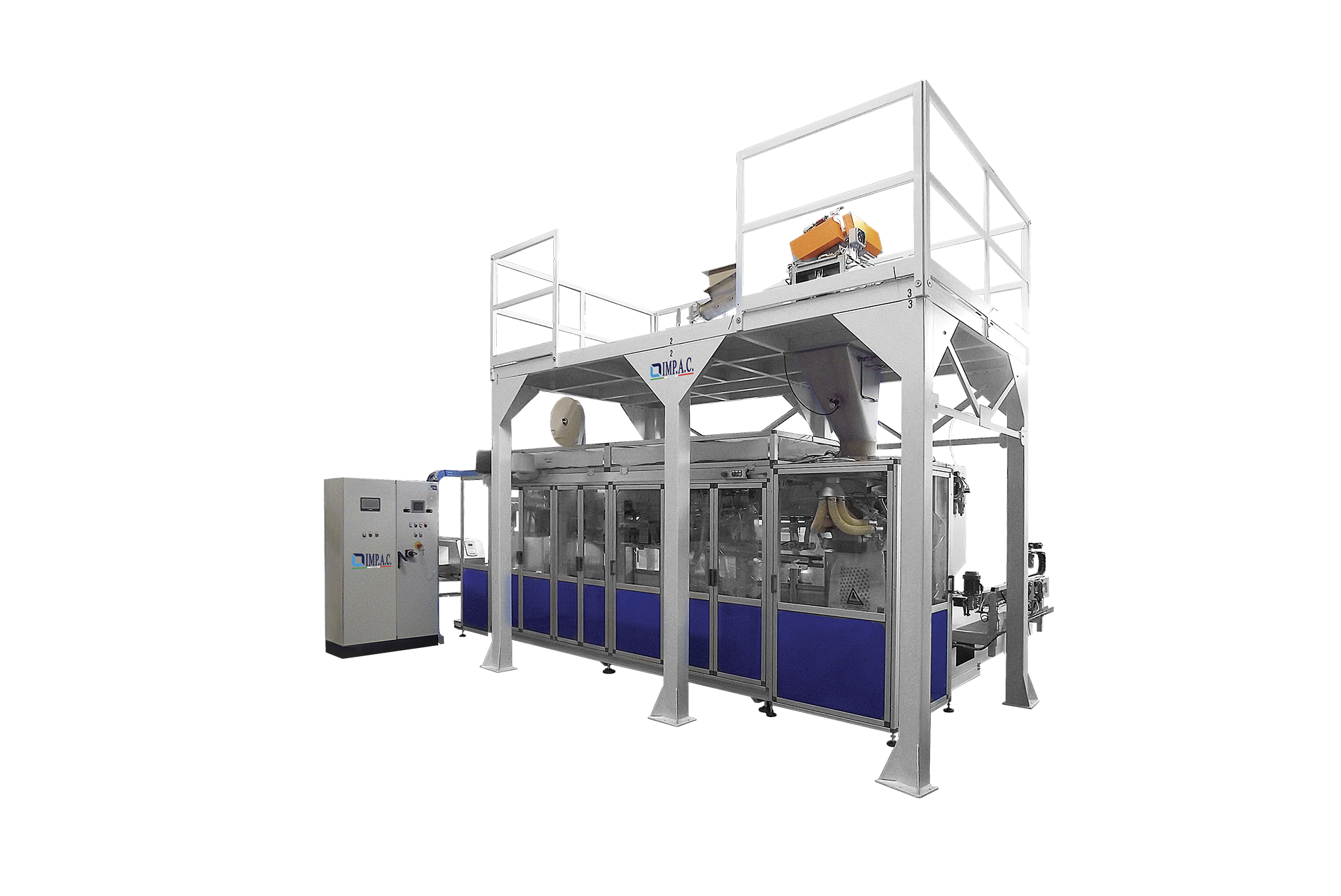

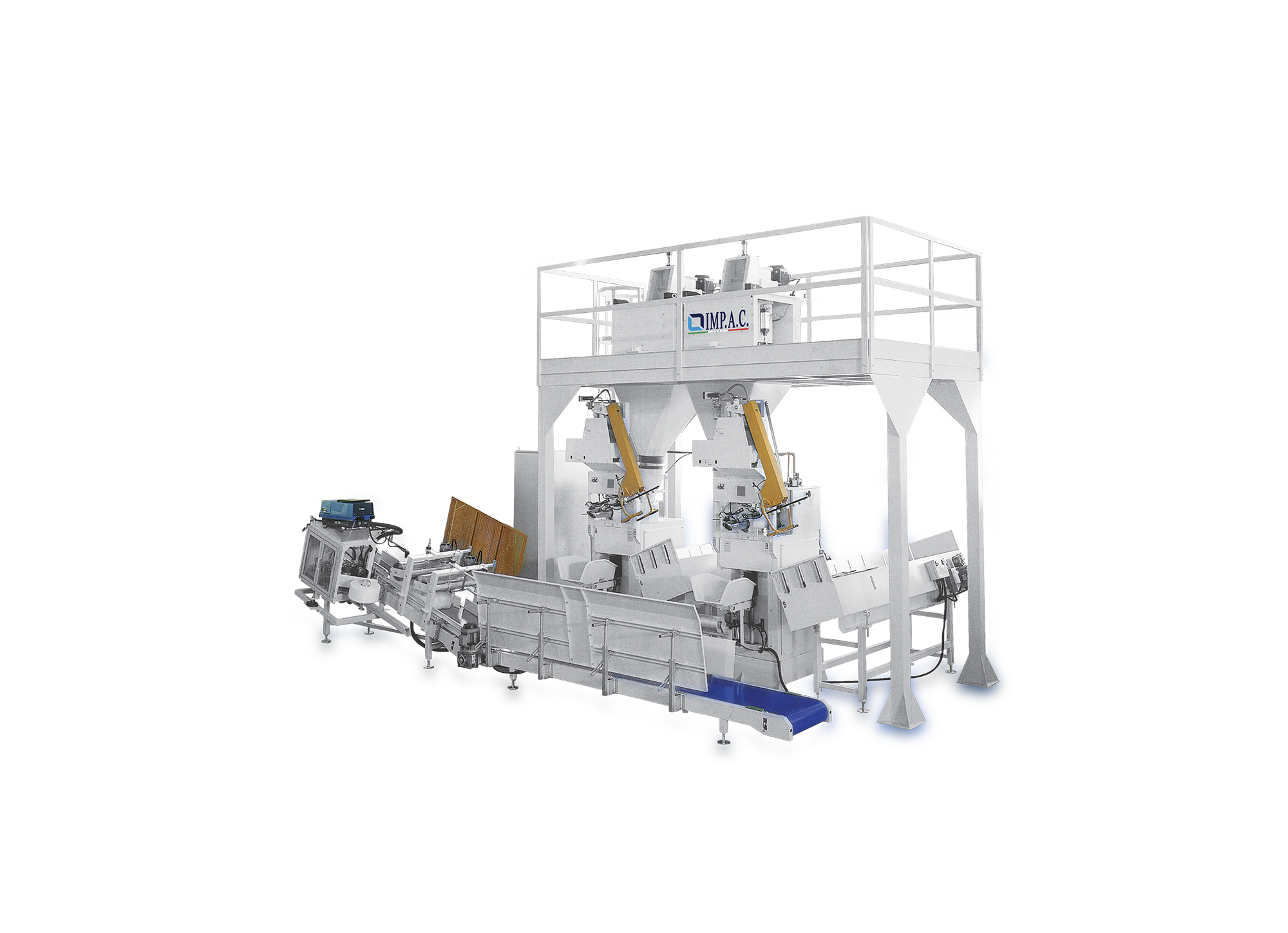

Designed to meet the needs of companies with several production lines running at the same time, the IMP.A.C. 13 AMY MULTILAYER palletiser is the ideal solution for handling several lines with medium to low capacities with maximum efficiency.

Thanks to its unique configuration, this system guarantees flawless organisation of operations: bags from one or more lines are accumulated in layers and pressed to be uniform and compact, then precisely oriented and transferred to a vertical and horizontal handling platform and transferred to the relevant pallet until the palletising cycles programmed for that pallet are completed.

With a maximum production capacity of 900 bags/hour, the IMP.A.C. 13 AMY is a reliable ally for increasing the efficiency and quality of palletising operations in production lines.

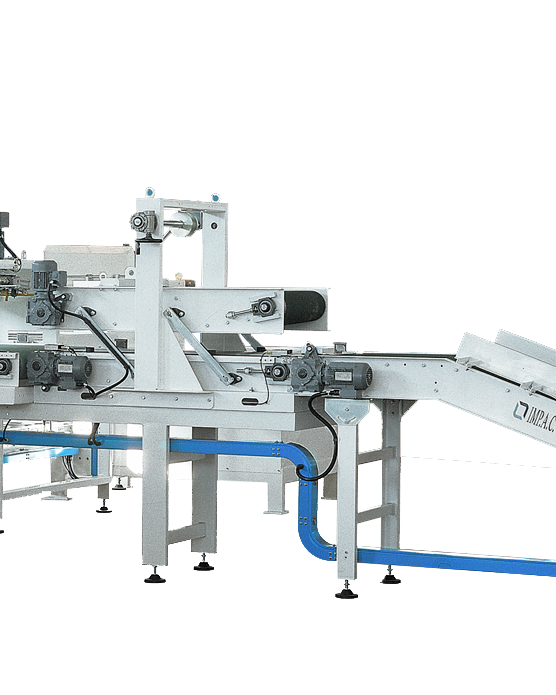

Multilayer Low level palletizer for bags

Max. production: 900 bags/h

Bag dimensions

Max. 900 x 500 x h. 250 mm

Min. 300 x 200 x h. 80 mm

Pallet dimensions

Max. 1200 x 1000 x h. 140 mm

Min. 1000 x 800 x h. 100 mm

Layer dimensions

Max. 1300 x 1100 mm

Standard full pallet height

1600 mm

Operating pressure

6 bar

Compressed air consumption

170 Nl/min

Max. full pallet weight

2000 Kg

Operational capacity

3 layers/min with a limit of 900 bags/h

Installed power

18 KW

Electric voltage

400 V / 50 Hz

Control voltage

24 V

Indicative weight

13000 Kg

Product benefits

__ Accuracy in bag handling

__ Accuracy in bag handling

The bags are carefully pressed and oriented to ensure uniformity and compactness, reducing the risk of errors.

__ Advanced automation

__ Advanced automation

Modular PLC programming ensures total control of each stage, with the possibility of customising the configuration for different formats and palletising schemes.

__ Optimising space and productivity

__ Optimising space and productivity

The ability to handle bags of different sizes and characteristics at the same time allows optimal utilisation of the equipment, without operational interruptions.