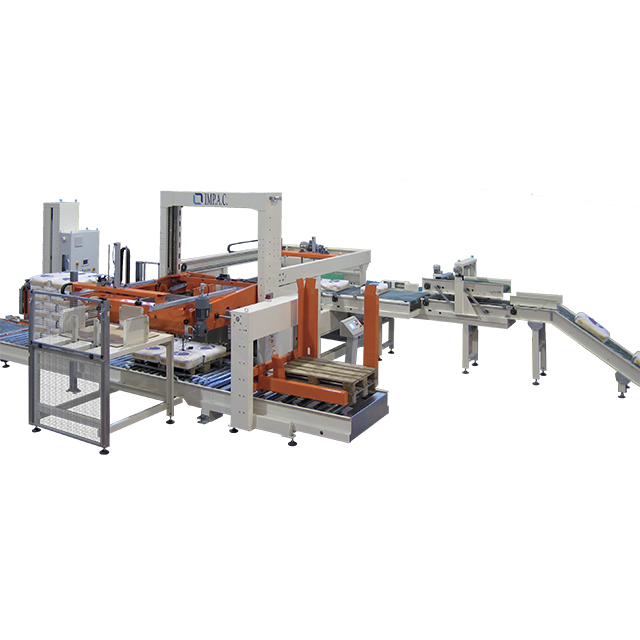

Designed for precision and efficiency, the IMP.A.C. 12 AL palletiser is the ideal solution for operations with production requirements up to 800 bags/hour.

Fully automatic, it combines advanced automation and user-friendliness, making it perfect for optimising the palletising process.

The IMP.A.C. 12 AL palletiser represents the synthesis of high technology and reliability, perfect for increasing productivity and optimising workflow in the bag handling sector.

Low level palletizer for bags

Max. production: 800 bags/h

Bag dimensions

Max. 900 x 500 x h. 250 mm

Min. 300 x 200 x h. 80 mm

Pallet dimensions

Max. 1200 x 1000 x h. 140 mm

Min. 1000 x 800 x h. 100 mm

Layer dimensions

Max. 1300 x 1100 mm

Standard full pallet height

1600 mm

Operating pressure

6 bar

Compressed air consumption

120 Nl/min

Max. full pallet weight

2000 Kg

Operational capacity

2.5 layers/min with a limit of 800 bags/h

Installed power

11,5 KW

Electric voltage

400 V / 50 Hz

Control voltage

24 V

Indicative weight

8500 Kg

Product benefits

__ Production efficiency

__ Production efficiency

Automatic bag orientation and pre-forming to ensure uniformity and compactness.

__ Precise handling

__ Precise handling

Movable platform with vertical and horizontal movements for optimal layer positioning.

__ Versatility

__ Versatility

Compatible with different bag sizes and load configurations.

__ Advanced automation

__ Advanced automation

The programmable modular system (PLC) allows various formats, patterns and layer quantities to be managed, adapting to different production requirements.

__ Continuous cycle

__ Continuous cycle

Automatic pallet change management to ensure business continuity.