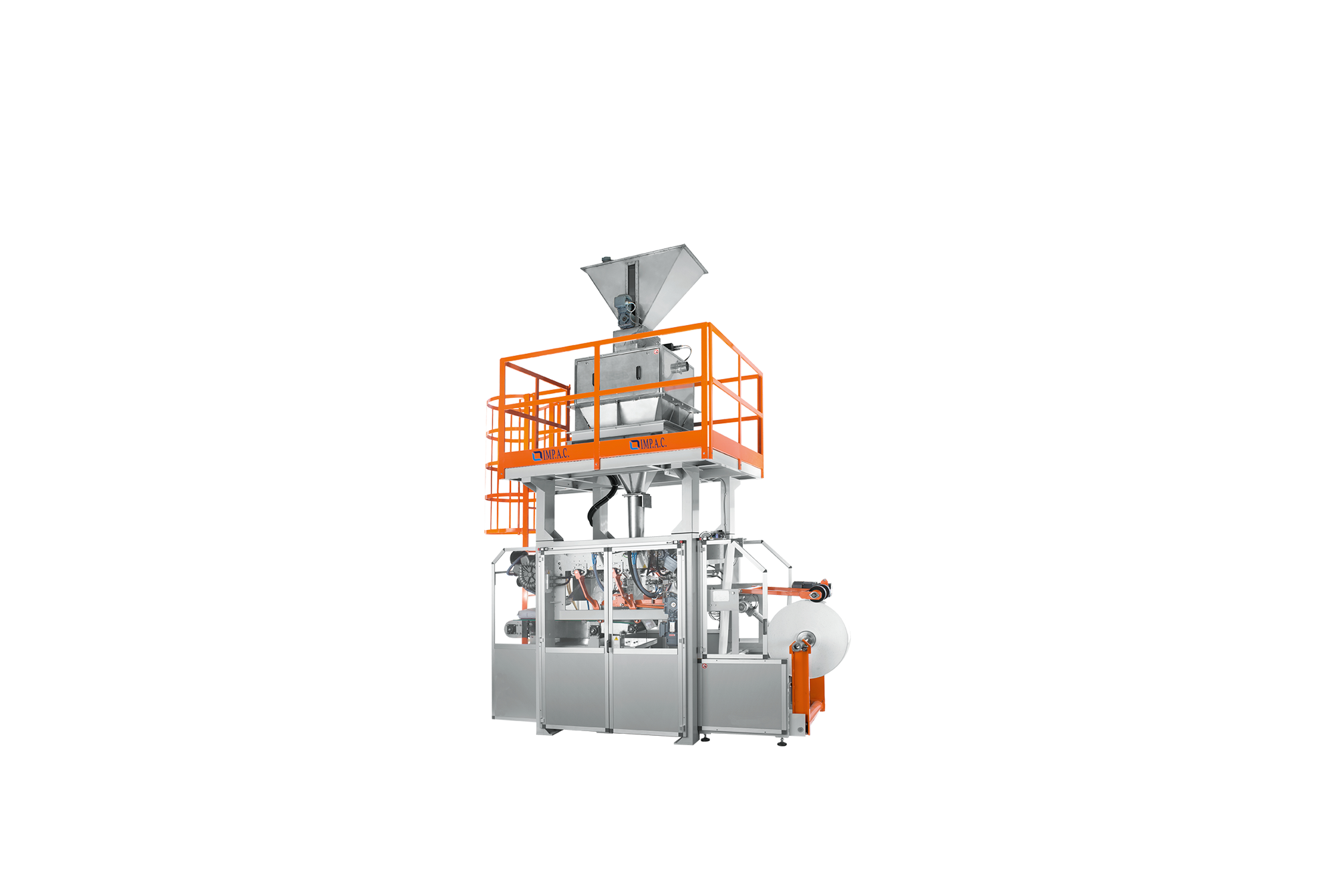

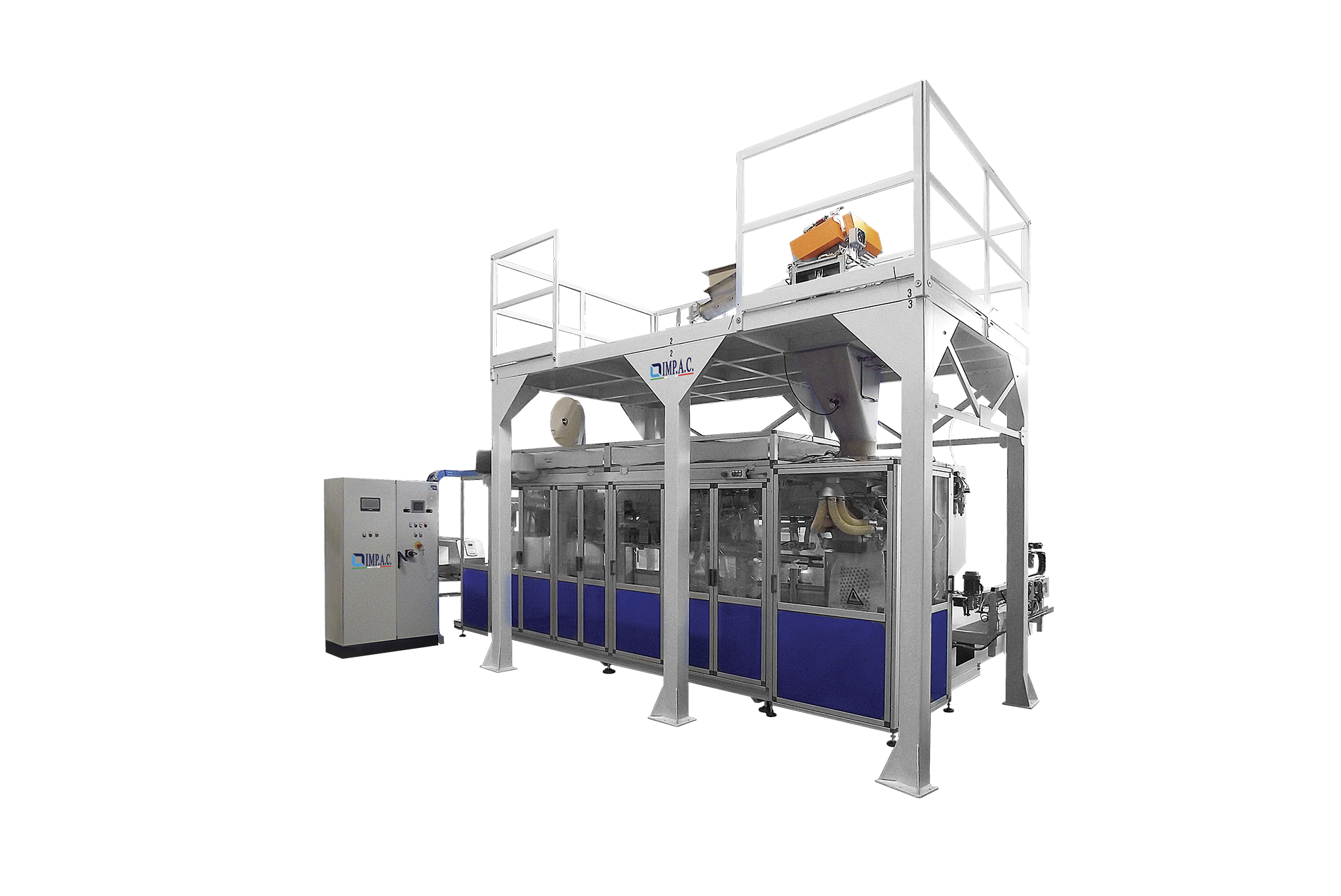

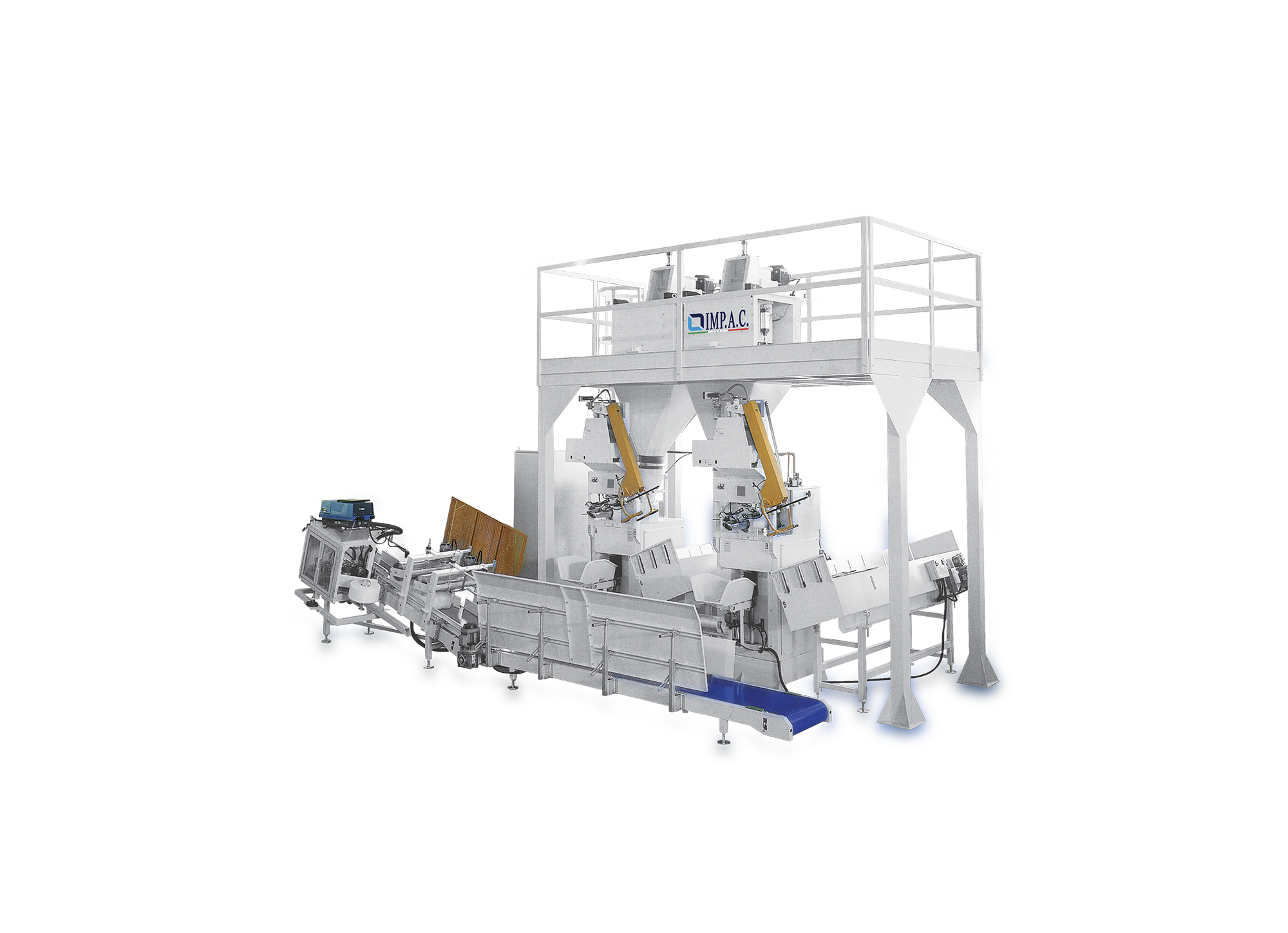

Perfect for low to medium production rates, the IMP.A.C. 12 APT palletiser guarantees efficiency and reliability, with a production capacity of up to 500 bags/hour.

Thanks to its modular design, this model offers the possibility to evolve with the user’s needs, integrating accessories such as roller conveyors and empty pallet magazines.

The fully automated operating cycle is repeated until the pallet is completed, the pallet is manually evacuated and replaced with an empty one for a new process, ensuring continuity and productivity.

Low level palletizer for bags on the pallet at the ground

Max. production: 500 bags/h

Bag dimensions

Max. 900 x 500 x h. 250 mm

Min. 300 x 200 x h. 80 mm

Pallet dimensions

Max. 1200 x 1000 x h. 140 mm

Min. 1000 x 800 x h. 100 mm

Layer dimensions

Max. 1300 x 1100 mm

Standard full pallet height

1600 mm

Operating pressure

6 bar

Compressed air consumption

100 Nl/min

Max. full pallet weight

2000 Kg

Operational capacity

2 layers/min with limit of 500 bags/h

Installed power

7,5 KW

Electric voltage

400 V / 50 Hz

Control voltage

24 V

Indicative weight

5500 Kg

Product benefits

__ Adaptability to production needs

__ Adaptability to production needs

The modular design allows the configuration to be customised according to volumes and operational needs.

__ Optimised bag management

__ Optimised bag management

Bags are pressed to ensure uniformity and compactness, optimising pallet stability

__ Precise and safe handling

__ Precise and safe handling

Modular PLC programming ensures total control of each stage, with the possibility of customising the configuration for different formats and palletising schemes.

__ Advanced automation

__ Advanced automation

The programmable PLC system can handle different bag sizes, formation patterns and numbers of layers, adapting to various production requirements.