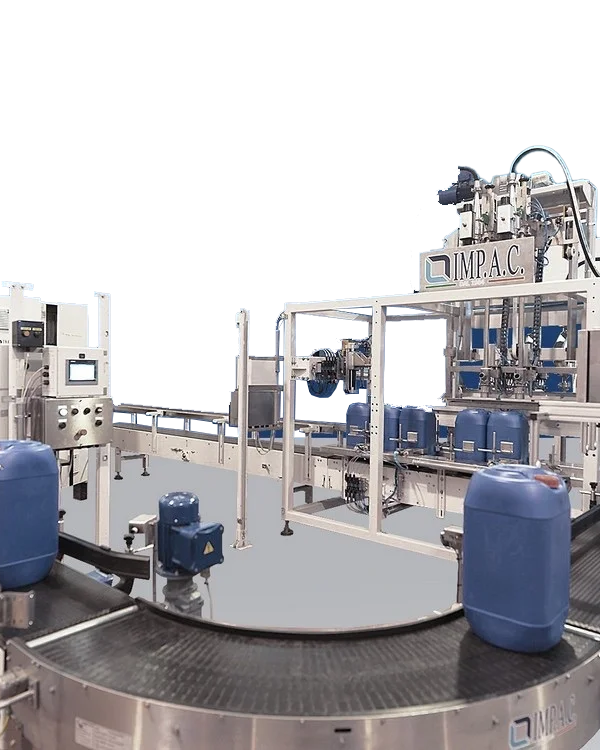

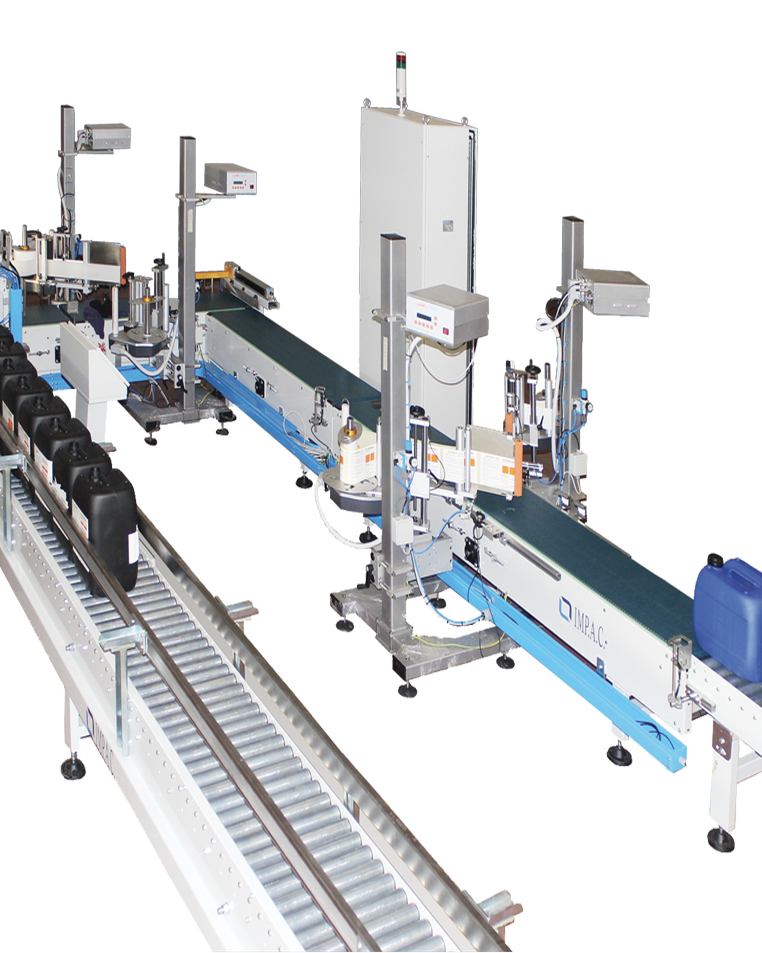

The IMP.A.C. 56 AT-100 is an automatic, compact system for filling and closing single canisters with a capacity ranging from 5 to 25 litres.

Designed for precision, safety and efficiency, the machine is ideal for dosing chemicals and related products, ensuring weight control during filling thanks to the integrated load cell system.

Production capacity

• 120 canisters/hour with 5-liter containers

• 90 cans/hour with 25-liter containers

Available options and accessories

Interchangeable filling nozzles – Suitable for different viscosities and product characteristics.

ATEX compliance (Zone 1 and 2) – Version certified for operation in explosion-hazardous environments.

Exhaust system – For safe elimination of fumes and vapours, ensuring a protected working environment.

Industrial applications

Chemical industry – Filling of solvents, paints, industrial oils and detergents.

Pharmaceutical industry – Dosing of sensitive liquid products with high standards of precision.

Agrochemicals – Filling of liquid fertilisers and agricultural products.

Lubricants and Automotive – Filling of engine oils, lubricants and technical fluids.

Thanks to its high reliability and flexibility, the IMP.A.C. 56 AT-100 is the ideal solution for production lines requiring precision, safety and advanced automation.

Compact automatic filling and sealing machine for single canisters

Max. production120 canisters/h of 5 litres90 25-litre canisters/hour

Type container

Tanks

Container size

Max. 300 x 350 x H600 - Ø350 mm

Min. 150 x 200 x H200 - Ø150 mm

Weight tolerance

20 g

Compressed air consumption (in case of IP 55 protection)

30 to 50 Nl/min

Air pressure

6 bar

Total empty weight

1200 Kg

Installed power (in case of ATEX zone 1 protection)

0.2 KW to 2.5 KW - 400 V

Container weight

Max. 25 l

Min. 5 l

Nozzle height adjustment

200/600 mm

Production time = cycle time + Filling time (TR)

20 s + TR

Compressed air consumption (in case of ATEX zone 1 protection)

5000 Nl/min

Container handling

Motorized

Installed power (in case of IP 55 protection)

2,5 KW - 400 V

Product benefits

__ Versatility

__ Versatility

Compatible with canisters from 5 to 50 litres, adapting to different production needs.

__ Advanced automation

__ Advanced automation

The system handles filling and closing automatically, reducing operator intervention to a minimum.

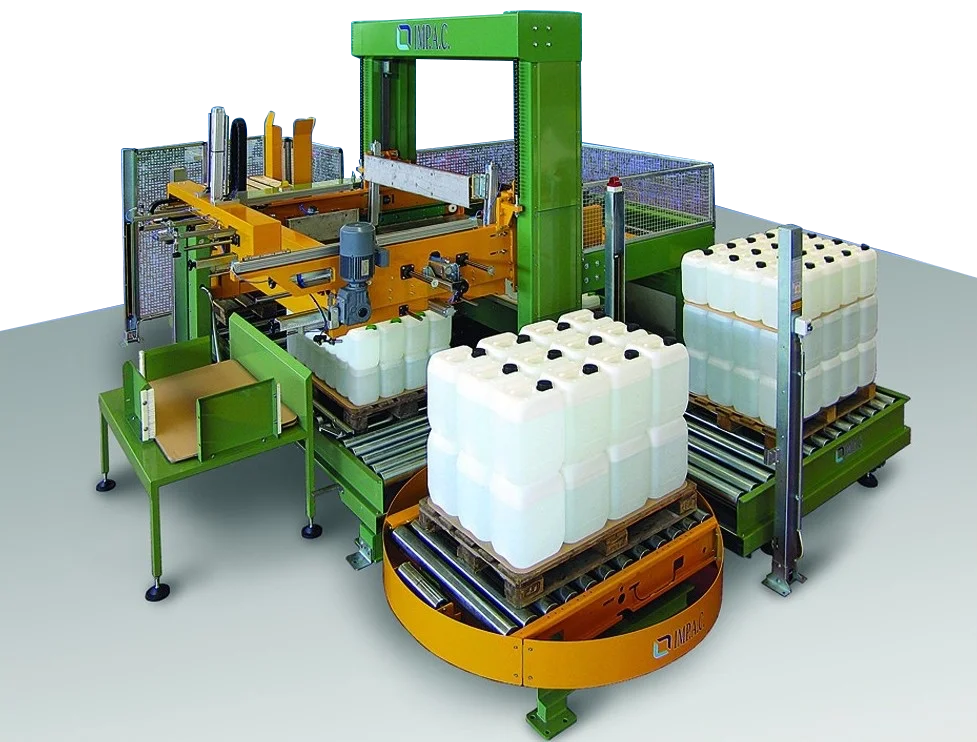

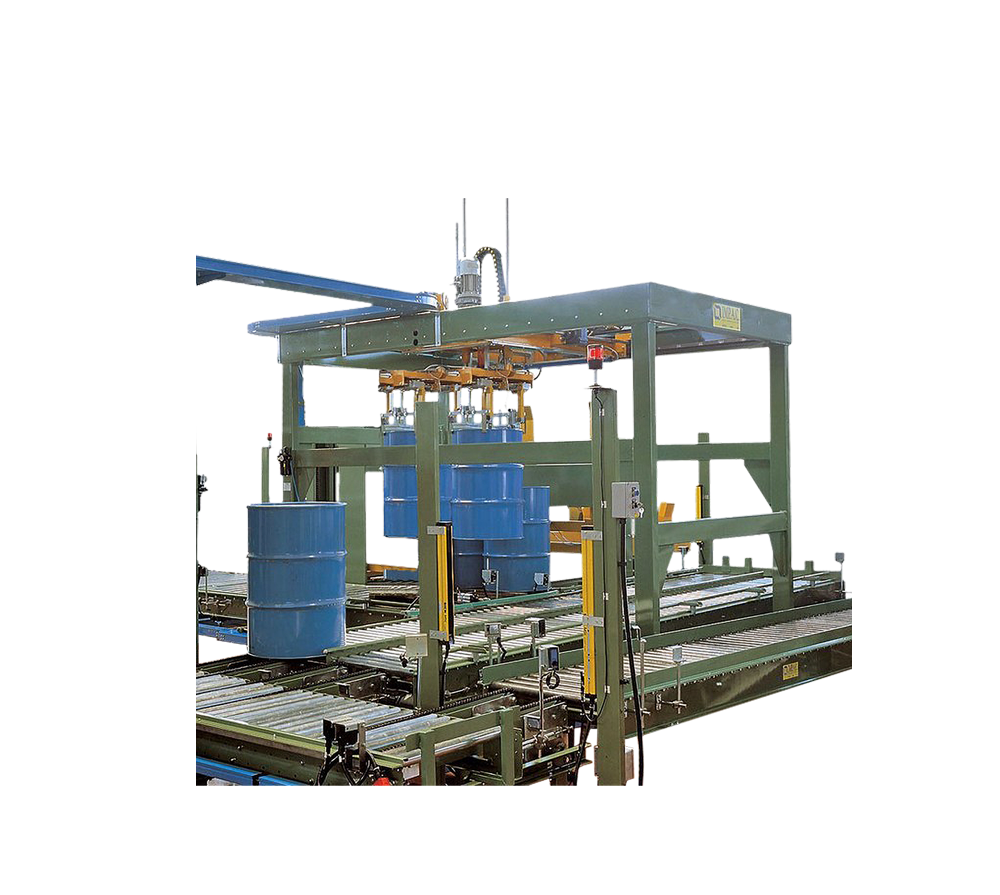

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

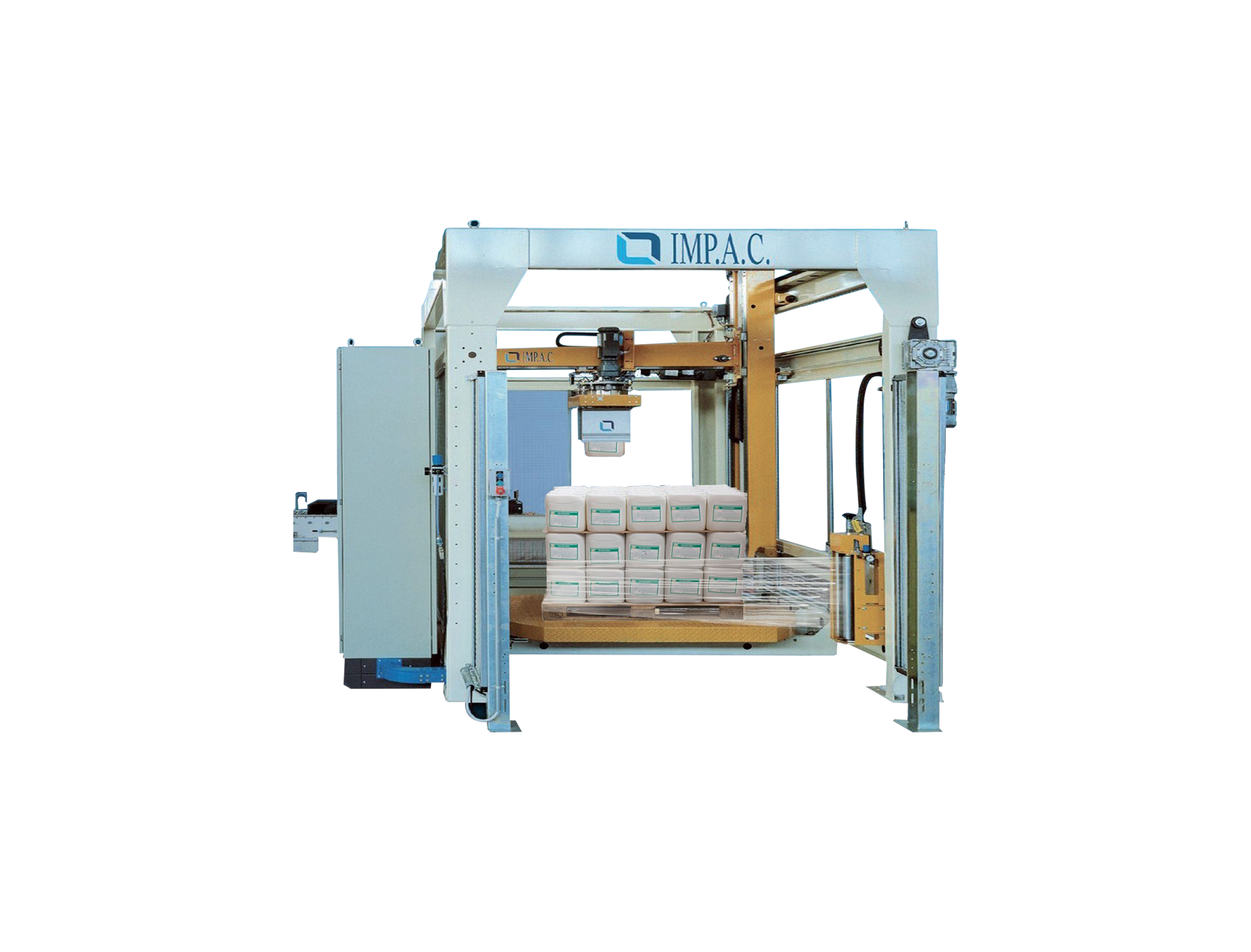

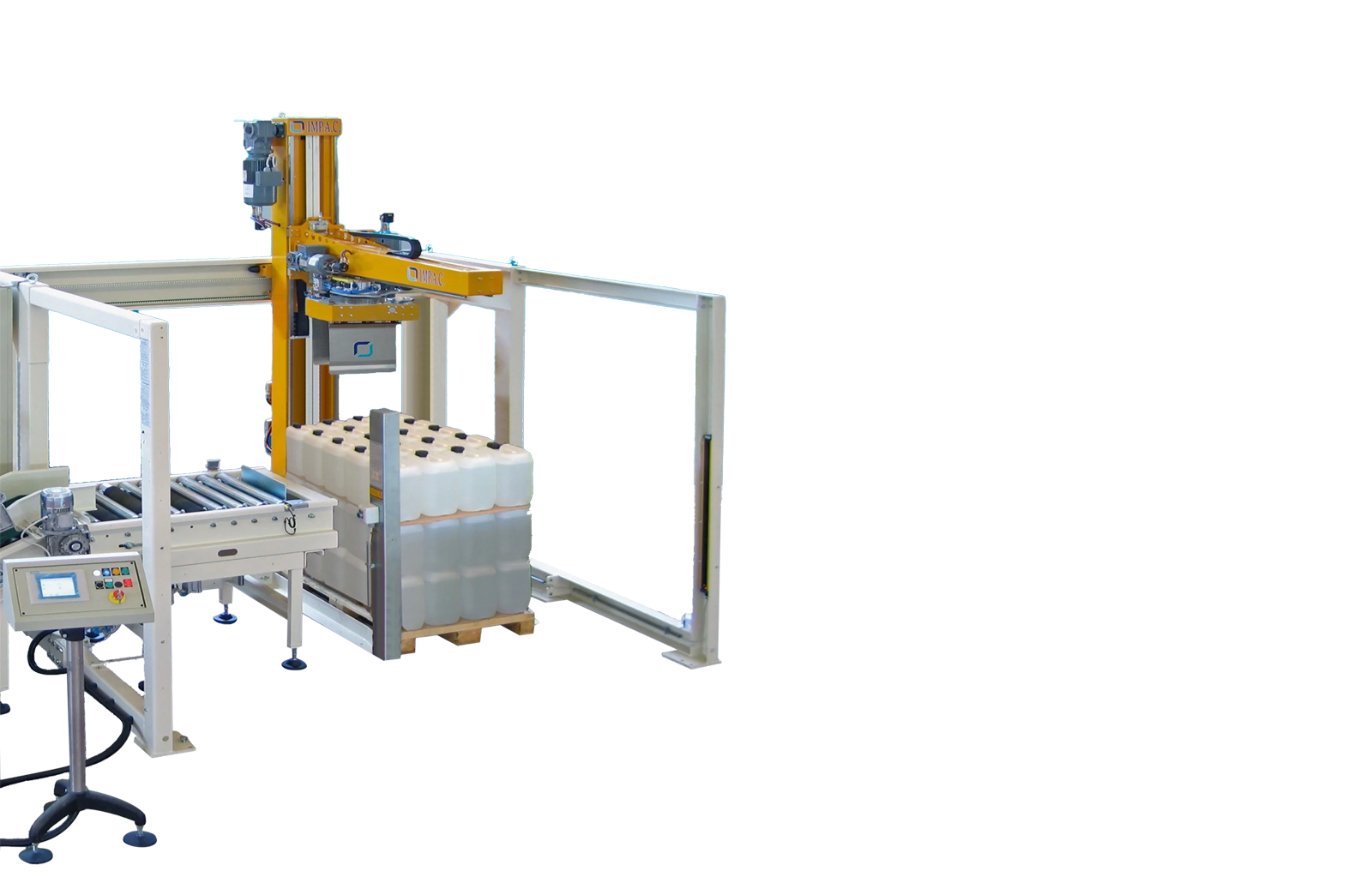

- Stretch wrapping machines

- Stretch hood machines

- Low-Level Palletizer for cans

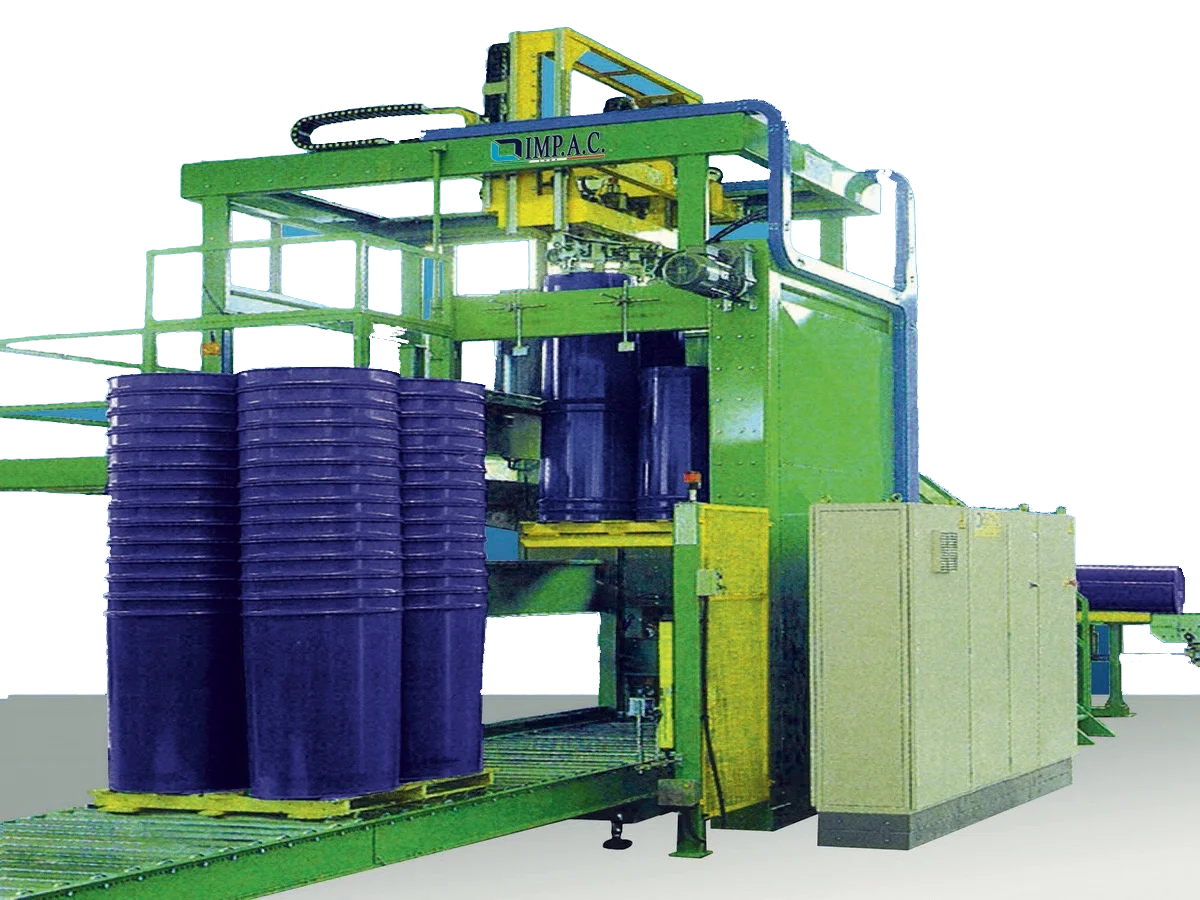

- Cartesian robots for drums, jerrycans and pails

- Monocolumn Robot Palletizer and Depalletizer for cans pails and drums

- High level Robotic palletizer for conical drums

- Anthropomorphic Robot Palletizer and Depalletizer for cans, pails and drums