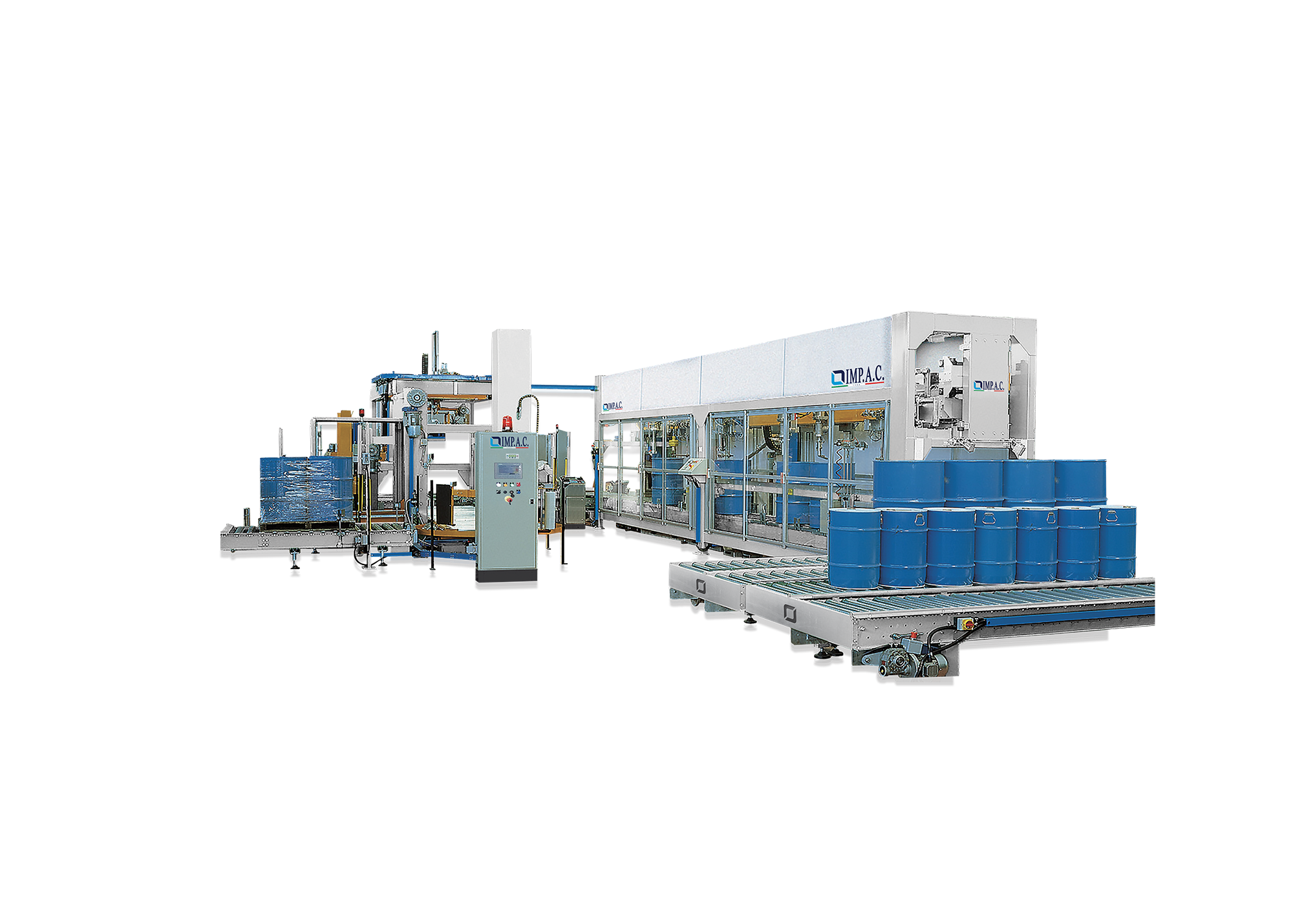

IMP.A.C. 56 A2 ASAutomatic self-adjusting in-line filling machine with orientation, uncorking, double filling nozzle, capping and sealing

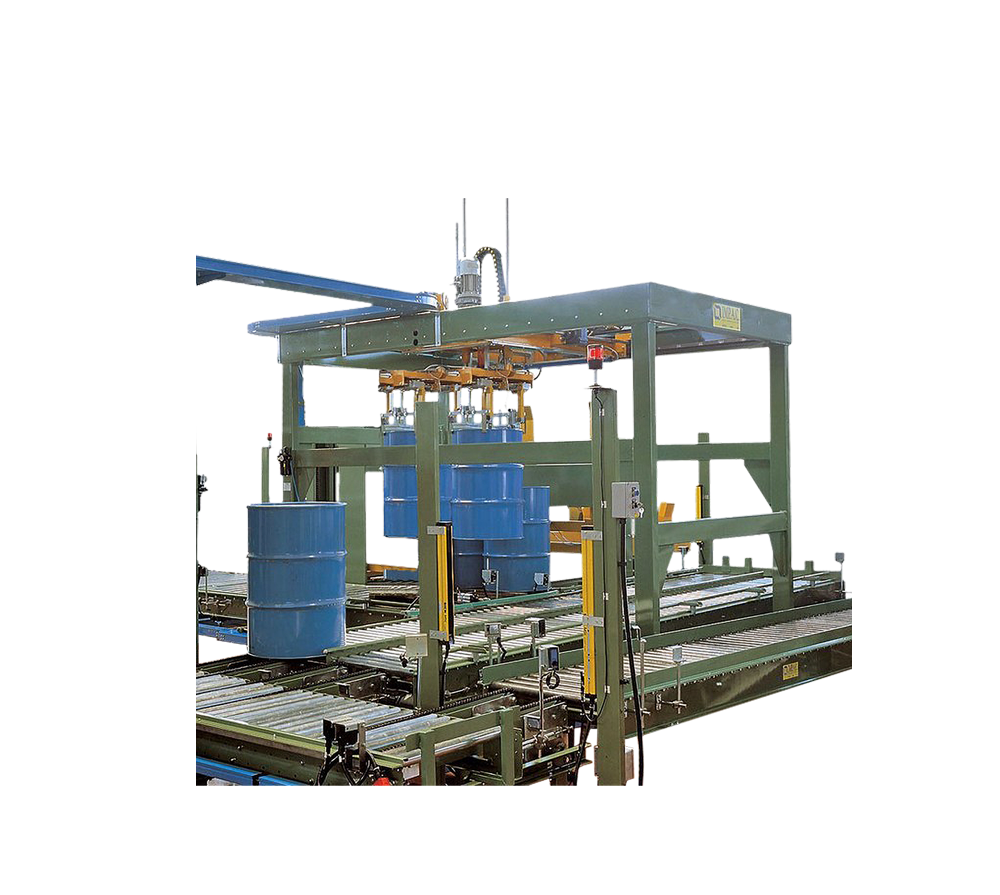

The IMP.A.C. 56 A2 AS is an ideal plant for automating the filling process of chemicals in 2’ spout and open top drums ranging from 60 to 220 litres.

The plant is complete with:

• Latest generation PLC to manage automatic format change

• Weighing system with load cells for weight control during the filling process

• Automatic devices for orienting, uncorking, capping and sealing containers.

Main features:

• 120 cycles/hour

• available for different types of packaging

• high output

• possibility of integration with company management systems

• customisable layout

• easy-to-use HMI

• extreme versatility in packaging

• safety

• automatic orientation

• automatic uncorking/tapping

• cap presence control

• filling by weight/weight control

• automatic pallet handling

Can be supplemented with:

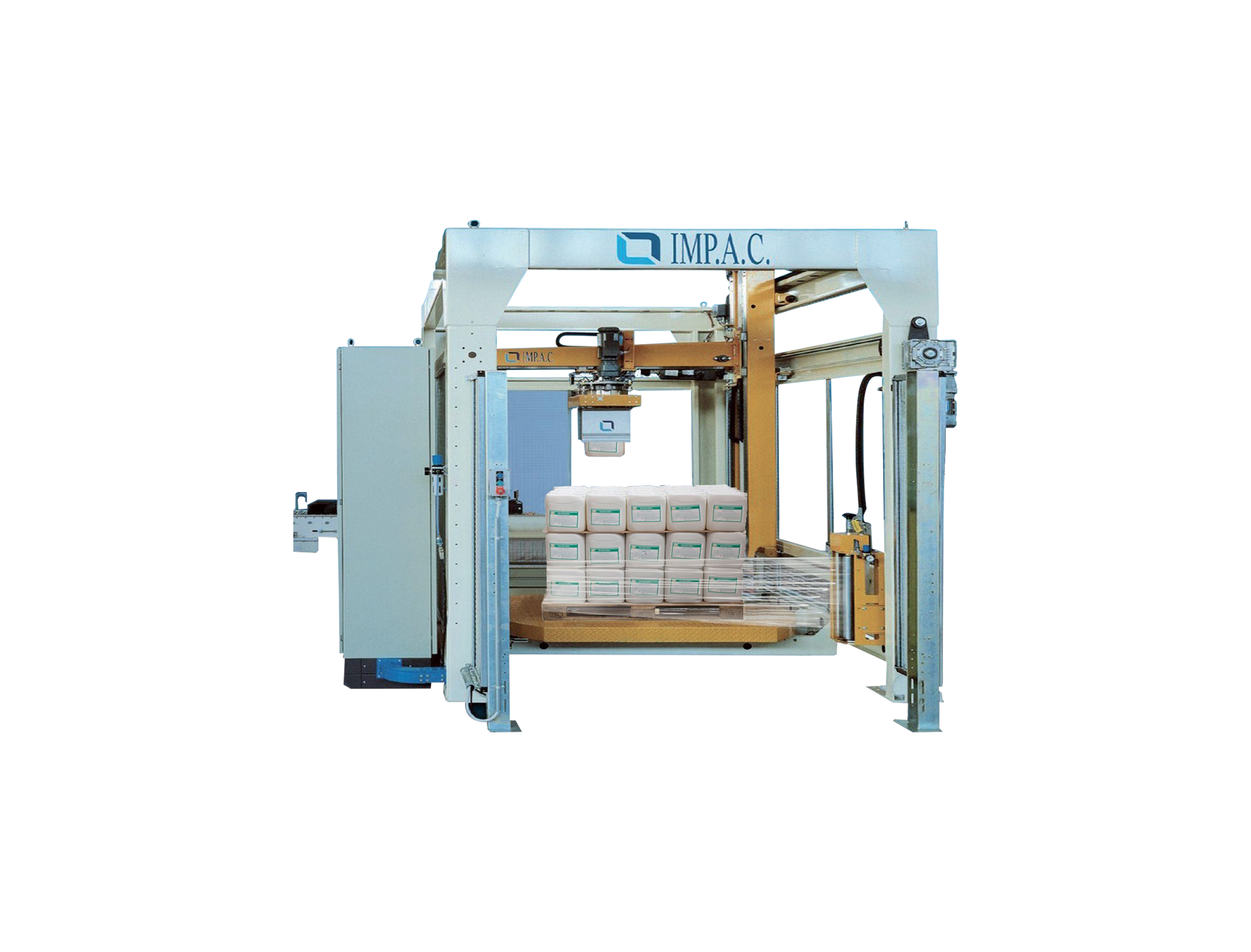

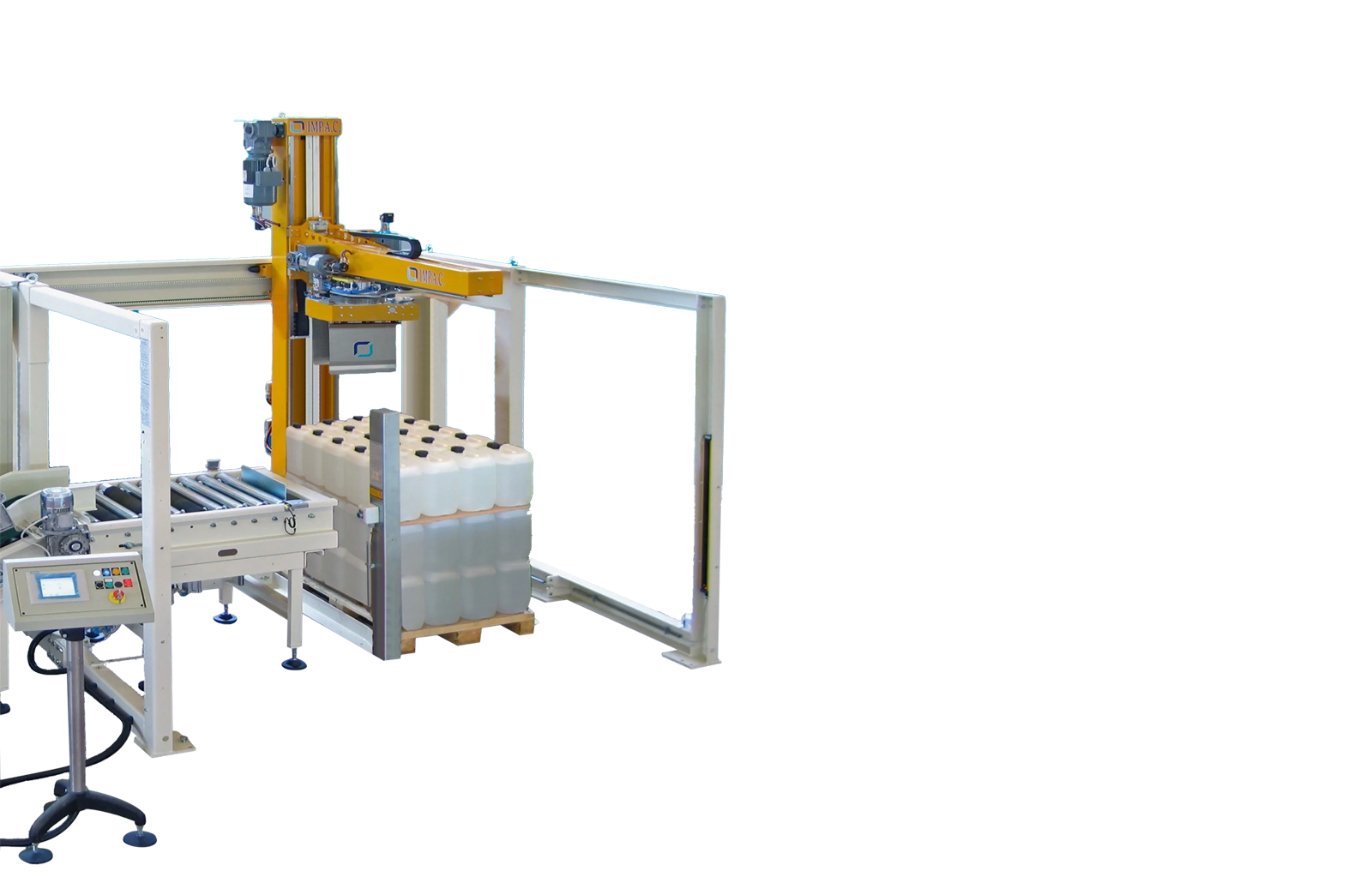

• winder

• hooder

• palletiser

Automatic self-adjusting in-line filling machine with orientation, uncorking, double filling nozzle, capping and sealing

Max Production:60 l / 120h drums200 l / 80h drums

Type container

Drums

Max. container size

Diameter 600 x h 1000 mm

Compressed air consumption

250 Nl/min

Air pressure

6 bar

Indicative weight

8000 kg

Container capacity

Min. 60 l

Max. 220 l

Operational capacity

up to 120 drums/h

Installed power

6,5 Kw / 400 V

Product benefits

__ Advanced automation

__ Advanced automation

120 cycles/hour

__ Versatility

__ Versatility

Availability for different types of packaging

__ Customizable layout

__ Customizable layout

Adaptable to various needs

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

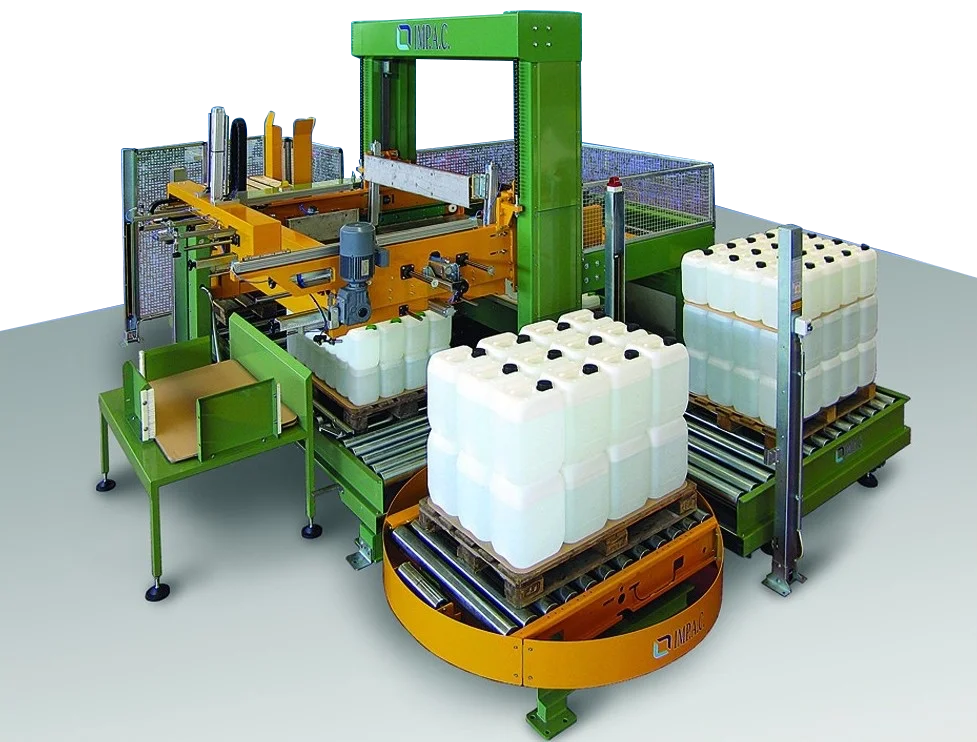

- Stretch wrapping machines

- Stretch hood machines

- Low-Level Palletizer for cans

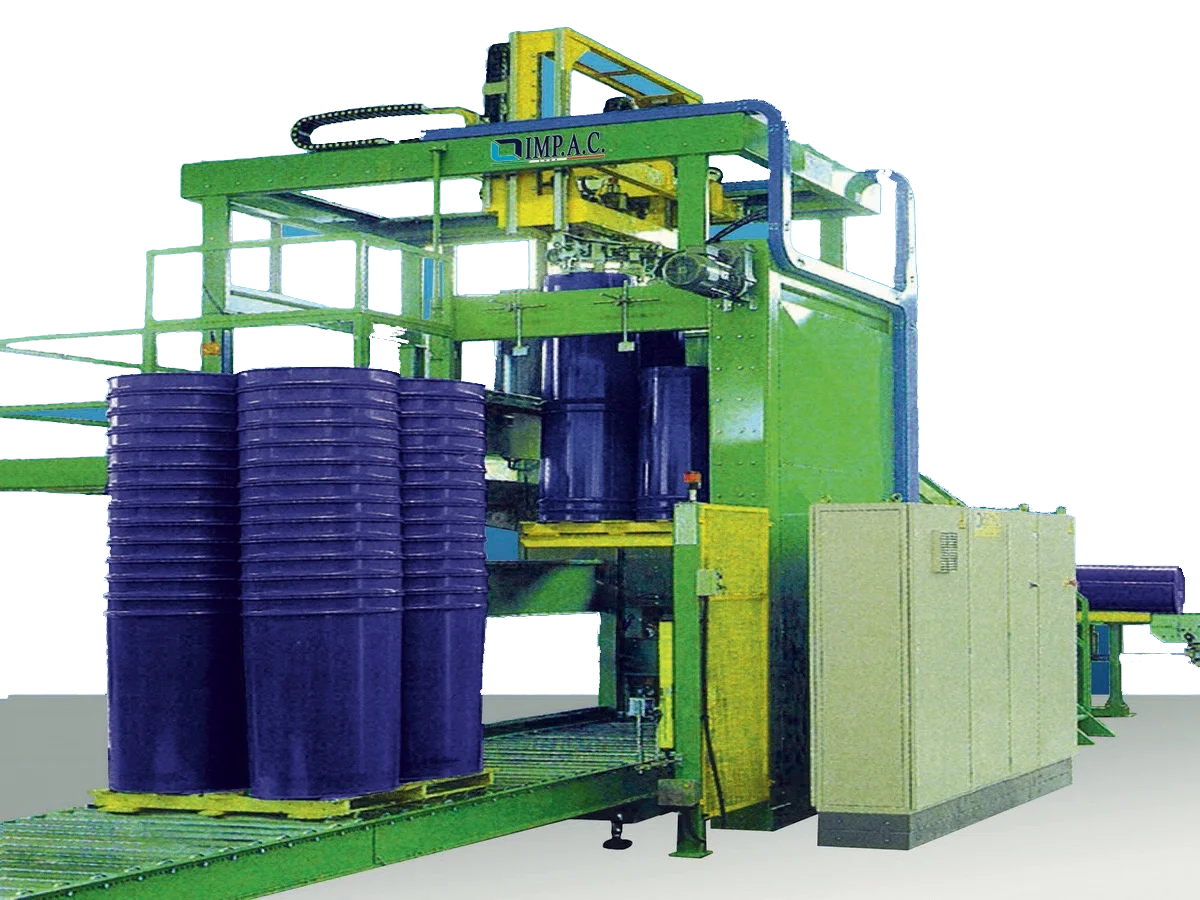

- Cartesian robots for drums, jerrycans and pails

- Monocolumn Robot Palletizer and Depalletizer for cans pails and drums

- High level Robotic palletizer for conical drums

- Anthropomorphic Robot Palletizer and Depalletizer for cans, pails and drums