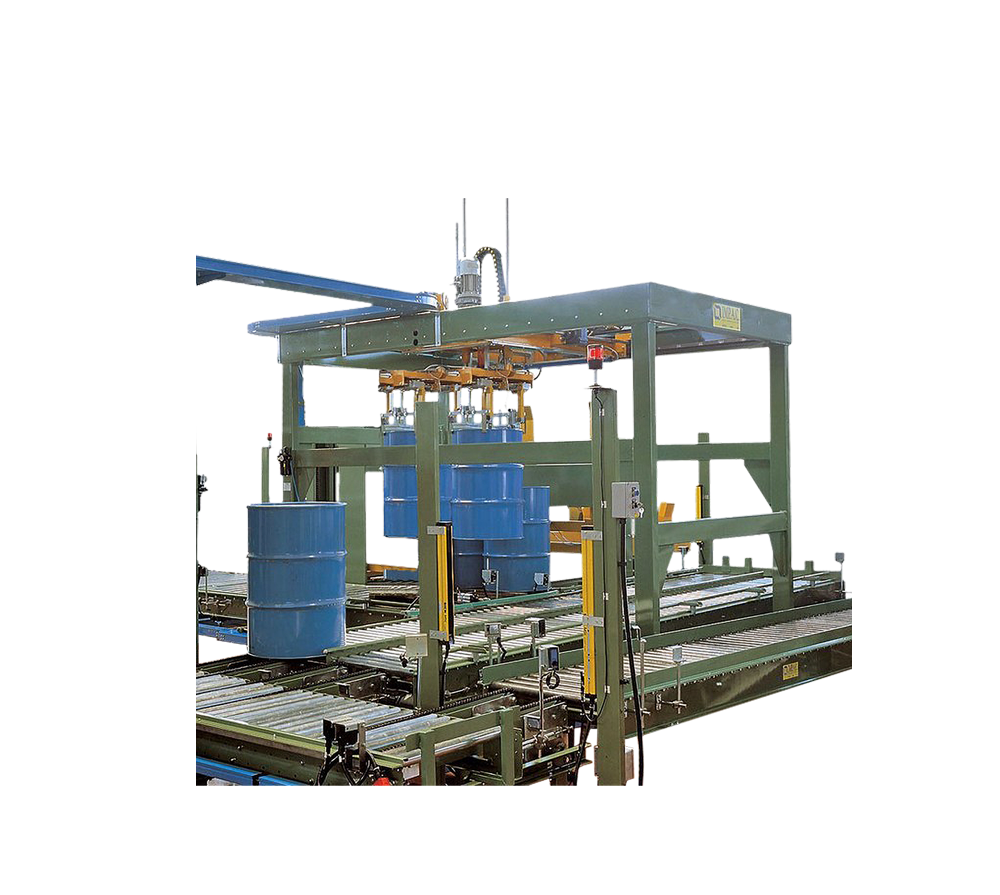

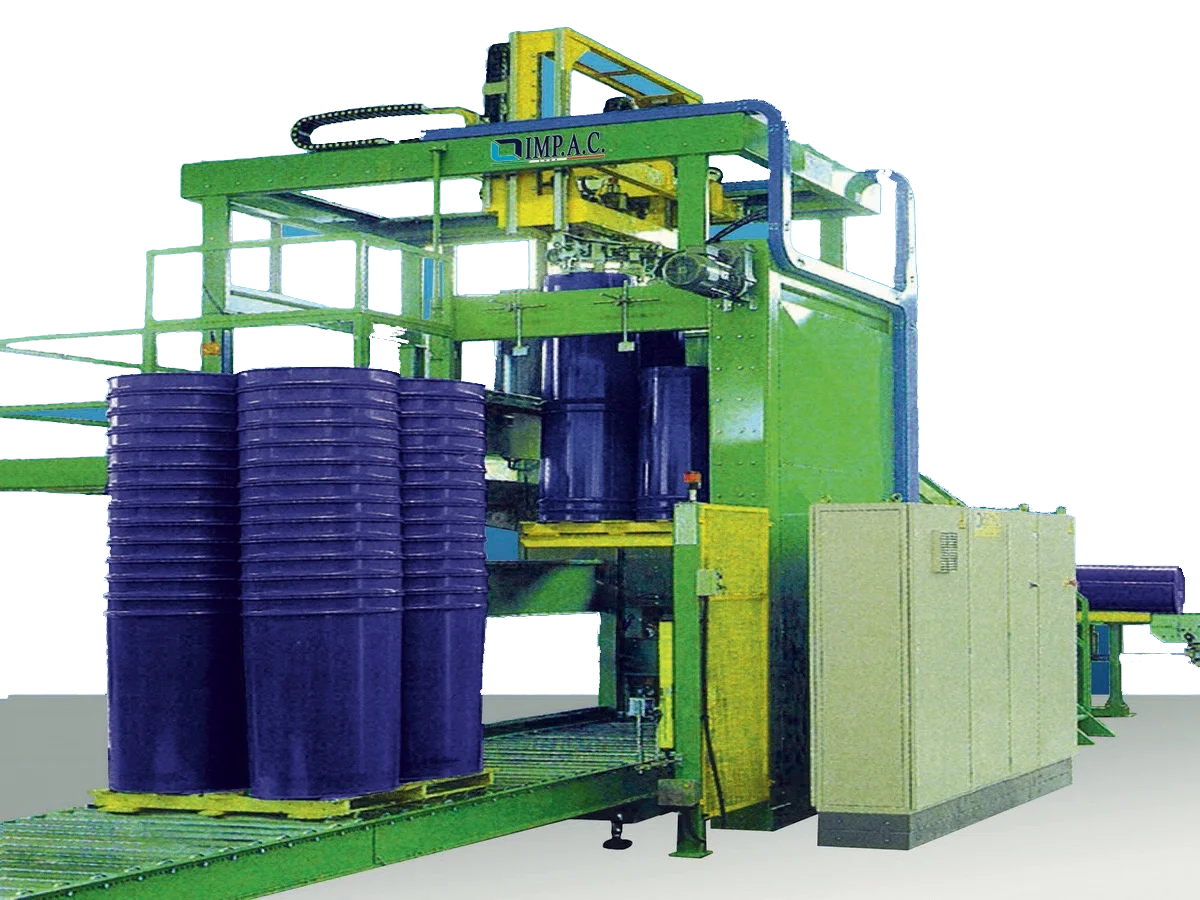

The IMP.A.C. 56 A 4P 1500 is an automatic filling line for IBCs and drums that is ideal for automating the filling process of chemicals in open top drums on pallets and IBCs with weights ranging from 50 to 1500 litres.

The plant is complete with:

• Latest generation PLC with automatic format change

• Weighing system with load cells for weight control during the filling phase

Main features:

• 40 drums/h – 10 IBCs/h

• Available for different types of packaging

• High production

• Possibility of integration with company management systems

• Customisable layout

• User-friendly HMI

• Extreme packaging versatility

• Security

• Filling by weight/weight control

• Automatic pallet handling

Can be integrated with:

• Sealing machines

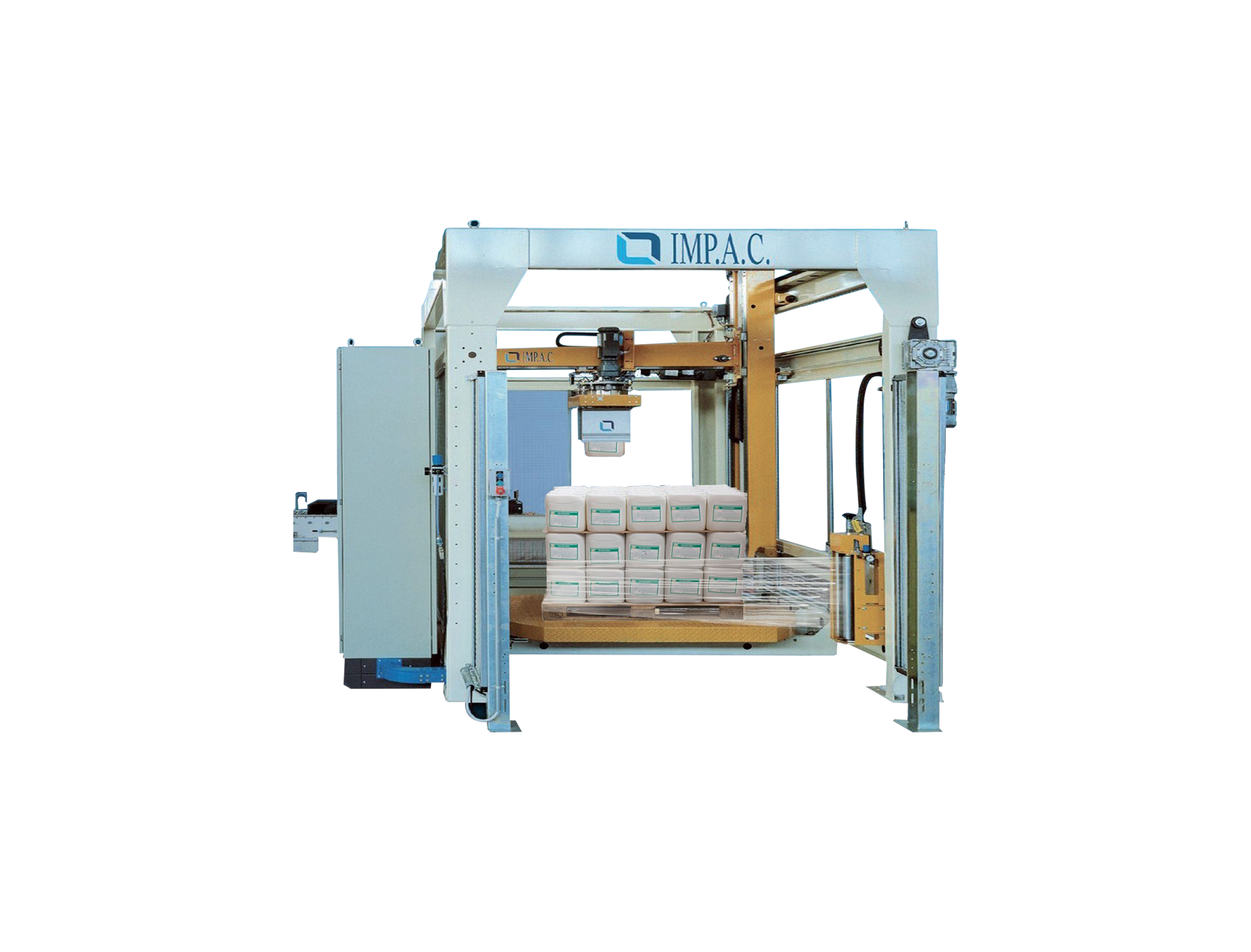

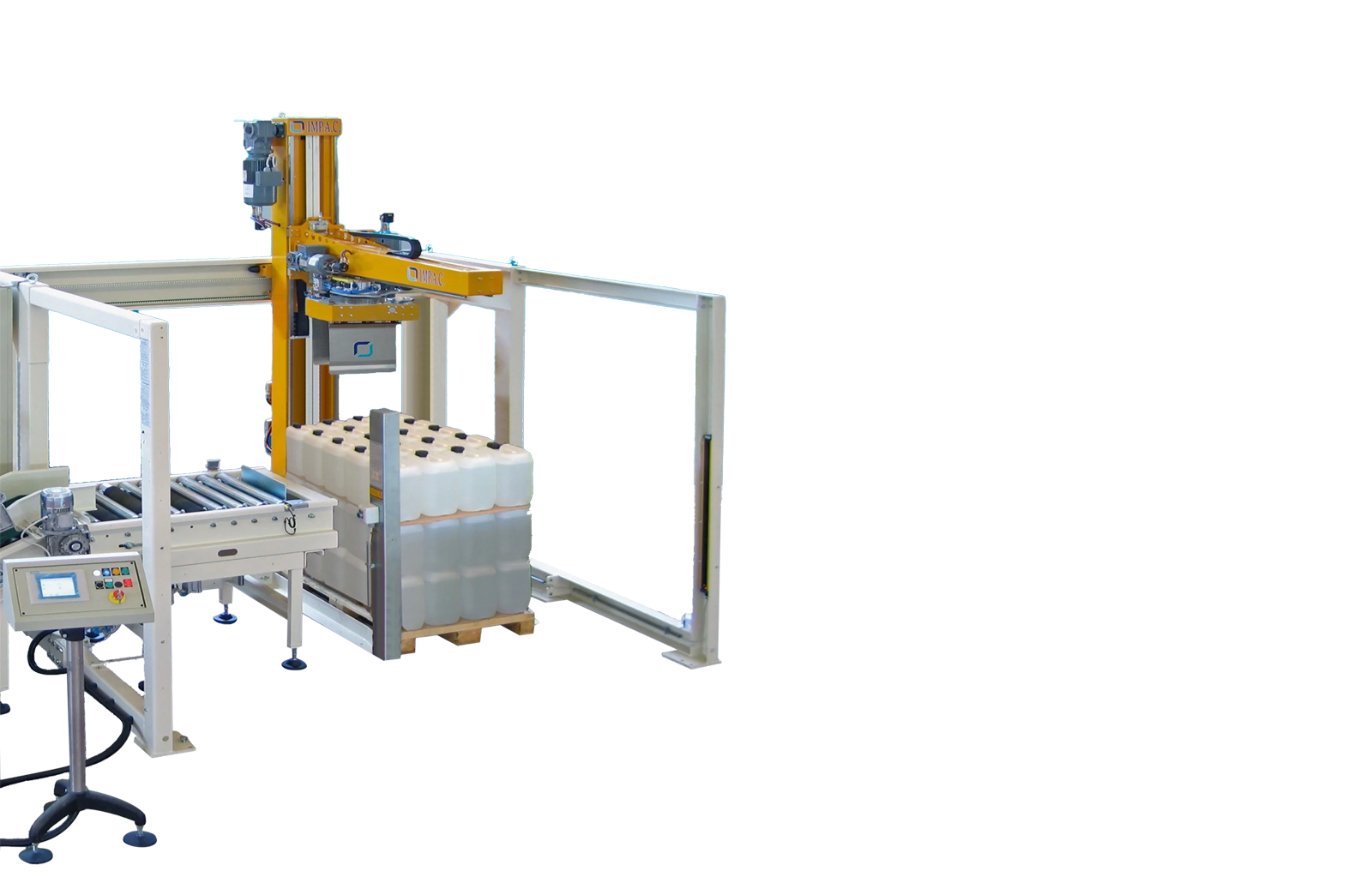

• Winder

• Hooding machine

• Strapping machines

Automatic filling line for IBCs and open top drums

Max Production:40 drums/h10 IBC/h

Type container

Open top drums - IBC

Max. container size

1200 x 1000 by h 1200 mm

Air pressure

6 bar

Installed power

2,5 Kw / 400 V

Indicative weight

1500 kg

Container capacity

Min. 50 l

Max. 1500 l

Max. operating capacity.

40 drums/h

10 IBC/h

Product benefits

__ High production

__ High production

40 drums/h<br>10 IBC/h

__ Advanced automation

__ Advanced automation

PLC-controlled, allows working with different formats without operator intervention, possibility of integration with company management systems

__ Safety and reliability

__ Safety and reliability

Robust design and optimised configuration for safe filling even of hazardous products

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

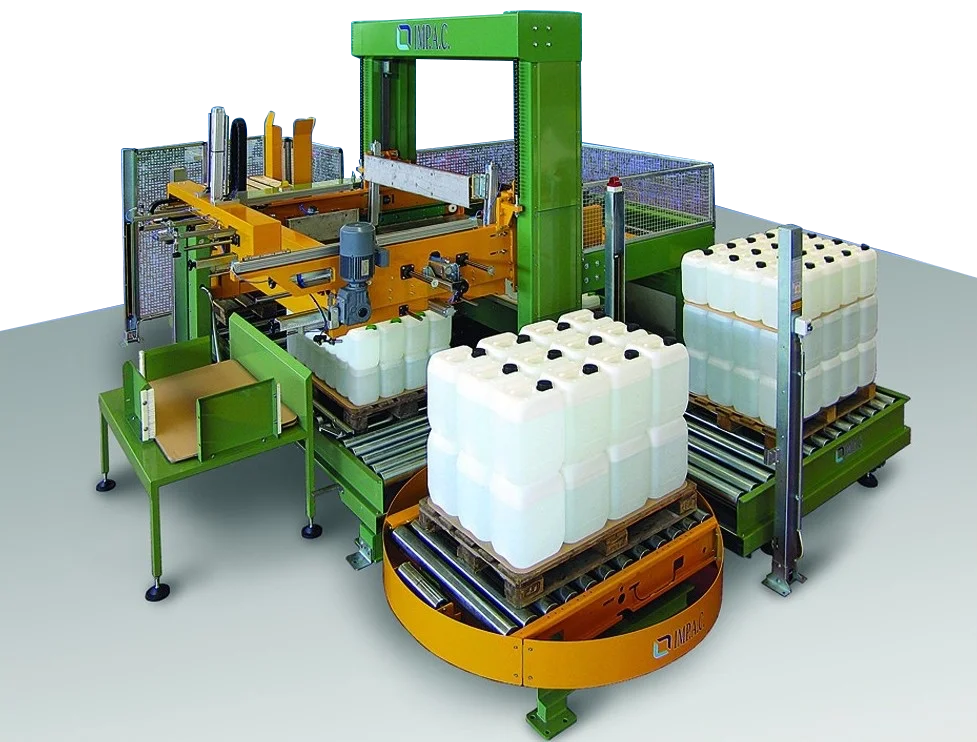

- Stretch wrapping machines

- Stretch hood machines

- Low-Level Palletizer for cans

- Cartesian robots for drums, jerrycans and pails

- Monocolumn Robot Palletizer and Depalletizer for cans pails and drums

- High level Robotic palletizer for conical drums

- Anthropomorphic Robot Palletizer and Depalletizer for cans, pails and drums