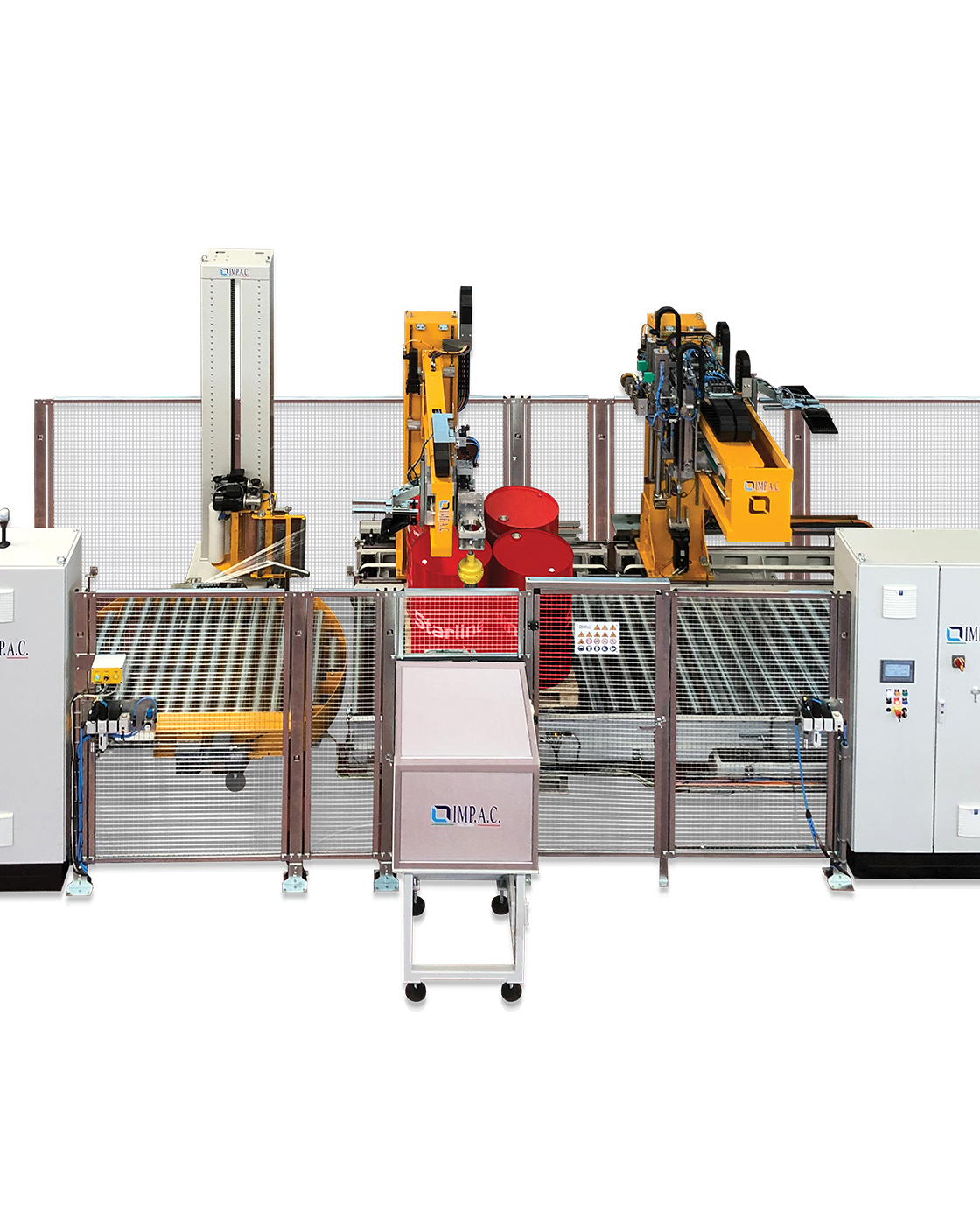

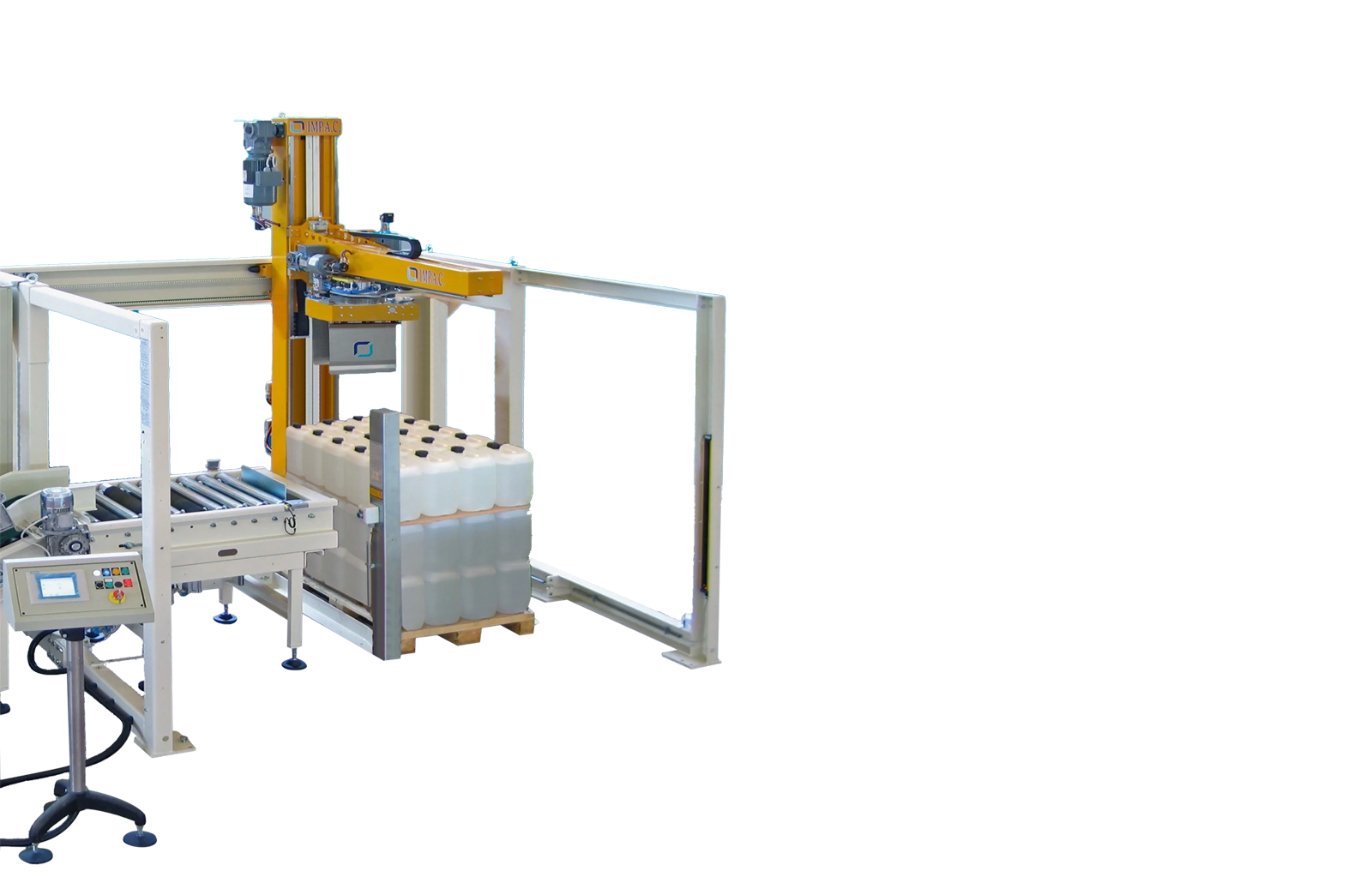

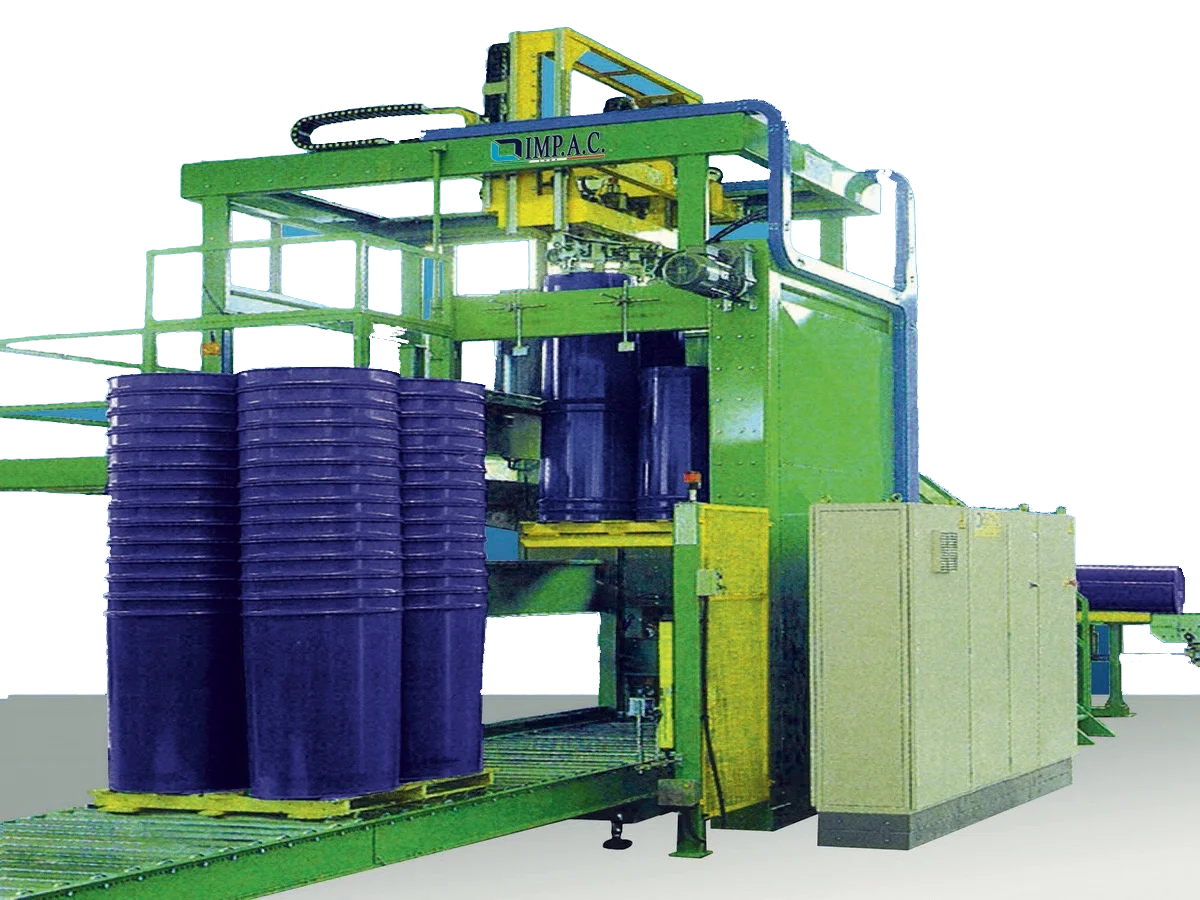

IMP.A.C. 56 A VISIONAutomatic bagging machine for palletised drums and IBCs with video camera for nozzle detection

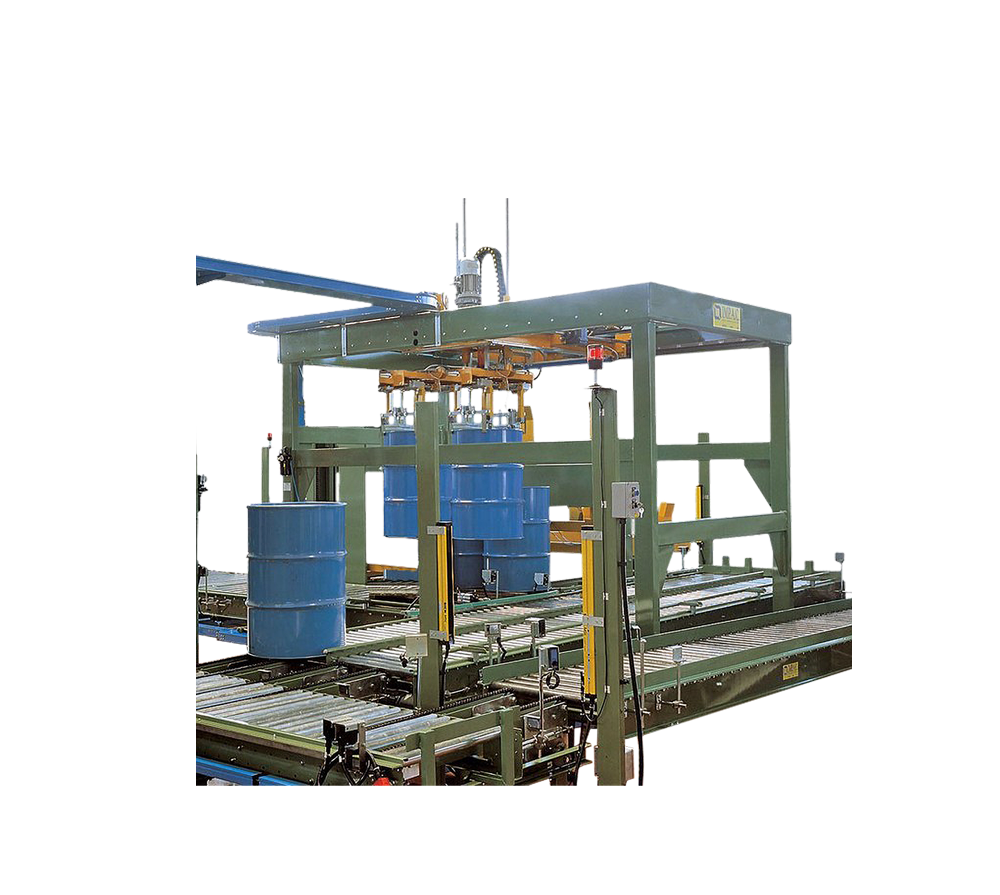

The IMP.A.C. 56 A VISION is an automatic filling system designed for filling chemicals and related products into 60 and 220 litre drums on pallets or into 1000 litre IBCs.

Thanks to the adjustable nozzle arm with three-axis movement, the plant provides flexibility and adaptability to different container configurations, optimising the production process.

Production capacity

• 40 drums/hour (60 or 220 liters on a pallet)

• 10 IBC/hour (from 1000 liters)

Operating Cycle

Arrival of containers on the motorised roller conveyor without cap.

Automatic positioning of the nozzle-holder arm on the container to be filled.

Controlled filling with automatic weight management via load cells.

End of filling and advancement of the container to the next stage.

Optional: suction system for safe management of vapours and fumes.

Available options and accessories

Fume and vapour extraction system – For a safer working environment.

ATEX version – For operation in explosion-hazardous environments.

Customised configurations – Adaptable to different production requirements.

Industrial applications

Chemical industry – Filling of solvents, resins, adhesives and reactive products.

Pharmaceutical industry – Handling of liquid active ingredients with high safety standards.

Agrochemicals – Filling of fertilisers, pesticides and liquid solutions for agriculture.

Lubricants and Automotive – Filling of industrial oils, lubricants and technical fluids.

Thanks to its advanced technology and fully automated handling, the IMP.A.C. 56 A VISION is the ideal solution for companies that require high precision, safety and efficiency in their brewing processes.

Automatic drum filling machine on pallet and IBC

Max Production:40 drums/h10 IBC/h

Type container

IBC Drums, Drums, Cisternettes

Paddle size

1200 x 1200 mm

Weight tolerance

500 g

Compressed air consumption

90 Nl/min

Air pressure

6 bar

Total empty weight

1500 Kg

Container weight

Max. 1500 Kg

Min. 50 Kg

Nozzle height adjustment

1000 mm

Production time = cycle time + Filling time (TR)

15 s + TR

Container handling

Motorized

Installed power

8 KW - 400 V

Product benefits

__ Versatility

__ Versatility

Suitable for 60/220 litre drums and 1000 litre IBCs, making it ideal for various industries.

__ Advanced automation

__ Advanced automation

Managed by PLC, it allows working with different formats without operator intervention.

__ Safety and reliability

__ Safety and reliability

Robust construction and optimised configuration for safe filling even of hazardous products.

__ 3-axis motion

__ 3-axis motion

The adjustable nozzle arm, together with the motorised roller conveyor, allows precise positioning for each container.

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

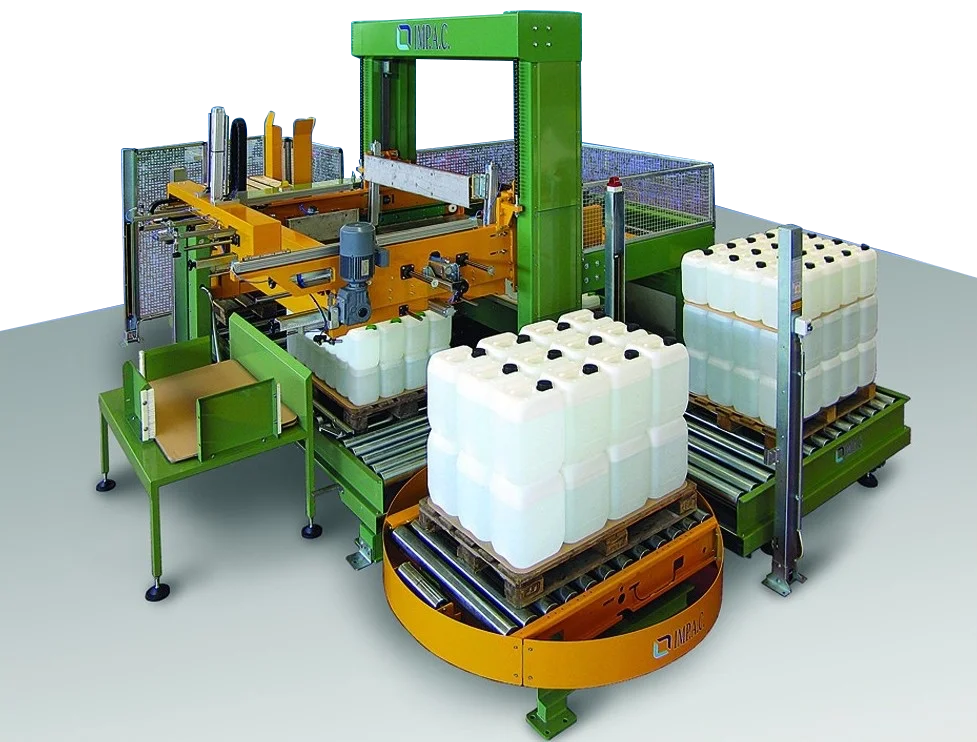

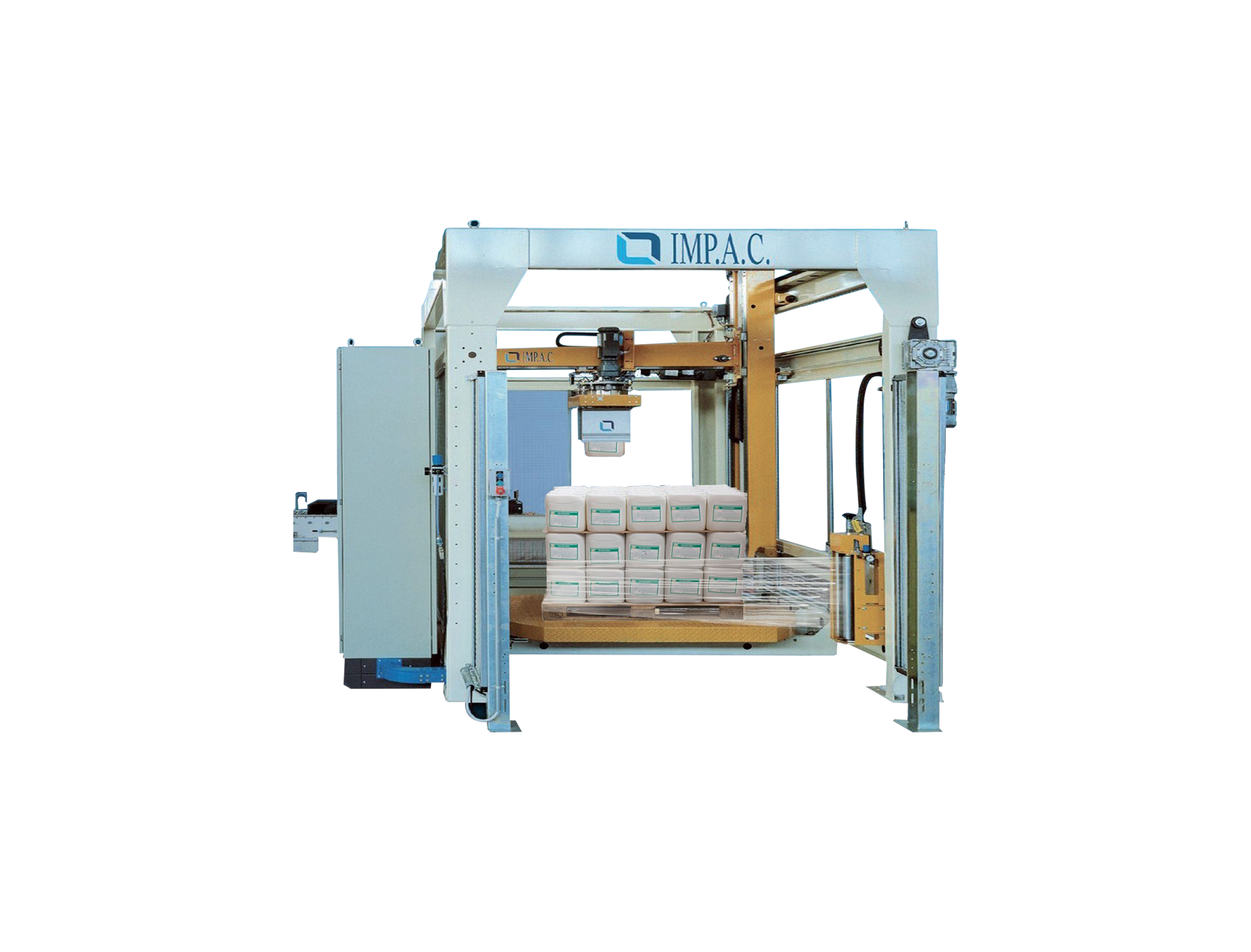

- Stretch wrapping machines

- Stretch hood machines

- Low-Level Palletizer for cans

- Cartesian robots for drums, jerrycans and pails

- Monocolumn Robot Palletizer and Depalletizer for cans pails and drums

- High level Robotic palletizer for conical drums

- Anthropomorphic Robot Palletizer and Depalletizer for cans, pails and drums