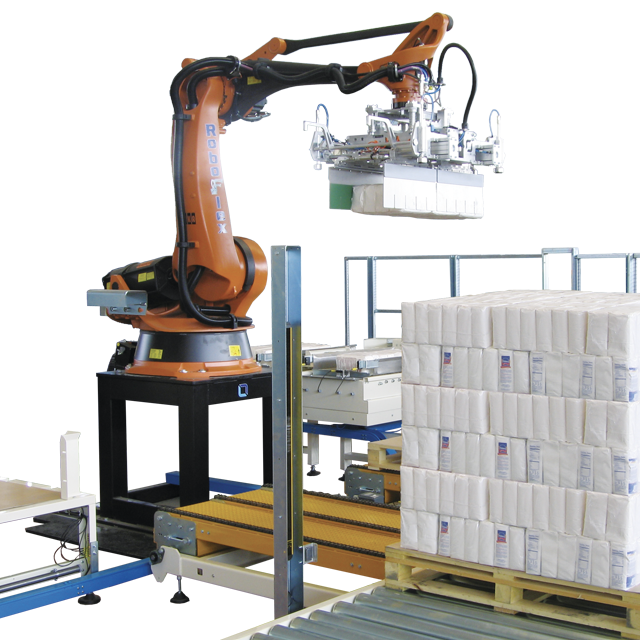

The IMP.A.C. RoboFlex A-1802 palletiser is an advanced robotic system for automatic full-row/layer palletising of 1 kg cartons, bundles and bags.

Equipped with a multi-grip clamp, the system retrieves the entire row of products from the preformer, ensuring precision and speed in pallet placement.

A distinctive feature of the RoboFlex A-1802 is the gripper with integrated gripper for empty pallets and layers, which allows fully automated handling of the palletising process. The layers are compact and perfectly aligned, avoiding overhangs from the pallet thanks to the total control of the spaces between one pack and the next both in the formation of the row in the preformer and in the depot, where precise side-to-side matching takes place.

The advanced technology of the system ensures that the shape of the packages remains unchanged, actually improving their regularity during palletizing. To increase pallet stability, layer crossing and the insertion of separator interlayers between layers can be implemented.

A further advantage of the RoboFlex A-1802 is its ability to handle two or more different product lines simultaneously, palletising them on separate pallets, thus maximising productivity and operational flexibility.

A programmable modular system (PLC) coordinates all the machine’s movements, making it adaptable to products of different sizes, configurations, and palletizing patterns.

IMP.A.C. RoboFlex A-1802 an ideal solution for companies looking for efficiency, quality and maximum automation in their entire row/layer palletising processes.

Anthropomorphic palletizer for boxes and bundles

Max. production:

600 cycles/h:

Maximum layer size

Max. 1400 x 1250 mm

Paddle size

Max. 1200 x 1000 mm x h 140

Min. 1000 x 800 mm x h 80

Standard full pallet height

1600 mm

Compressed air consumption

100 Nl/min

Control voltage

24 V

Max. full pallet weight

2000 Kg

Operational capacity

600 cycles/h:

Installed power

15 KW

Operating pressure

6 bar

Indicative weight

6000 Kg

Product benefits

__ High precision and palletizing quality

__ High precision and palletizing quality

No deformation of packs during the palletising process.

__ Operational flexibility

__ Operational flexibility

Multiple product lines can be managed simultaneously, optimising productivity.

__ Advanced automation

__ Advanced automation

Programmable PLC for fully automated management of the palletising cycle.

__ Optimisation of space and stability

__ Optimisation of space and stability

Cross formation of the layers for greater pallet hold.

__ Increased efficiency and reduced costs

__ Increased efficiency and reduced costs

Less wastage of packaging material due to precise layer management.