Automatic Palletizer for Lying 1 Kg Bags and Bundles in a Row with Mobile Pallet and Top Feeding.

Production Max:

- 100 bags/min

- 40 bundles/min

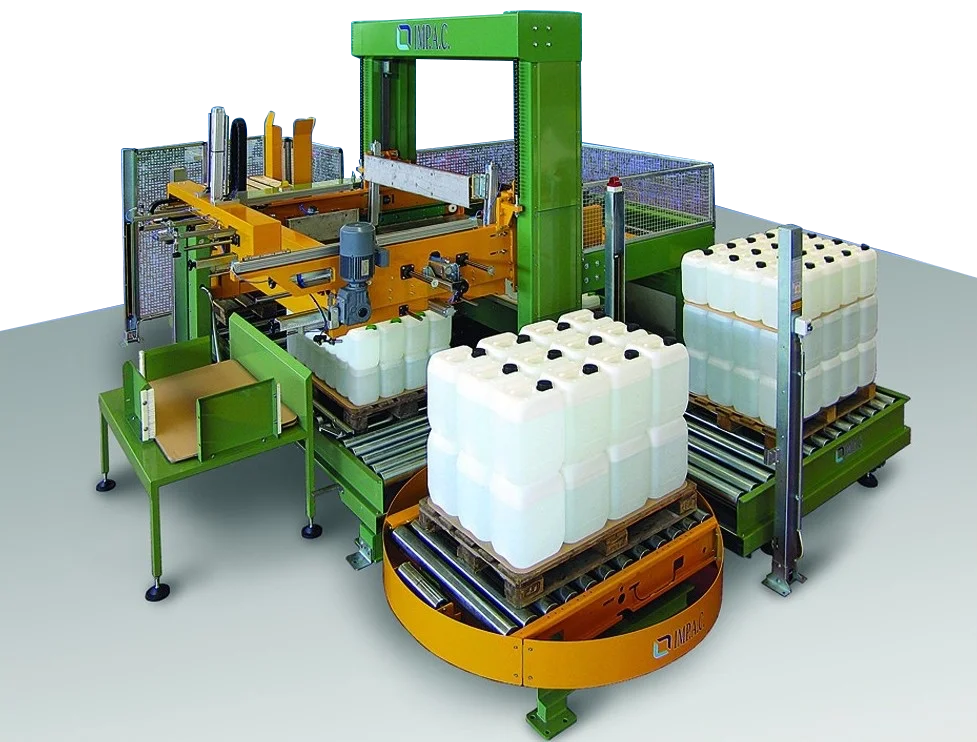

The IMP.A.C. 21-31 AFS palletizer is designed to ensure maximum efficiency and versatility, working with both bags and bundles. Thanks to its production capacity and optimized space management, this machine is ideal for a variety of industrial applications.

Advantages:

- Operational speed: up to 100 bags/min or 25 bundles/min.

- Versatility: compatible with a wide range of formats and configurations.

- Precision in palletizing: uniform and compact layers.

- Total automation: reliable control for uninterrupted operations.

The IMP.A.C. 21-31 AFS represents a comprehensive solution to optimize palletizing processes in high-productivity environments.

High-level palletizer for 1 kg bags, boxes and bundles.

Max Production:

6000 bags/h

Bag dimensions

Max. 250 x 150 x h. 100 mm

Min. 100 x 70 x h. 30 mm

Bundle size

Max. 300 x 300 x h. 300 mm

Min. 120 x 60 x h. 100 mm

Layer dimensions

Max. 1300 x 900 mm

Min. 700 x 600 mm

Standard full pallet height

1600 mm

Paddle size

Max. 1200 x 800 x h. 140 mm

Min. 800 x 600 x h. 100 mm

Compressed air consumption

90 Nl/min

Max. full pallet weight

1500 Kg

Operational capacity

4 layers/min with a limit of 6000 1 kg bags/h

4 layers/min with a limit of 1500 bundles/h

Installed power

14 KW

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

6500 Kg

Product benefits

__ Combined management of bags and bundles

__ Combined management of bags and bundles

The bags coming from the production line are gathered in rows to form a compact layer.

__ Accumulation and preforming system

__ Accumulation and preforming system

Each layer is precisely formed and transferred to a platform with a central opening.

__ Synchronized movement

__ Synchronized movement

The platform releases the layer onto the movable pallet, positioned accurately thanks to photoelectric sensors.