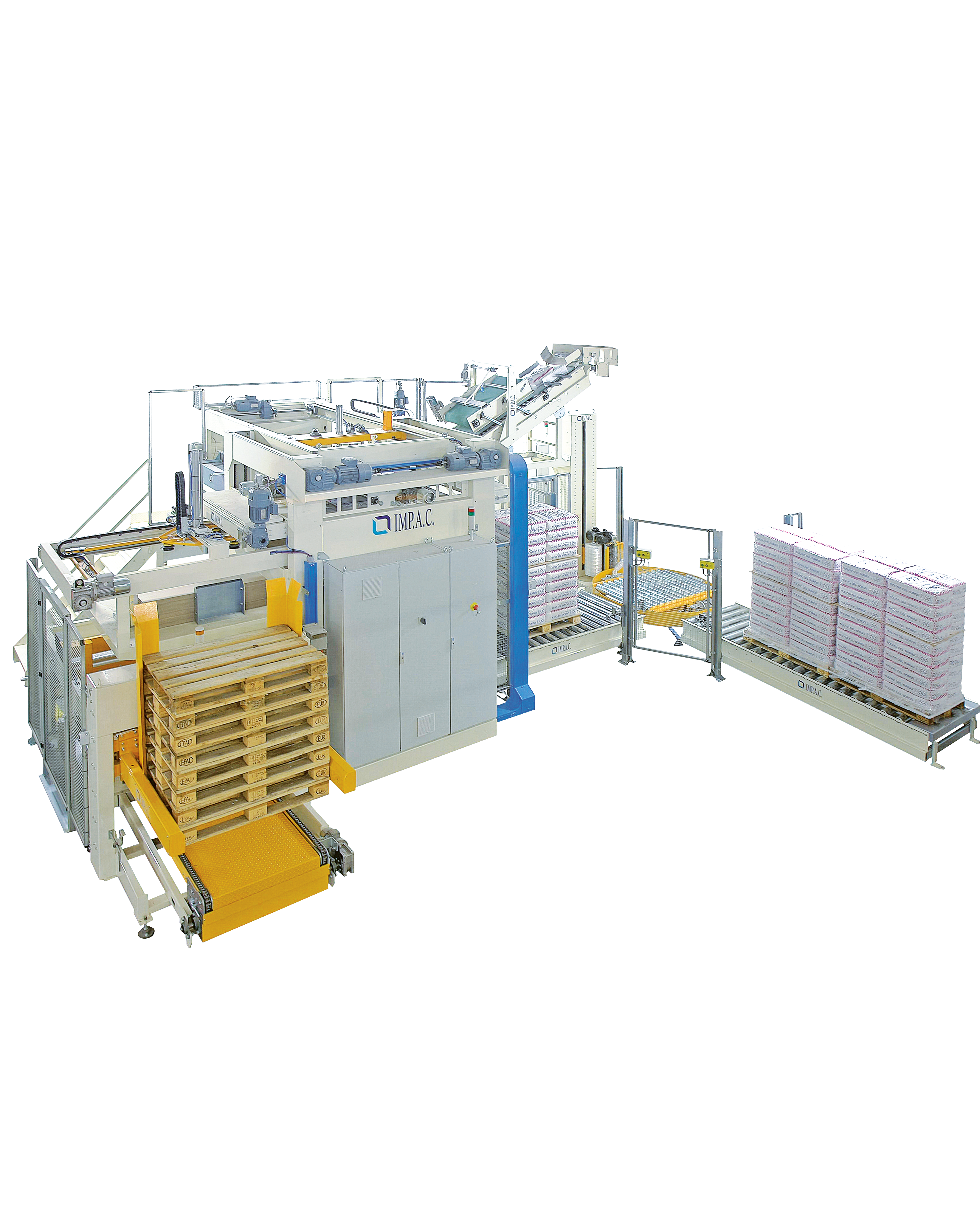

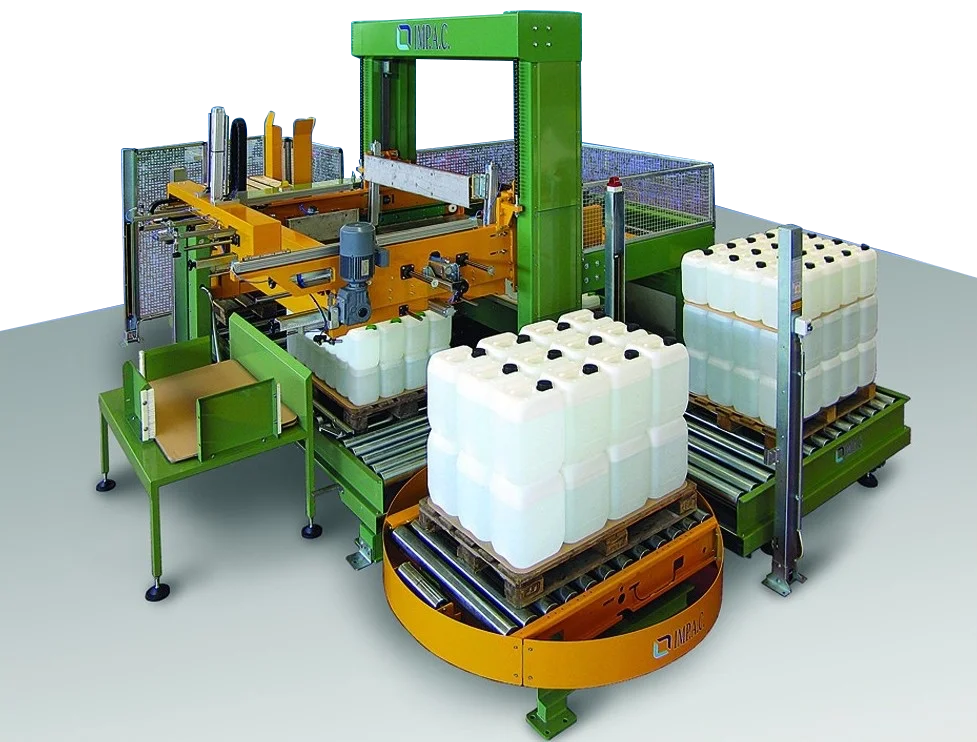

The IMP.A.C. 11 A automatic palletizer is the ideal solution for operations with production needs up to 1100 bags/h, requiring high flexibility to handle bags of varying sizes and weights ranging from 5 to 50 kg.

Operation

- Pressing of the bags: Each bag, coming from the production line, is pressed to ensure uniformity and compactness.

- Orientation and preforming: The bag is oriented according to the preset configuration and initiated into the layer preforming area.

- Layer deposition: The formed layer is transferred to a platform with a central opening, which deposits the layer directly onto the pallet.

- Automatic pallet movement: the lifter positions the pallet using a photoelectric barrier for optimum precision.

- Continuous cycle: the cycle repeats until the pallet is completed, which is evacuated and replaced automatically.

Applications

Suitable for industries requiring reliable and flexible palletising, the IMP.A.C. 11 A model offers excellent performance for handling bags with variable formats and configurations.

High-level bag palletizer

Max production: 1100 bags/h

Bag dimensions

Max. 1100 x 550 x h. 250 mm

Min. 300 x 150 x h. 60 mm

Pallet dimensions

Max. 1200 x 1000 x h. 140 mm

Min. 1000 x 800 x h. 100 mm

Layer dimensions

Max. 1300 x 1100 mm

Standard full pallet height

1600 mm

Compressed air consumption

100 Nl/min

Max. full pallet weight

2000 Kg

Operational capacity

4 states per minute with limit 1100 bags/h

Installed power

11,5 KW

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

8500 Kg

Product benefits

__ Versatility

__ Versatility

Compatible with a wide range of bag sizes and weights.

__ Accuracy

__ Accuracy

Movement synchronisation managed by a programmable PLC system.

__ High productivity

__ High productivity

Capable of meeting medium to high production rates with efficiency.

__ Full automation

__ Full automation

Reduced manual intervention thanks to a fully automated process.