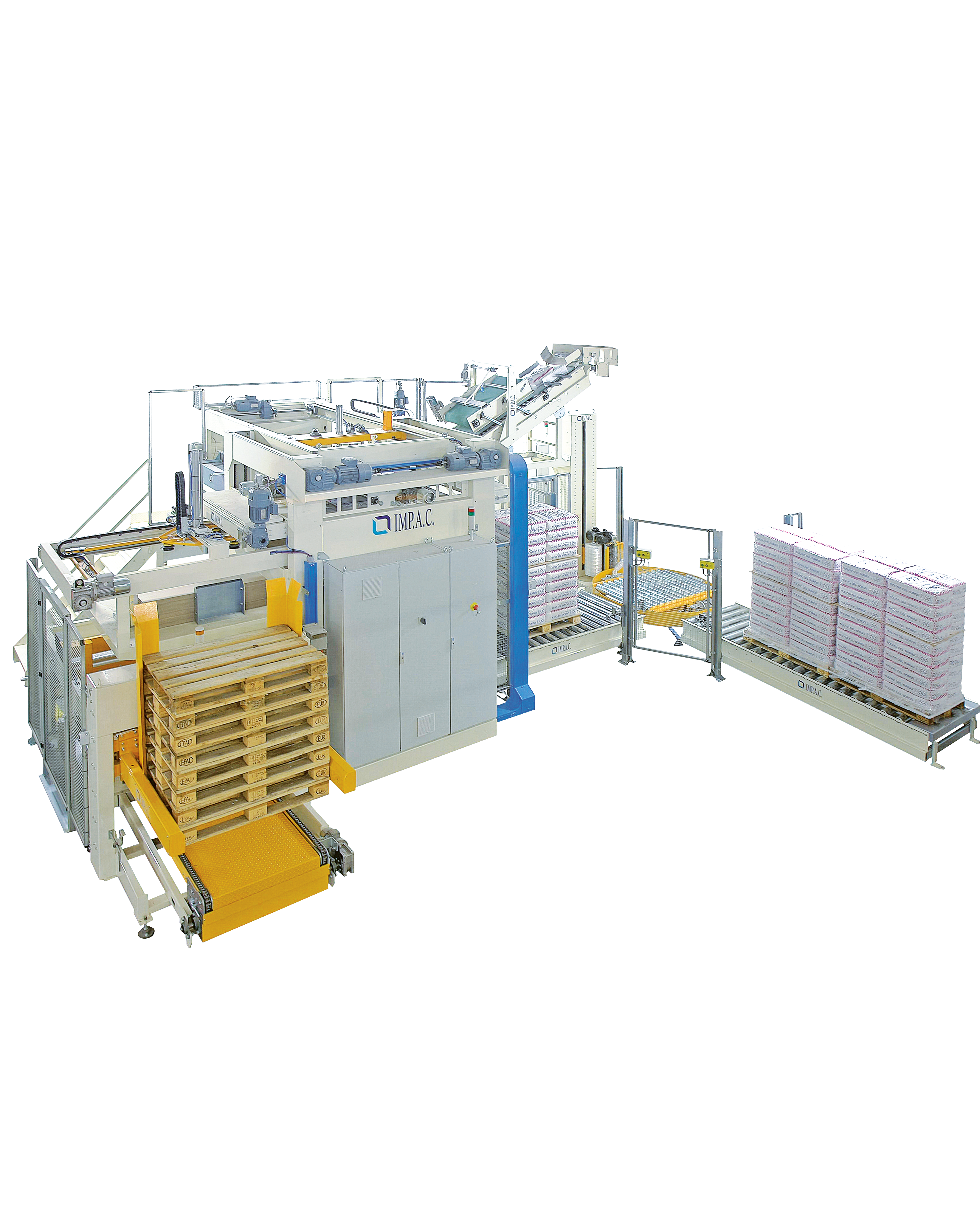

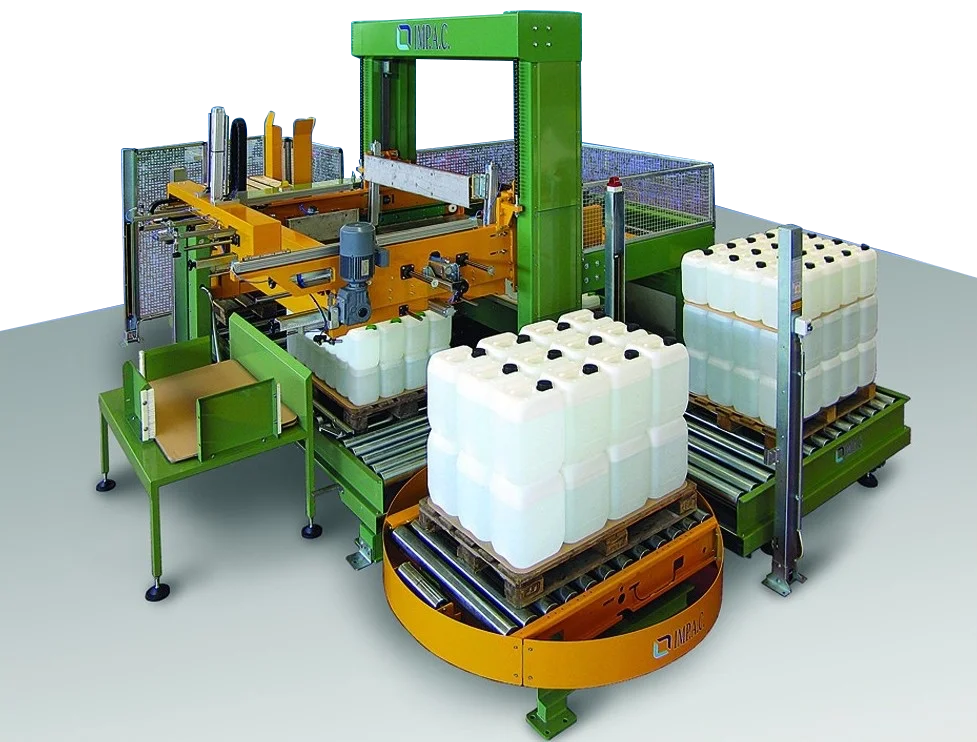

The IMP.A.C. 11 - 21 AVS model is a high-capacity palletizer designed to meet the needs of companies that produce large quantities of packaged products, such as bags, cartons, and bundles.

Advantages

- High efficiency: designed to support high production rates.

- Precision and uniformity: ensures compact and well-aligned layers.

- Complete automation: minimizes manual intervention.

- Flexibility: configurable for different formats and palletizing patterns.

High-level palletiser for bags 1, 5, 10, 12.5 kg.

Max Production:

1800/2000 bags/h

160 bags/min from 1 kg

Bag dimensions

Max. 450 x 300 x h. 200 mm

Min. 150 x 100 x h. 50 mm

Pallet dimensions

Max. 1200 x 1000 x h. 150 mm

Layer dimensions

Max. 1300 x 300 mm

Standard full pallet height

1600 mm

Compressed air consumption

150 Nl/min

Electric voltage

400 V / 50 Hz

Max. full pallet weight

1500 Kg

Operational capacity

1800/2000 bags/h

160 bags/min from 1 kg

Installed power

15,5 KW

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

11000 Kg

Product benefits

__ High production capacity

__ High production capacity

Up to 1100 bags/hour

__ Advanced automation

__ Advanced automation

The pallet is lowered automatically with each layer deposit and, once completed, is transferred to a conveyor. At the same time, an empty pallet is moved to the loading position.

__ Optimised management

__ Optimised management

Each bag is compacted, oriented and transferred to the preforming section of the layer.

__ Precise storage

__ Precise storage

A complete layer is transferred to the loading station, where a sliding gate deposits it onto the pallet evenly.

__ Smart control

__ Smart control

Programmable modular system (PLC) to adapt to different bag sizes, configurations and number of layers.