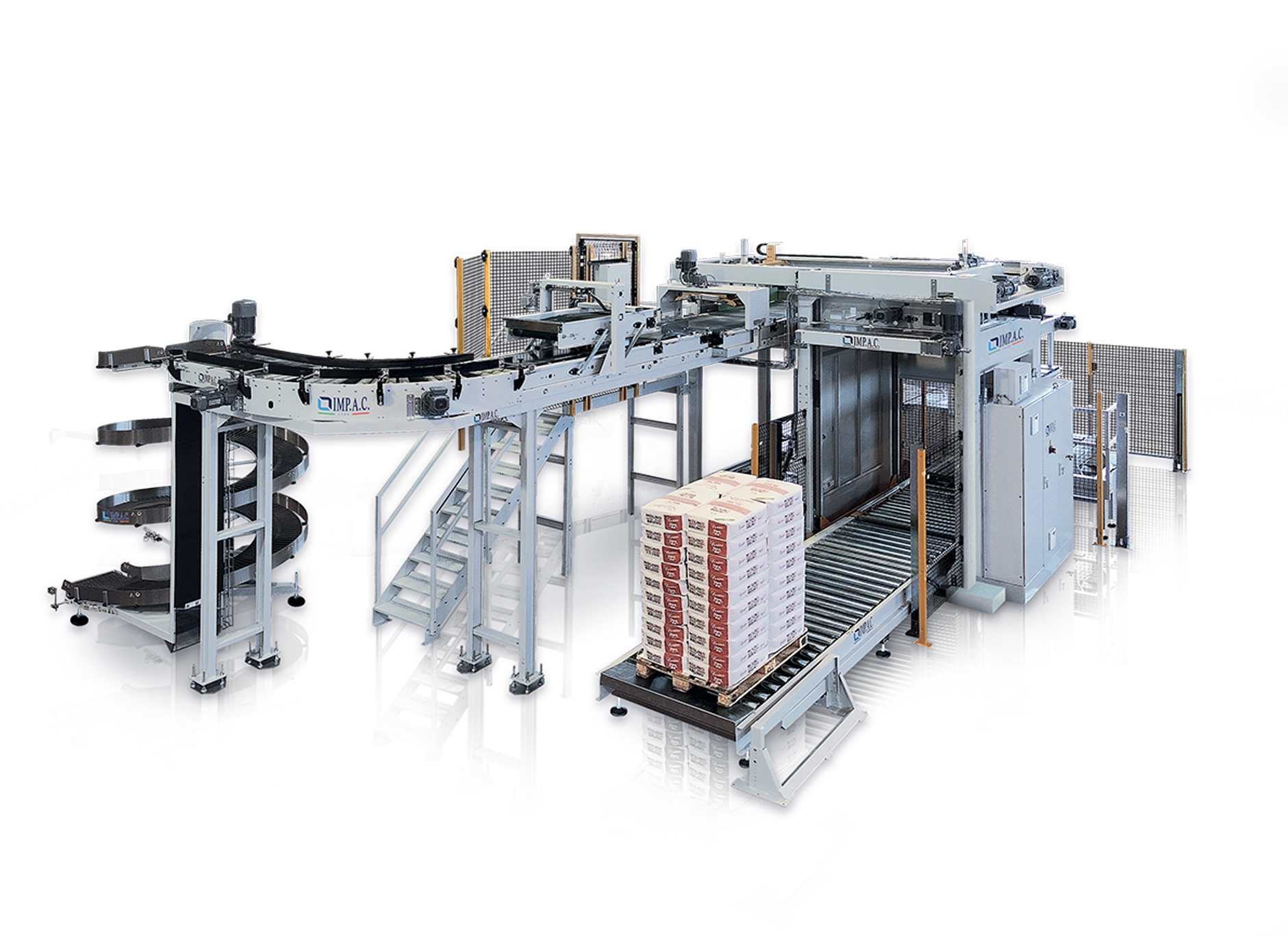

Automatic top-loading palletiser with movable pallet for sacks from 1 kg to 50 kg IMP.A.C. 11 AVS

The IMP.A.C. 11 AVS is a high-capacity palletiser designed to meet the needs of companies producing large quantities of bagged products, such as flour, cement, lime, glues, plasters and fertilisers.

Advantages

- High efficiency: designed to support high production rates.

- Precision and uniformity: ensures compact and well-aligned layers.

- Complete automation: minimizes manual intervention.

- Flexibility: configurable for different formats and palletizing patterns.

High-level palletiser for bags from 5 kg to 25 kg

Max. production

2000/2400 bags/h

Bag dimensions

Max. 800 x 450 x h. 250 mm

Min. 300 x 150 x h. 60 mm

Pallet dimensions

Max. 1200 x 1000 x h. 140 mm

Min. 1000 x 800 x h. 100 mm

Layer dimensions

Max. 1300 x 1100 mm

Standard full pallet height

1600 mm

Compressed air consumption

150 Nl/min

Electric voltage

400 V / 50 Hz

Max. full pallet weight

2000 Kg

Operational capacity

7 layers/min with limit of 2400 bags/h

Installed power

18 KW

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

13000 Kg

Product benefits

__ High production capacity

__ High production capacity

Up to 2400 bags/h.

__ Advanced automation

__ Advanced automation

The pallet is lowered automatically with each layer deposit and, once completed, is transferred to a conveyor. At the same time, an empty pallet is moved to the loading position.

__ Optimised management

__ Optimised management

Each bag is compacted, oriented and transferred to the preforming section of the layer.

__ Precise storage

__ Precise storage

A complete layer is transferred to the loading station, where a sliding gate deposits it onto the pallet evenly.

__ Smart control

__ Smart control

Programmable modular system (PLC) to adapt to different bag sizes, configurations and number of layers.

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

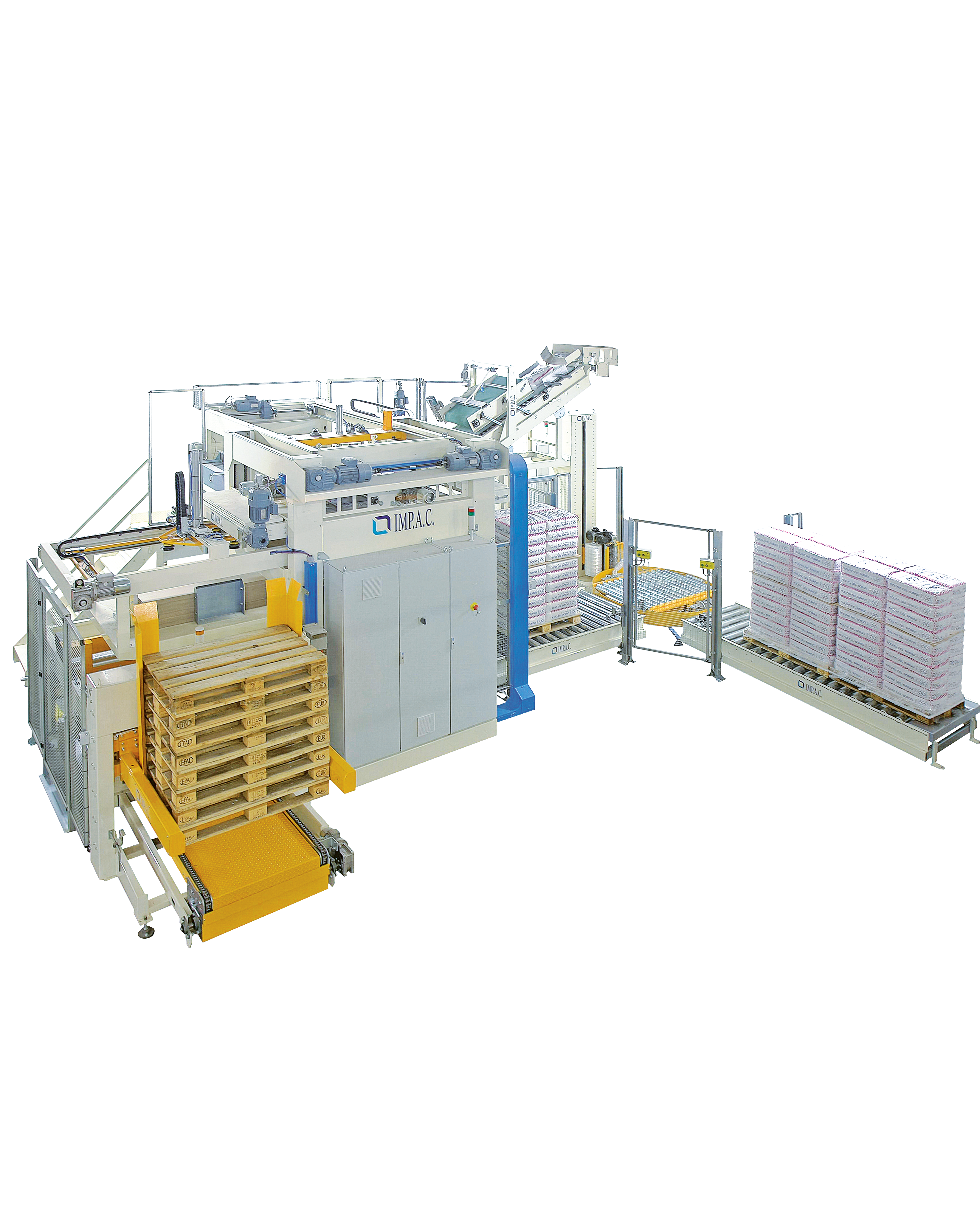

IMP.A.C. 11 AVS High-level bag palletizer for high capacity with mobile pallet.

The IMP.A.C. 11 AS / 11 AV model is a high-capacity palletizer designed to meet the needs of companies producing large quantities of bagged products, such as flour, cement, lime, adhesives, plasters, and fertilizers.

Advantages

- High efficiency: designed to support high production rates.

- Precision and uniformity: ensures compact and well-aligned layers.

- Complete automation: minimizes manual intervention.

- Flexibility: configurable for different formats and palletizing patterns.

High-level bag palletizer high-speed capacity

Maximum Production:

11 AS: 1500 bags/h

11 AV: 1800 bags/h

Bag dimensions

Max. 800 x 450 x h. 250 mm

Min. 300 x 150 x h. 60 mm

Pallet dimensions

Max. 1200 x 1000 x h. 140 mm

Min. 1000 x 800 x h. 100 mm

Layer dimensions

Max. 1400 x 1250 mm

Standard full pallet height

1600 mm

Compressed air consumption

100 Nl/min

Max. full pallet weight

2000 Kg

Operational capacity

11 AS: 5 layers/min with a limit of 1500

11 AV: 6 layers/min with a limit of 1800

Installed power

11 AS: 15 KW

11 AV: 18 KW

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

11 AS: 10000 Kg

11 AV: 12000 Kg

Product benefits

__ High production capacity

__ High production capacity

Up to 2400 bags/h.

__ Advanced automation

__ Advanced automation

The pallet is lowered automatically with each layer deposit and, once completed, is transferred to a conveyor. At the same time, an empty pallet is moved to the loading position.

__ Optimised management

__ Optimised management

Each bag is compacted, oriented and transferred to the preforming section of the layer.

__ Precise storage

__ Precise storage

A complete layer is transferred to the loading station, where a sliding gate deposits it onto the pallet evenly.

__ Smart control

__ Smart control

Programmable modular system (PLC) to adapt to different bag sizes, configurations and number of layers.

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

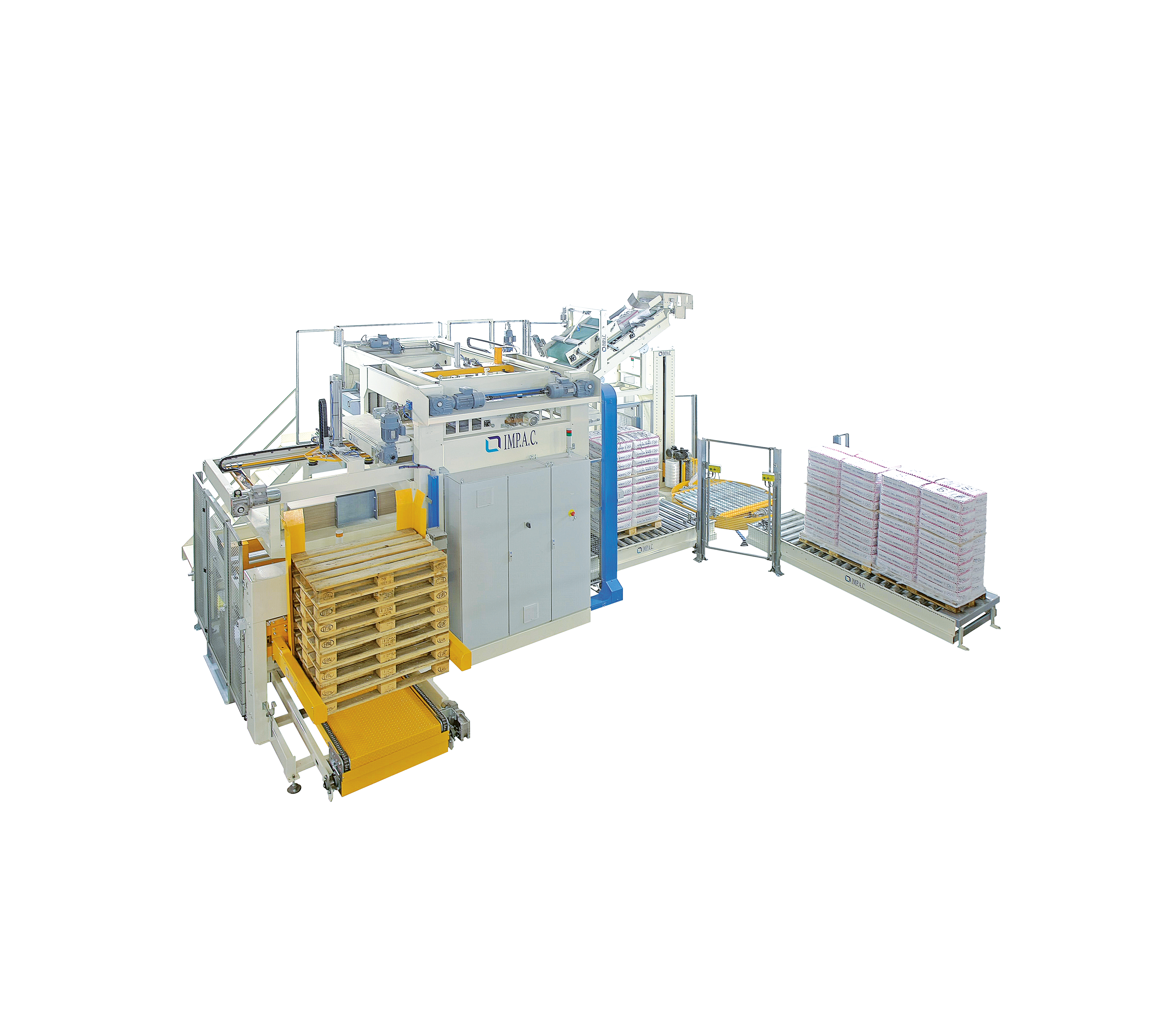

IMP.A.C. 11 A Mobile pallet bag palletizer with top feed

The IMP.A.C. 11 A automatic palletizer is the ideal solution for operations with production needs up to 1100 bags/h, requiring high flexibility to handle bags of varying sizes and weights ranging from 5 to 50 kg.

Operation

- Pressing of the bags: Each bag, coming from the production line, is pressed to ensure uniformity and compactness.

- Orientation and preforming: The bag is oriented according to the preset configuration and initiated into the layer preforming area.

- Layer deposition: The formed layer is transferred to a platform with a central opening, which deposits the layer directly onto the pallet.

- Automatic pallet movement: the lifter positions the pallet using a photoelectric barrier for optimum precision.

- Continuous cycle: the cycle repeats until the pallet is completed, which is evacuated and replaced automatically.

Applications

Suitable for industries requiring reliable and flexible palletising, the IMP.A.C. 11 A model offers excellent performance for handling bags with variable formats and configurations.

High-level bag palletizer

Max production: 1100 bags/h

Bag dimensions

Max. 1100 x 550 x h. 250 mm

Min. 300 x 150 x h. 60 mm

Pallet dimensions

Max. 1200 x 1000 x h. 140 mm

Min. 1000 x 800 x h. 100 mm

Layer dimensions

Max. 1300 x 1100 mm

Standard full pallet height

1600 mm

Compressed air consumption

100 Nl/min

Max. full pallet weight

2000 Kg

Operational capacity

4 states per minute with limit 1100 bags/h

Installed power

11,5 KW

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

8500 Kg

Product benefits

__ Versatility

__ Versatility

Compatible with a wide range of bag sizes and weights.

__ Accuracy

__ Accuracy

Movement synchronisation managed by a programmable PLC system.

__ High productivity

__ High productivity

Capable of meeting medium to high production rates with efficiency.

__ Full automation

__ Full automation

Reduced manual intervention thanks to a fully automated process.