IMP.A.C. 21-22 APT Automatic Palletizer with Ground Pallet for Bags

IMP.A.C. 21-22 APT High-level palletizer for bags, boxes and bundles on the pallet at the ground

High-level palletizer for bags, boxes and bundles on the pallet at the ground.

Max. production: 500 bags/h

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

IMP.A.C. 21-31 AFS Automatic Palletizer for Lying 1 Kg Bags and Bundles in a Row with Mobile Pallet and Top Feeding

Automatic Palletizer for Lying 1 Kg Bags and Bundles in a Row with Mobile Pallet and Top Feeding.

Production Max:

- 100 bags/min

- 40 bundles/min

The IMP.A.C. 21-31 AFS palletizer is designed to ensure maximum efficiency and versatility, working with both bags and bundles. Thanks to its production capacity and optimized space management, this machine is ideal for a variety of industrial applications.

Advantages:

- Operational speed: up to 100 bags/min or 25 bundles/min.

- Versatility: compatible with a wide range of formats and configurations.

- Precision in palletizing: uniform and compact layers.

- Total automation: reliable control for uninterrupted operations.

The IMP.A.C. 21-31 AFS represents a comprehensive solution to optimize palletizing processes in high-productivity environments.

High-level palletizer for 1 kg bags, boxes and bundles.

Max Production:

6000 bags/h

Bag dimensions

Max. 250 x 150 x h. 100 mm

Min. 100 x 70 x h. 30 mm

Bundle size

Max. 300 x 300 x h. 300 mm

Min. 120 x 60 x h. 100 mm

Layer dimensions

Max. 1300 x 900 mm

Min. 700 x 600 mm

Standard full pallet height

1600 mm

Paddle size

Max. 1200 x 800 x h. 140 mm

Min. 800 x 600 x h. 100 mm

Compressed air consumption

90 Nl/min

Max. full pallet weight

1500 Kg

Operational capacity

4 layers/min with a limit of 6000 1 kg bags/h

4 layers/min with a limit of 1500 bundles/h

Installed power

14 KW

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

6500 Kg

Product benefits

__ Combined management of bags and bundles

__ Combined management of bags and bundles

The bags coming from the production line are gathered in rows to form a compact layer.

__ Accumulation and preforming system

__ Accumulation and preforming system

Each layer is precisely formed and transferred to a platform with a central opening.

__ Synchronized movement

__ Synchronized movement

The platform releases the layer onto the movable pallet, positioned accurately thanks to photoelectric sensors.

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

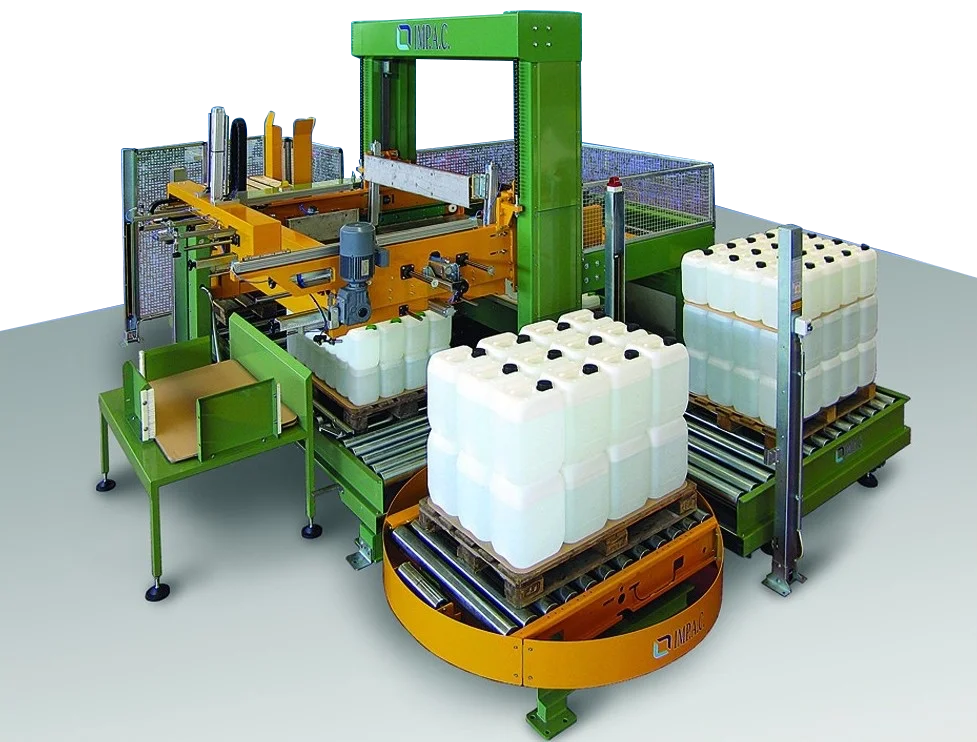

IMP.A.C. 21 AVS Automatic palletizer with mobile pallet for boxes and bundles.

The IMP.A.C. 21 AVS palletizer is the ideal solution for high productivity needs, with a maximum capacity of 2500 cartons-bundles/hour.

Its high versatility makes it suitable for palletizing cartons with dimensions ranging from 400x300xh250 mm to 500x400xh300 mm, making it applicable in a wide range of industrial sectors.

Competitive advantages

- Increased efficiency due to the ability to handle large volumes.

- Programmable configuration to adapt to different types of boxes and layouts.

- Precision and reliability in every stage of the palletizing process.

IMP.A.C. 21 AVS: the ideal partner for maximizing productivity and optimizing workflow.

High-level palletiser for boxes and bundles.

Max production: 2500 cartons-bundles/hour

Cardboard dimensions

Max. 400 x 300 x h. 250

Min. 200 x 150 x h. 25

Pallet dimensions

Max. 1200 x 1000 x h. 140

Min. 1000 x 800 x h. 100

Layer dimensions

Max. 1300 x 1100

Standard full pallet height

1600 mm

Compressed air consumption

150 Nl/min

Max. full pallet weight

1500 Kg

Operational capacity

5.5 layers with a limit of 50 cartons/min

Installed power

15 KW

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

7000 Kg

Product benefits

__ High productivity

__ High productivity

Designed to handle production capacities exceeding 2500 cartons-bundles/hour.

__ Advanced automation

__ Advanced automation

Managed by a programmable modular system (PLC) to adapt to different formations and configurations.

__ Dimensional versatility

__ Dimensional versatility

It supports cartons and bundles of various sizes, ensuring operational flexibility.

__ Precision in layer formation

__ Precision in layer formation

Each box is oriented and arranged according to the predefined configuration.

__ Synchronized movements

__ Synchronized movements

Central-opening platform for accurate layer placement on the pallet.

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

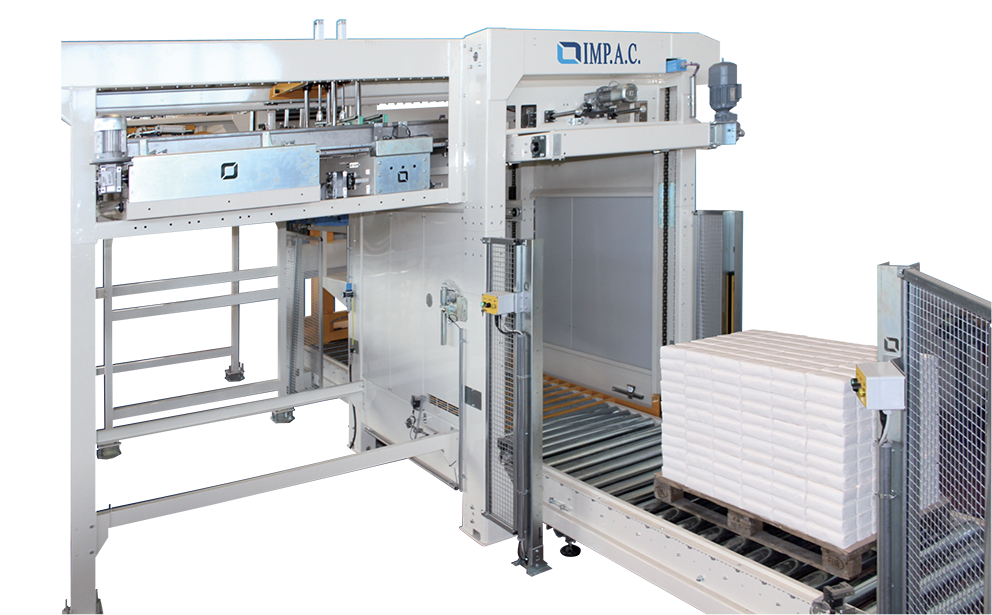

IMP.A.C. 21 AV Automatic palletizer with mobile pallet for boxes and bundles.

The IMP.A.C. 21 AV palletizer is the ideal solution for high productivity needs, with a maximum capacity of 2000 cartons-bundles/hour.

Its high versatility makes it suitable for palletizing boxes with dimensions ranging from 200x150x25 mm to 500x400x300 mm, making it applicable across a wide range of industrial sectors.

Competitive advantages

- Increased efficiency due to the ability to handle large volumes.

- Programmable configuration to adapt to different types of boxes and layouts.

- Precision and reliability in every stage of the palletizing process.

IMP.A.C. 21 AV: the ideal partner to maximize productivity and optimize workflow.

High-level palletizer for boxes and bundles high speed capacity.

Max production: 2000 cartons-bundles/h

Cardboard dimensions

Max. 500 x 400 x h. 300

Min. 200 x 150 x h. 25

Pallet dimensions

Max. 1200 x 1000 x h. 140

Min. 1000 x 800 x h. 100

Layer dimensions

Max. 1300 x 1100

Standard full pallet height

1600 mm

Compressed air consumption

150 Nl/min

Max. full pallet weight

1500 Kg

Operational capacity

5 layers with a limit of 40 cartons/min

Installed power

13 KW

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

7000 Kg

Product benefits

__ High productivity

__ High productivity

Designed to handle production capacities exceeding 2000 cartons-bundles/hour.

__ Advanced automation

__ Advanced automation

Managed by a programmable modular system (PLC) to adapt to different formations and configurations.

__ Dimensional versatility

__ Dimensional versatility

It supports cartons and bundles of various sizes, ensuring operational flexibility.

__ Precision in layer formation

__ Precision in layer formation

Each box is oriented and arranged according to the predefined configuration.

__ Synchronized movements

__ Synchronized movements

Central-opening platform for accurate layer placement on the pallet.

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

IMP.A.C. 21 A Automatic palletizer with mobile pallet for boxes and bundles.

The IMP.A.C. 21 A palletizer is the ideal solution for high productivity needs, with a maximum capacity of 1500 boxes-bundles/hour.

Its high versatility makes it suitable for palletizing boxes with dimensions ranging from 200x150x25 mm to 500x400x300 mm, making it applicable across a wide range of industrial sectors.

Competitive advantages

- Increased efficiency due to the ability to handle large volumes.

- Programmable configuration to adapt to different types of boxes and layouts.

- Precision and reliability in every stage of the palletizing process.

IMP.A.C. 21 A: the ideal partner to maximize productivity and optimize workflow.

High-level palletizer for boxes and bundles.

Max production: 1500 cartons/bundles/hour.

Bag dimensions

Max. 500 x 400 x h. 300

Min. 200 x 150 x h. 25

Pallet dimensions

Max. 1200 x 1000 x h. 140

Min. 1000 x 800 x h. 100

Layer dimensions

Max. 1300 x 1100

Standard full pallet height

1600 mm

Compressed air consumption

100 Nl/min

Max. full pallet weight

1500 Kg

Operational capacity

4 layers with a limit of 30 cartons per minute.

Installed power

9 KW

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

7000 Kg

Product benefits

__ High productivity

__ High productivity

Designed to handle production capacities exceeding 1500 cartons-bundles/hour.

__ Advanced automation

__ Advanced automation

Managed by a programmable modular system (PLC) to adapt to different formations and configurations.

__ Dimensional versatility

__ Dimensional versatility

It supports cartons and bundles of various sizes, ensuring operational flexibility.

__ Precision in layer formation

__ Precision in layer formation

Each box is oriented and arranged according to the predefined configuration.

__ Synchronized movements

__ Synchronized movements

Central-opening platform for accurate layer placement on the pallet.