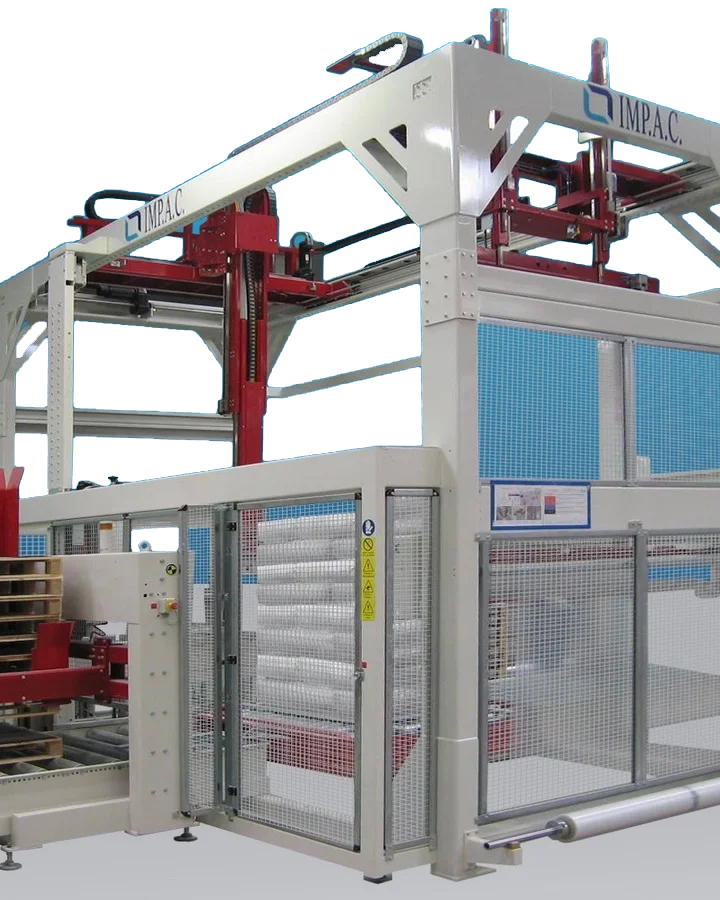

Cartesian bucket palletising robot with integrated automatic winder and cover top IMP.A.C. ROBOTEX 526 A-PR+TOP

Cartesian bucket palletising robot with integrated automatic winder and cover top IMP.A.C. ROBOTEX 526 A-PR+TOP

Cartesian bucket palletising robot with built-in automatic winder and cover top

Production Max:

230 buckets/hour basic solution

400 buckets/hour quick solution

Bucket/tank dimensions

Max. 120 x 250 mm<br>Min. 5 litres

Bundle size

Max. 1300 x 1200 x h. 140 mm<br>Min. 800 x 600 x h. 100 mm

Maximum layer size

Max. 1400 x 1250 mm

Standard full pallet height

1600 mm

Compressed air consumption

100 Nl/min

Max. full pallet weight

2000 Kg

Operational capacity

230-400 buckets/h

Installed power

8,1 KW

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

6000 Kg

The IMP.A.C. ROBOTEX 526 A-PR+TOP is an innovative, fully automatic palletiser designed for high performance and maximum efficiency in bucket handling, thanks to its integrated automatic winder and top cover system.

Perfect for production rates of up to 400 buckets/hour, it integrates perfectly at the end of the line of fully automated production plants.

Key features

- Versatility of use: ideal for buckets of different capacities, from 5 to 65 litres, using a single piece of equipment.

- Automatic winder and top cover: ensure load stability and superior protection during handling and storage.

- Compact design: allows installation in confined spaces thanks to small overall dimensions.

- Complete automation: includes roller conveyors for automatic handling of empty and full pallets.

- Cartesian motion: ensures precise positioning via encoder for optimal results every time.

- Customisable programming: configurable for handling different bucket sizes, layouts and number of layers.

- Advanced PLC control: synchronises movements in a modular and programmable manner for smooth operation.

The IMP.A.C. ROBOTEX 526 A-PR+TOP is the ideal choice for anyone looking for a complete, reliable and innovative solution for automated palletising of buckets with top wrapping and protection.

Product benefits

__ Production up to 400 buckets/h

__ Production up to 400 buckets/h

__ Automatic winder with integrated top cover

__ Automatic winder with integrated top cover

__ Compatible with buckets from 5 to 65 litres

__ Compatible with buckets from 5 to 65 litres

__ Compact solution for small spaces

__ Compact solution for small spaces

__ Total automation due to the absence of operators

__ Total automation due to the absence of operators

__ High precision thanks to encoder control

__ High precision thanks to encoder control

Nothing found.

Cartesian can palletising robot with built-in automatic winder IMP.A.C. ROBOTEX 526 A-PR

Cartesian can palletising robot with built-in automatic winder

Production Max:

270 canisters/h basic solution

450 canisters/h quick solution

Tank dimensions

Max. 120x h 250<br>Min. 5 litres

Bundle size

Max. 1300 x 1200 x h. 140 mm<br>Min. 800 x 600 x h. 100 mm

Maximum layer size

Max. 1400 x 1250 mm

Standard full pallet height

1600 mm

Compressed air consumption

100 Nl/min

Max. full pallet weight

2000 Kg

Operational capacity

270-450 canisters/h

Installed power

8,1 KW

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

6000 Kg

The IMP.A.C. ROBOTEX 526 A-PR is an innovative, fully automatic palletiser, designed to optimise canister handling thanks to its versatility and integrated automatic wrapping system.

Perfect for production rates of up to 450 cans/h, it is ideal for production facilities where there is no operator presence.

Key features

- Versatility of use: palletisation of canisters with a capacity ranging from 5 to 65 litres using the same equipment.

- Integrated automatic winder: ensures load stability, allowing unstable and slippery canisters to be handled.

- Compact design: ideal for installation in small spaces.

- Complete automation: the system includes roller conveyors for automatic handling of empty and full pallets.

- Cartesian motion: ensures precise and reliable positioning using encoders.

- Customisable programming: configurable to handle different tank sizes, formations and number of layers.

- Advanced PLC system: synchronises movements in a modular and programmable way for optimal performance.

The IMP.A.C. ROBOTEX 526 A-PR is the ideal solution for anyone looking for a reliable, versatile and fully automatic system for palletising and canister wrapping.

Product benefits

__ Production up to 450 cans/h

__ Production up to 450 cans/h

__ Automatic winder for load stability

__ Automatic winder for load stability

__ Compatible with canisters from 5 to 65 litres

__ Compatible with canisters from 5 to 65 litres

__ Complete automation for unmanned operation

__ Complete automation for unmanned operation

__ High accuracy thanks to encoder control

__ High accuracy thanks to encoder control

Nothing found.

Cartesian bag palletising robot with built-in automatic winder IMP.A.C. ROBOTEX 126 A-PR

Cartesian bag palletising robot with built-in automatic winder

Production Max:

270 bags/hour basic solution

450 bags/hour fast solution

Nothing found.

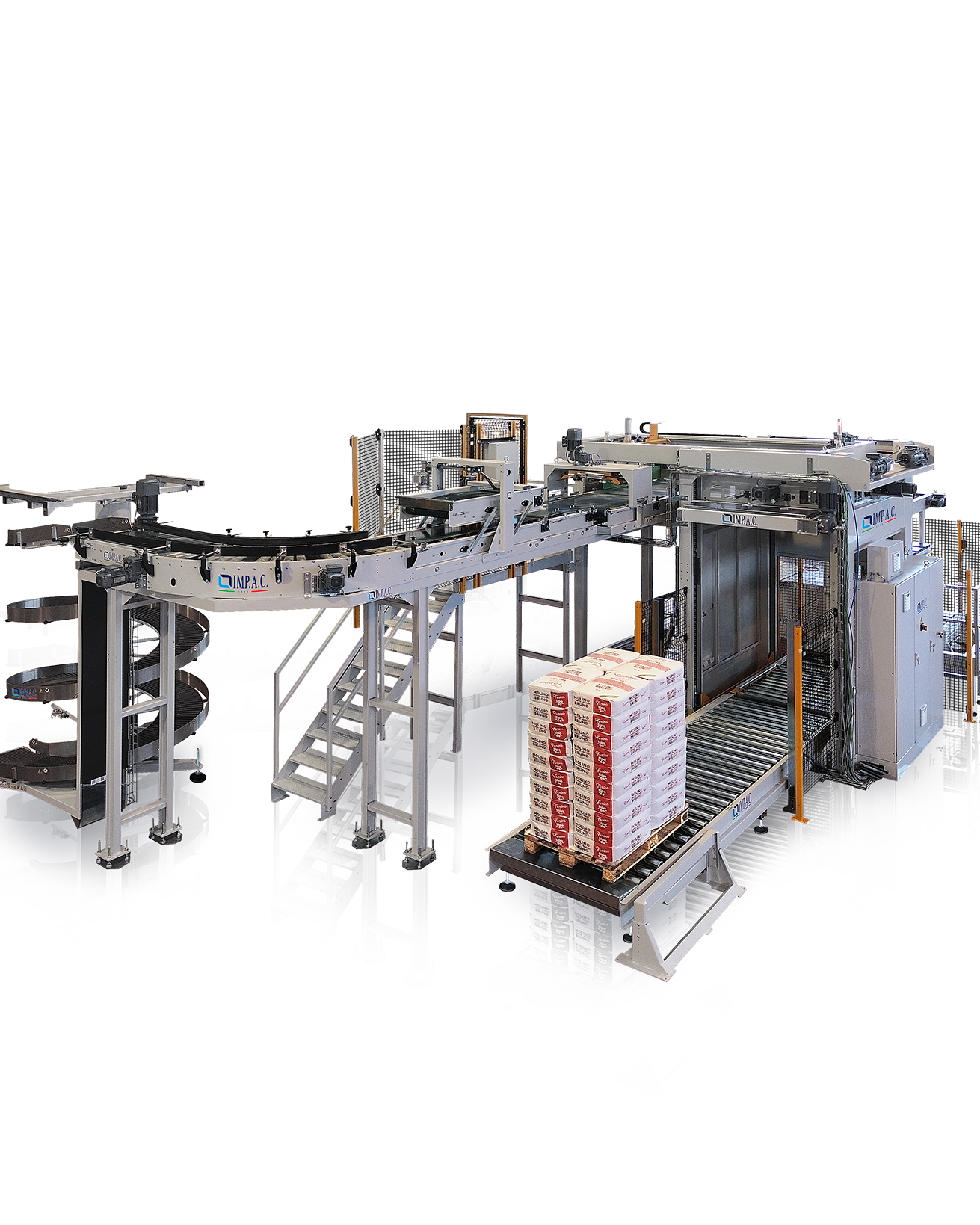

Top-feed mobile palletiser for high output IMP.A.C. 11 AV

Movable pallet palletiser with top feeding for high output.

Max. production: 1700 bags/h

Bag dimensions

Max. 1100 x 550 x h. 250 mm<br>Min. 300 x 150 x h. 60 mm

Pallet dimensions

Max. 1300 x 1200 x h. 140 mm<br>Min. 1000 x 800 x h. 100 mm

Layer dimensions

Max. 1400 x 1250 mm

Standard full pallet height

1600 mm

Compressed air consumption

100 Nl/min

Max. full pallet weight

2000 Kg

Operational capacity

6 layers/min with limit of 1700 bags/h

Installed power

13,5 KW

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

12000 Kg

The IMP.A.C. 11 AV palletiser is designed for high throughputs, with a palletising capacity of up to 1700 bags per hour.

This model is highly versatile and suitable for working with both small (2 kg) and large (up to 50 kg) bags, ensuring wide use in various industries.

The sack from an upstream line is compacted and made uniform, then orientated according to the pre-set formation and directed towards the layer pre-forming zone. The composite layer is then transferred to a centrally opening platform, which opens to deposit the layer on top of the pallet in the loading position. A lifter, using a photoelectric barrier system, correctly positions the pallet for the next layer deposit. The cycle continues repeating itself until the pallet is completed, which is then evacuated and replaced for the new cycle.

All synchronisms are managed by a programmable modular system (PLC), which allows the machine to be configured to palletise bags of different sizes, formations and number of layers.

This model is the ideal solution for companies needing a powerful, flexible and easy-to-configure palletiser for various production requirements.

Product benefits

__ High production capacity

__ High production capacity

Up to 1700 sacks/h.

__ Flexibility

__ Flexibility

For working with bags of various sizes (from 2 kg to 50 kg).

__ Modular system

__ Modular system

Programmable (PLC) for precise movement management.

__ High precision

__ High precision

Synchronisation of movements with photoelectric barrier.

__ Configurability

__ Configurability

Possibility of palletising different configurations and numbers of layers.

Nothing found.

Automatic self-regulating multipallet palletizer with top feeding IMP.A.C. 13 AMP

Automatic self-regulating multipallet palletizer with top feeding

Max production: 1100 bags/h

Bag dimensions

Max. 1100 x 550 x h. 250 mm<br>Min. 300 x 150 x h. 60 mm

Pallet dimensions

Max. 1300 x 1200 x h. 140 mm<br>Min. 1000 x 800 x h. 100 mm

Layer dimensions

Max. 1400 x 1250 mm

Standard full pallet height

1600 mm

Compressed air consumption

100 Nl/min

Max. full pallet weight

2000 mm

Operational capacity

4 layers/min with a limit of 1100 bags/h

Installed power

13,5 KW

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

10500 Kg

The "MULTIPALLET" IMP.A.C. 13 AMP palletizer is the ideal solution for operations with multiple production lines (2, 3, or 4) running simultaneously, requiring medium-to-high capacity and maximum flexibility.

With a production capacity of 1,100 bags/hour, the system is fully self-regulating to adapt to different types of bags to be palletized.

The system includes dedicated conveyor lines for each production line, capable of accumulating the necessary bags to form a complete pallet. Each line directs the bags to a specific accumulation conveyor until the required quantity is reached. Afterwards, the bags are retrieved by the palletizer, which automatically adjusts to the preset format.

The process includes:

- Bag compression, to uniform and compact it.

- Precise orientation, according to the predefined formation.

- Layer preformation, transferred to a platform with a central opening.

- Layer deposition on the pallet, thanks to the mobile platform and the lifter with photoelectric positioning.

The cycle continues until the pallet is complete, which is automatically evacuated and replaced to ensure operational continuity.

Ideal for:

- Industries with high production capacities and the need to manage multiple bag formats in parallel.

Product benefits

__ Self-regulating system

__ Self-regulating system

It automatically adjusts operation to different types and formats of bags.

__ Synchronized movements

__ Synchronized movements

Managed by a programmable modular system (PLC) to adapt to different formations and configurations.

__ High flexibility

__ High flexibility

Supports multiple production lines simultaneously.

__ Adaptability

__ Adaptability

Programmable for bags of various sizes, layer configurations, and palletizing patterns.

__ Modular design

__ Modular design

Easily integrable with conveyor and accumulation lines.

Nothing found.

Mobile platform sack and bundle palletiser with ground pallet and top feeding IMP.A.C. 11-12 APT

IMP.A.C. 11-12 APT

Mobile platform sack and bundle palletiser with ground pallet and top feeding

Mobile platform sack and bundle palletiser with floor pallet and top feeding

Max. output: 500 bags/h

8 bundles/min

Bag dimensions

Max. 1100 x 550 x h. 250 mm<br>Min. 400 x 300 x h. 80 mm

Bundle size

Max. 800 x 500 x h. 250 mm<br>Min. 300 x 200 x h. 80 mm

Paddle size

Max. 1300 x 1200 x h. 140 mm<br>Min. 1000 x 800 x h. 100 mm

Standard full pallet height

1550 mm

Compressed air consumption

100 Nl/min

Max. full pallet weight

2000 Kg

Operational capacity

2 layers/min with limit of 500 bags/h

Installed power

7,5 KW

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

3500 Kg

The IMP.A.C. 11-12 APT palletiser is designed to meet the needs of low to medium outputs of sacks and bundles, offering maximum versatility and reliable performance.

Thanks to its compact design, it can be easily installed even in small spaces.

Production Max:

- 500 sacks/hour

- 8 bundles/min

Advantages

- Compactness: ideal for limited spaces.

- Flexibility: handling sacks and bundles with variable formats.

- Reliability: synchronised operations and customisable programming for consistent productivity.

- Ease of use: full automation with minimal operator intervention required.a

The IMP.A.C. 11-12 APT is the ideal choice to optimise productivity while maintaining high quality standards even for low to medium production.

Product benefits

__ Modularity

__ Modularity

The machine can be adapted and expanded according to increasing user requirements, with the addition of roller conveyors and an empty pallet magazine.

__ Accuracy

__ Accuracy

Each bag or bundle is pressed to ensure uniformity and compactness before being oriented and sent to the layer pre-forming area.

__ Optimised movements

__ Optimised movements

The vertical and horizontal platform system ensures correct positioning and transfer of the layers on the pallet.

__ Intelligent automation

__ Intelligent automation

The process is completely managed by a programmable modular system (PLC), which enables the handling of bags and bundles of different sizes, configurations and numbers of layers.

Nothing found.

IMP.A.C. 11 AS mobile pallet palletiser with top feed

Mobile pallet palletiser with top feeding

Max. production: 1800 bags/h

Nothing found.

Bottom-fed palletizer for cardboard drums IMP.A.C. 52 AF

Bottom-fed palletizer for cardboard drums

Max production: 30 full drums/h

Bag dimensions

Pallet dimensions

Layer dimensions

Standard full pallet height

Operating pressure

Compressed air consumption

Max. full pallet weight

Operational capacity

Installed power

Operating pressure

Control voltage

Indicative weight

Product benefits

Nothing found.

IMP.A.C. 22 ASA automatic self-adjusting special palletiser

Special self-adjusting automatic palletiser with stationary pallet

Max. production: 600 cardboard/hour

Bag dimensions

Max. 2400 x 1200 x h. 400<br>Min. 300 x 150 x h. 25

Pallet dimensions

Max. 2000 x 1200 x h. 140<br>Min. 1000 x 600 x h. 100

Layer dimensions

Max. 2500 x 1300

Standard full pallet height

1550 mm

Operating pressure

6 bar

Compressed air consumption

150 Nl/min

Max. full pallet weight

2000 Kg

Operational capacity

2.5 layers at a limit of 15 cardboard/min

Installed power

16 KW

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

13000 Kg

The IMP.A.C. 22 ASA palletiser is designed to meet the most complex challenges of modern production lines, ensuring maximum flexibility and adaptability.

Thanks to its unique features, this model is ideal for applications requiring the management of an unlimited number of formats with variable dimensions, from a minimum of 300x150xH=25 mm to a maximum of 2400x1200xH=400 mm.

It is widely used in the furniture industry, both for packaged and KIT products.

With a production capacity of up to 600 cardboard/hour, the IMP.A.C. 22 ASA stands out as a highly specialised, high-performance solution designed to improve operational efficiency and guarantee flawless results in any production environment.

Product benefits

__ Versatility and precision

__ Versatility and precision

It handles very different carton sizes, adapting automatically to configuration changes.

__ Intelligent automation

__ Intelligent automation

The system is fully co-ordinated by a programmable modular PLC, ensuring smooth and reliable management of the entire process.

Nothing found.

IMP.A.C. 22 AL automatic stationary palletiser

Automatic stationary palletiser

Max. production: 2000 cardboard/h

Cardboard dimensions

Min. 200 x 150 x h. 25 mm

Max. 500 x 400 x h. 300 mm

Pallet dimensions

Min. 1000 x 800 x h. 100 mm

Max. 1200 x 1000 x h. 140 mm

Layer dimensions

Max. 1300 x 1100 mm

Standard full pallet height

1550 mm

Operating pressure

6 bar

Compressed air consumption

150 Nl/min

Max. full pallet weight

1500 Kg

Operational capacity

3.5 states at the limit of 35 carboards/min

Installed power

9,5 KW

Operating pressure

6 bar

Operating pressure

Control voltage

Indicative weight

8000 Kg

The IMP.A.C. 22 A palletiser is the ideal solution for tasks requiring a smooth and precise palletising process, guaranteeing versatility and reliable performance in any production environment.

Designed to handle cartons from an upstream line, the system automatically orients the containers according to the predefined formation, transferring them to the layer pre-forming area. Each layer is then handled by a platform with vertical and horizontal movements:

- Vertical movement for precise positioning of the layer drain.

- Horizontal movement to transfer the layer onto the pallet.

The cycle repeats automatically until the pallet is completed, which is evacuated and replaced with an empty pallet, ready for a new cycle. All synchronisms are managed by a programmable modular system (PLC), which guarantees precise and reliable operation.

Thanks to its advanced technology, the machine can be configured to palletise cardboard boxes of different sizes, patterns and numbers of layers, offering extraordinary operational flexibility.

Product benefits

__ Operational flexibility

__ Operational flexibility

Support for cartons of various sizes, patterns and layers.

Nothing found.