Semi-automatic Big-Bag weighing and emptying system with forks IMP.A.C. 96 SA 20

The IMP.A.C. 96-SA 20 is a semi-automatic plant designed for weighing and emptying Big-Bags, with a production capacity of up to 20 bags/hour.

Thanks to its compact design and forklift capability, it is a versatile and efficient solution for industries that need to control weight and empty bags safely and accurately.

Operating Cycle

Loading the Big-Bag

– The full Big-Bag is placed on the supporting forks by threading the 4 shoulder straps through the hooks.

– The load cell system performs the weighing, allowing accurate weight control.

Emptying

• The operator opens the unloading mouth of the Big-Bag, allowing the material to flow.

• The product is discharged to its intended destination (hopper, conveyor, container, etc.).

End of cycle

• Once emptying is complete, the empty Big-Bag is removed.

• The system is ready for a new cycle.

Industrial applications

The IMP.A.C. 96-SA 20 is widely used in sectors such as:

Chemical and pharmaceutical industry – Controlled emptying of raw materials in powder or granule form.

Construction industry – Unloading of bulk materials such as cement, sand and gravel.

Agro-food industry – Handling of flour, cereals and granular foodstuffs.

Recycling industry – Handling of materials for recovery.

Thanks to its mobility, user-friendliness and weighing accuracy, the IMP.A.C. 96 SA 20 is the ideal solution for companies needing an efficient and reliable system for Big-Bag management.

Semi-automatic Big-Bag weighing and emptying system with forks

Max Production: 20 Big-Bags/h

Maximum production

10-20 Big-Bags/h

Tolerance on 10 weighings

+/- 0,3%

Support system

Hanging with 4 suspenders

Weighing system

IP67 load cells

Supply voltage

220 V

Air pressure

6 bar

Big-Bag Weight

Max. 2000 Kg

Min. 50 Kg

Max Size. Big-Bag

1100 x 1100 H=1800 mm

Installed power

0,1 KW

Protection

IP55

Compressed air consumption

50 Nl/min

Indicative weight

1000 Kg

Product benefits

__ Compatible with various materials

__ Compatible with various materials

Suitable for powders, granules, sand, pebbles and other bulk materials.

__ Industrial ruggedness

__ Industrial ruggedness

Designed for intensive use in production environments.

Automatic Big-Bag weighing and filling system with hydraulic platform and Big-Bag handling roller conveyors IMP.A.C. 95 A 20 L

IMP.A.C. 95-A 20/L

Automatic Big-Bag weighing and filling system with hydraulic platform and powered roller conveyors

The IMP.A.C. 95-A 20/L is an automatic plant designed for weighing and filling Big-Bags with a production capacity of 20-30 bags/hour.

Thanks to the hydraulic platform and motorised roller conveyors, it guarantees a fully automated process, optimising pallet handling and minimising operator intervention. The system is PLC-controlled, which precisely manages the filling, unloading and transferring of the bag.

Technology and Operation

Operating Cycle

Preparation:

• The empty pallet is automatically positioned on the lifting platform by means of a motorised roller conveyor.

• The operator activates the pneumatic hooks and secures the 4 straps of the empty sack.

• The bag mouth is inserted into the pneumatic bag spout system.

Filling:

• When the start button is pressed, the bag is spread with a flow of air to facilitate filling.

• The filling valve opens and the product flows into the bag.

• The weight is controlled via load cells, automatically stopping filling when the preset value is reached.

Release and handling:

• The operator releases the bag mouth from the locking system and closes the bag.

• When the evacuation button is pressed, the hydraulic platform rises, lifting the Big-Bag to relieve the shoulder straps of weight.

• The pneumatic hooks disengage, releasing the shoulder straps.

• The hydraulic platform descends and the pallet with the Big-Bag is evacuated automatically by a motorised roller conveyor.

The IMP.A.C. 95-A 20/L is the ideal solution for companies requiring an automated Big-Bag filling system, ensuring an efficient, safe and fully integrated production cycle.

Automatic Big-Bag weighing and filling system with hydraulic platform and Big-Bag handling roller conveyors

Max Production: 30 Big-Bags/h

Maximum production

20-30 Big-Bags/h

Tolerance on 10 weighings

+/- 0,3%

Support system

Hanging with 4 suspenders

Weighing system

IP67 load cells

Supply voltage

380 V

Air pressure

6 bar

Big-Bag Weight

Max. 2000 Kg

Min. 50 Kg

Max Size. Big-Bag

1100 x 1100 H=1800 mm

Installed power

5 KW

Protection

IP55

Compressed air consumption

100 Nl/min

Indicative weight

3000 Kg

Product benefits

__ Automated Handling

__ Automated Handling

Motorised roller conveyors allow the automatic transfer of pallets, increasing productivity.

__ Versatility and customizable adjustments

__ Versatility and customizable adjustments

Adaptable to all types of Big-Bags.

__ Full automation

__ Full automation

Integrated PLC for efficient and repeatable process.

__ Industrial Reliability

__ Industrial Reliability

Rugged structure designed for continuous use in production environments.

__ Hydraulic platform

__ Hydraulic platform

Facilitates Big-Bag release by reducing operator effort.

__ Compatibility with advanced accessories

__ Compatibility with advanced accessories

• Auger product feeding system for more precise dosing.<br>• Automatic Big-Bag warehouse and loader for more efficient production flow management.

Semi-automatic Big-Bag weighing and filling system with hydraulic platform IMP.A.C. 95 SA 20 L

IMP.A.C. 95-SA 20/L

Semi-automatic Big-Bag weighing and filling system with hydraulic platform

The IMP.A.C. 95-SA 20/L is a semi-automatic plant designed for weighing and filling Big-Bags with a production capacity of 15-20 bags/hour.

Thanks to its hydraulic platform, it offers an optimised process that reduces operating effort, increasing safety and precision in filling operations. The system is PLC-controlled, allowing the automation of filling, unloading and handling of the bag on a pallet.

Technology and Operation

Operating Cycle

Preparation:

• The operator manually places the empty pallet on the platform.

• Using a button, the pneumatic hooks for attaching the sack are activated.

• The empty sack is fastened by inserting the 4 shoulder straps into the hooks and the sack mouth into the pneumatic sack mouth system.

Filling:

• When the start button is pressed, the bag is spread with a flow of air to facilitate filling.

• The filling valve opens and the product flows into the bag.

• The weight is controlled via load cells, automatically stopping filling when the preset weight is reached.

Release and handling:

• The operator releases the bag mouth from the locking system and proceeds to close the bag.

• By pressing the evacuation button, the hydraulic platform rises, lifting the Big-Bag to relieve the shoulder straps of weight.

• The pneumatic hooks disengage, leaving the shoulder straps free.

• The hydraulic platform descends and the full Big-Bag is manually evacuated by forklift truck.

The IMP.A.C. 95-SA 20/L is the ideal choice for medium to high production environments, ensuring an efficient, precise and safe filling cycle.

Semi-automatic Big-Bag weighing and filling system with hydraulic platform

Max Production: 20 Big-Bags/h

Maximum production

15-20 Big-Bags/h

Tolerance on 10 weighings

+/- 0,3%

Support system

Hanging with 4 suspenders

Weighing system

IP67 load cells

Supply voltage

380 V

Air pressure

6 bar

Big-Bag Weight

Max. 2000 Kg

Min. 50 Kg

Max Size. Big-Bag

1100 x 1100 H=1800 mm

Installed power

2 KW

Protection

IP55

Compressed air consumption

70 Nl/min

Indicative weight

2000 Kg

Product benefits

__ Hydraulic platform

__ Hydraulic platform

It facilitates the release of the Big-Bag by reducing working time and improving safety.

__ Versatility and customizable adjustments

__ Versatility and customizable adjustments

Adaptable to all types of Big-Bags.

__ Intelligent automation

__ Intelligent automation

Integrated PLC for precise control of operations.

__ Integration with power systems

__ Integration with power systems

Option for auger feeding for optimised material handling.

__ Highest reliability

__ Highest reliability

Robust construction designed for intensive use in industrial environments.

Semi-automatic Big-Bag weighing and filling system with forks IMP.A.C. 95 SA 20

The IMP.A.C. 95 SA 20 is a semi-automatic machine designed for weighing and filling Big-Bags, with a production capacity of up to 20 bags per hour.

Thanks to its mobility and ease of use, it is the ideal solution for construction sites and storage warehouses, ensuring a fast and efficient process for materials of different grain sizes (powders, sand, granules, pebbles, etc.).

Technology and Operation

Filling and weighing system

• The empty sack is hung on the brackets and secured by the operator, who attaches the 4 supporting braces and connects the sack mouth to the hopper collector.

• Once ready, the filling cycle starts by pressing the start button.

• The load cell system monitors the weight of the incoming material, automatically stopping the flow when the preset value is reached.

• The full Big-Bag is then removed with a standard forklift truck for storage or transport.

Additional modes of use

Emptying and weight control – The system can also be used to check and adjust the weight of already filled Big-Bags, offering a versatile solution for logistics and material transport.

The IMP.A.C. 95 SA 20 is a reliable and versatile solution for those who require efficiency, precision and mobility in industrial bag filling and weighing processes.

Semi-automatic Big-Bag weighing and filling system with forks

Max Production: 20 Big-Bags/h

Maximum production

15-20 Big-Bags/h

Tolerance on 10 weighings

+/- 0,3%

Support system

Hanging with 4 suspenders

Weighing system

IP67 load cells

Supply voltage

220 V

Air pressure

6 bar

Big-Bag Weight

Max. 2000 Kg

Min. 50 Kg

Max Size. Big-Bag

1100 x 1100 H=1800 mm

Installed power

0,1 KW

Protection

IP55

Compressed air consumption

50 Nl/min

Indicative weight

1000 Kg

Product benefits

__ Operational flexibility

__ Operational flexibility

Suitable for a wide range of materials, from powders to pebbles.

__ High mobility

__ High mobility

It can be moved with a forklift, making it ideal for construction sites and warehouses.

__ Ease of use

__ Ease of use

Intuitive and quick operations with semi-automatic interface.

__ Precise weight control

__ Precise weight control

The load cell system ensures exact filling, avoiding waste or overloading.

__ Adaptability

__ Adaptability

It can be used for both filling and checking and emptying Big-Bags.

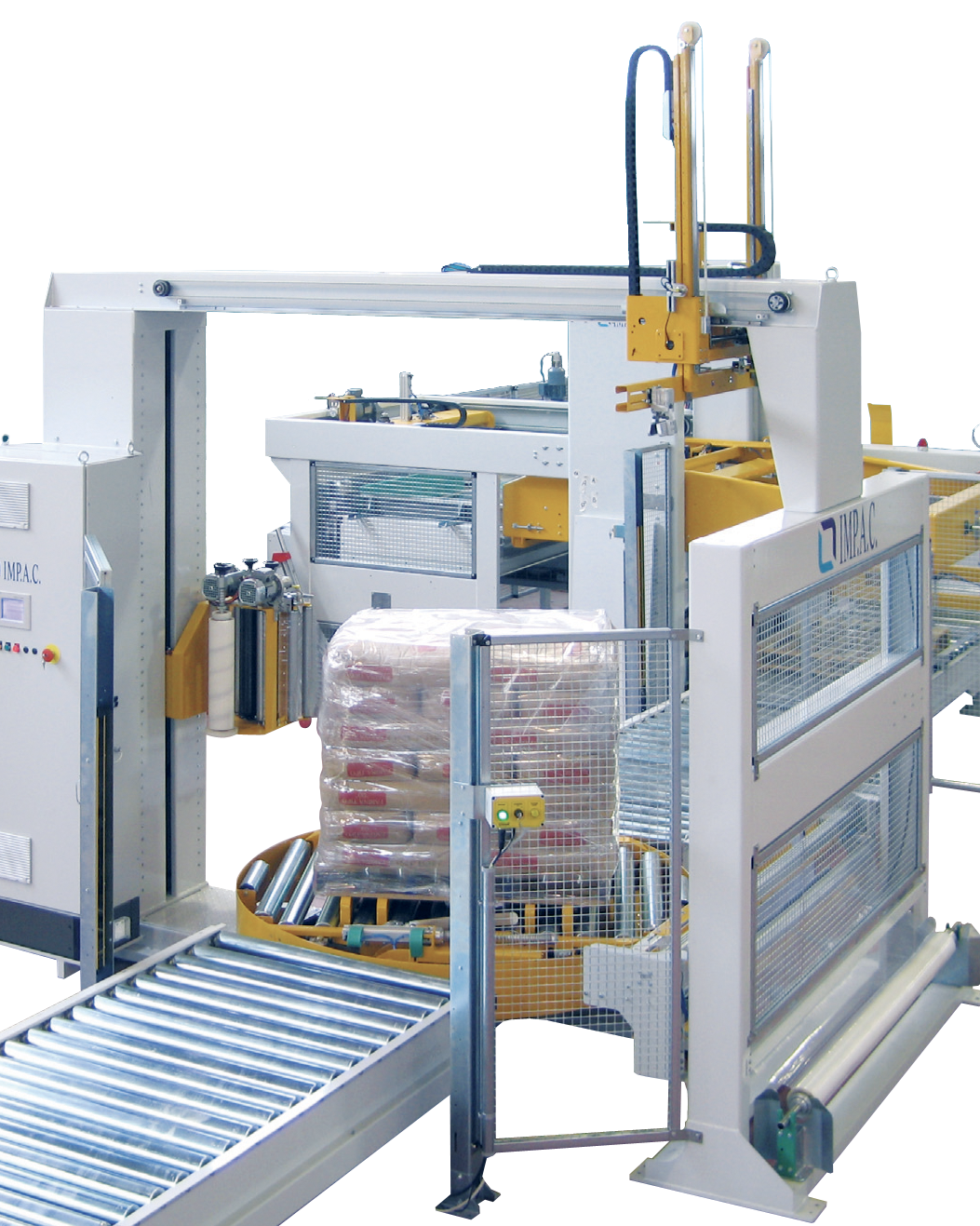

Automatic cap cover with stretch film Max Production: 30 pallets/h IMP.A.C. STRETCH A 30

Automatic Hooding Machine with Stretch Film

Max Production: 30 pallets/h

Pallet dimensions

Max. 1200 x 1200 mm

Pallet dimensions

Max. 2100 mm<br>Min.300 mm

Type of film

Stretchable, elastic polyethylene

Compressed air consumption

70 Nl/min

Auxiliary voltage

24 V

Compressed air consumption

150 Nl/min

Full pallet weight

Max. 200Kg

Operational capacity

30 pallets/h

Installed power

11 KW

Film thickness

Max. 200 micron<br>Min.80 micron

Air pressure

6 bar

Indicative weight

5500 Kg

The IMP.A.C. STRETCH A 30 is an automatic cap cover designed to ensure maximum protection and load stabilization, thanks to the extension of the cap beneath the pallet.

Ideal for high-production lines (up to 30 pallets/h), this machine is perfect for packaging unstable products that are difficult to handle with conventional wrapping systems.

Thanks to the innovative cold stretch technology, the film adapts without the need for heating, ensuring a hermetic, durable, and cost-effective wrap. The cap cover automatically adjusts to the height of the load, creating customized caps for each pallet.

Technology and Operation

Stretch film cap covering system

The IMP.A.C. STRETCH A 30 uses a tubular film that is unwound, cut, and sealed to form a cap, which is then stretched and securely attached to the pallet in an optimal way.

Automatic adjustment to the load height

Thanks to the detection sensors, the machine adjusts in real time to the pallet’s dimensions, optimizing material consumption and ensuring a uniform and secure result.

Automated operating cycle

Pallet dimension entry and detection.

Unwinding of the film from the tubular roll.

Opening of the film and gripping at four points.

Cutting and sealing to form the cap.

Mechanical crimping of the film at the four corners.

Stretching of the cap by lowering the mobile frame.

Release of the cap under the pallet for an airtight seal.

Automated evacuation of the pallet.

The IMP.A.C. STRETCH A 30 is the perfect solution for companies that need a reliable, fast, and high-performance cap covering system, capable of ensuring safety and optimal protection for every type of load.

Product benefits

__ Total protection

__ Total protection

The stretch cap covers the entire pallet, including the base, protecting it from dust, moisture, and weather conditions.

__ Optimization of film consumption

__ Optimization of film consumption

Dimensional detection system to reduce waste.

__ Fully automatic process

__ Fully automatic process

No manual intervention required, improving efficiency and productivity.

__ Perfect for unstable loads

__ Perfect for unstable loads

Ideal stabilization for products that are difficult to wrap with traditional systems.

__ Suitable for high-production lines

__ Suitable for high-production lines

High performance up to 30 pallets/h for industrial plants.

Nothing found.

Automatic cap cover with stretch film and ground-level pallet IMP.A.C. STRETCH APT.

Automatic cap cover with stretch film and ground-level pallet.

Max Production: 30 pallets/h

Pallet dimensions

Max. 1200 x 1200 mm

Pallet dimensions

Max. 2100 mm<br>Min.300 mm

Type of film

Stretchable, elastic polyethylene

Compressed air consumption

70 Nl/min

Auxiliary voltage

24 V

Compressed air consumption

120 Nl/min

Full pallet weight

Max. 200Kg

Operational capacity

30 pallets/h

Installed power

9 KW

Film thickness

Max. 200 micron<br>Min.80 micron

Air pressure

6 bar

Indicative weight

4500 Kg

The IMP.A.C. STRETCH APT is an automatic cap cover designed to ensure maximum protection and load stabilization by extending the cap all the way under the pallet.

Ideal for medium production lines (up to 30 pallets/h), this machine is particularly suited for unstable products that cannot be handled with spiral wrapping.

The innovative cold stretch cap covering system ensures effective and customized coverage for each pallet, automatically adjusting to the height of the goods and creating caps with optimized length.

Technology and Operation

Stretch film cap covering system

The IMP.A.C. STRETCH APT uses the cold stretch film technique to ensure optimal adhesion to the load, without the need for heating or thermal shrinkage.

Automatic adjustment to pallet height

The machine automatically detects the dimensions of the pallet and creates a custom cap, optimizing material consumption and enhancing load protection.

Optimized operating cycle.

Pallet positioning and dimensional detection.

Unwinding the film from the tubular roll.

Opening and gripping the film at four points.

Cutting and welding to form the cap.

Mechanical gathering of the film at the four corners.

Unfolding the cap via the mobile frame with shape control.

Releasing the cap under the pallet for an airtight seal.

Manual pallet evacuation.

The IMP.A.C. STRETCH APT is the ideal solution for companies that require reliable and durable protection for their pallets, minimizing the risk of damage and improving the efficiency of the packaging process.

Product benefits

__ Suitable for unstable loads

__ Suitable for unstable loads

Perfect for products that are difficult to wrap with traditional systems.

__ Optimization of film consumption

__ Optimization of film consumption

Creation of custom caps to reduce material waste.

__ Fully automatic process

__ Fully automatic process

Automatic height adjustment and controlled cap application.

__ High protection and stabilization

__ High protection and stabilization

The stretch hood covers the entire pallet, including the bottom side, for complete protection.

__ Easy integration

__ Easy integration

Compatible with medium-capacity production lines up to 30 pallets/h.

Nothing found.

Semi-automatic wrapping system with turining platform (also available in version with rotating idle roller conveyor) IMP.A.C. SA 15

IMP.A.C. SA 15

Semi-automatic wrapping system with turining platform (available with rotating idle roller conveyor)

Semi-automatic wrapping system with turining platform (also available with rotating idle roller conveyor)

Max Production: 20 pallets/h

Max pallet dimensions.

Max. 1300 x 1000 mm

Compressed air consumption

40 Nl/min

Auxiliary voltage

24 V

Max weight of full pallet

1500 Kg

Standard full pallet height

1600 mm

Operational capacity

20 pallets/hour

Potenza installata

1,2 KW

Operating pressure

6 bar

Peso indicativo

900 Kg

L'IMP.A.C. SA 15 is a semi-automatic stretch wrapper designed to ensure efficient and controlled wrapping in facilities with low to medium production needs, with a capacity of up to 20 pallets/hour.

Thanks to the rotating platform, the pallet is wrapped evenly and stably, while the film tensioning system, available in either mechanical or electro-pneumatic versions, ensures perfect film application according to operational needs.

Technology and Operation

Configurable automatic cycle

The wrapping process is fully automatic and managed by a PLC, with the ability to customize the wrapping parameters to suit various production needs.

Manual film attachment and cutting

The operator manually attaches the film at the beginning and cuts it at the end of the cycle, ensuring intuitive operational control.

Customizable film tensioning

The machine can be equipped with a mechanical tensioning system (for a simpler and more reliable solution) or an electropneumatic system (for more precise control of the film tension).

Version with rotating idle roller (optional)

The IMP.A.C. SA 15 can be equipped with a roller conveyor with safety brake, ideal for facilitating the manual placement of the pallet on the platform and enhancing operational safety.

The IMP.A.C. SA 15 is the ideal solution for those seeking a versatile, reliable, and configurable semi-automatic wrapper, perfect for optimizing the palletizing process with a compact footprint and maximum operational efficiency.

Product benefits

__ Production up to 20 pallets/h

__ Production up to 20 pallets/h

Perfect for medium-intensity wrapping needs.

__ Customizable film tensioning

__ Customizable film tensioning

Mechanical or electropneumatic option.

__ Free roller conveyor with brake (optional)

__ Free roller conveyor with brake (optional)

Greater safety and convenience in pallet positioning.

__ Rotating platform

__ Rotating platform

Smooth movement and uniform wrapping.

__ Automatic wrapping cycle

__ Automatic wrapping cycle

Configurable according to operational needs.

Nothing found.

IMP.A.C. PR SA Semi-automatic stretch wrapper with rotating motorized roller conveyor.

Semi-automatic stretch wrapper with rotating motorized roller conveyor

Max Production: 20 pallets/h

Max pallet dimensions.

Max. 1300 x 1000 mm

Compressed air consumption

40 Nl/min

Auxiliary voltage

24 V

Max weight of full pallet

2000 Kg

Standard full pallet height

2200 mm

Operational capacity

20 pallets/hour

Installed power

1,8 KW

Operating pressure

6 bar

Indicative weight

1600 Kg

The IMP.A.C. PR SA is a semi-automatic stretch wrapper designed to efficiently handle pallet wrapping in low to medium production capacity plants, with a maximum speed of 20 pallets/hour.

Thanks to the motorized rotating roller conveyor, the movement of pallets is smooth and controlled, while the electro-pneumatic film tensioning device ensures perfect film adhesion, enhancing load stability.

Technology and Operation

Semi-automatic cycle with PLC management

The operator starts the wrapping process, which is fully automated thanks to PLC electronic management, ensuring precision and repeatability of the cycle.

Manual film attachment and cutting

The operator manually attaches the film at the beginning and cuts it at the end of the cycle, maintaining control over the loading and unloading stages.

Electropneumatic film tensioning

The tensioning system ensures uniform application of the film, preventing waste and improving pallet protection.

Upper pressing option

Available upon request, the upper pressing option ensures greater load stability during the wrapping cycle, particularly useful for unstable or irregular pallets.

The IMP.A.C. PR SA represents a reliable, efficient, and versatile solution, perfect for companies that require a semi-automatic wrapping system with a high level of control and operational precision.

Product benefits

__ Production up to 20 pallets/h

__ Production up to 20 pallets/h

Ideal for small and medium production needs.

__ Electropneumatic film tensioning

__ Electropneumatic film tensioning

Perfect film adhesion for enhanced load protection.

__ Optional top press for enhanced load stability

__ Optional top press for enhanced load stability

Increased stability for unstable pallets.

__ Smooth movement

__ Smooth movement

Motorized roller conveyor for controlled pallet transport.

__ Partial automation

__ Partial automation

Wrapping is automatically managed, with manual start and end operations.

Nothing found.

Single Coil Winder IMP.A.C. H 01

Single Coil Winder

Max Production: 30 Coils/h

Nothing found.

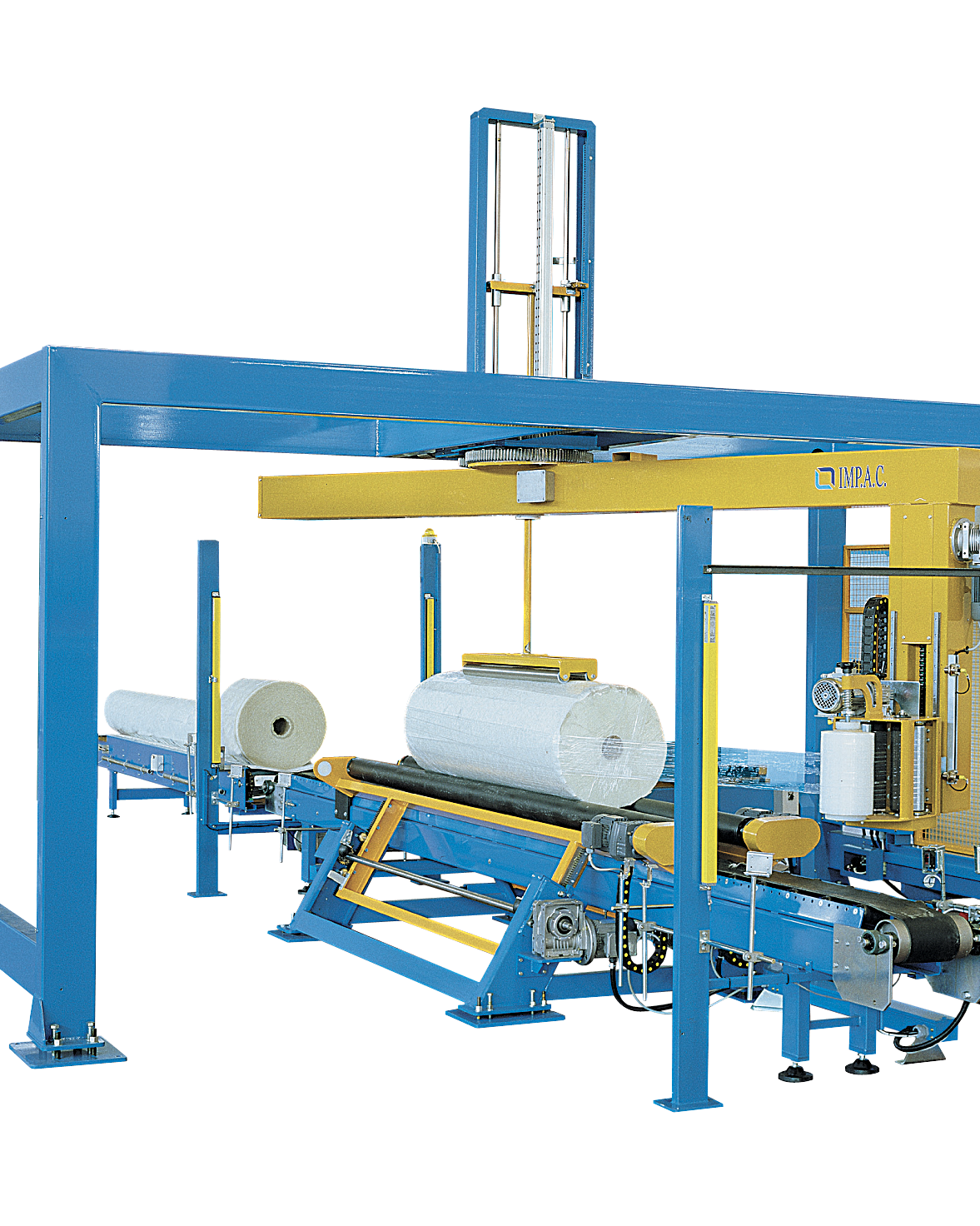

AUTOMATIC WRAPPER/PACKAGING MACHINE WITH SELF-ADJUSTING ROTARY ARM FOR COILS IMP.A.C. BR ASA

IMP.A.C. BR ASA

Automatic Wrapper/Packaging Machine with Self-Adjusting Rotary Arm for Coils

Automatic Wrapper/Packaging Machine with Self-Adjusting Rotary Arm for Coils

Max Production: 30 Coils/h

Max Coil Diameter

1000 mm

Max Film Coil Size

Ø 250 x h 300 mm

Compressed air consumption

150 Nl/min.

Auxiliary voltage

24 V

Maximum coil height

3.100 mm

Operational capacity

30 coils/hour

Installed power

6 KW

Operating pressure

6 bar

Indicative weight

4500 Kg

Nothing found.