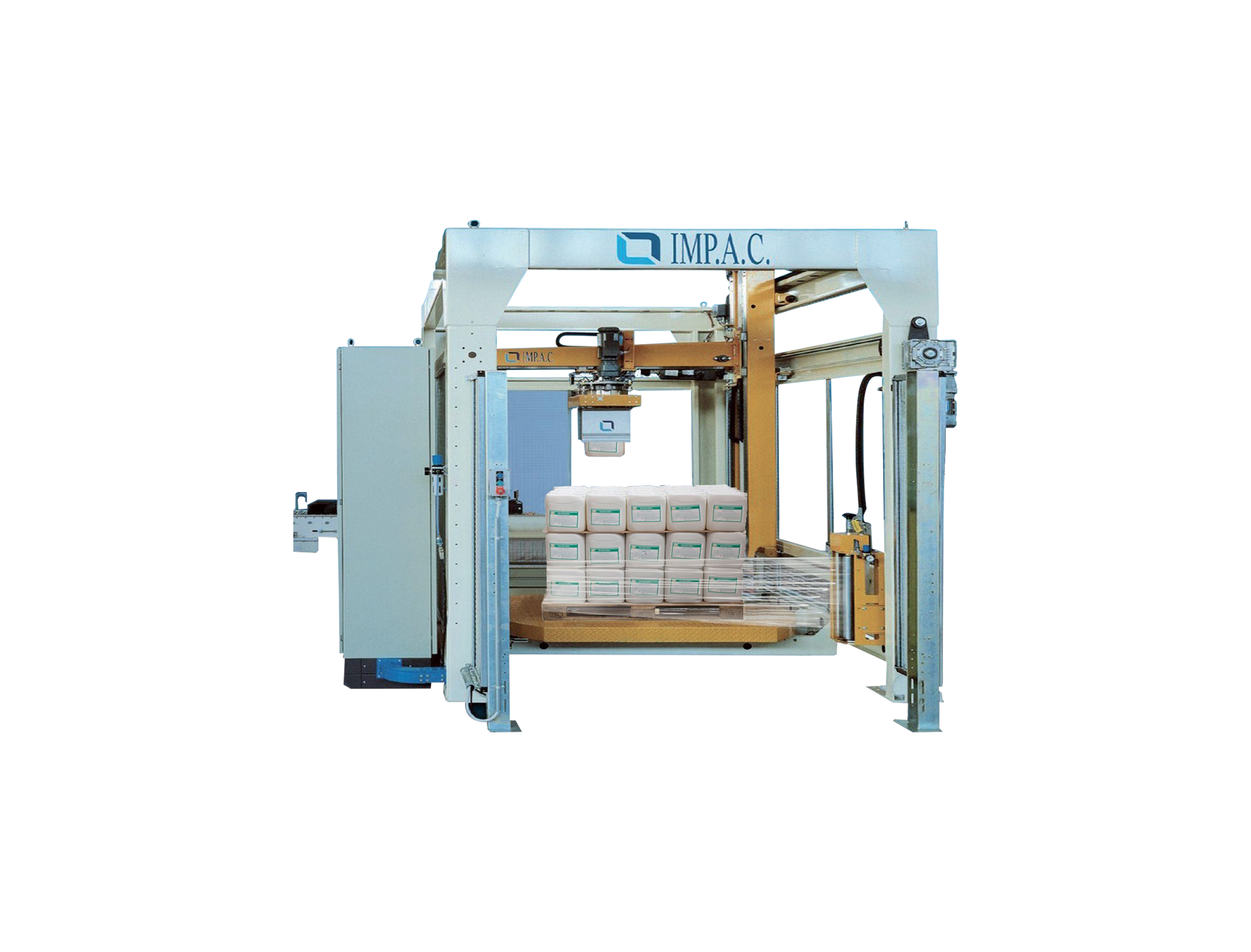

IMP.A.C. ROBOTEX 525 A-PR+TOP Cartesian bucket palletising robot with integrated automatic winder and cover top

IMP.A.C. ROBOTEX 525 A-PR+TOP

Cartesian bucket palletising robot with integrated automatic winder and cover top

The IMP.A.C. ROBOTEX 525 A-PR+TOP is an advanced, fully automatic solution for palletising buckets.

With a compact design and integrated functionality, this machine is ideal for efficiency, load stability and precision, fitting perfectly into fully automated production facilities.

Key features

- Operational versatility: suitable for handling buckets with sizes and weights ranging from 5 to 65 litres, using a single piece of equipment.

- Integrated winder and cover top: guarantee maximum load stability, making it possible to palletise even unstable or slippery buckets.

- Compactness: small dimensions for installation in limited spaces.

- Total automation: elimination of the need for operator supervision.

- Cartesian system: positioning control with encoders ensures high precision and reliability.

- Advanced synchronisation: movements are coordinated by a programmable modular system (PLC), allowing complete customisation of configurations.

The IMP.A.C. ROBOTEX 525 A-PR+TOP is the ideal solution for companies looking for reliability, precision and high automation in the palletising process, guaranteeing excellent results even under complex operating conditions.

Cartesian bucket palletising robot with built-in automatic winder and cover top

Production Max:

230 buckets/hour basic solution

400 buckets/hour quick solution

Bucket dimensions

Max. diameter 400 mm x h 500

Max. diameter 200 mm x h 180

Paddle size

Max. 1200 x 1000 mm x h 140

Min. 1000 x 800 mm x h 80

Maximum layer size

Max. 1300 x 1100 mm

Standard full pallet height

1600 mm

Compressed air consumption

200 Nl/min

Max. full pallet weight

2000 Kg

Operational capacity

230-400 buckets/h

Installed power

9 KW

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

6000 Kg

Product benefits

__ Production up to 400 buckets/h

__ Production up to 400 buckets/h

__ Combined palletising and wrapping for stable loads

__ Combined palletising and wrapping for stable loads

__ Suitable for buckets of different sizes and weights

__ Suitable for buckets of different sizes and weights

__ Small footprint for optimised installation space

__ Small footprint for optimised installation space

__ Programmable management for maximum operational flexibility

__ Programmable management for maximum operational flexibility

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

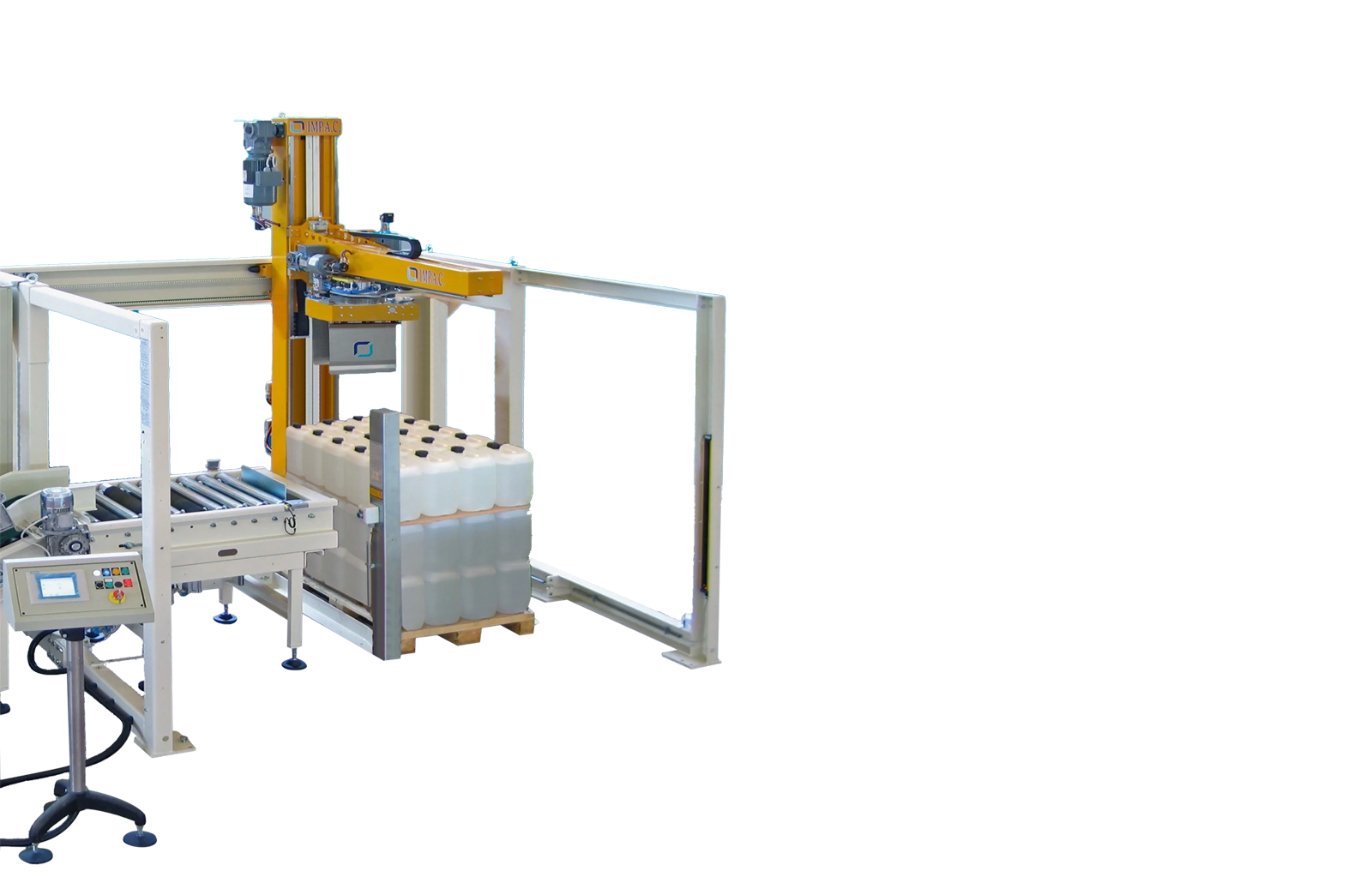

IMP.A.C. ROBOTEX 525 A-PR Cartesian palletising robot with built-in automatic winder

IMP.A.C. ROBOTEX 525 A-PR

Cartesian canister palletising robot with built-in automatic winder

The IMP.A.C. ROBOTEX 525 A-PR is an innovative, fully automatic palletiser designed to efficiently and accurately handle end-of-line requirements.

With its compact design and advanced functionality, it is an ideal solution for companies needing a high-performance and versatile system for palletising canisters

Key features

- Palletising versatility: handles canisters with formats and weights ranging from 5 to 65 kg using a single fixture.

- Integrated pallet wrapper: allows palletising and pallet wrapping at the same time, ensuring maximum load stability.

- Compactness: small dimensions for installation in limited spaces.

- Full automation: eliminates the need for operator supervision, optimising operational efficiency.

- Cartesian accuracy: positioning control via encoders guarantees high accuracy.

- Advanced modular control: all movements and synchronisms are managed by a programmable system (PLC), ensuring reliability and customisation.

The IMP.A.C. ROBOTEX 525 A-PR is a machine designed to meet the challenges of modern automated production, providing high operational flexibility, precision and reliability, making it ideal for fully automated production facilities.

Cartesian can palletising robot with built-in automatic winder

Production Max:

270 canisters/h basic solution

450 canisters/h quick solution

Tank dimensions

Max. 30 litres

Min. 5 litres

Paddle size

Max. 1200 x 1000 mm x h 140

Min. 1000 x 800 mm x h 80

Maximum layer size

Max. 1300 x 1100 mm

Standard full pallet height

1600 mm

Compressed air consumption

150 Nl/min

Max. full pallet weight

1500 Kg

Operational capacity

270-450 canisters/h

Installed power

8,5 KW

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

6000 Kg

Product benefits

__ Production up to 450 cans/h

__ Production up to 450 cans/h

__ Suitable for canisters of different sizes and weights

__ Suitable for canisters of different sizes and weights

__ Load stability thanks to integrated winder

__ Load stability thanks to integrated winder

__ Compact design for small spaces

__ Compact design for small spaces

__ Total automation for maximum efficiency

__ Total automation for maximum efficiency

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

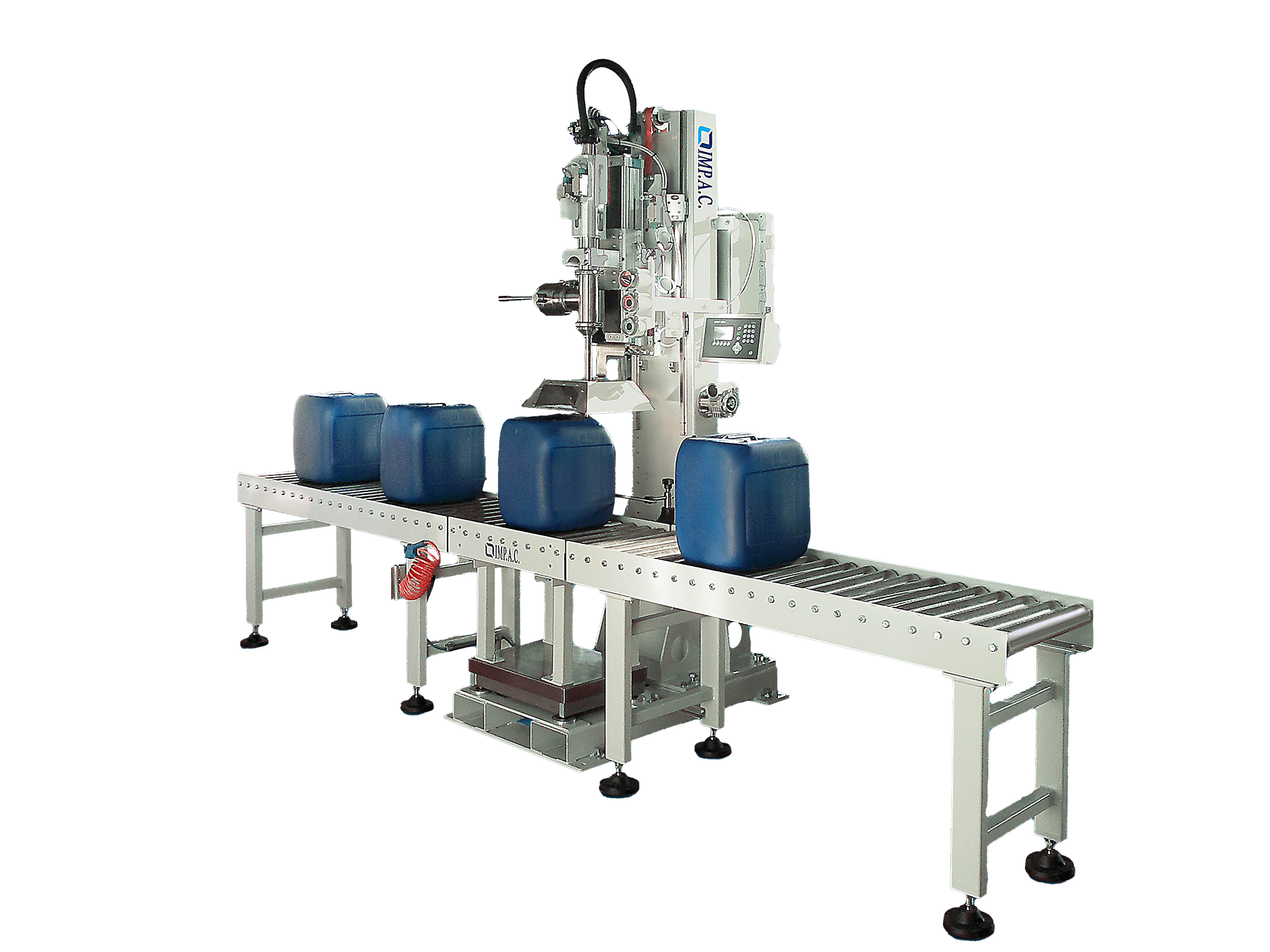

IMP.A.C. ROBOTEX 525 A-SA Cartesian palletising robot with floor pallet (also available in multi-pallet version)

IMP.A.C. ROBOTEX 525 A-SA

Cartesian palletising robot with floor pallet

(also available in multi-pallet version)

The IMP.A.C. ROBOTEX 525 A-SA is a Cartesian robot designed for automatic palletising of canisters, ideal for low throughputs.

Thanks to its compact dimensions (4000×2400 mm), it is a versatile, high-performance solution for space-constrained production lines.

Key features

- Compactness and versatility: designed to occupy small spaces and to palletise canisters of different sizes and weights.

- Complete automation: the palletising cycle is fully automated, eliminating the need for an operator.

- Cartesian precision: the Cartesian axis movement system guarantees accurate positioning thanks to encoder control.

- Flexible programming: different layouts, formations and numbers of layers can be configured to meet production requirements.

- Advanced PLC control: all synchronisms and movements are managed by a programmable modular system, ensuring efficiency and reliability.

The ROBOTEX 525 A-SA IMP.A.C. is the perfect solution for companies looking for a compact, high-performance machine for automatic palletising of canisters, guaranteeing reliability, efficiency and adaptability to specific production requirements.

Cartesian palletising robot with floor pallet (also available in multi-pallet version)

Max. production: 300 cans/h

Can dimensions

Max. 30 litres

Min. 5 litres

Paddle size

Max. 1200 x 1000 mm x h 140

Min. 1000 x 800 mm x h 80

Maximum layer size

Max. 1300 x 1100 mm

Standard full pallet height

1600 mm

Compressed air consumption

100 Nl/min

Max. full pallet weight

2000 Kg

Operational capacity

300 cans/h

Installed power

6,5 KW

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

3500 Kg

Product benefits

__ Production up to 300 cans/h

__ Production up to 300 cans/h

__ Suitable for small spaces

__ Suitable for small spaces

__ High positioning accuracy thanks to encoder control

__ High positioning accuracy thanks to encoder control

__ Total automation for greater efficiency

__ Total automation for greater efficiency

__ Flexibility for different palletising configurations

__ Flexibility for different palletising configurations

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

IMP.A.C. ROBOTEX 525 A-PT Cartesian palletising robot with floor pallet (also available in multi-pallet version)

IMP.A.C. ROBOTEX 525 A-PT

Cartesian palletising robot with floor pallet

(also available in multi-pallet version)

The IMP.A.C. ROBOTEX 525 A-PT is a Cartesian robot designed for automatic palletising of canisters, optimised for low throughput and featuring a compact design with a small footprint of only 4000x2400 mm.

Ideal for fully automated production lines, this system guarantees precision and efficiency, eliminating the need for an operator.

Key features

- Compactness: designed for limited space, it adapts easily to space-constrained industrial configurations.

- Complete automation: enables fully automatic palletising of canisters, with the possibility of programming different formations and layouts; they are picked individually or in rows.

- Cartesian motion: guarantees precision thanks to an encoder-controlled positioning system.

- Versatility: suitable for tanks of different sizes and load configurations.

- Advanced PLC control: all movements and synchronisms are managed via a programmable modular system, ensuring smoothness and reliability.

The IMP.A.C. ROBOTEX 525 A-PT is the ideal solution for companies requiring a compact and versatile machine for palletising canisters, ensuring efficiency, precision and reliability in production processes.

Cartesian palletising robot with floor pallet (also available in multi-pallet version)

Max. production: 300 cans/h

Can dimensions

Max. 30 litres

Min. 5 litres

Paddle size

Max. 1200 x 1000 mm x h 140

Min. 1000 x 800 mm x h 80

Maximum layer size

Max. 1300 x 1100 mm

Standard full pallet height

1600 mm

Compressed air consumption

100 Nl/min

Max. full pallet weight

2000 Kg

Operational capacity

300 cans/h

Installed power

5 KW

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

3500 Kg

Product benefits

__ Production up to 300 cans/h

__ Production up to 300 cans/h

__ Compact design for small spaces

__ Compact design for small spaces

__ Maximum precision thanks to encoder control

__ Maximum precision thanks to encoder control

__ Programmable for customised layouts and various tank formats

__ Programmable for customised layouts and various tank formats

__ Easy integration into fully automated lines

__ Easy integration into fully automated lines

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

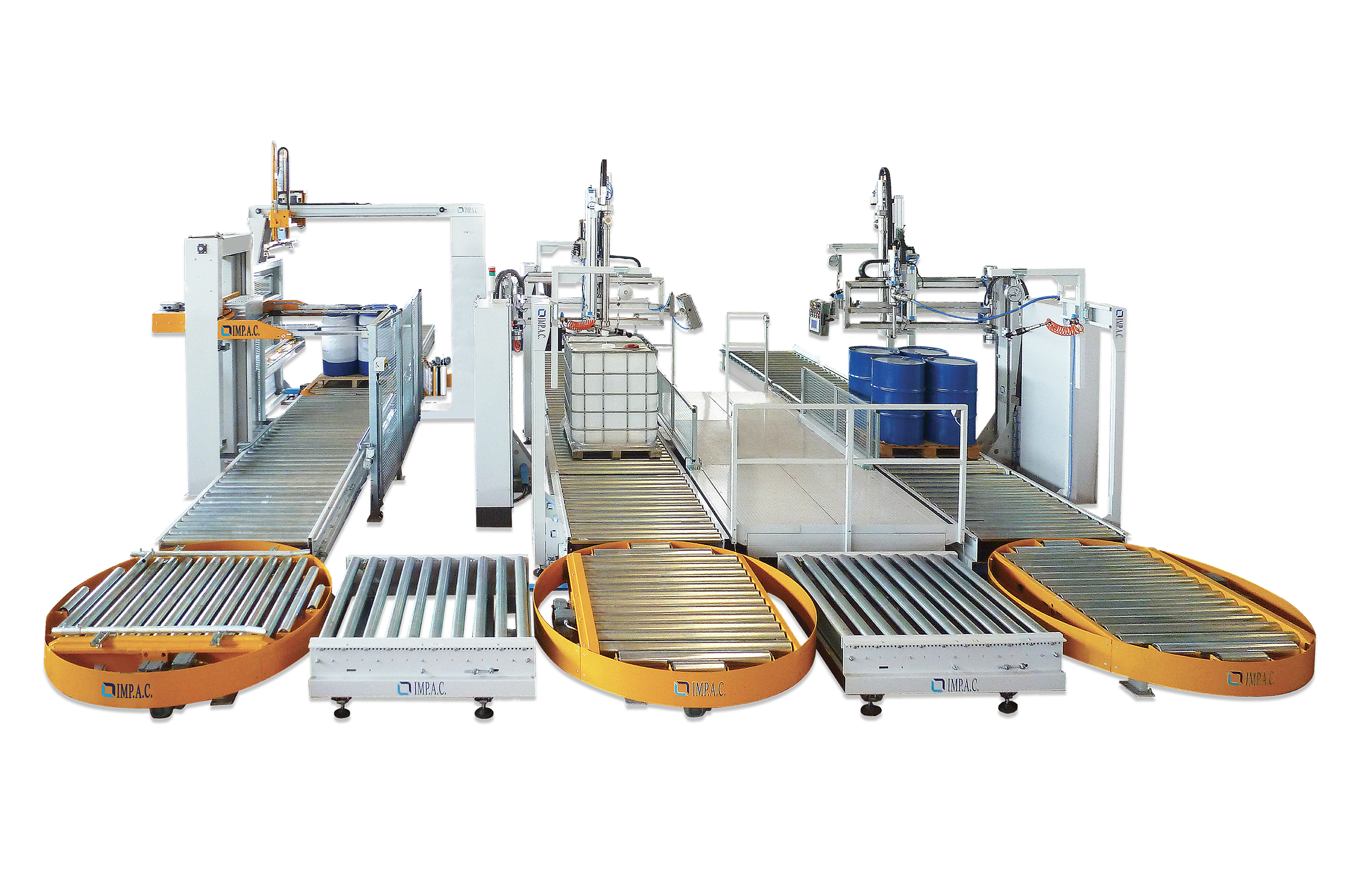

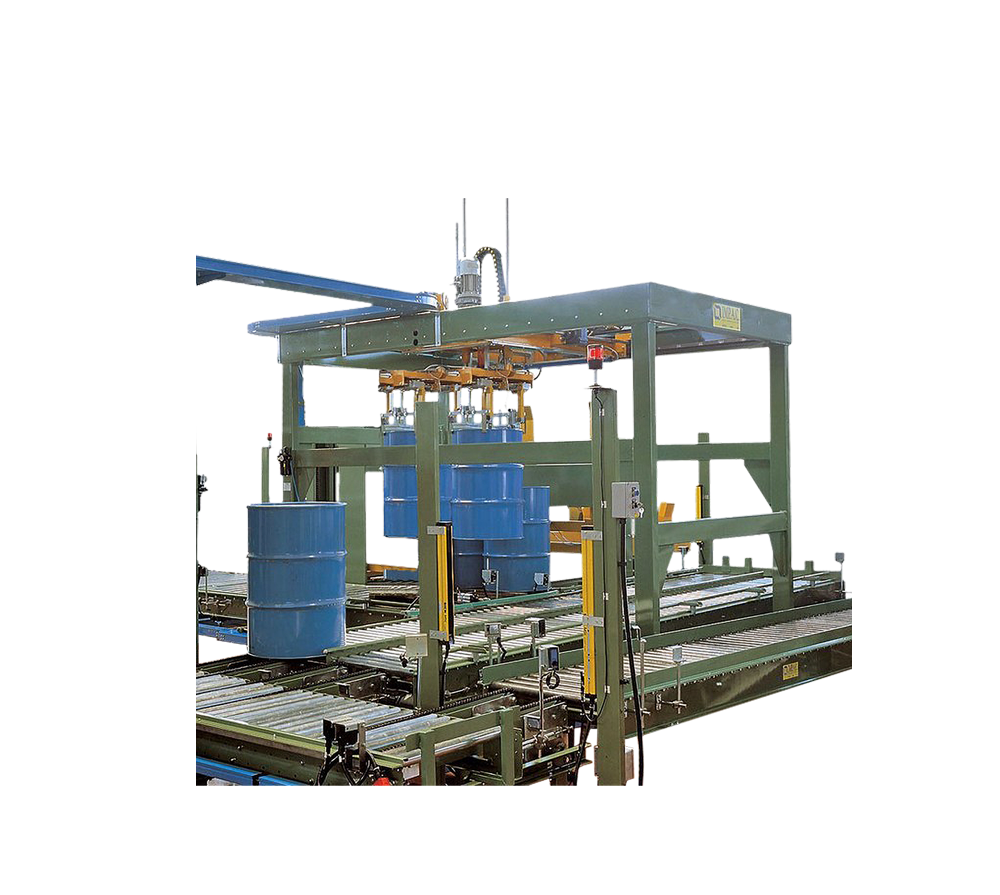

IMP.A.C. ROBOTEX 525 A Cartesian drum palletising robot

The IMP.A.C. ROBOTEX 525 A is a fully automatic palletiser designed to precisely and efficiently handle drums, both empty and full.

This solution is ideal for integration at the end of the line of fully automated production plants, where there is no operator presence, ensuring constant productivity and reliability.

Key features

- Versatility of use: optimised for handling empty and full drums, with capacity to palletise up to 300 empty drums/hour or 120 full drums/hour.

- Complete automation: equipped with roller conveyors for automatic handling of empty and full pallets.

- Cartesian handling: ensures precise positioning via encoder, for consistently accurate drum placement.

- Compact design: adaptable to different industrial configurations due to small footprint.

- Customisable programming: configurable for handling drums of different sizes, layouts and number of layers.

- Advanced PLC control: modularly synchronises all movements for smooth and reliable operation.

The IMP.A.C. ROBOTEX 525 A is an ideal solution for those who need a reliable, versatile and precise machine for automatic drum palletising, optimising the production process and reducing operating costs.

Cartesian drum palletising robot

Production Max:

300 empty drums/h

120 full drums/h

Drum dimensions

Max 600x h 1000 mm

Min 350x h 500 mm

Paddle size

Max. 1200 x 1000 mm x h 140

Min. 1000 x 800 mm x h 80

Maximum layer size

1300x1300 mm

Standard full pallet height

1600 mm

Compressed air consumption

100 Nl/min

Max. full pallet weight

2000 Kg

Max. drum weight

260 kg

Operational capacity

300 empty drums/hour

120 full drums/h

Installed power

7 KW

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

5500 Kg - 5800 Kg

Product benefits

__ Production up to 300 empty drums/h or 120 full drums/h

__ Production up to 300 empty drums/h or 120 full drums/h

__ Guaranteed accuracy thanks to encoder control system

__ Guaranteed accuracy thanks to encoder control system

__ Suitable for different end-of-line configurations

__ Suitable for different end-of-line configurations

__ Complete automation without the need for an operator

__ Complete automation without the need for an operator

__ Programmable for customised layouts

__ Programmable for customised layouts

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

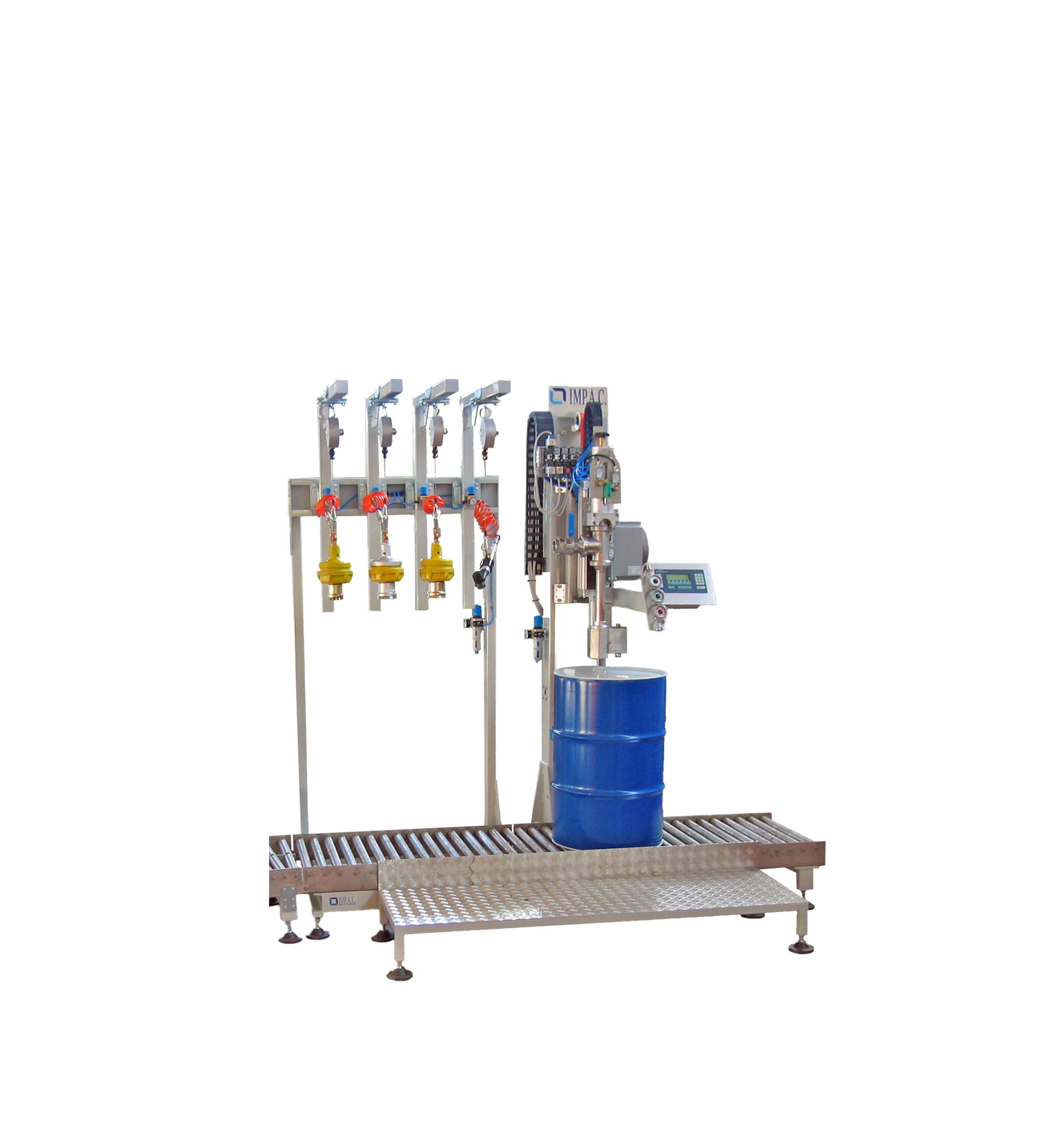

IMP.A.C. ROBOTEX 526 A-SA Cartesian can palletising robot with built-in semi-automatic winder

IMP.A.C. ROBOTEX 526 A-SA

Cartesian can palletising robot with built-in semi-automatic winder

The ROBOTEX 526 A-SA IMP.A.C. is designed to meet the requirements of low production rates, providing a maximum capacity of 300 canisters/hour.

Thanks to its integrated semi-automatic winder, the machine offers greater stability to the palletised load, making it ideal for a wide range of applications.

Key features

- Integrated semi-automatic winder: ensures a stable and compact load, improving efficiency and safety during transport and storage.

- Automated cycle: the canister, coming from the upstream line, is picked up, oriented and placed on the pallet according to the set programme.

- Cartesian motion: ensures precise and reliable positioning via encoder control.

- Customisable programming: allows the machine to be configured to handle different canister sizes, formations and number of layers.

- Advanced PLC: all movement synchronisms are managed by a programmable modular system for optimal control and consistent performance.

The IMP.A.C. ROBOTEX 526 A-SA is the ideal choice for those looking for an efficient, precise and versatile solution for palletising canisters, with the addition of a semi-automatic winder for increased load stability.

Cartesian can palletising robot with built-in semi-automatic winder

Max. production: 300 cans/h

Can dimensions

Max. 30 litres

Min. 5 litres

Paddle size

Max. 1200 x 1000 mm x h 140

Max. 1000 x 800 mm x h 80

Maximum layer size

Max. 1300 x 1100 mm

Standard full pallet height

1600 mm

Compressed air consumption

100 Nl/min

Max. full pallet weight

2000 Kg

Operational capacity

240-300 canisters/h

Installed power

6,5 KW

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

4000 Kg

Product benefits

__ Load stability thanks to the winder

__ Load stability thanks to the winder

__ Ideal for small productions

__ Ideal for small productions

__ High accuracy and reliability with encoder control

__ High accuracy and reliability with encoder control

__ Adaptability to canisters of different sizes and configurations

__ Adaptability to canisters of different sizes and configurations

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

IMP.A.C. ROBOTEX 526 A-PT Cartesian bucket palletising robot with roller conveyors (also available in multi-pallet version)

IMP.A.C. ROBOTEX 526 A-PT

Cartesian bucket palletising robot with roller conveyors (also available in multi-pallet version)

The ROBOTEX 526 A-PT IMP.A.C. palletiser is designed for reliability and efficiency in low volume production, with a maximum output of 300 canisters/hour.

Its compact dimensions (3500×2400 mm) make it ideal for small spaces without compromising on performance.

Key features

- Compact design: designed to occupy minimum space, it is perfect for installations with size limitations.

- Fully automated cycle: the canister, coming from the upstream line, is picked, positioned and placed on the pallet according to the set programme. Once completed, the pallet is evacuated and replaced automatically; they are picked up individually or in rows.

- Cartesian motion: ensures precise positioning thanks to encoder control.

- Flexible programming: the machine can be configured to work with different canister sizes, formations and number of layers.

- Advanced PLC: all movement synchronisms are managed by a programmable modular system to maximise precision and operational efficiency.

The IMP.A.C. ROBOTEX 526 A-PT is the perfect solution for those who need a compact, efficient and versatile palletiser for canisters of any size.

Compact Cartesian palletising robot with floor pallet (also available in multi-pallet version)

Max. production: 300 cans/h

Can dimensions

Max. 30 litres<br>Min. 5 litres

Paddle size

Max. 1200 x 1000 mm x h 140

Min. 1000 x 800 mm x h 80

Maximum layer size

Max. 1300 x 1100 mm

Standard full pallet height

1600 mm

Compressed air consumption

100 Nl/min

Max. full pallet weight

2000 Kg

Operational capacity

300 cans/h

Installed power

5 KW

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

3500 Kg

Product benefits

__ Suitable for limited spaces

__ Suitable for limited spaces

__ Ideal for small productions

__ Ideal for small productions

__ Precision and reliability ensured by encoder control

__ Precision and reliability ensured by encoder control

__ Flexibility for different formats and configurations

__ Flexibility for different formats and configurations

One solution, many integrations.

The machine adapts perfectly to all indicated installations.

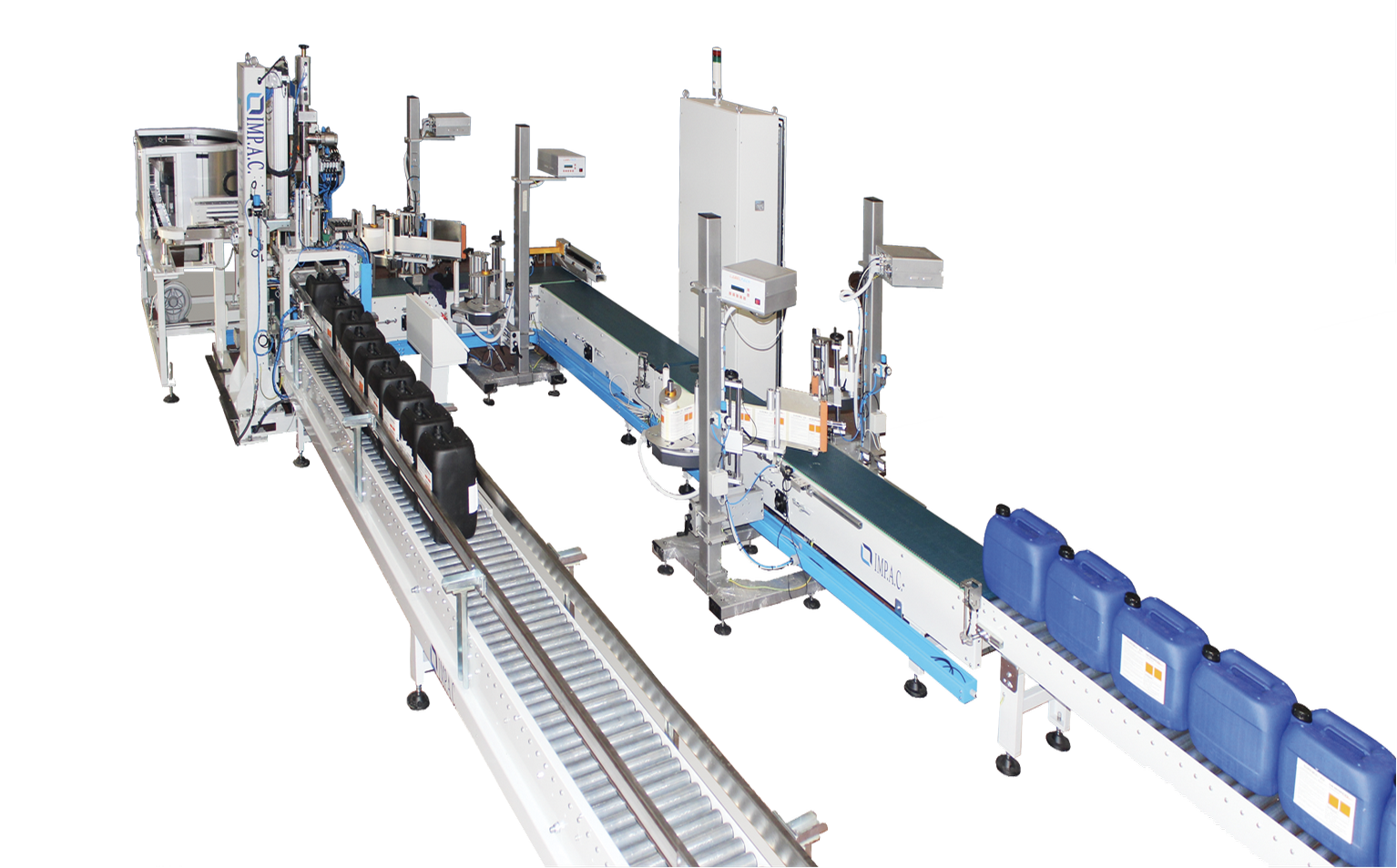

IMP.A.C. ROBOTEX 526 A Cartesian bucket palletising robot with roller conveyors (also available in multi-pallet version)

IMP.A.C. ROBOTEX 526 A

Cartesian bucket palletising robot with roller conveyors (also available in multi-pallet version)

The IMP.A.C. ROBOTEX 526 A palletiser is a fully automatic machine designed for efficiency and reliability in end-of-line processes.

Equipped with roller conveyors for handling empty and full pallets, it integrates perfectly into automated production plants that do not require the constant presence of an operator.

Key features

- High productivity: handles up to 500 buckets/h, ideal for high-performance production lines.

- Universal compatibility: suitable for buckets of various sizes, formations and configurations.

- Automatic gripper: the bucket, coming from the upstream line, is picked up, positioned and placed on the pallet according to the set programme.

- Advanced synchronisation: movements are managed by a programmable modular system (PLC) with encoder control.

- Automated cycle: when the pallet is completed, it is evacuated and replaced, allowing a new cycle to start immediately.

The IMP.A.C. ROBOTEX 526 A is the ideal choice for anyone looking for a reliable, flexible and efficient palletiser for buckets of any size or weight.

Cartesian bucket palletising robot with roller conveyors (also available in multi-pallet version)

Production Max:

300 buckets/hour basic solution

500 buckets/hour quick solution

Bucket dimensions

Max. diameter 400 mm x 500 h

Min. diameter 200 mm x 180 h

Can dimensions

Max. litres 30

Min. litres 5

Paddle size

Max. 1200 x 1000 mm x h 140

Min. 1100 x 800 mm x h 80

Maximum layer size

Max. 1300 x 1100 mm

Standard full pallet height

1600 mm

Compressed air consumption

100 Nl/min

Operational capacity

300-500 buckets/h

Installed power

7 KW

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

5000 Kg

Product benefits

__ Fully automatic

__ Fully automatic

__ Versatility for different formats

__ Versatility for different formats

__ Positioning accuracy with encoder

__ Positioning accuracy with encoder

__ Easy integration into existing production lines

__ Easy integration into existing production lines