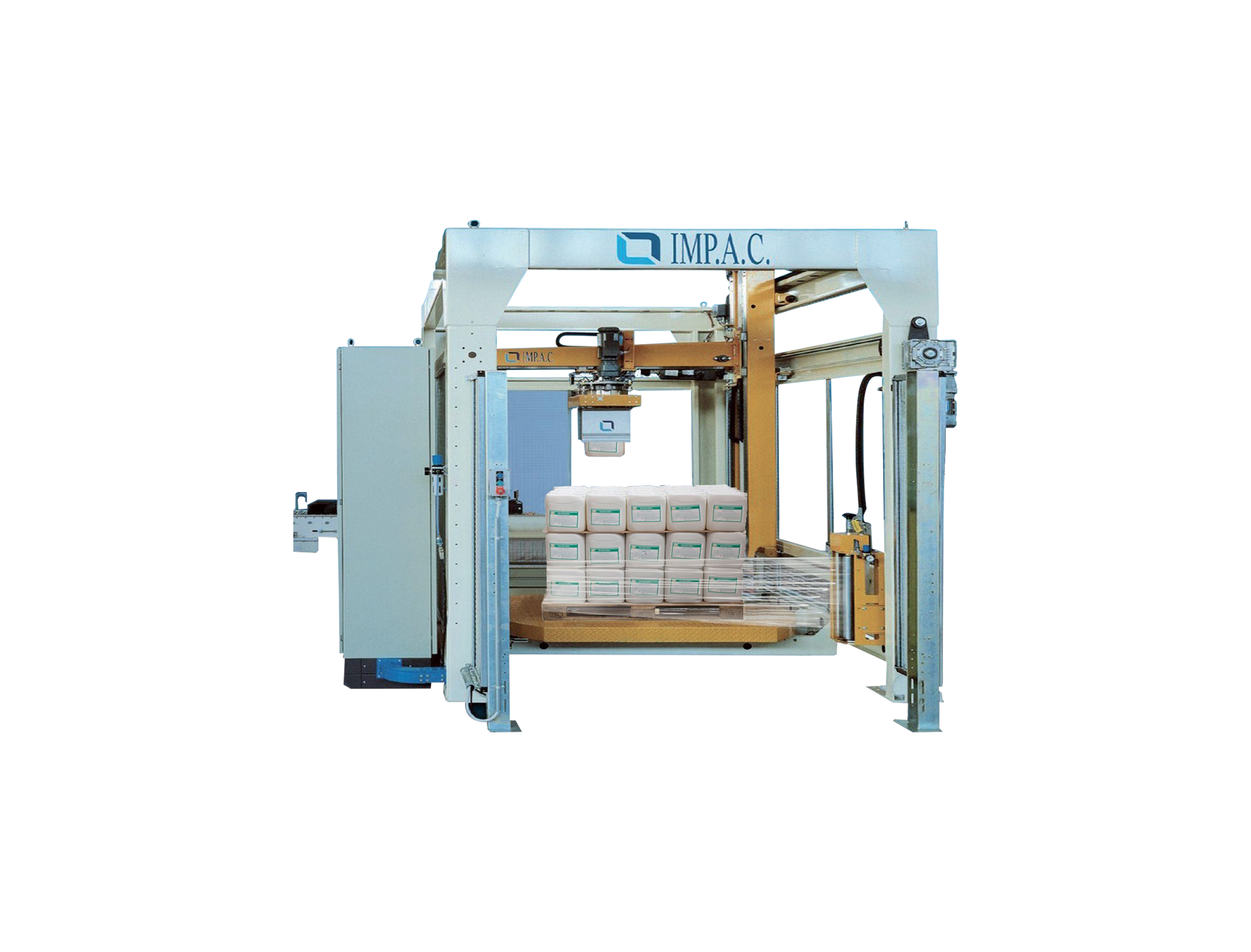

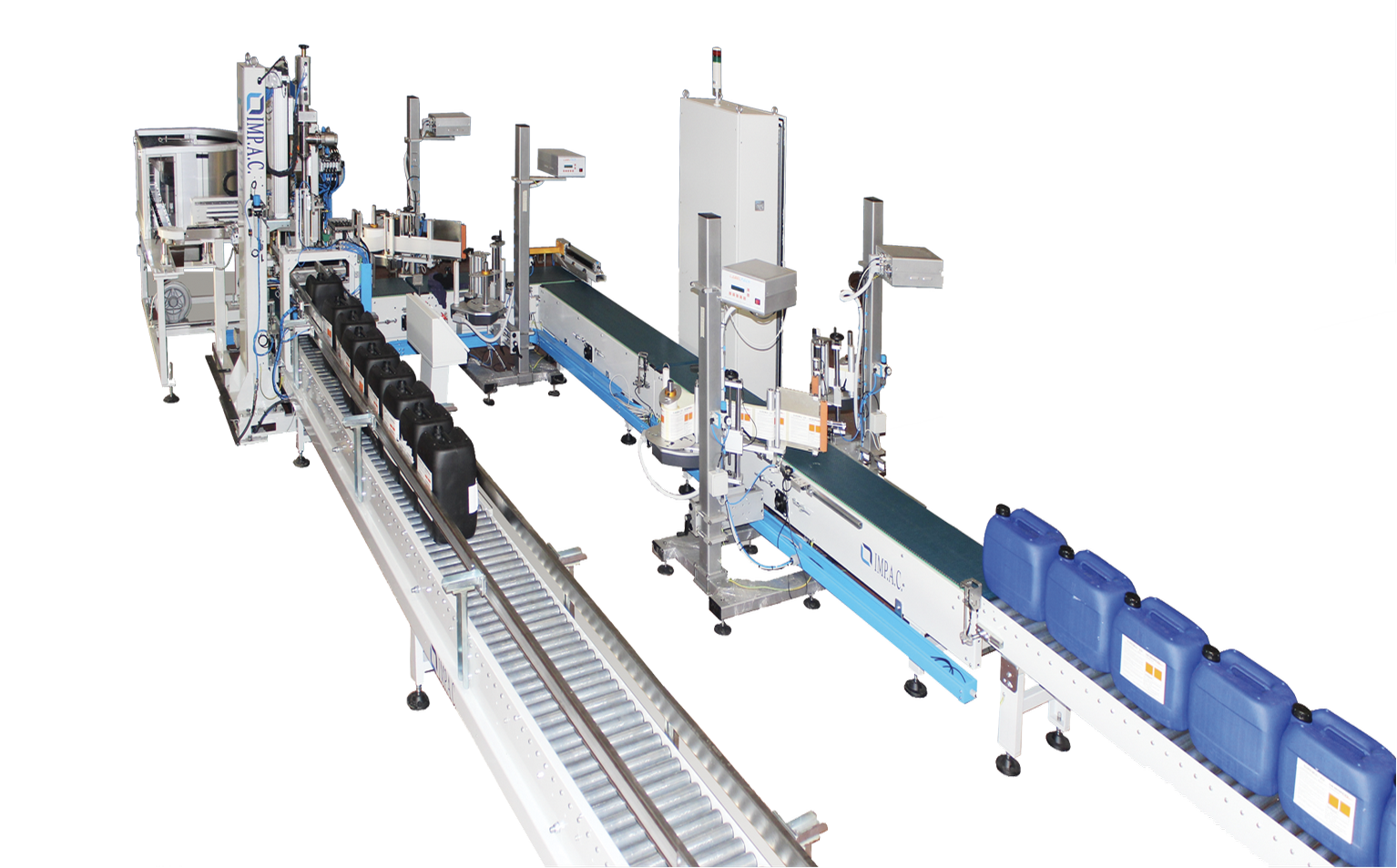

IMP.A.C. ROBOTEX 526 A-SACartesian can palletising robot with built-in semi-automatic winder

The ROBOTEX 526 A-SA IMP.A.C. is designed to meet the requirements of low production rates, providing a maximum capacity of 300 canisters/hour.

Thanks to its integrated semi-automatic winder, the machine offers greater stability to the palletised load, making it ideal for a wide range of applications.

Key features

- Integrated semi-automatic winder: ensures a stable and compact load, improving efficiency and safety during transport and storage.

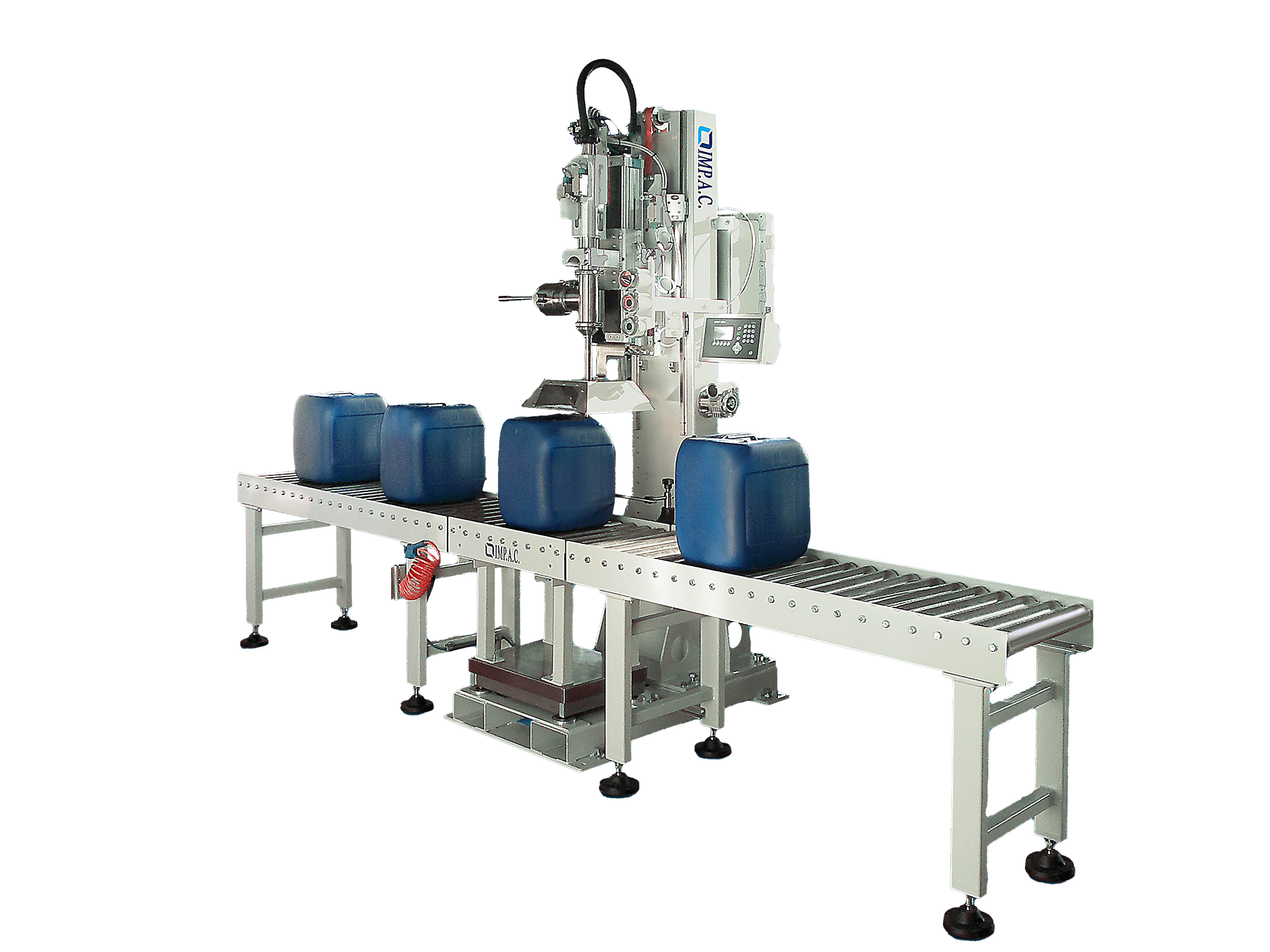

- Automated cycle: the canister, coming from the upstream line, is picked up, oriented and placed on the pallet according to the set programme.

- Cartesian motion: ensures precise and reliable positioning via encoder control.

- Customisable programming: allows the machine to be configured to handle different canister sizes, formations and number of layers.

- Advanced PLC: all movement synchronisms are managed by a programmable modular system for optimal control and consistent performance.

The IMP.A.C. ROBOTEX 526 A-SA is the ideal choice for those looking for an efficient, precise and versatile solution for palletising canisters, with the addition of a semi-automatic winder for increased load stability.

Cartesian can palletising robot with built-in semi-automatic winder

Max. production: 300 cans/h

Can dimensions

Max. 30 litres

Min. 5 litres

Paddle size

Max. 1200 x 1000 mm x h 140

Max. 1000 x 800 mm x h 80

Maximum layer size

Max. 1300 x 1100 mm

Standard full pallet height

1600 mm

Compressed air consumption

100 Nl/min

Max. full pallet weight

2000 Kg

Operational capacity

240-300 canisters/h

Installed power

6,5 KW

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

4000 Kg

Product benefits

__ Load stability thanks to the winder

__ Load stability thanks to the winder

__ Ideal for small productions

__ Ideal for small productions

__ High accuracy and reliability with encoder control

__ High accuracy and reliability with encoder control

__ Adaptability to canisters of different sizes and configurations

__ Adaptability to canisters of different sizes and configurations