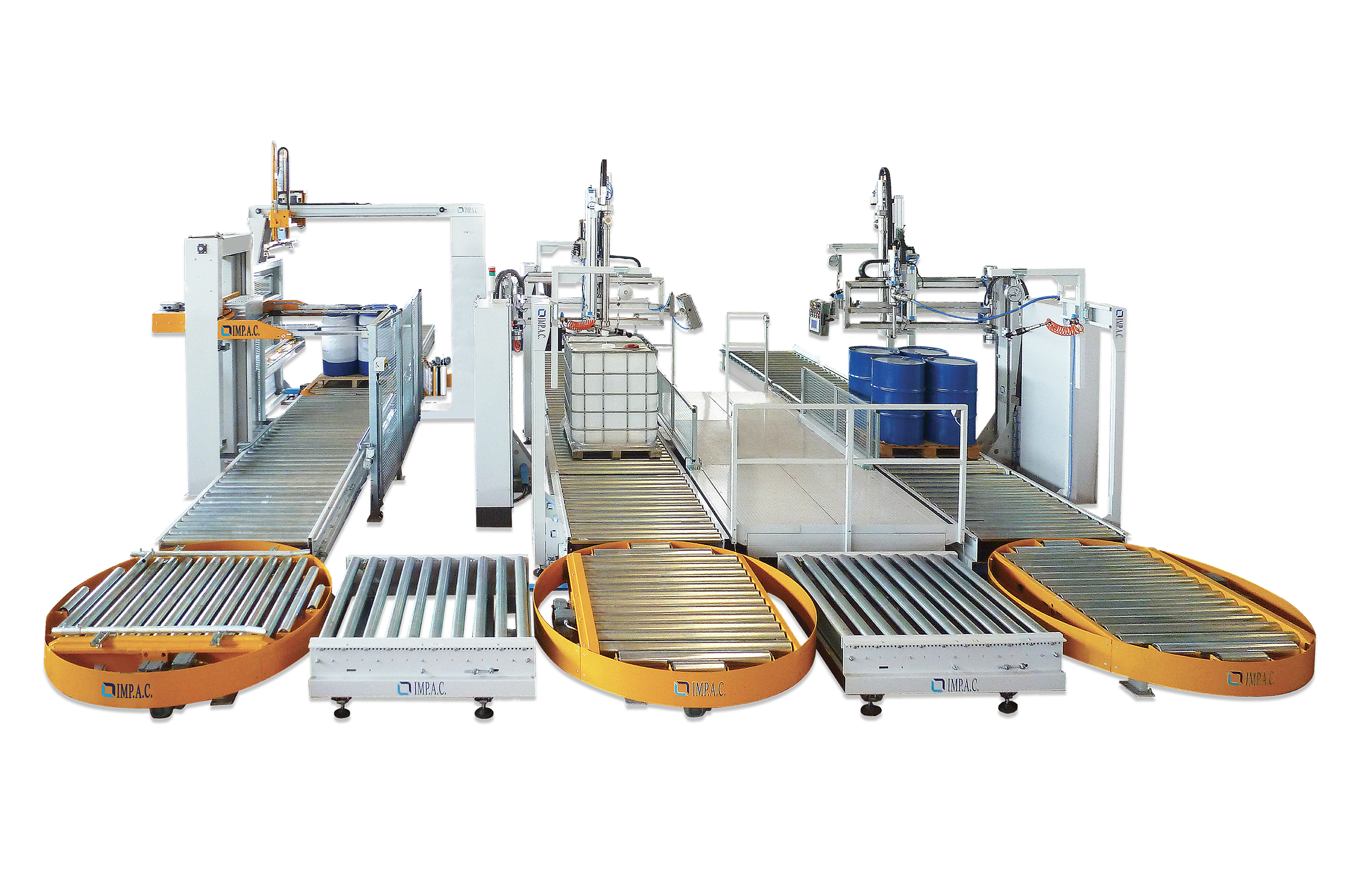

IMP.A.C. ROBOTEX 525 A-PTCartesian palletising robot with floor pallet(also available in multi-pallet version)

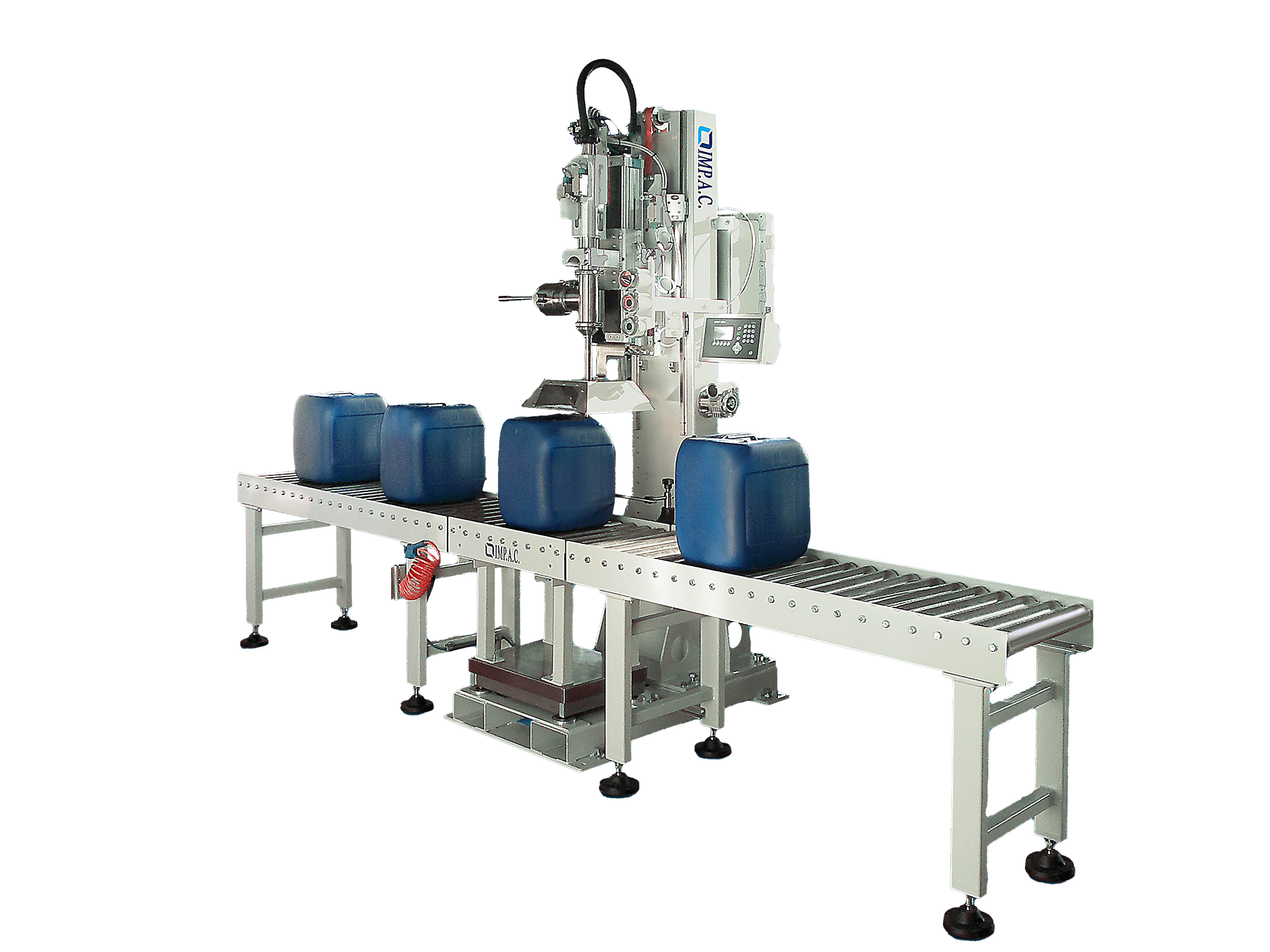

The IMP.A.C. ROBOTEX 525 A-PT is a Cartesian robot designed for automatic palletising of canisters, optimised for low throughput and featuring a compact design with a small footprint of only 4000x2400 mm.

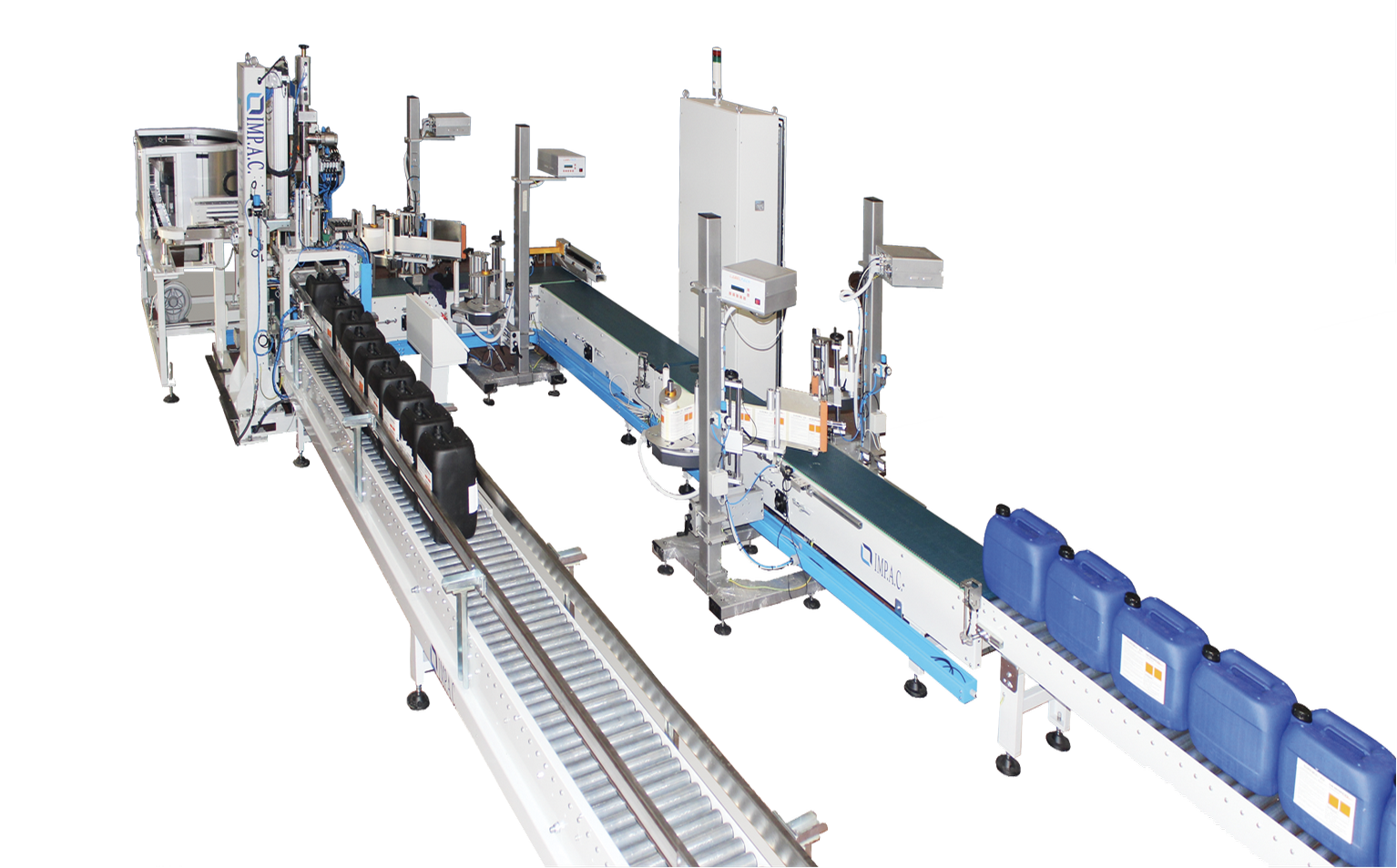

Ideal for fully automated production lines, this system guarantees precision and efficiency, eliminating the need for an operator.

Key features

- Compactness: designed for limited space, it adapts easily to space-constrained industrial configurations.

- Complete automation: enables fully automatic palletising of canisters, with the possibility of programming different formations and layouts; they are picked individually or in rows.

- Cartesian motion: guarantees precision thanks to an encoder-controlled positioning system.

- Versatility: suitable for tanks of different sizes and load configurations.

- Advanced PLC control: all movements and synchronisms are managed via a programmable modular system, ensuring smoothness and reliability.

The IMP.A.C. ROBOTEX 525 A-PT is the ideal solution for companies requiring a compact and versatile machine for palletising canisters, ensuring efficiency, precision and reliability in production processes.

Cartesian palletising robot with floor pallet (also available in multi-pallet version)

Max. production: 300 cans/h

Can dimensions

Max. 30 litres

Min. 5 litres

Paddle size

Max. 1200 x 1000 mm x h 140

Min. 1000 x 800 mm x h 80

Maximum layer size

Max. 1300 x 1100 mm

Standard full pallet height

1600 mm

Compressed air consumption

100 Nl/min

Max. full pallet weight

2000 Kg

Operational capacity

300 cans/h

Installed power

5 KW

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

3500 Kg

Product benefits

__ Production up to 300 cans/h

__ Production up to 300 cans/h

__ Compact design for small spaces

__ Compact design for small spaces

__ Maximum precision thanks to encoder control

__ Maximum precision thanks to encoder control

__ Programmable for customised layouts and various tank formats

__ Programmable for customised layouts and various tank formats

__ Easy integration into fully automated lines

__ Easy integration into fully automated lines