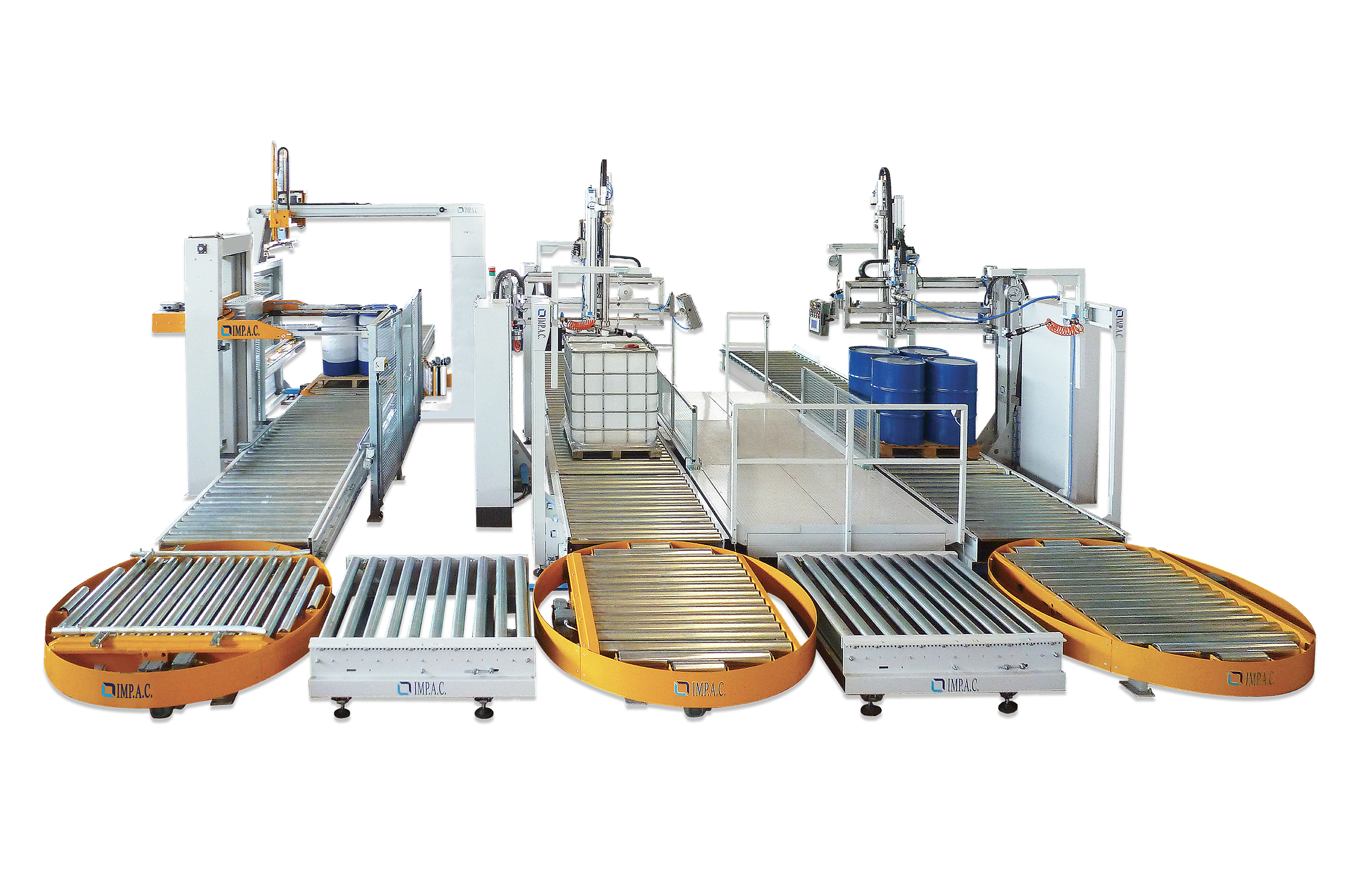

IMP.A.C. ROBOTEX 525 A-PRCartesian canister palletising robot with built-in automatic winder

The IMP.A.C. ROBOTEX 525 A-PR is an innovative, fully automatic palletiser designed to efficiently and accurately handle end-of-line requirements.

With its compact design and advanced functionality, it is an ideal solution for companies needing a high-performance and versatile system for palletising canisters

Key features

- Palletising versatility: handles canisters with formats and weights ranging from 5 to 65 kg using a single fixture.

- Integrated pallet wrapper: allows palletising and pallet wrapping at the same time, ensuring maximum load stability.

- Compactness: small dimensions for installation in limited spaces.

- Full automation: eliminates the need for operator supervision, optimising operational efficiency.

- Cartesian accuracy: positioning control via encoders guarantees high accuracy.

- Advanced modular control: all movements and synchronisms are managed by a programmable system (PLC), ensuring reliability and customisation.

The IMP.A.C. ROBOTEX 525 A-PR is a machine designed to meet the challenges of modern automated production, providing high operational flexibility, precision and reliability, making it ideal for fully automated production facilities.

Cartesian can palletising robot with built-in automatic winder

Production Max:270 canisters/h basic solution450 canisters/h quick solution

Tank dimensions

Max. 30 litres

Min. 5 litres

Paddle size

Max. 1200 x 1000 mm x h 140

Min. 1000 x 800 mm x h 80

Maximum layer size

Max. 1300 x 1100 mm

Standard full pallet height

1600 mm

Compressed air consumption

150 Nl/min

Max. full pallet weight

1500 Kg

Operational capacity

270-450 canisters/h

Installed power

8,5 KW

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

6000 Kg

Product benefits

__ Production up to 450 cans/h

__ Production up to 450 cans/h

__ Suitable for canisters of different sizes and weights

__ Suitable for canisters of different sizes and weights

__ Load stability thanks to integrated winder

__ Load stability thanks to integrated winder

__ Compact design for small spaces

__ Compact design for small spaces

__ Total automation for maximum efficiency

__ Total automation for maximum efficiency