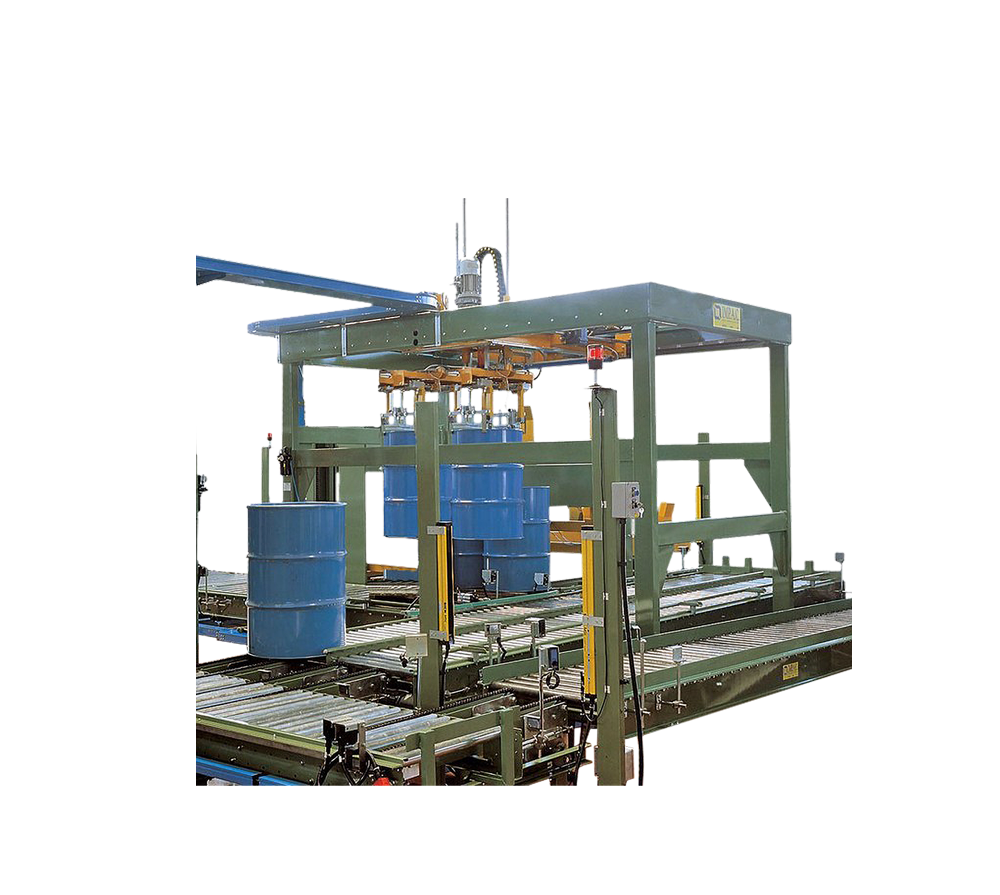

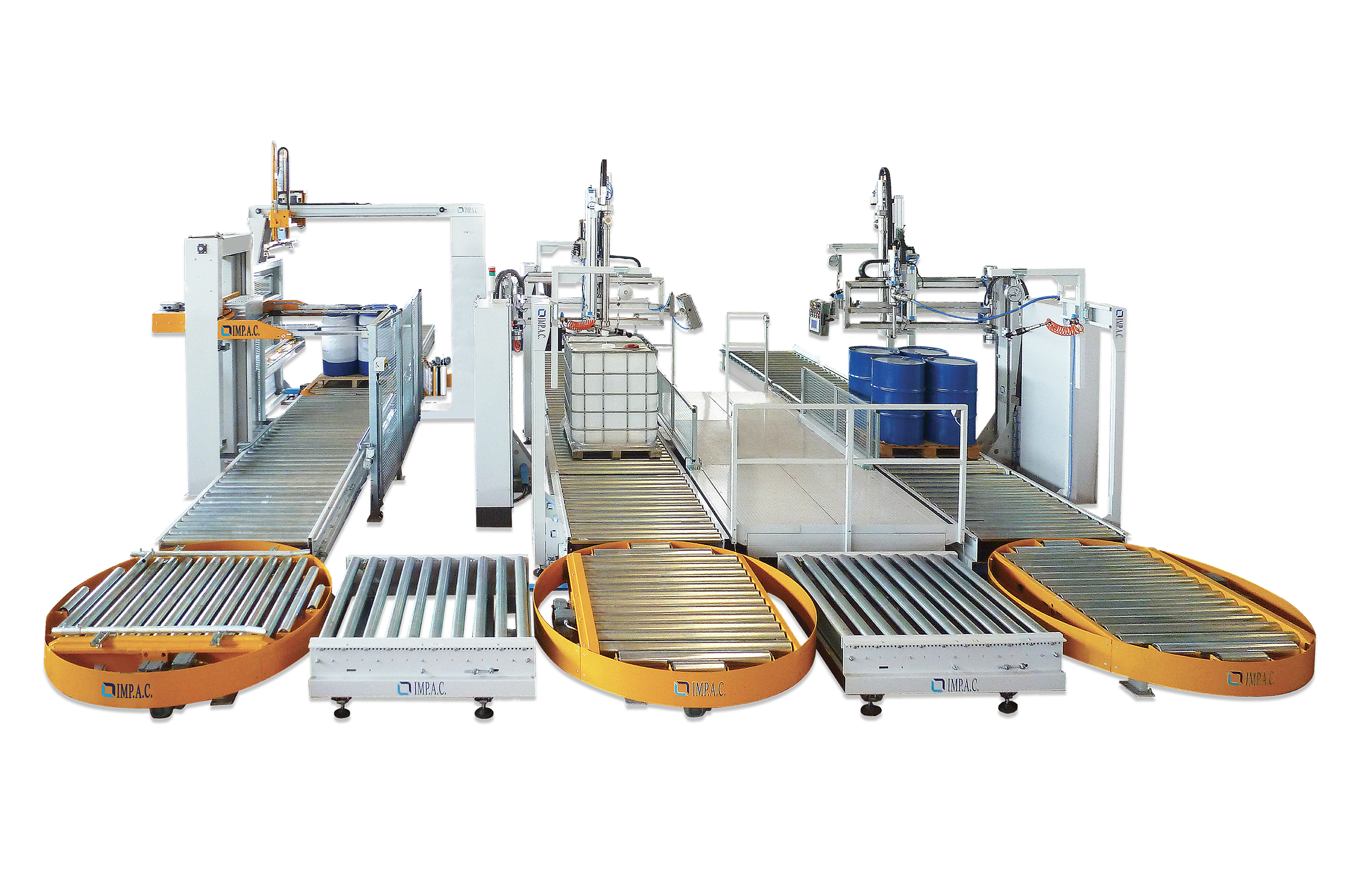

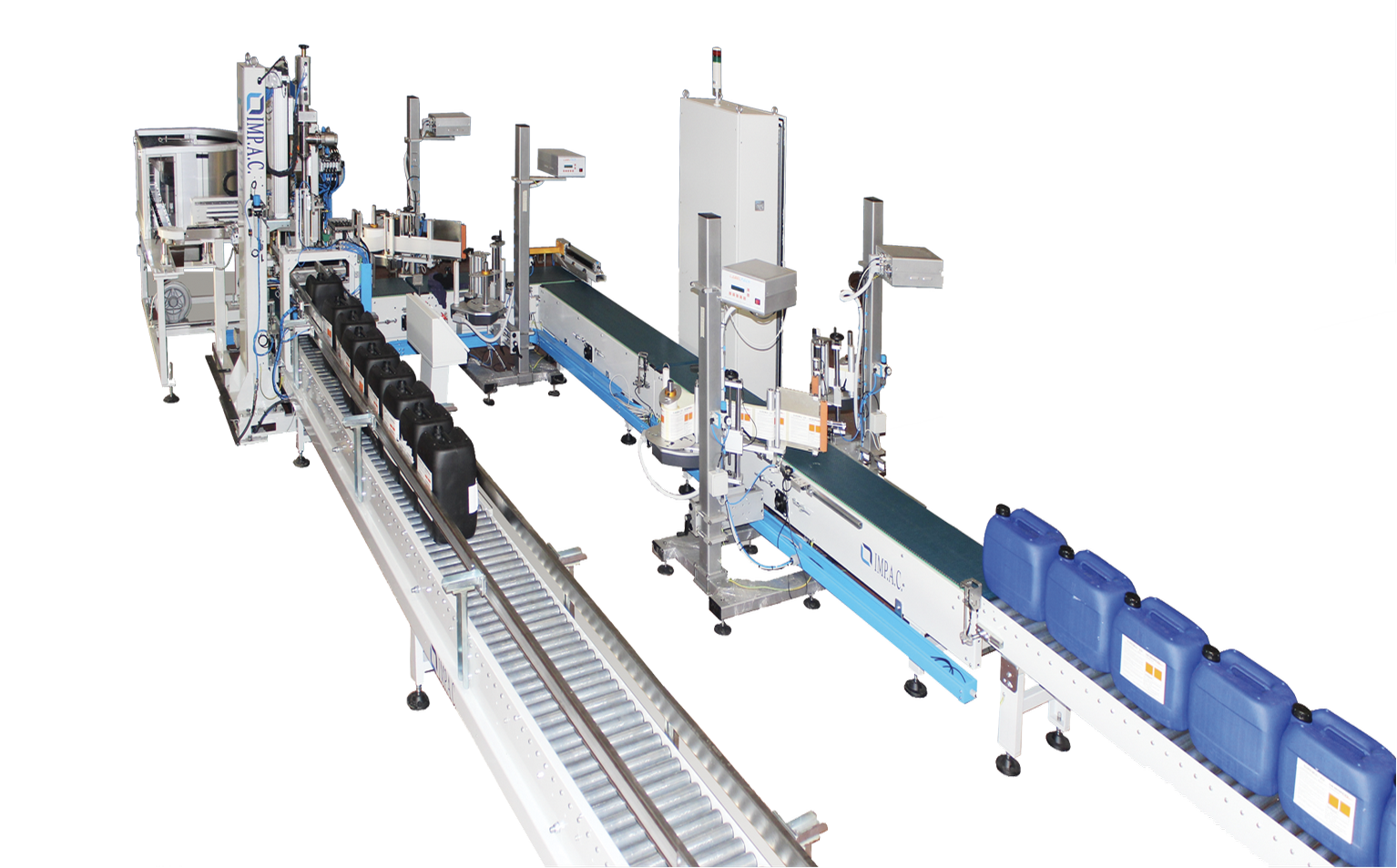

The IMP.A.C. ROBOTEX 525 A is a fully automatic palletiser designed to precisely and efficiently handle drums, both empty and full.

This solution is ideal for integration at the end of the line of fully automated production plants, where there is no operator presence, ensuring constant productivity and reliability.

Key features

- Versatility of use: optimised for handling empty and full drums, with capacity to palletise up to 300 empty drums/hour or 120 full drums/hour.

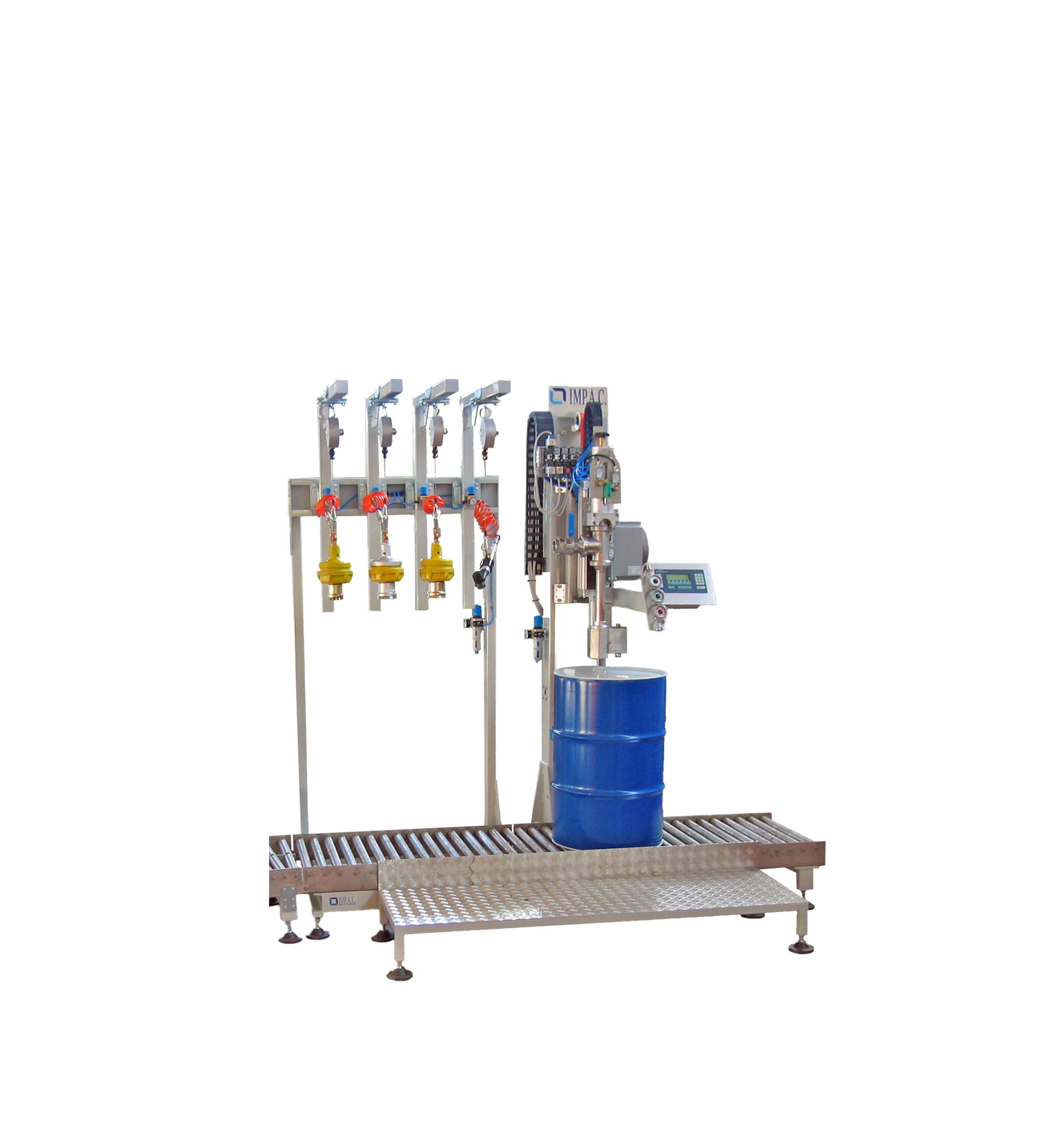

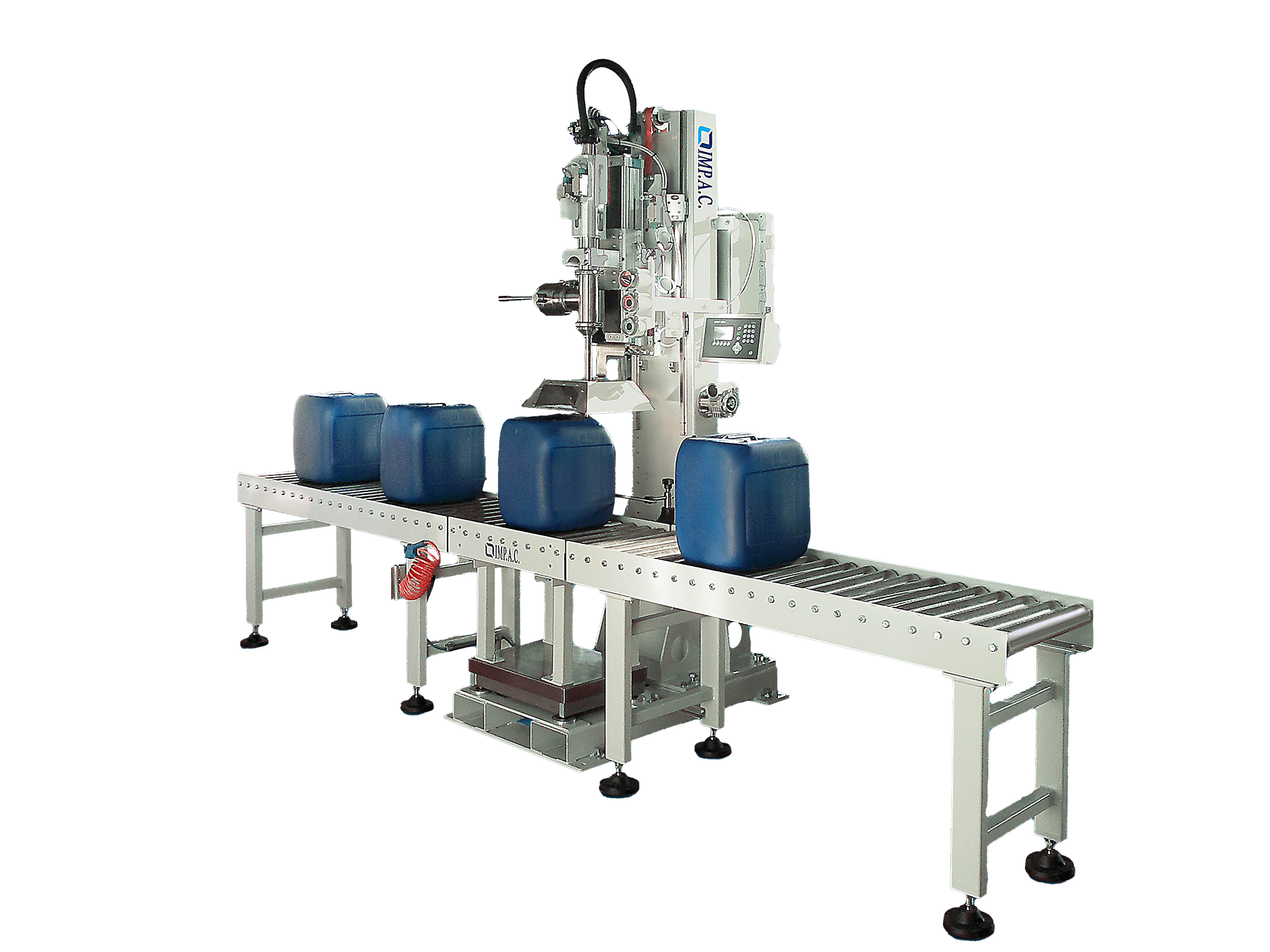

- Complete automation: equipped with roller conveyors for automatic handling of empty and full pallets.

- Cartesian handling: ensures precise positioning via encoder, for consistently accurate drum placement.

- Compact design: adaptable to different industrial configurations due to small footprint.

- Customisable programming: configurable for handling drums of different sizes, layouts and number of layers.

- Advanced PLC control: modularly synchronises all movements for smooth and reliable operation.

The IMP.A.C. ROBOTEX 525 A is an ideal solution for those who need a reliable, versatile and precise machine for automatic drum palletising, optimising the production process and reducing operating costs.

Cartesian drum palletising robot

Production Max:300 empty drums/h120 full drums/h

Drum dimensions

Max 600x h 1000 mm

Min 350x h 500 mm

Paddle size

Max. 1200 x 1000 mm x h 140

Min. 1000 x 800 mm x h 80

Maximum layer size

1300x1300 mm

Standard full pallet height

1600 mm

Compressed air consumption

100 Nl/min

Max. full pallet weight

2000 Kg

Max. drum weight

260 kg

Operational capacity

300 empty drums/hour

120 full drums/h

Installed power

7 KW

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

5500 Kg - 5800 Kg

Product benefits

__ Production up to 300 empty drums/h or 120 full drums/h

__ Production up to 300 empty drums/h or 120 full drums/h

__ Guaranteed accuracy thanks to encoder control system

__ Guaranteed accuracy thanks to encoder control system

__ Suitable for different end-of-line configurations

__ Suitable for different end-of-line configurations

__ Complete automation without the need for an operator

__ Complete automation without the need for an operator

__ Programmable for customised layouts

__ Programmable for customised layouts