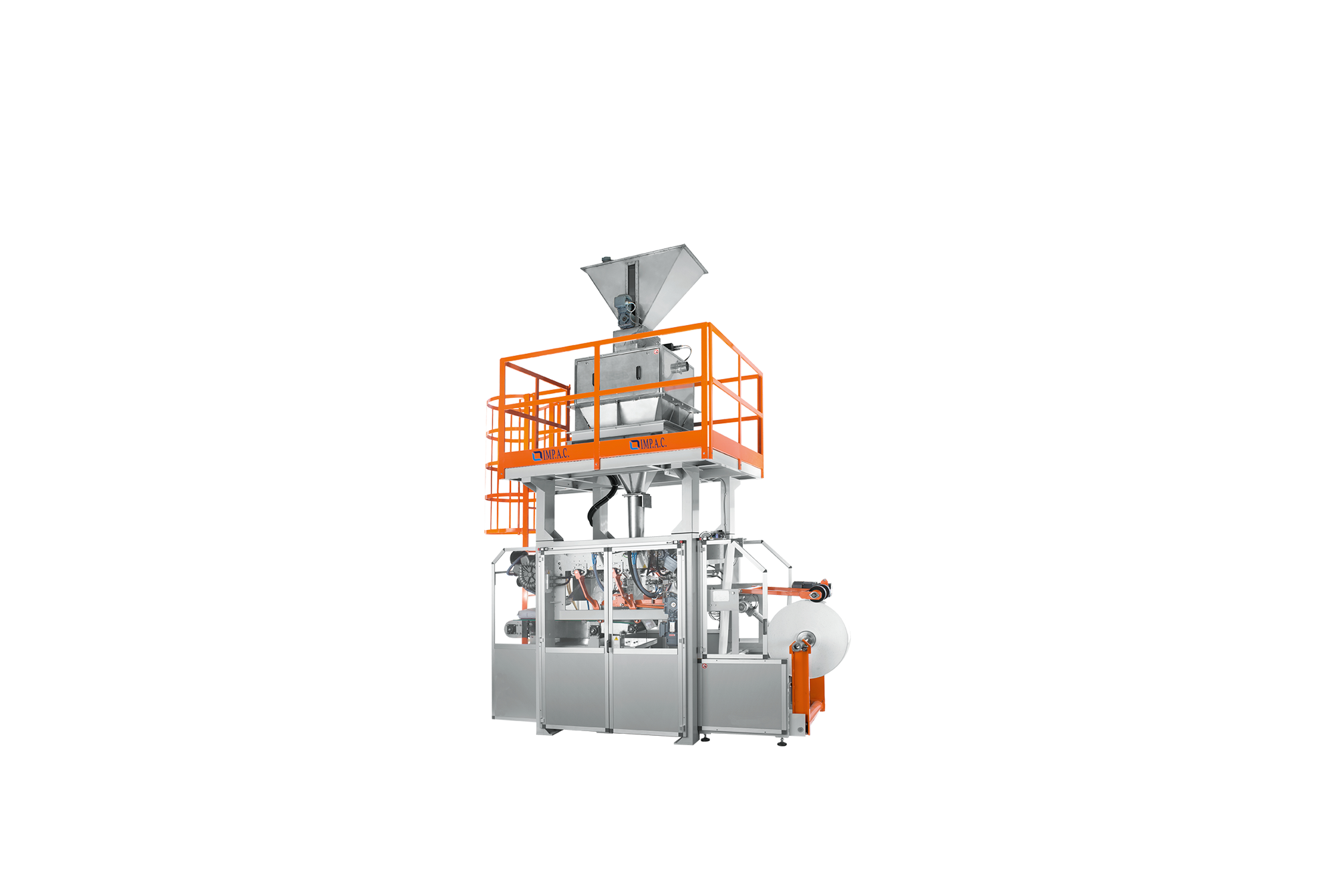

The IMP.A.C. 22-32 AVC palletizer/packaging machine is the ideal choice for industrial operations requiring high performance and flexibility in handling 1-5 kg vertical bags and 10-15 kg bundles.

Thanks to the combination of high speed and precision, this machine ensures optimal productivity in every industrial sector.

Reliability and innovation

The IMP.A.C. 22-32 AVC model represents a technologically advanced solution for optimizing packaging and palletizing processes, ensuring efficiency and precision in every operational cycle. Perfect for meeting the most complex production needs.

Palletizer/packaging machine for 1 kg vertical bags and bundles with bottom feed

Max Production: 180 bags per minute6 bundles per minute

Bag and bundle dimensions

Max. 180 x 110 x h. 80 mm

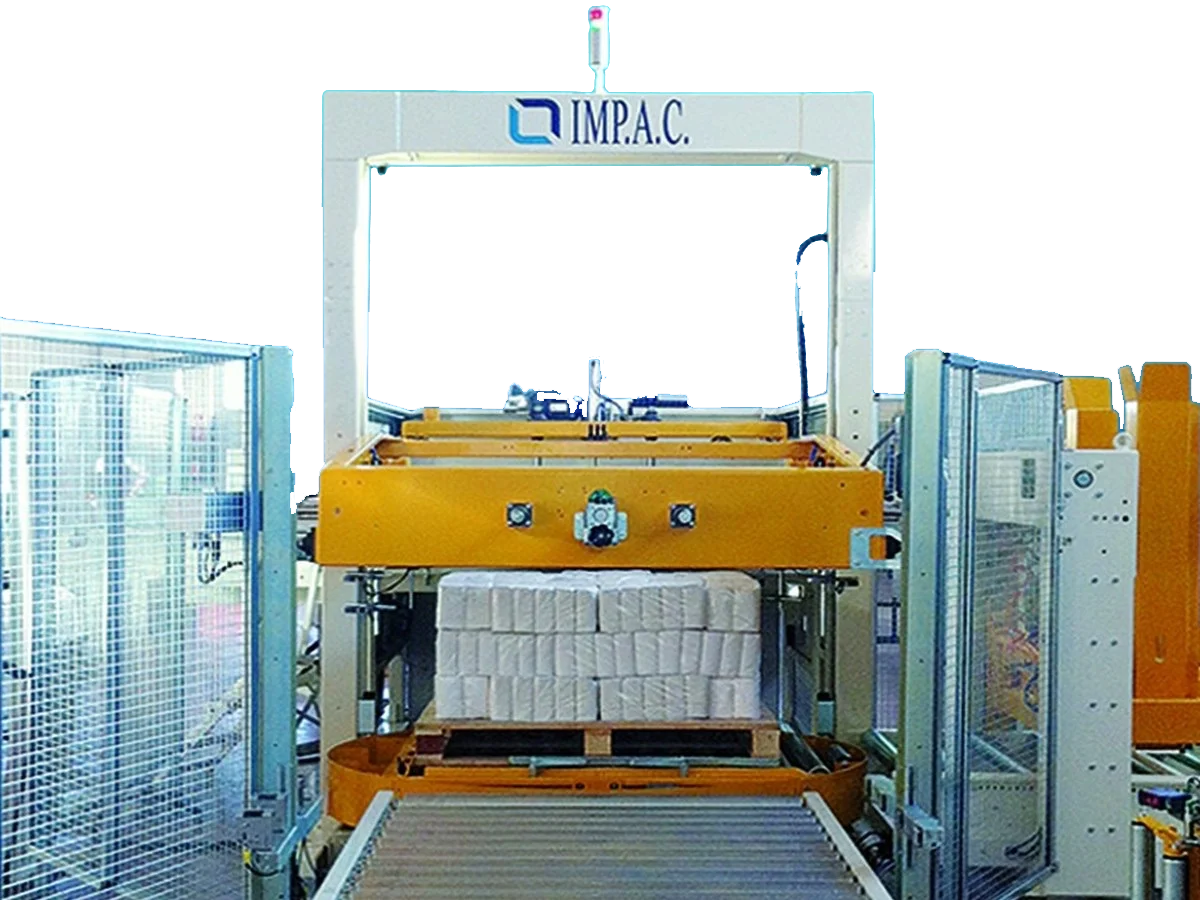

Pallet dimensions

Max. 1300 x 1200 x h. 140 mm

Min. 1000 x 800 x h. 100 mm

Layer dimensions

Max. 1400 x 1250 mm

Standard full pallet height

1600 mm

Max. full pallet weight

2000 Kg

Compressed air consumption

100 Nl/min

Installed power

13,5 KW

Operational capacity

6 layers per minute with a limit of 180 bags per minute

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

12000 Kg

Product benefits

__ Operational versatility

__ Operational versatility

It efficiently palletizes both light bags (1-5 kg) and heavier bundles (10-15 kg), adapting to different configurations.

__ High productivity

__ High productivity

Designed to handle up to 1700 bags-bundles per hour, with a speed of 180 bags per minute and 15 bundles per minute.

__ Layer optimization

__ Layer optimization

The bags and bundles are compressed, made uniform, and oriented according to the predefined formation, ensuring a stable and precise arrangement.

__ Central opening mechanism

__ Central opening mechanism

The dedicated platform enables fast and accurate layer placement onto the pallet.

__ Advanced automation

__ Advanced automation

All movements are synchronized through a programmable modular PLC, ensuring smooth operation and adaptability to different needs.