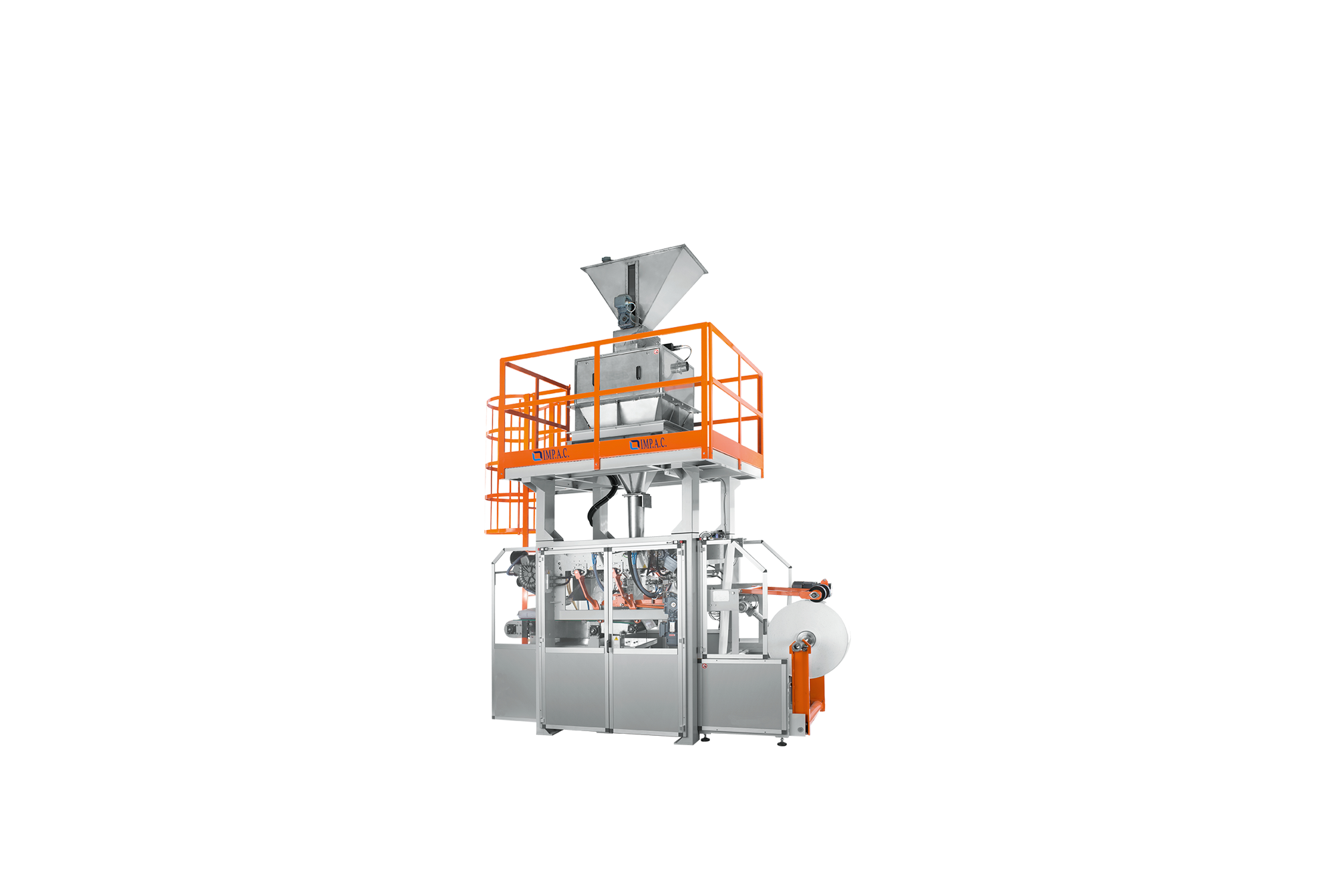

The IMP.A.C. 22 AL automatic palletizer represents a versatile and reliable solution for medium production, optimizing palletizing management.

Designed to adapt to a wide range of production needs, it allows palletizing cartons of different sizes, layer patterns, and configurations, ensuring precise and consistent results.

/With a production capacity of up to 1000 cartons/hour, the IMP.A.C. 22 AL model stands out for its operational efficiency and ability to meet the needs of diverse industrial sectors.

Low level palletizer for boxes and bundles

Max Production: 1000 cartons/hour

Cardboard dimensions

Max. 500 x 400 x h. 300

Min. 200 x 150 x h. 25

Pallet dimensions

Max. 1200 x 1000 x h. 140

Min. 1000 x 800 x h. 100

Layer dimensions

Max. 1300 x 1100

Standard full pallet height

1600 mm

Compressed air consumption

120 Nl/min

Max. full pallet weight

1500 Kg

Operational capacity

2 layers per minute with a limit of 15 cartons per minute

Installed power

8,5 KW

Operating pressure

6 bar

Control voltage

24 V

Indicative weight

7500 Kg

Product benefits

__ Optimised movements

__ Optimised movements

Equipped with a platform with vertical and horizontal movements for proper positioning and transfer of the layer onto the pallet.

__ Total automation

__ Total automation

Each phase of the cycle is managed by a programmable modular system (PLC), ensuring synchronization and complete control.

__ Operational flexibility

__ Operational flexibility

It can be configured to handle cartons of various sizes and layering patterns, addressing the specific needs of each production.

__ Efficiency without compromise

__ Efficiency without compromise

The work cycle is continuous, with an automatic pallet replacement system to minimize downtime.