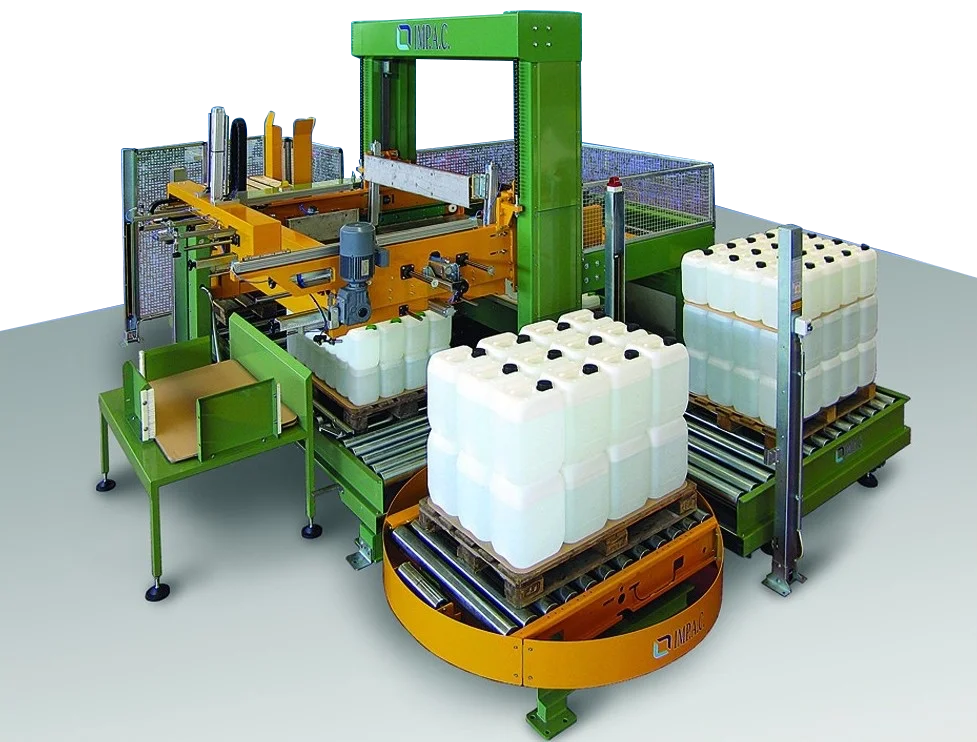

The IMP.A.C. 52 A palletizer is an advanced solution designed to meet the needs of operations with high production capacities.

This fully automatic model ensures the palletizing of containers up to 1200 cans/hour, making it ideal for industries with high production rates.

Competitive advantages

- High production capacity, ideal for high-performance packaging lines.

- Complete automation, minimizing manual interventions.

- Versatility, with the ability to adapt to multiple can and pallet configurations.

- Operational reliability, thanks to precision components and advanced synchronization.

This machine represents an excellent choice for companies that require a fast, precise palletizing system adaptable to various production needs.

A low level palletizer for cans

Max Production: 1200 cans/hour

Can dimensions

From 5L to 30L

Pallet dimensions

Max. 1200 x 1000 x h.140

Min. 1200 x 800 x h.140

Layer dimensions

1200 x 1000

Standard full pallet height

1600 mm

Operating pressure

6 bar

Compressed air consumption

150 Nl

Operational capacity

1200 cans/hour

Installed power

13 Kw

Indicative weight

7500 Kg

Control voltage

24 V

Max pallet weight

1500 Kg

Product benefits

__ Automatic pallet management

__ Automatic pallet management

The full pallet is automatically evacuated and replaced with an empty one, optimizing the loading cycles.

__ Synchronized movements

__ Synchronized movements

The mobile platform, combined with the sliding gate, ensures the precise transfer of layers onto the pallet.

__ Operational reliability

__ Operational reliability

Thanks to precision components and advanced synchronization.